Molten iron vanadium-extracting calcium-controlling coolant and process therefor

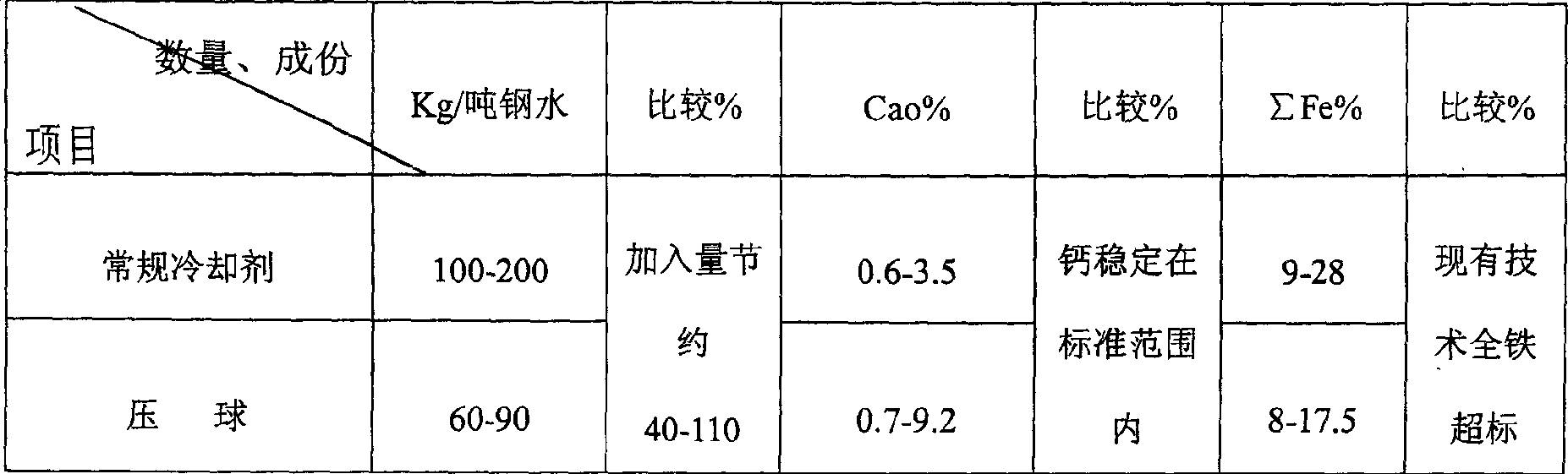

A coolant and calcium process technology, applied in furnaces, hearth furnaces, furnace types, etc., can solve the problem of unstable calcium content in vanadium slag, unstable iron content in vanadium slag, unstable calcium oxide content in vanadium slag, affecting ferrovanadium Extraction rate and other problems, to shorten the blowing time, stabilize the calcium oxide content of vanadium slag, improve the grade and extraction rate of vanadium slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below by embodiment, the present invention will be further described.

[0011] In the embodiment, the iron fine powder is sampled in batches to analyze the calcium, total iron, and vanadium components. Similarly, the semi-steel scale is also to be analyzed in batches for calcium and iron oxide content components, and then the iron fine powder is separately analyzed. The powder and iron oxide scale are dried (drum type gas dryer), and the two are stacked separately after drying, and the ingredients of each batch are marked. After the ingredients are proportioned according to the batch, they are sent to the mixer. Add comprehensive agent (500kg for one batch) and mix well, then send it to the briquetting machine (double-roller briquetting machine Φ25mm) by belt conveyor, form it, put it into an iron basket (about 50kg), and transport it to the tunnel worker's gas drying room (rack type discharge car) drying for 2-3 hours, put into the silo for later use. Process flow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com