Process for producing metal-resin bonded object, and metal-resin bonded object

A technology of a manufacturing method and a joining method, which is applied to the manufacture of metal-resin joints and the field of metal-resin joints, and can solve problems such as damaged appearance, lack of versatility, and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13 and comparative example 1~7

[0047] Hereinafter, the method for producing the metal-resin bonded body and the metal-resin bonded body in the present invention will be specifically described based on Examples and Comparative Examples.

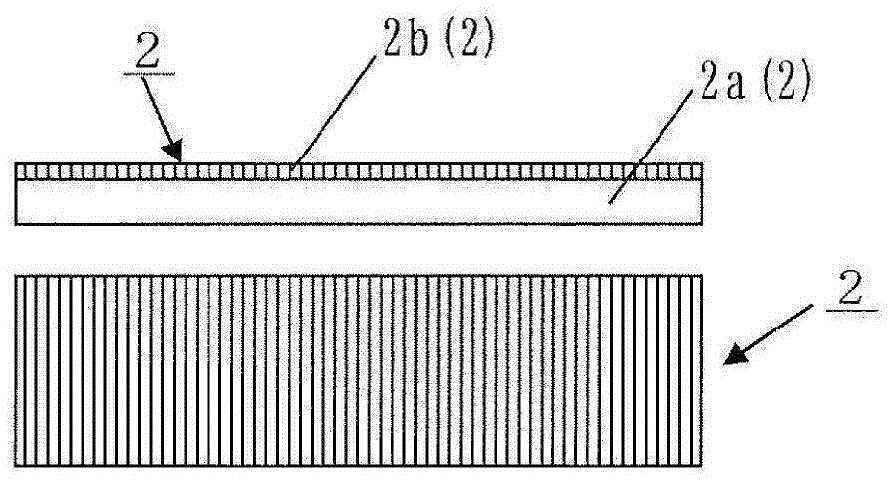

[0048] In addition, in the following examples and comparative examples, an aluminum plate material (aluminum member) formed of an aluminum alloy plate (JIS A5052-H34) with a width of 30 mm x a length of 90 mm x a thickness of 3 mm was used as a metal member. The resin sheet that is laminated on the bonding surface of the aluminum member to form the resin bonding layer uses an olefin sheet (trade name: Admar, manufactured by Mitsui Chemicals, Ltd.) with a size of 30 mm in width x 90 mm in length x 0.1 to 10 mm in thickness. 30mm x length 90mm x thickness 3mm polypropylene molded sheet (PP molded body).

[0049] 〔Pretreatment of aluminum sheet P1〕

[0050] First, put the aluminum plate in 30wt%-nitric acid aqueous solution for 5 minutes at room temperature, then wash it thor...

Embodiment 14~15 and comparative example 8~9

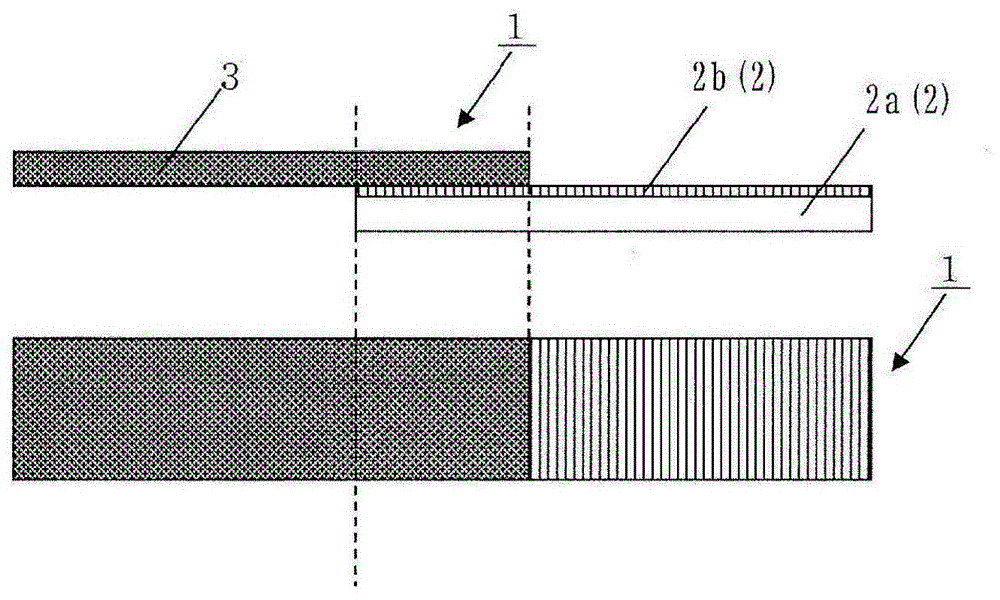

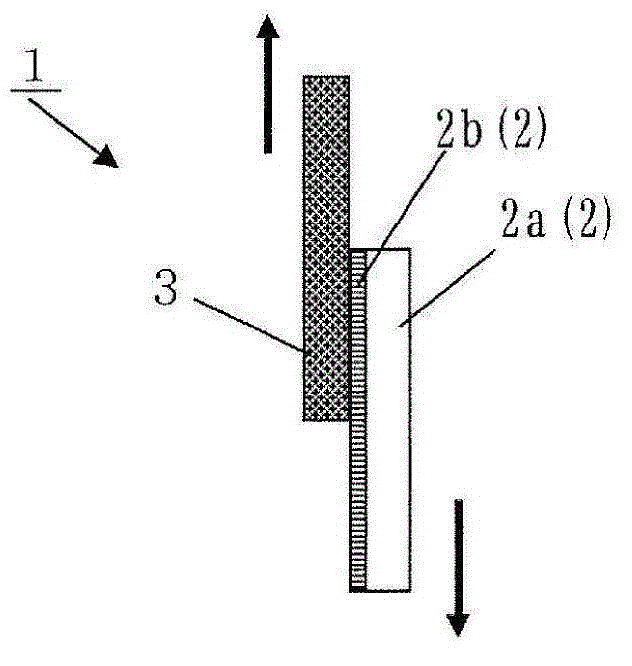

[0073] Next, the above-mentioned PP molded body (resin member) 3 is superimposed on the olefin sheet (resin bonding layer) 2b of the prepared aluminum resin laminated sheet 2, and it is placed in an ultrasonic welding machine (TELSONIC) Made by the company: USP-2000), ultrasonic welding was carried out under the conditions of frequency 20kHz, amplitude 50%, and welding time 1 second, and prepared such figure 2 A test piece (metal-resin bonded body) 1 in which a PP molded body is bonded to the bonding surface of the aluminum plate shown is shown.

[0074] In addition, in Examples 14 and 15 and Comparative Examples 8 and 9, except that the bonding method was changed to the above-mentioned ultrasonic welding, the same shear tensile strength test and deep drawability evaluation test as in Examples 1 to 13 were implemented. .

[0075] Table 2 shows the evaluation results of the shear tensile strength test and the deep drawability evaluation test.

[0076] [Table 2]

[0077] ...

Embodiment 18~20 and comparative example 10

[0080] Next, the prepared olefin sheet (resin bonding layer) 2b of the aluminum resin laminate 2 was set on a mold in an injection molding machine (ST10R2V manufactured by NISSEI Co., Ltd.), and the injection molding time (including dwell pressure) Time) 5 seconds, injection molding speed 60mm / second, holding pressure 90MPa, barrel temperature 280°C and mold temperature 50°C molding conditions to injection mold PP resin, prepared as figure 2 A test piece (metal-resin bonded body) 1 in which a PP molded body is bonded to the bonding surface of the aluminum plate shown is shown.

[0081] In Examples 18 to 20 and Comparative Example 10, the same shear tensile strength test and deep drawability evaluation test as in Examples 1 to 17 were performed except that the joining method was changed to the above-mentioned injection welding.

[0082] Table 3 shows the evaluation results of the shear tensile strength test and the deep drawability evaluation test.

[0083] [table 3]

[0084...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com