Fixing structure of fiber cover surface and sound absorbing component for vehicle

A fixed structure, fibrous technology, applied in the field of fixed structure of fibrous cover, can solve the problems of prolonged operation time, reduced appearance design, prolonged processing time, etc., and achieves the effect of strong joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

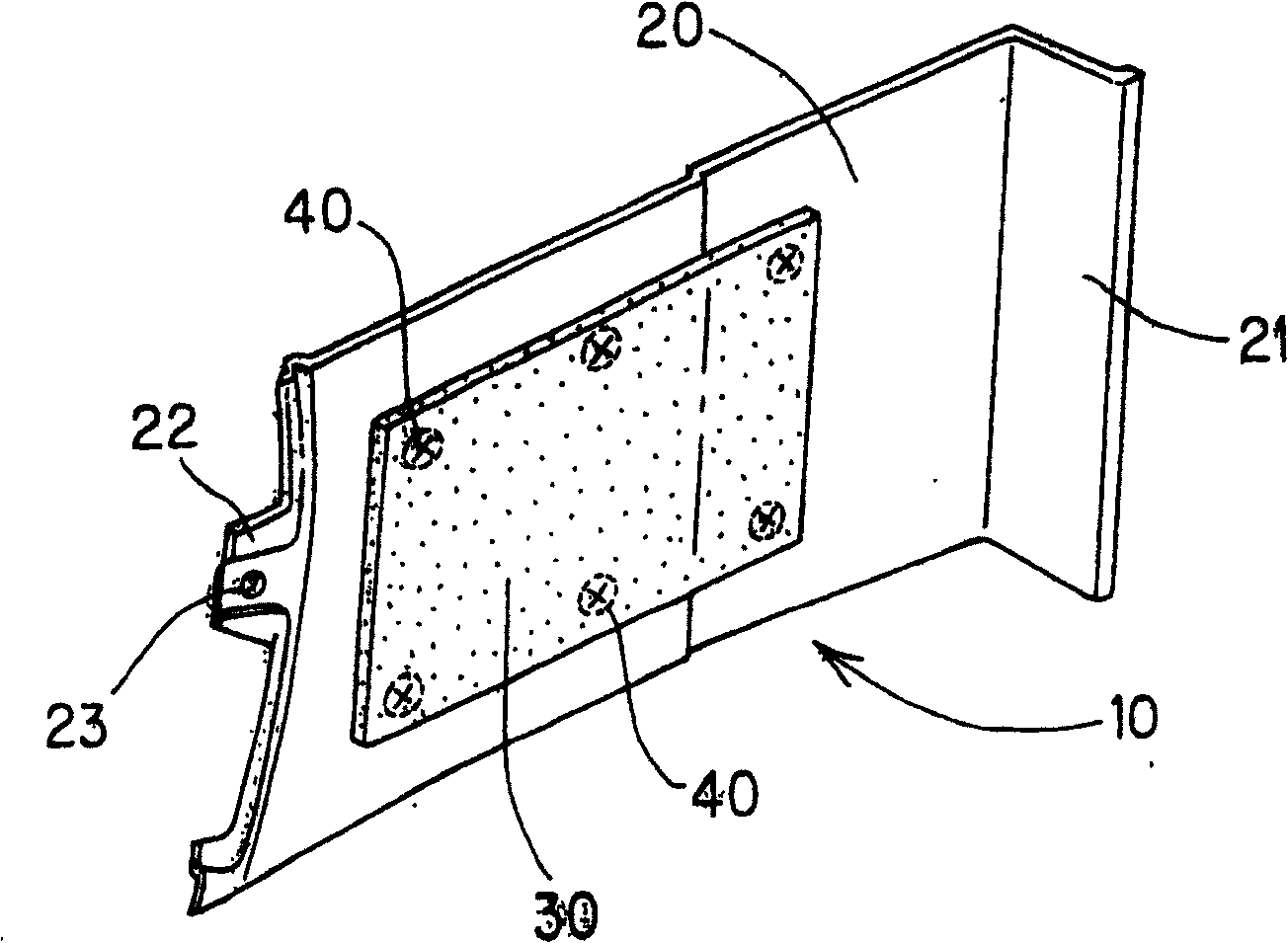

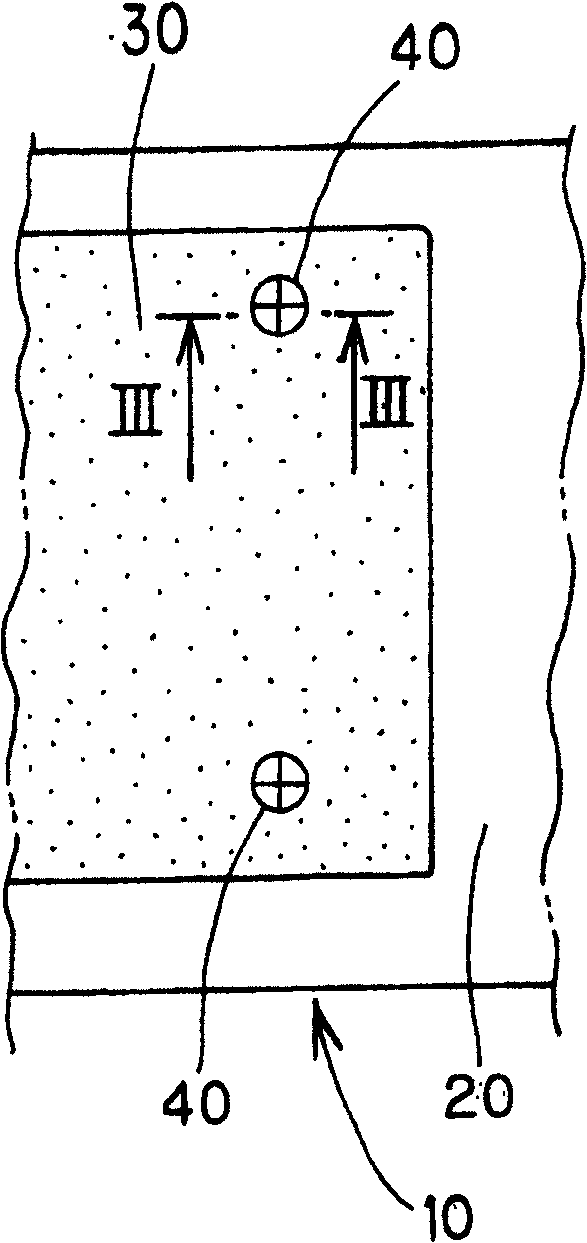

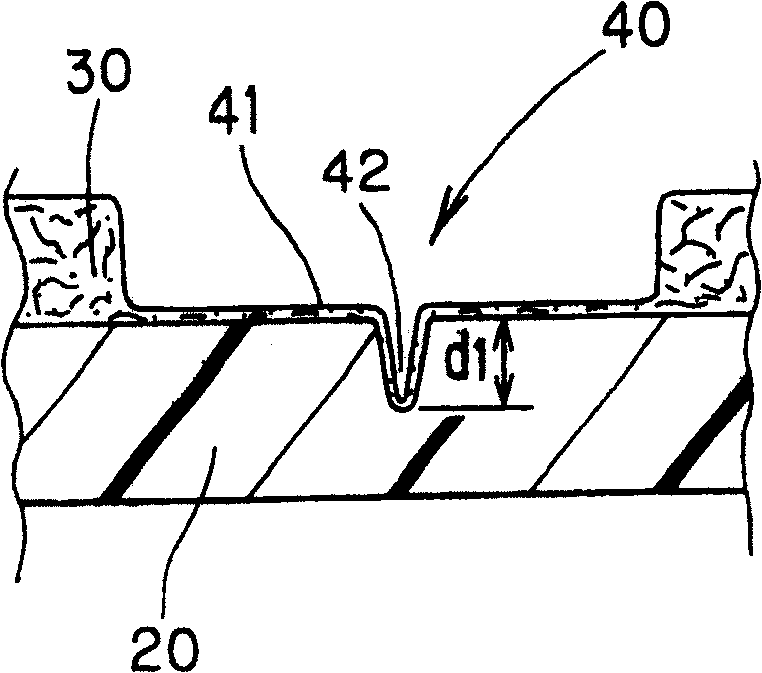

[0031] figure 1 ~ Figure 5 is a diagram showing the first embodiment of the present invention, figure 1 It is an oblique view of the luggage side decorations with the non-woven fabric cover bonded to the inside seen from the inside of the luggage; figure 2 It is a front view showing the non-woven fabric cover adhered to the main body of the luggage side decoration; image 3 Is a cross-sectional view showing the structure of the welded portion of the non-woven fabric cover; Figure 4 shows the shape of the ultrasonic horn used in the first embodiment, where (a) is a front view of the ultrasonic horn, (b) is (a) A view in the direction of the arrow; Figure 5 is a cross-sectional view showing the welding process of the fibrous cover using the ultrasonic horn shown in Figure 4; Figures 6-9 are each showing a modification of the first embodiment Illustrating.

[0032] figure 1 Wherein, 10 denotes the luggage side decoration on the indoor surface of the side wall panel in the trunk ...

Embodiment 2

[0045] Figure 10. Picture 11 10 is an explanatory diagram showing the structure of the ultrasonic horn with the shape of the ultrasonic horn changed, and (a) in FIG. 10 is a front view of the ultrasonic horn, and (b) in FIG. 10 ) Is the D view in (a). and Picture 11 It is an explanatory view showing the welded part of the nonwoven fabric cover formed by the ultrasonic horn shown in FIG. 10. The ultrasonic horn 50C shown in FIG. 10 is a flat pressing surface 51 at the front end of the horn and a sharp convex strip 52 is provided along the periphery of the pressing surface 51. Since the structure of the ultrasonic horn 50C is to form the convex strip 52 on the flat pressing surface 51 along its periphery, it is necessary to use an NC lathe in the first embodiment, and in the second embodiment, only a lathe is used Yes, so the processing cost of the ultrasonic horn 50C can be reduced.

[0046] Moreover, in the case of using the ultrasonic horn 50C, such as Picture 11 As shown, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com