Automatic assembling machine of light touch switch

An automatic assembly machine, tact switch technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of crushed shrapnel, riveting failure, and reduced machine assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

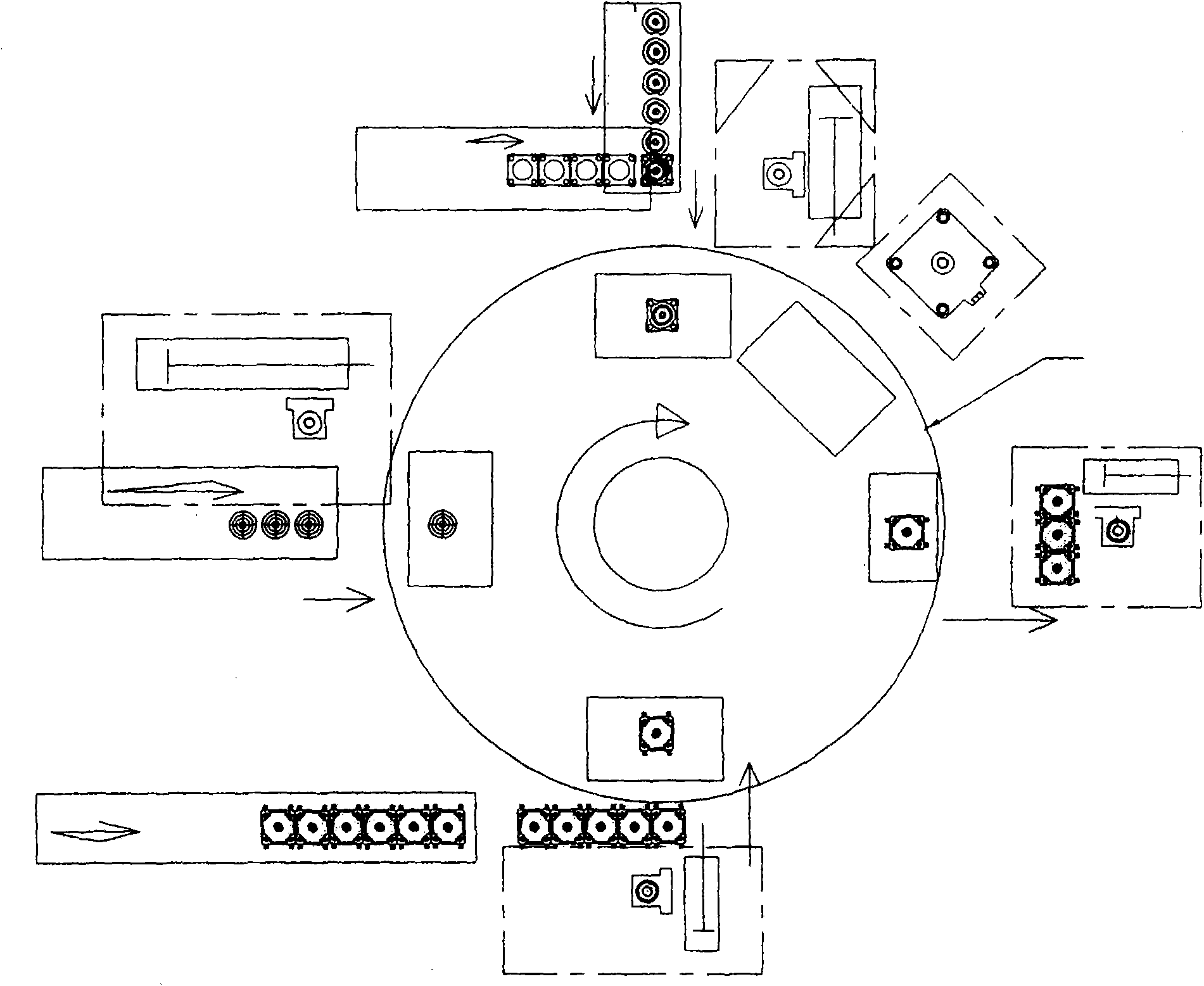

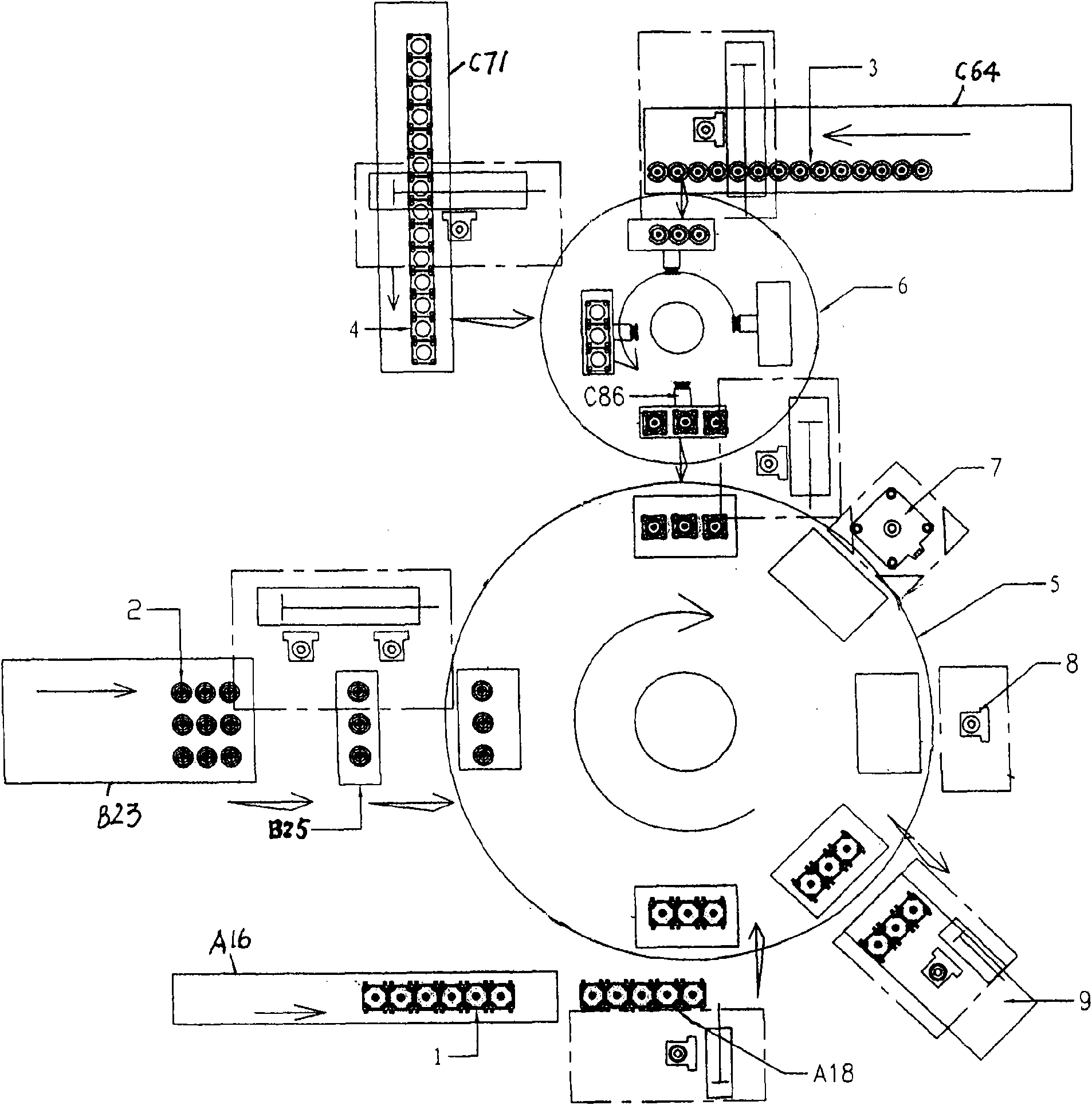

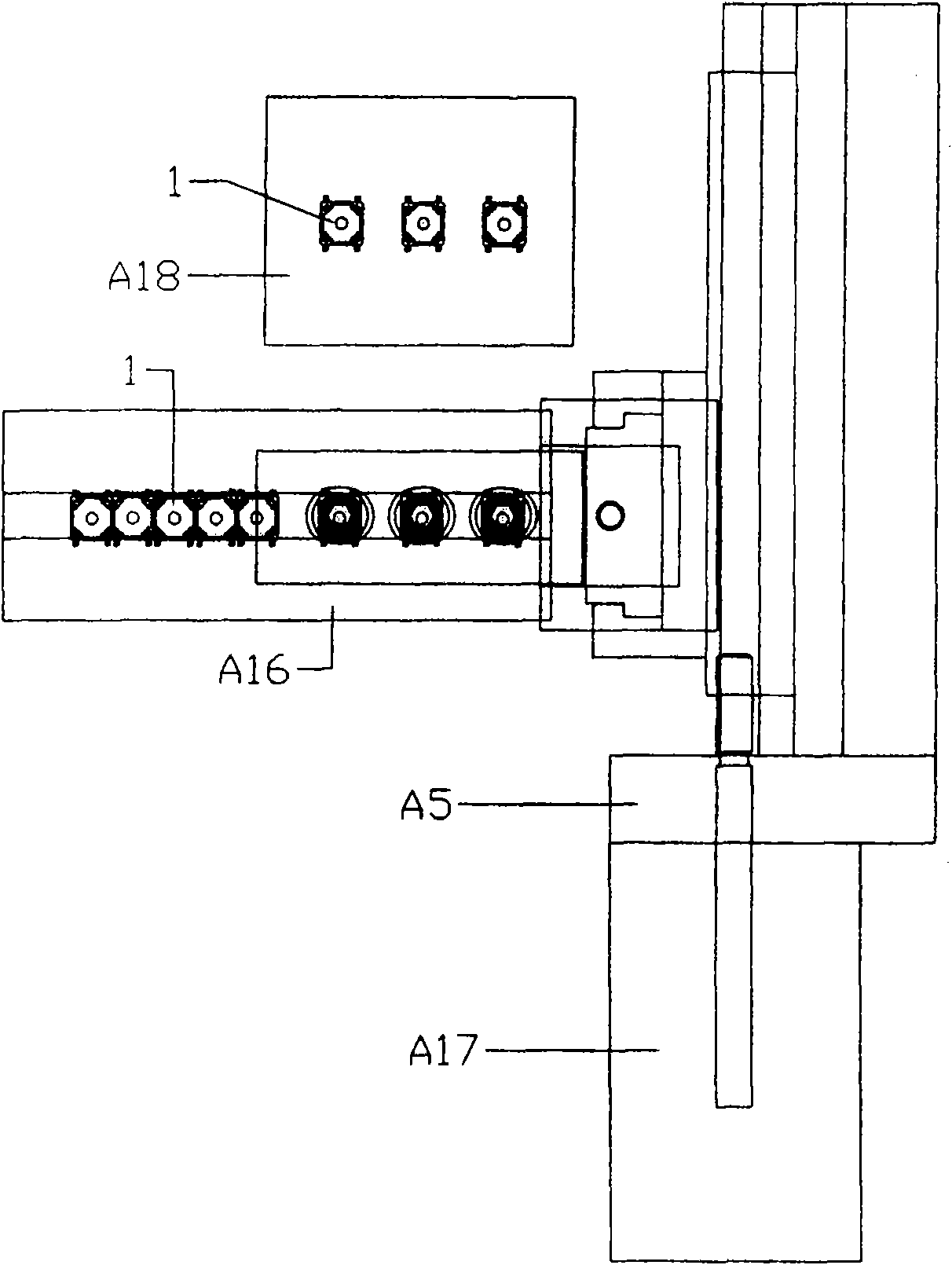

[0021] see figure 2 , an automatic assembly machine for tact switches, which includes an assembly jig, the assembly jig is fixed on the assembly main plate 5, and the assembly jig on the assembly main plate 5 is relatively several positioning stations and an indexing center plate 6 during rotation. , fix the transfer positioning station on the indexing station plate 6, and connect the air pipe joint C86 to the transfer positioning station. When there is material put into the transfer positioning station, vacuum suction will be generated, and the vacuum suction will stop when the material is taken away; when assembling the main disk 5 A base vacuum suction mechanism and a shrapnel vacuum suction mechanism are arranged on the side, and a button upper cover vacuum suction mechanism is arranged beside the indexing center plate 6.

[0022] see figure 2 , the assembly fixture is divided into assembly fixture A, assembly fixture B, assembly fixture C, assembly fixture D, assembly ...

Embodiment 2

[0039] Such as Figure 10 As shown, the assembly jig moves to the next station for assembly after each assembly is completed ( Figure 10 Shown by the arrow R in the middle), instead of rotating to the next station in the first embodiment (see figure 2 The assembly jig A in the assembly is rotated to the position of the assembly jig B), and other actions are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com