Intaglio printing machine capable of accurately and quickly positioning printing plate

A gravure printing machine, accurate technology, applied in printing presses, rotary printing machines, gravure rotary printing machines and other directions, can solve problems such as affecting production efficiency, time-consuming and labor-intensive, and existing errors, and achieves improved work efficiency and measurement accuracy. , the effect of reducing the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

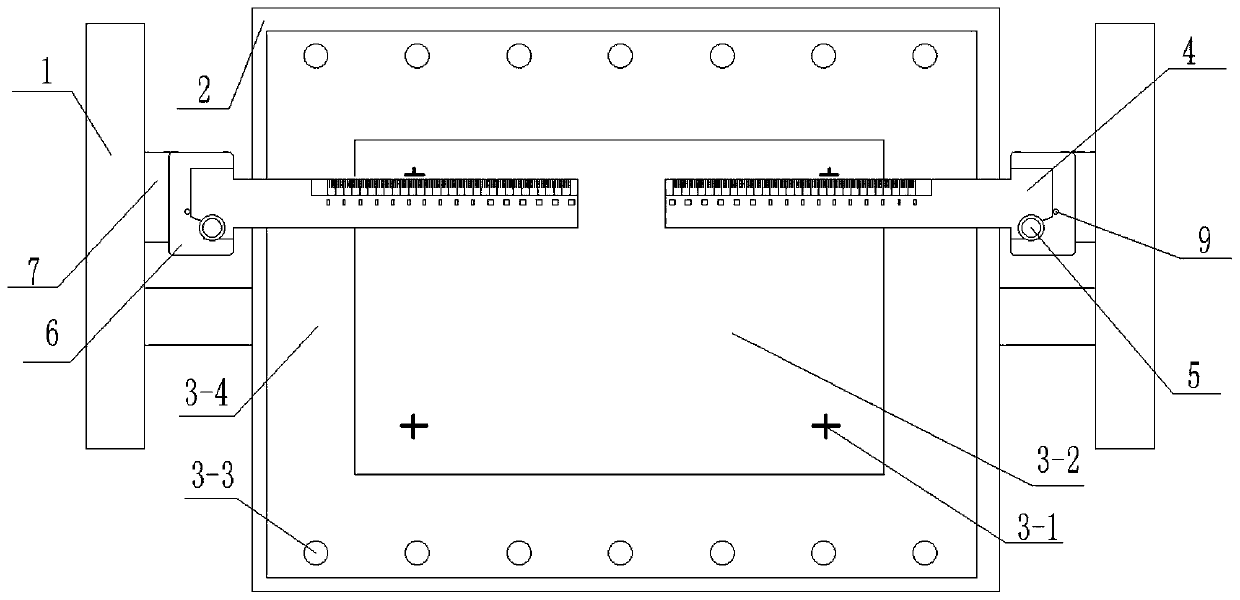

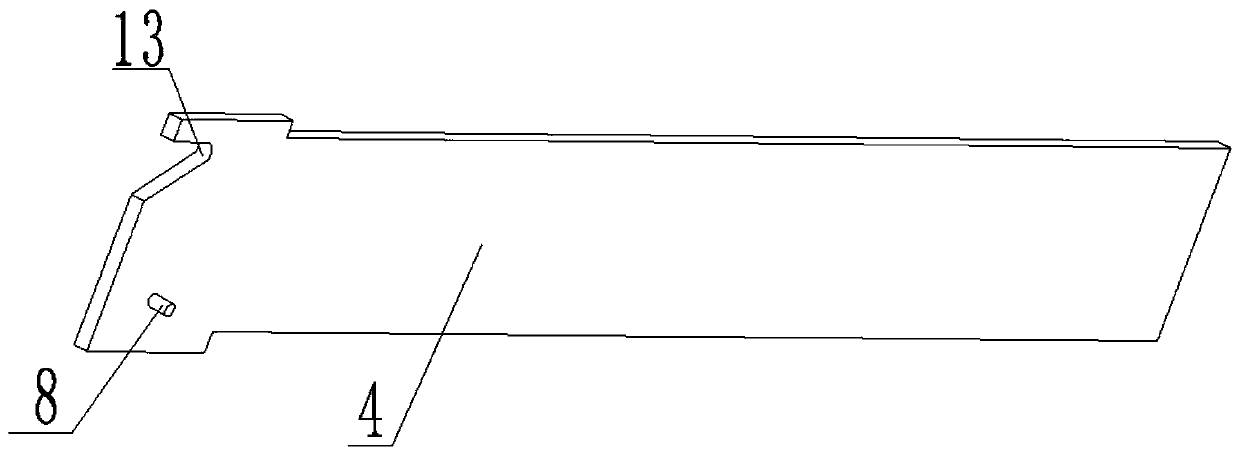

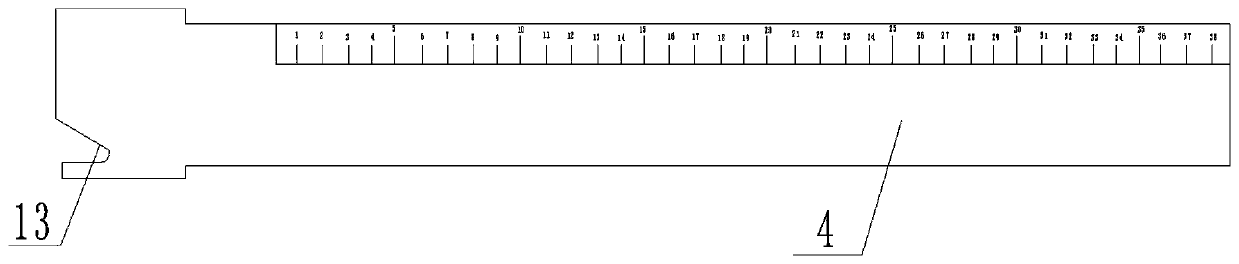

[0022] see figure 1 , 2 , 3, 4, 5, 6, 7 and Figure 8 , the present invention includes a fuselage 1, a printing plate cylinder 2 and a printing plate 3; the printing plate 3 is arranged on the printing plate cylinder 2; the printing plate cylinder 2 is arranged on the fuselage 1; when the printing plate 3 is on the printing plate When installing on the cylinder 2, it is necessary to manually fine-tune the position of the printing plate 3 so that the position of the printing plate 3 is installed correctly. In order to accurately install the printing plate 3 on the printing plate cylinder 2, the present invention is provided with a positioning calibration device; The calibration device is arranged on the fuselage 1; the positioning calibration device includes a base 7, a ruler holder 6, a ruler 4 and a fixing screw 5; the base 7 is arranged on the fuselage 1; the ruler holder 6 can be Rotate on the base 7; the scale holder 6 is provided with a threaded hole 10; the set screw 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com