Longitudinal beam structure for commercial vehicle

A commercial vehicle and longitudinal beam technology, which is applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of large vehicle load, poor working conditions, and bending, and achieve the reduction of frame weight, weight reduction, Overall weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

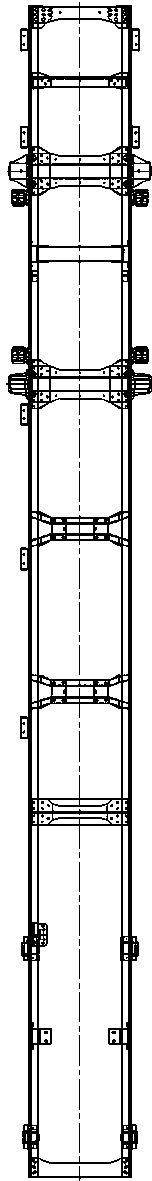

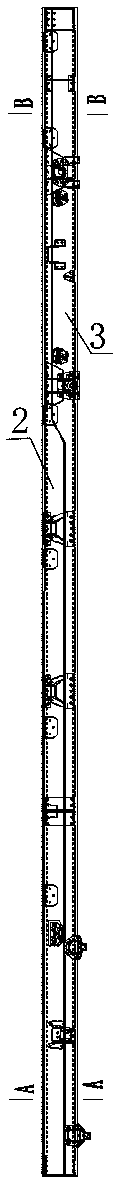

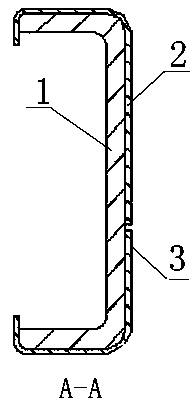

[0029] The invention is like Figure 1-11 Shown.

[0030] A commercial vehicle longitudinal beam structure, comprising a frame longitudinal beam, the frame longitudinal beam is a trough structure, and the inner and outer double layers are wrapped as a whole, and the inner structure 1 of the frame longitudinal beam is made of aluminum alloy material The main beam, the outer layer is a steel structure, and the outer steel structure is divided into upper and lower outer beams 2 and 3, and the gaps are correspondingly arranged. The upper and lower outer beams 2, 3 are bent inward and the cross section is "L" The "L" structure of the upper and lower outer beams wraps the inner layer of aluminum alloy material and is riveted into a whole.

[0031] The height of the front part of the upper outer beam 2 is greater than the height of the rear part of the upper outer beam 2, and the height of the rear part of the lower outer beam 3 is greater than the height of the front part of the lower o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com