Supporting plate nut riveting assisting device

A technology of auxiliary device and pallet nut, which is applied in the field of tool design, can solve problems such as small working surface, low production efficiency, and high labor intensity, and achieve the effects of reducing complexity and difficulty, reducing processing costs, and ensuring high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

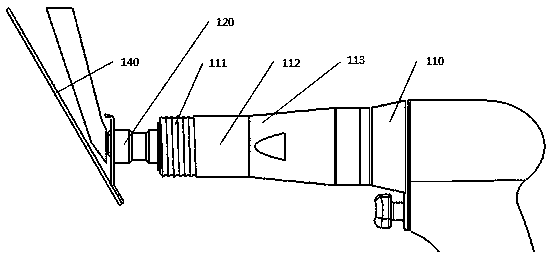

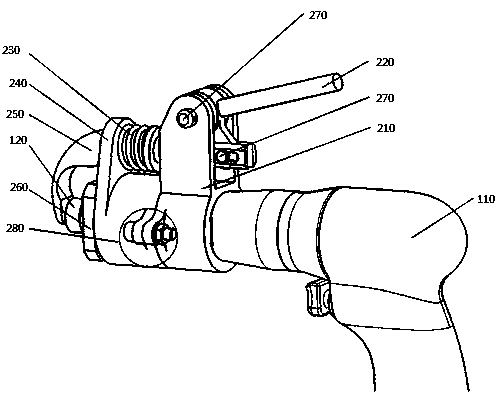

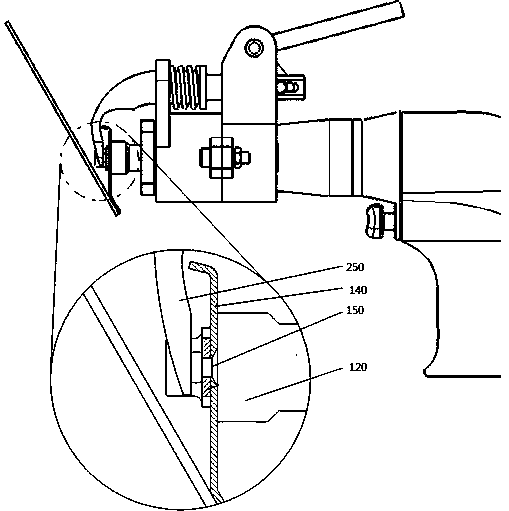

[0042] An auxiliary device for riveting a pallet nut, such as Figure 1-Figure 5 As shown, it includes a front frame 240, a rear frame 210, an elastic handle 220, an elbow top iron 250, and a lock nut 260. The front frame 240 includes a main body 241 and a large ear 242 vertically arranged on the main body 241. The rear frame 210 includes a cylinder 211 and a mounting seat 212 vertically arranged on the outside of the cylinder 211; Pass through the cylinder 211, the main body 241 in turn and connect with the lock nut 260; the mounting seat 212 includes upper convex plates arranged parallel to each other and a mounting plate arranged between adjacent upper convex plates, the mounting plate and The big ears 242 are arranged in parallel, and the big ears 242 and the mounting plate are respectively provided with a cavity 212c and a mounting plate 212b; one end of the elastic handle 220 is hingedly arranged on the top between adjacent upper convex plates, and is elastically One en...

Embodiment 2

[0045] This embodiment is further optimized on the basis of embodiment 1, as Figure 8 , Figure 9 As shown, the driving end of the elbow top iron 250 is provided with a through rectangular groove 252a, and the outer sides of the rectangular groove 252a are respectively provided with a plane, and the plane is provided with a through elliptical hole along the axis; The lug 223 is correspondingly provided with an elliptical hole, and the axis of the elliptical hole on the lug 223 coincides with the axis of the hinge hole of the elastic handle 220; the lug 223 is slidably connected in the rectangular groove 252a, so The lug 223 is connected to the rectangular groove 252a through a pin 270, and the pin 270 is slidably connected along the axis in the elliptical hole; the elbow top iron 250 includes an angled column 253, a first cylinder 253a, and a second cylinder connected in sequence. Two cylinders 252; the diameter of the first cylinder 253a is greater than the diameter of the ...

Embodiment 3

[0049] This embodiment is further optimized on the basis of embodiment 2, as Figure 7 As shown, the elastic handle 220 includes an annular cylinder 221, a cylinder handle 222, and a lug 223; the annular cylinder 221 is provided with a hinge hole along the axis, and the annular cylinder 221 is hingedly arranged The top between adjacent upper convex plates; the outer wall of the annular cylinder 221 is respectively connected with a lug 223 and a cylinder handle 222; An escape port 253c and a working plane 253b are arranged in sequence from top to bottom.

[0050] In the present invention, through the setting of the hinged hole, the pin hole on the mounting seat 212 of the annular column 221 and the rear frame 210 is hinged through the pin 270, so that the elastic handle 220 has a fulcrum when driving the elbow push iron 250, ensuring that the elbow pushes The drive of the iron 250; through the parallel setting of the working surface of the rivet card 120 and the working plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com