Belt wheel for V-belt type automatic variable speed gear

A technology of automatic speed change device and pulley, which is applied in the direction of transmission device, portable lifting device, hoisting device, etc., can solve the problem of difficulty in forming durable pulleys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

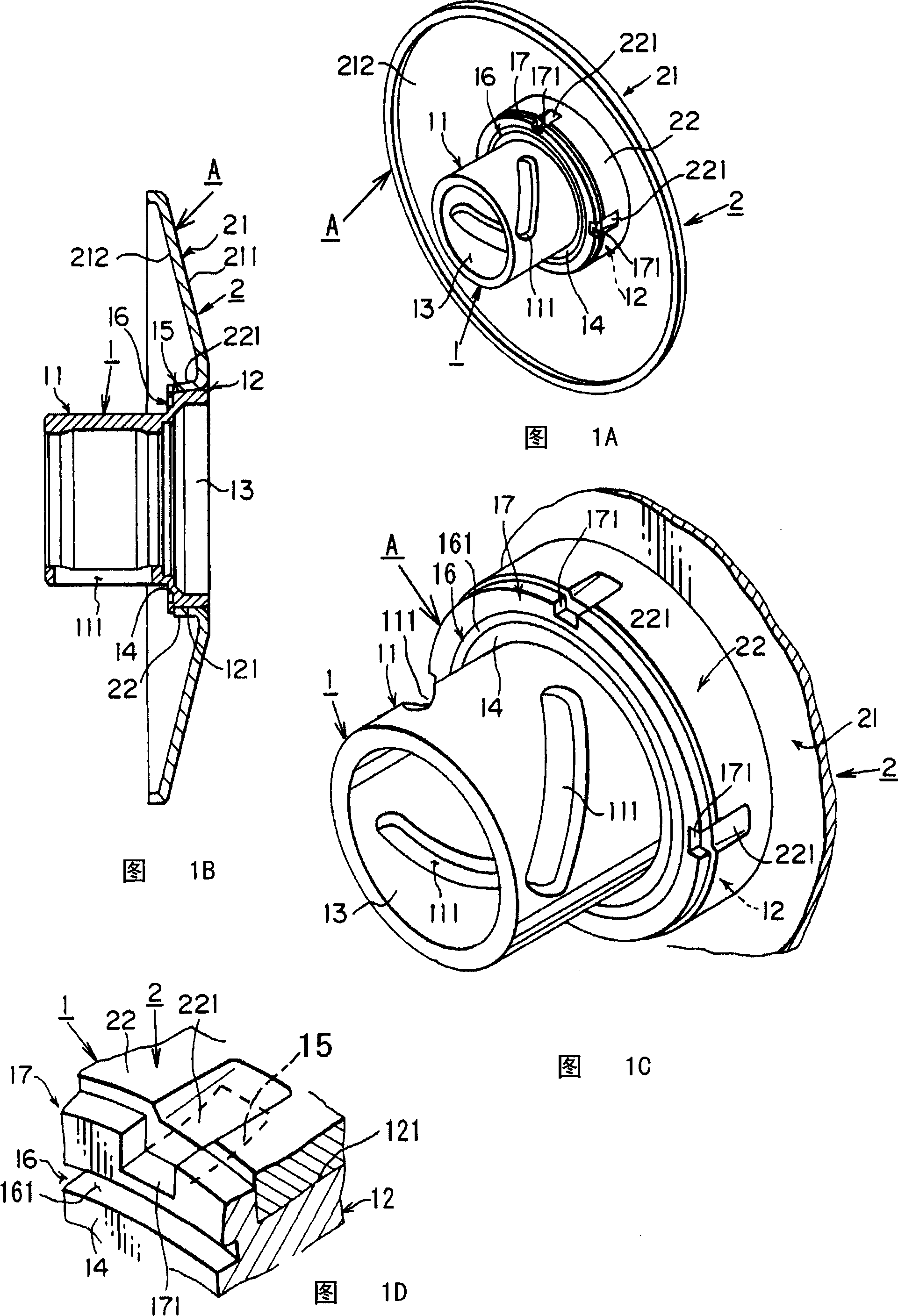

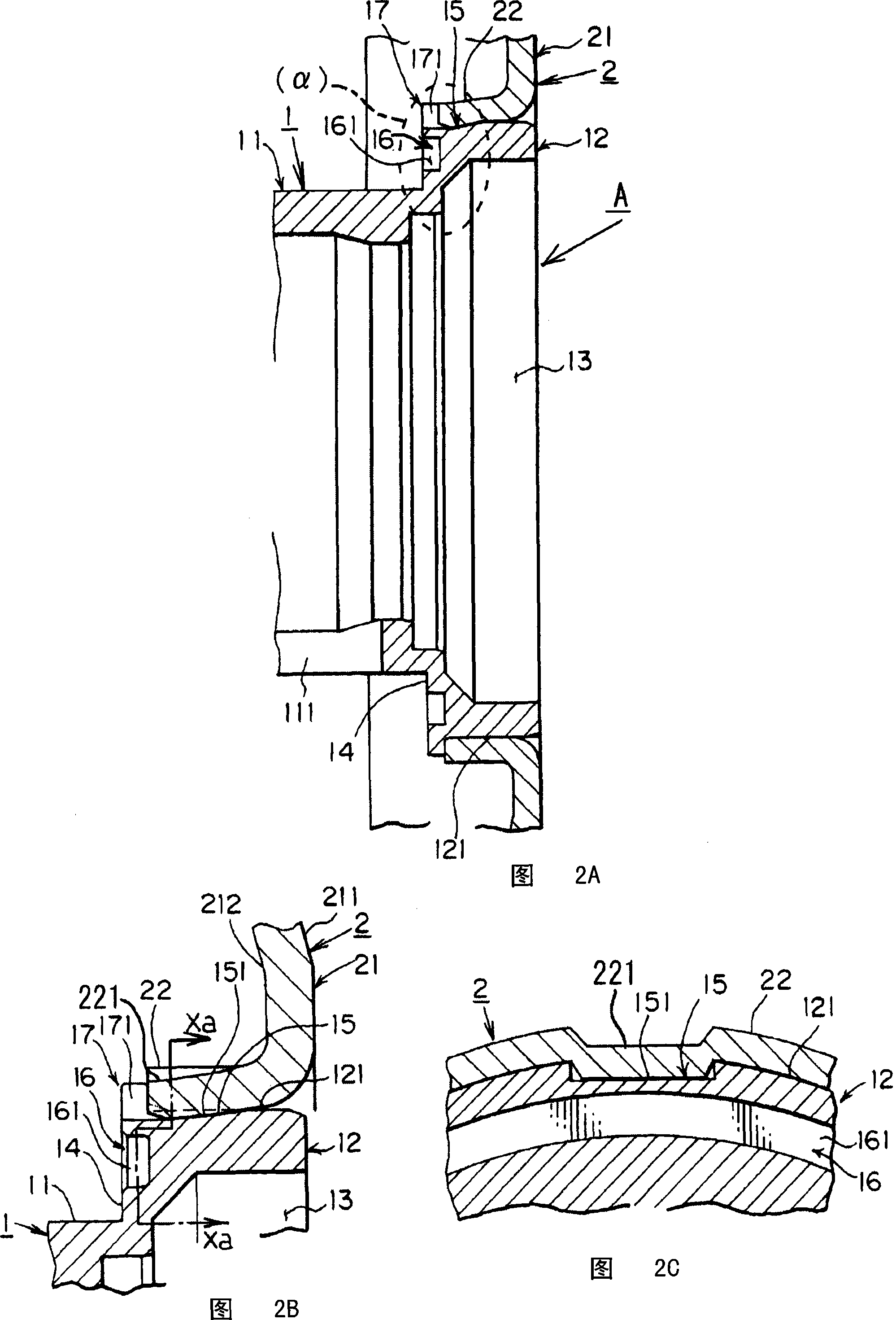

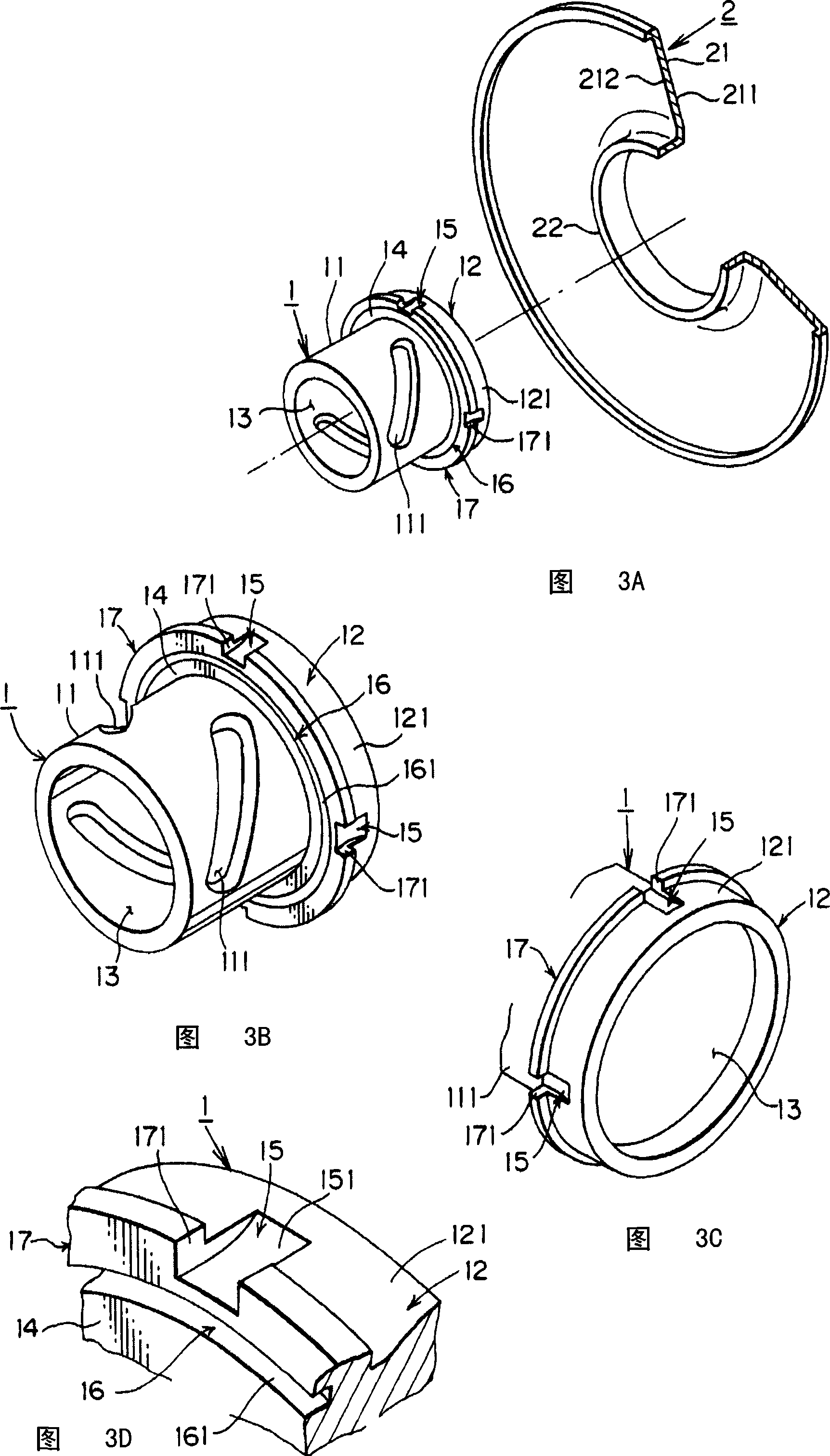

[0039] Hereinafter, the present invention will be described with reference to the drawings. First, Fig. 11 shows the situation in which the present invention is mounted on a V-belt type automatic transmission. The driven pulley mainly includes a movable pulley half body A, a fixed pulley half body 3 and a driven shaft 4 as shown in FIG. 11 . The movable sheave half A includes a hub member 1 and a movable sheave surface 2 .

[0040]As shown in FIGS. 3 and 4 , the hub member 1 includes a hub shaft portion 11 and a large-diameter cylindrical portion 12 formed on one end side of the hub shaft portion 11 in the axial direction. The large-diameter cylindrical portion 12 is formed in a substantially flat cylindrical shape, and is formed to have a larger diameter than the above-mentioned hub shaft portion 11 (see FIG. 4A ). Furthermore, the above-mentioned large-diameter cylindrical portion 12 is formed as a disc perpendicular to the axial direction of the above-mentioned hub member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com