Barbed nail roller assembly

A technology of nailing rollers and components, which is applied in the direction of fiber opening and cleaning machines, etc., can solve the problems of difficult correction of cladding boards, lower work efficiency, skewed or loose nails, etc., and achieve the effects of reducing vibration, ensuring riveting quality, and easy correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

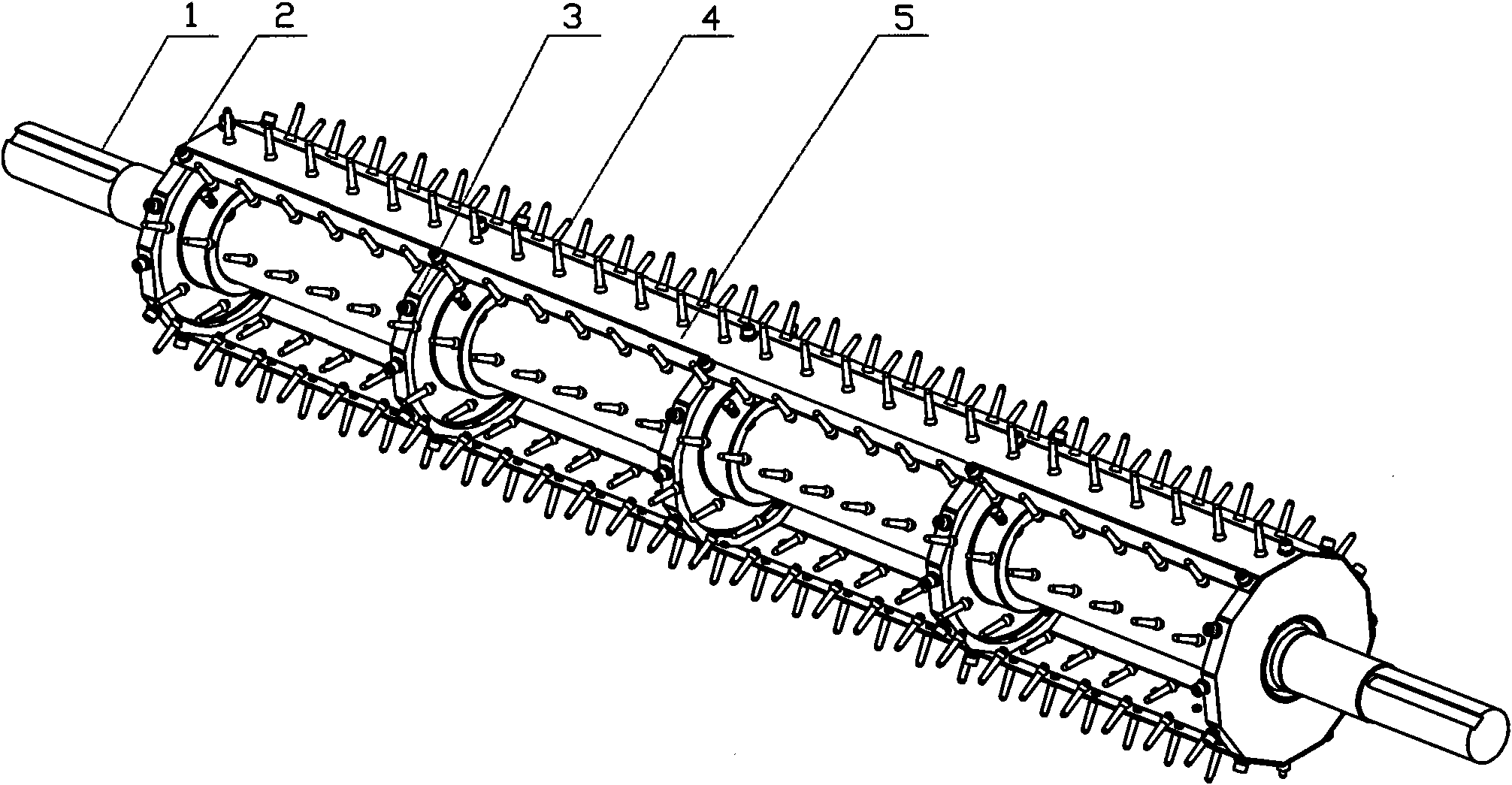

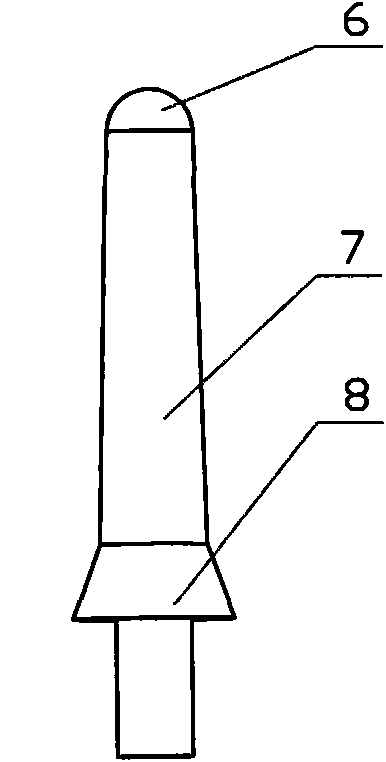

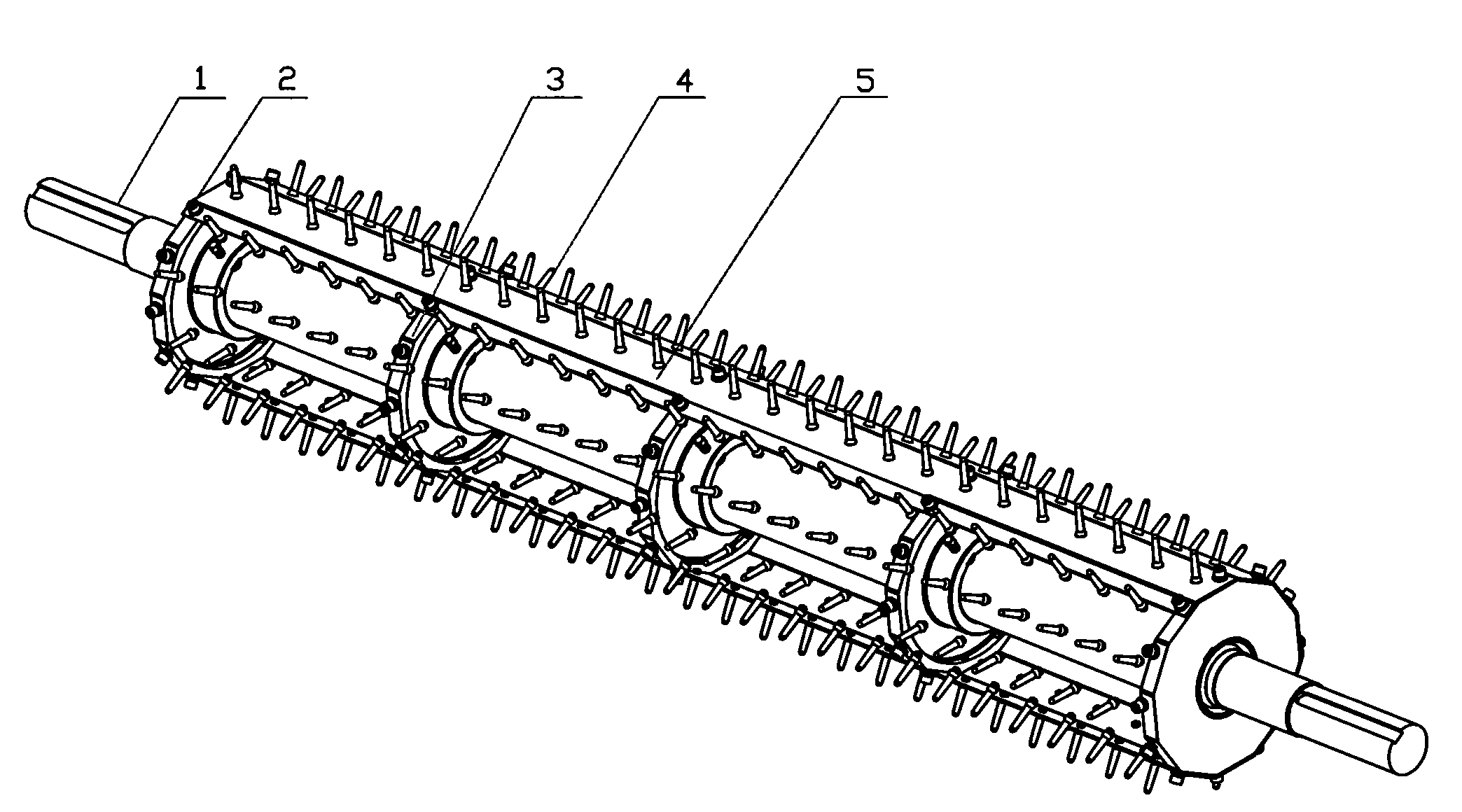

[0020] Refer to the attached figure 1 , which shows a spike roller assembly, including a pipe shaft 1, a set of flanges 3 arranged axially and coaxially with the pipe shaft, and fixed on the flanges to form a column The cladding plate 5 of the body, wherein the cladding plate is uniformly provided with thorns 4, the flange is a regular prism structure, and the cladding plate is composed of several pieces that are divisible by the regular prism. Blocks are used to form the sides of the cylinder; the spikes are spherical taper machine rivet spikes.

[0021] It has been verified that the radial runout of the spike roller is less than 1.5 mm, which fully meets the upper limit of 2.5 mm required by the specification, and can greatly prolong the service life of the supports of the spike roller assembly.

[0022] Further, those skilled in the art can select or combine the following technical means according to the basic solution and the concept of the present invention:

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com