Patents

Literature

70results about How to "Guarantee riveting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

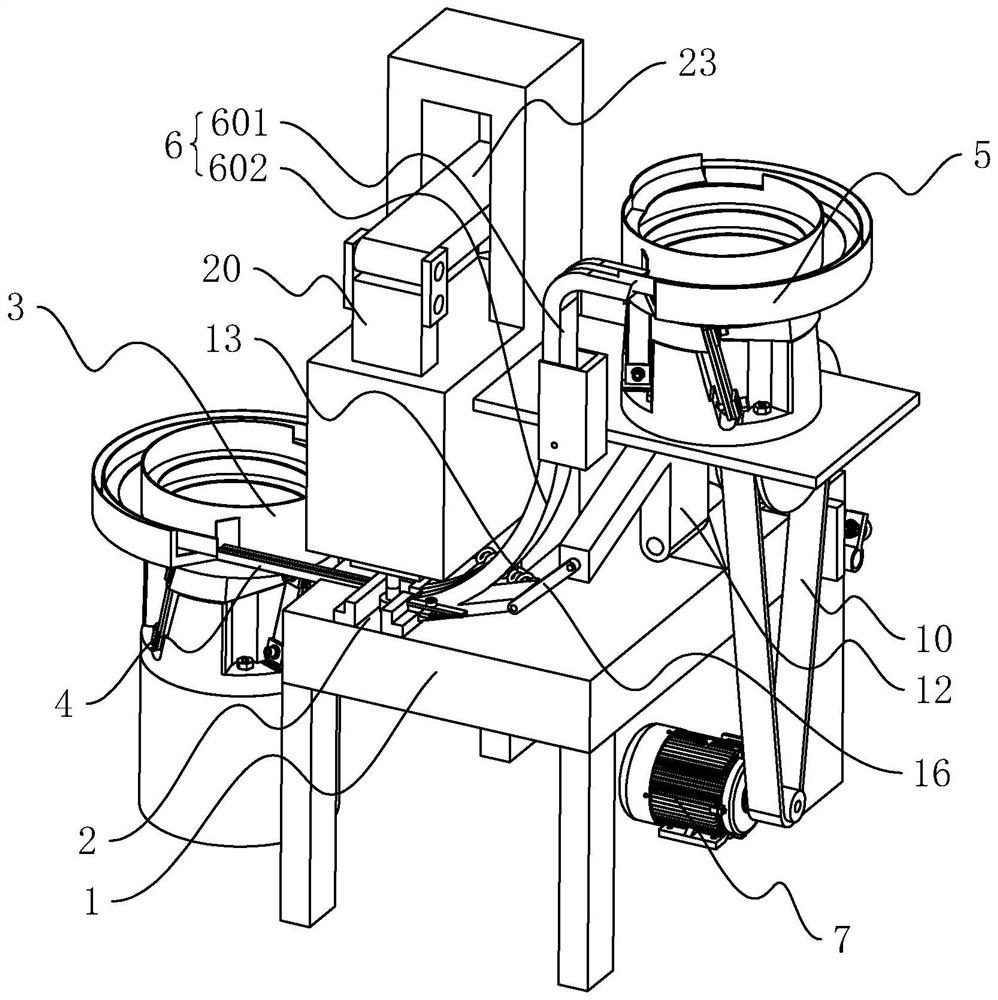

Semi-automatic rotary riveting fixture and riveting method thereof

ActiveCN106624727AHigh precisionStable mechanical structureMetal working apparatusSemi automaticEngineering

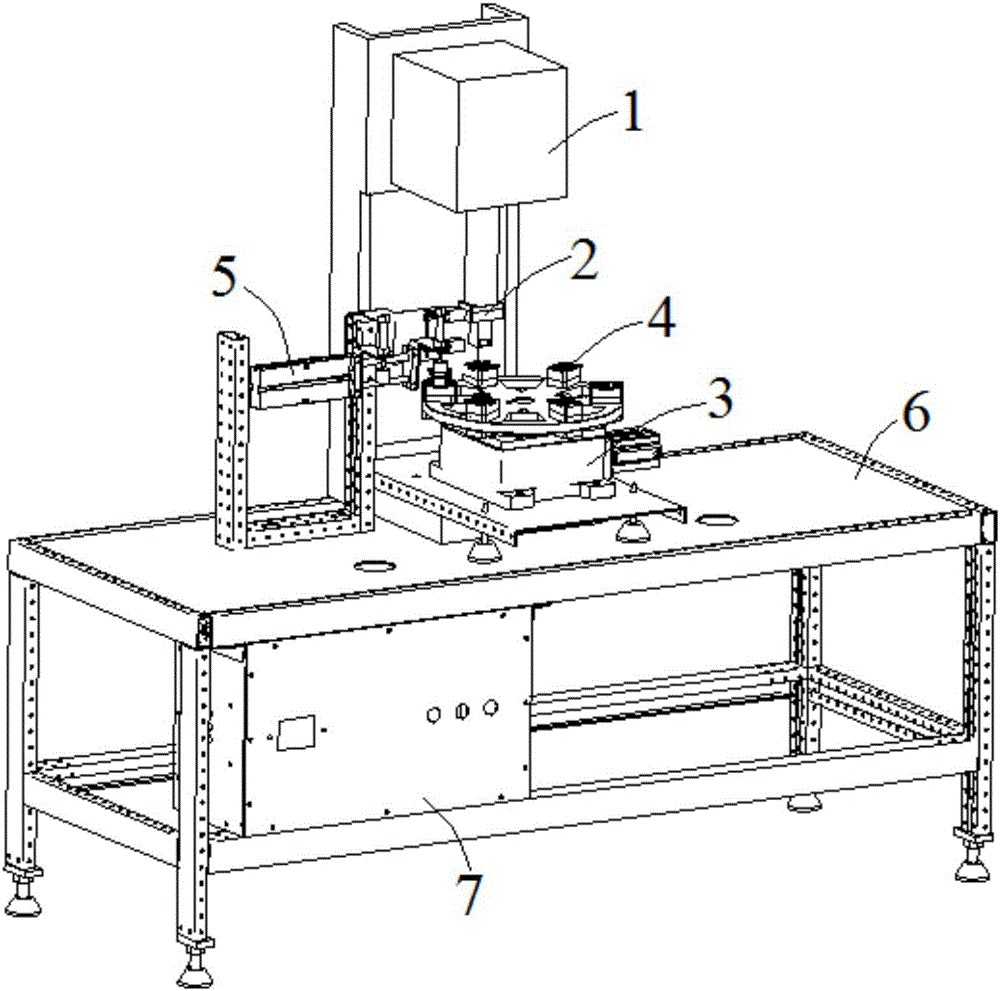

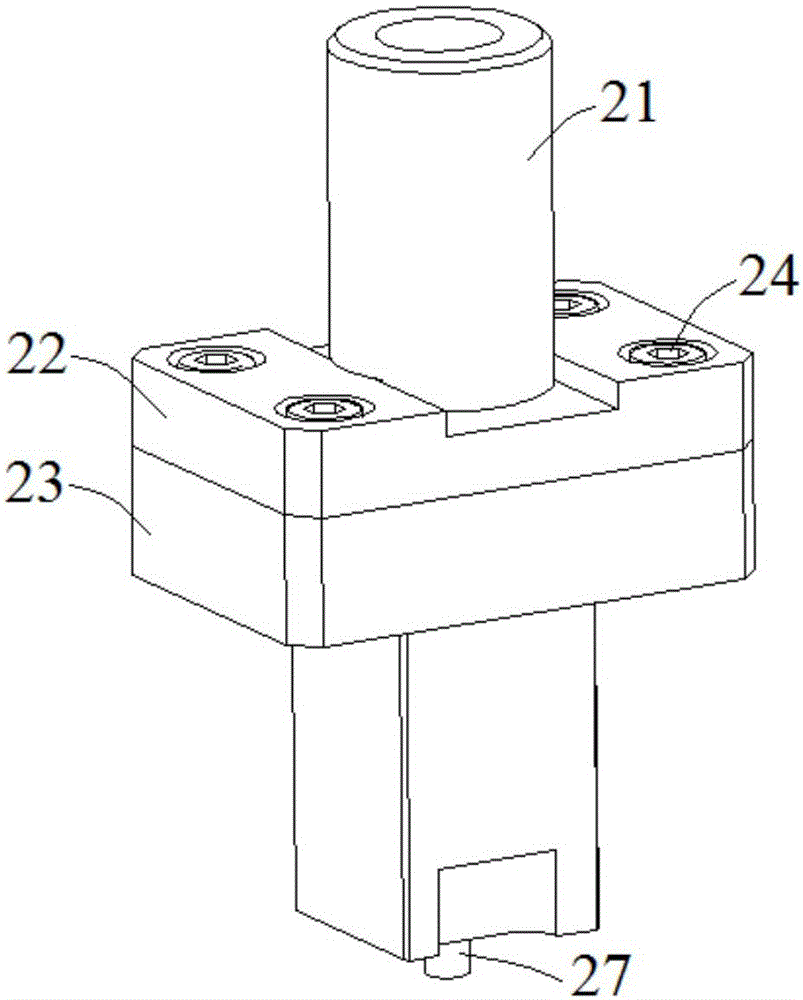

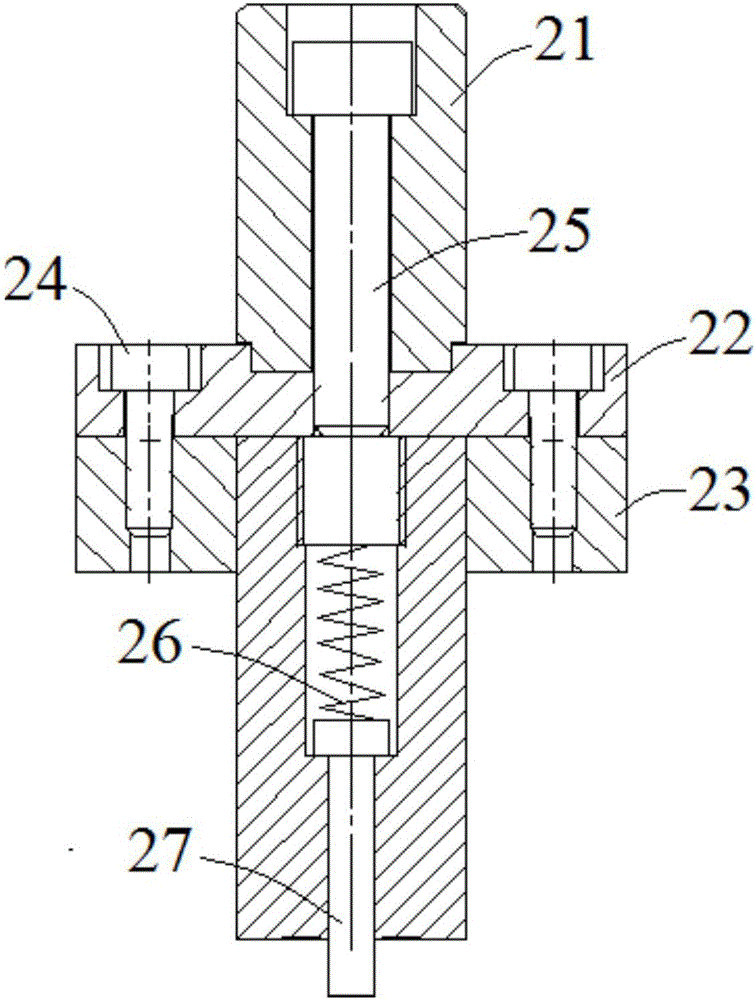

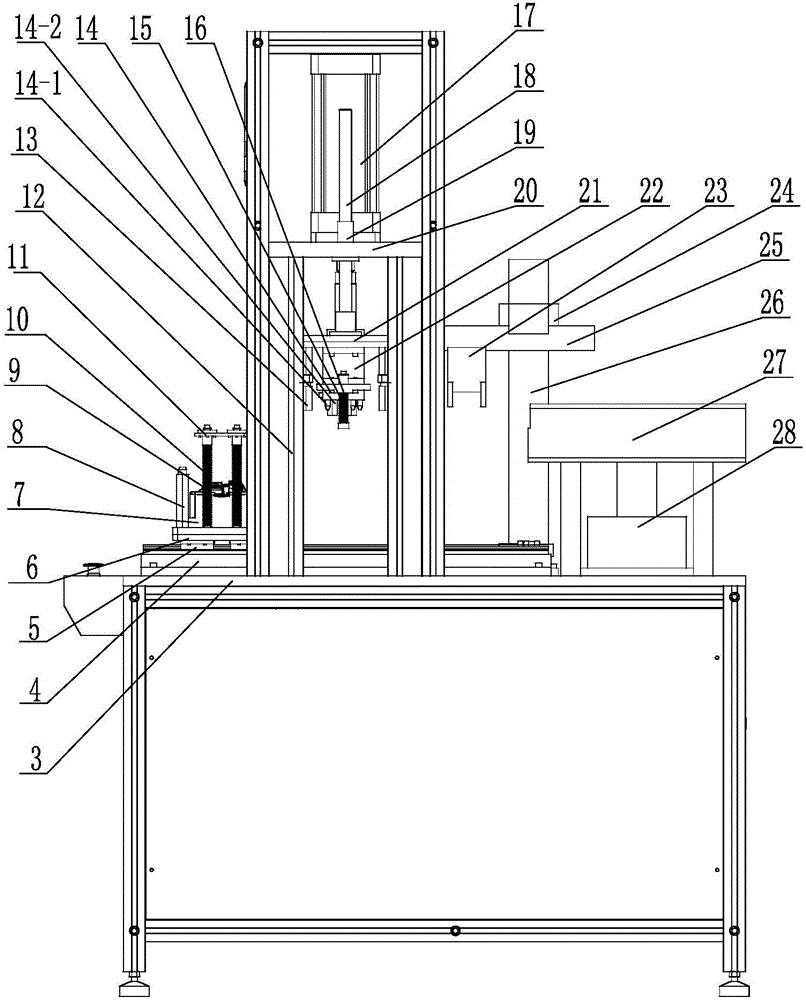

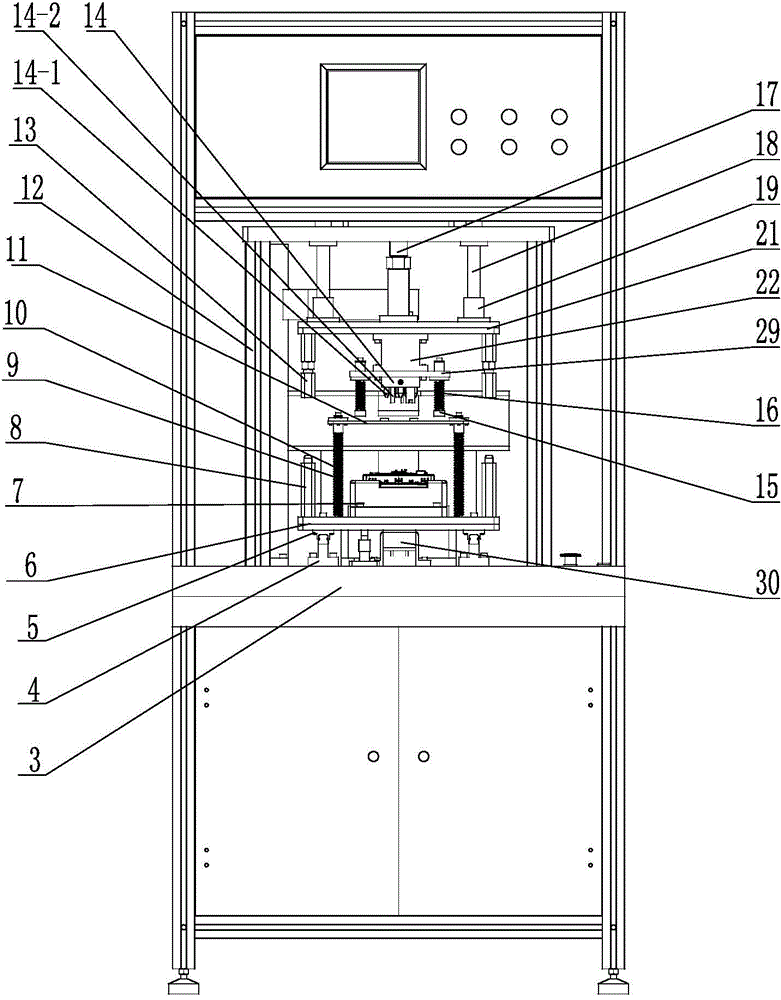

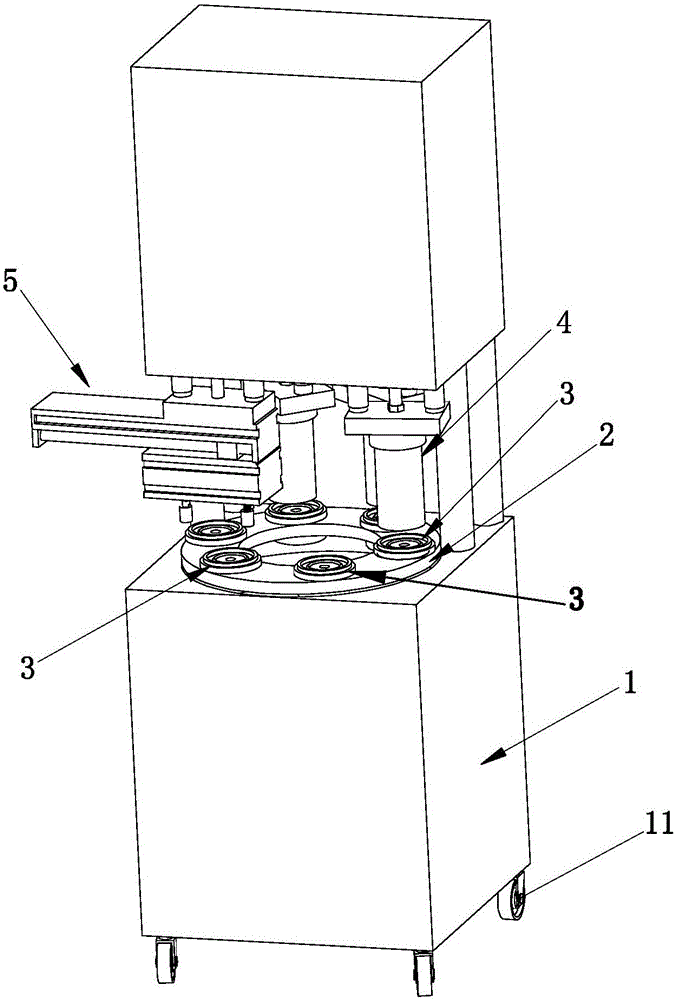

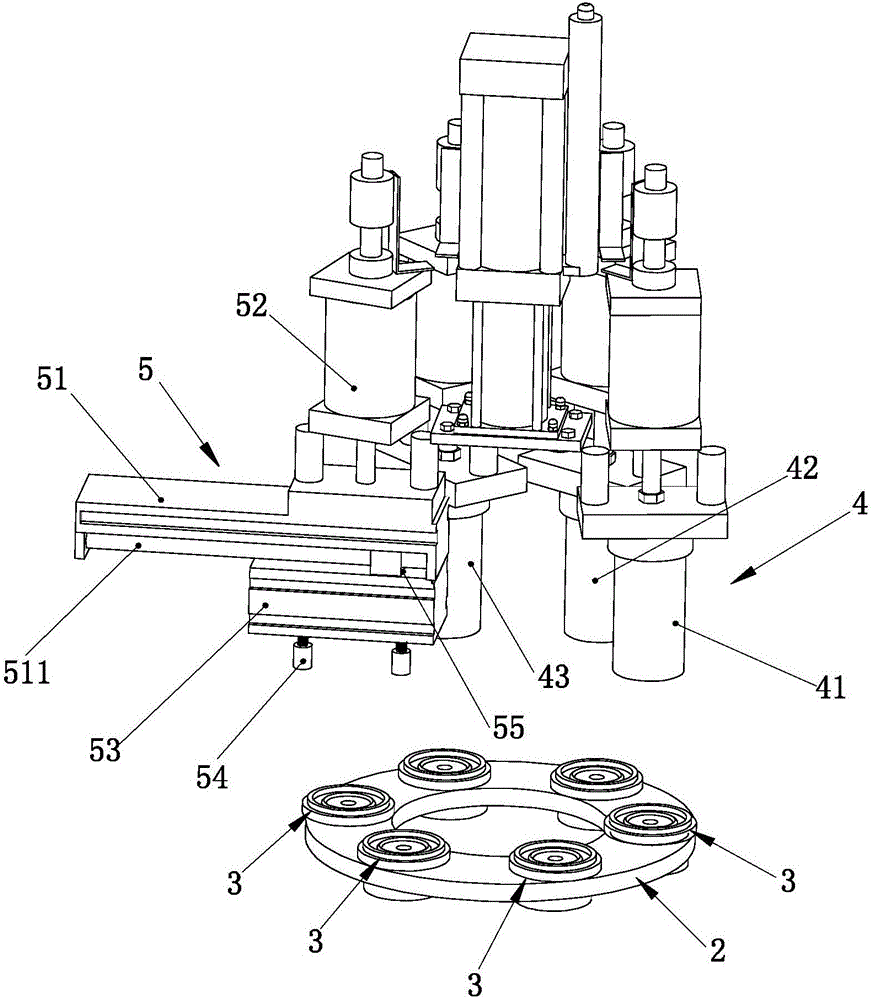

The invention discloses a semi-automatic rotary riveting fixture and a riveting method thereof, and belongs to the technical field of riveting fixtures. The semi-automatic rotary riveting fixture disclosed by the invention comprises a pressing machine, an upper die, lower dies, a material taking unit and an electronic control unit, wherein the upper die is connected with the pressing machine, an indexing unit is arranged below the upper die, the indexing unit comprises a pneumatic divider and an indexing disc, and the pneumatic divider drives the indexing disc to rotate in a horizontal direction; a plurality of the lower dies are provided, and are movably arranged on the indexing disc at an equal interval; the material taking unit is arranged at the side of the indexing unit, and is used for absorbing the riveted parts; and the electronic control unit is used for controlling the mechanisms to cooperatively act. According to the semi-automatic rotary riveting fixture and the riveting method thereof which are disclosed by the invention, two or more parts can be riveted in one process, the three steps of loading, riveting and material taking are completed simultaneously, and only the upper die and the lower die need to be replaced if different parts need to be replaced for riveting due to a creative modularized design, thus the use range of the equipment is expanded, and the working efficiency is increased.

Owner:JIANGSU DAQO KFINE ELECTRIC

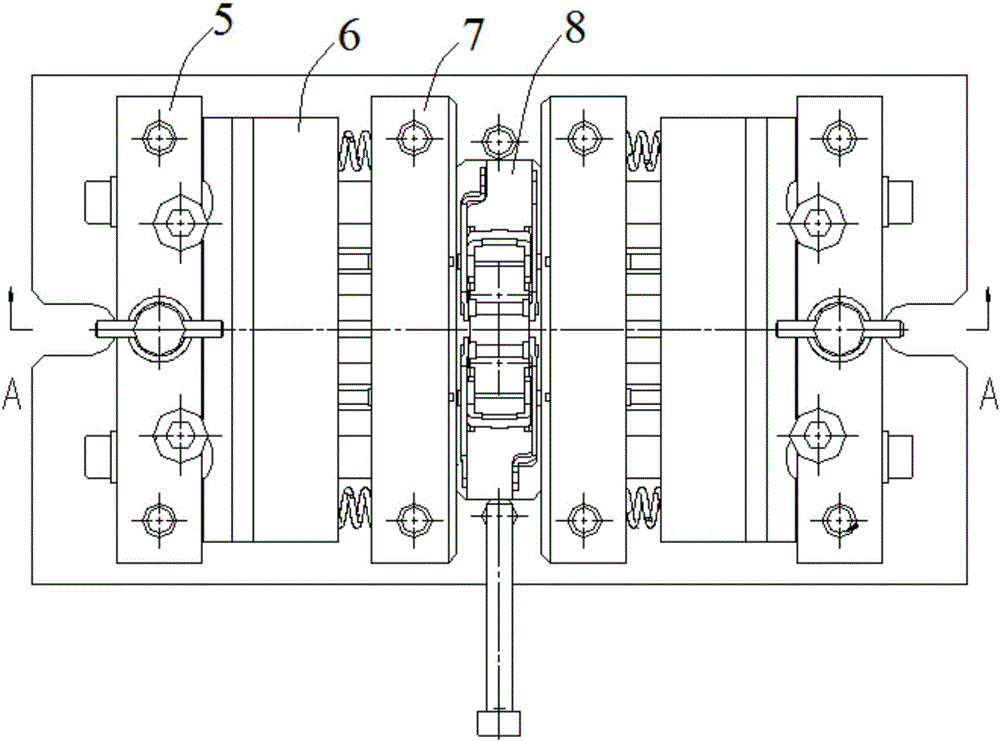

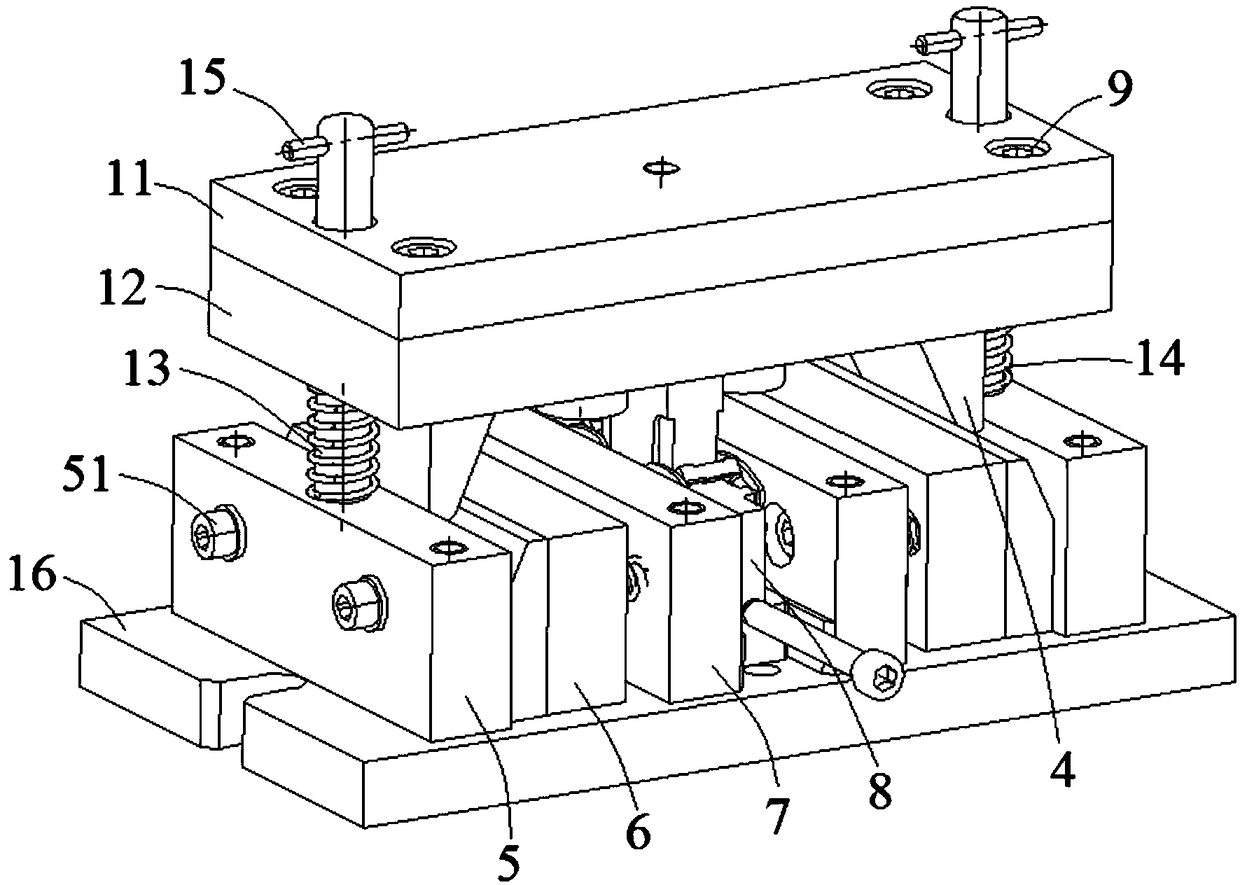

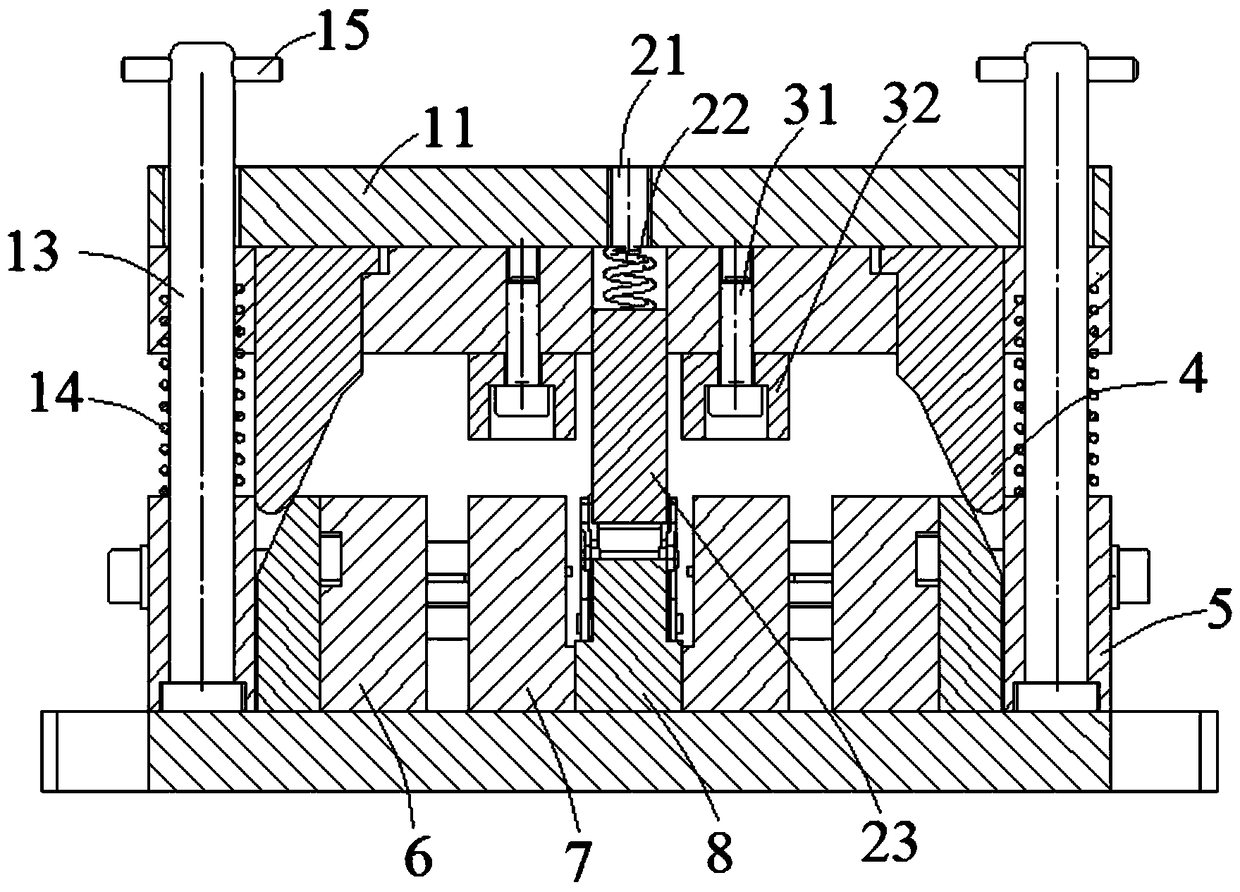

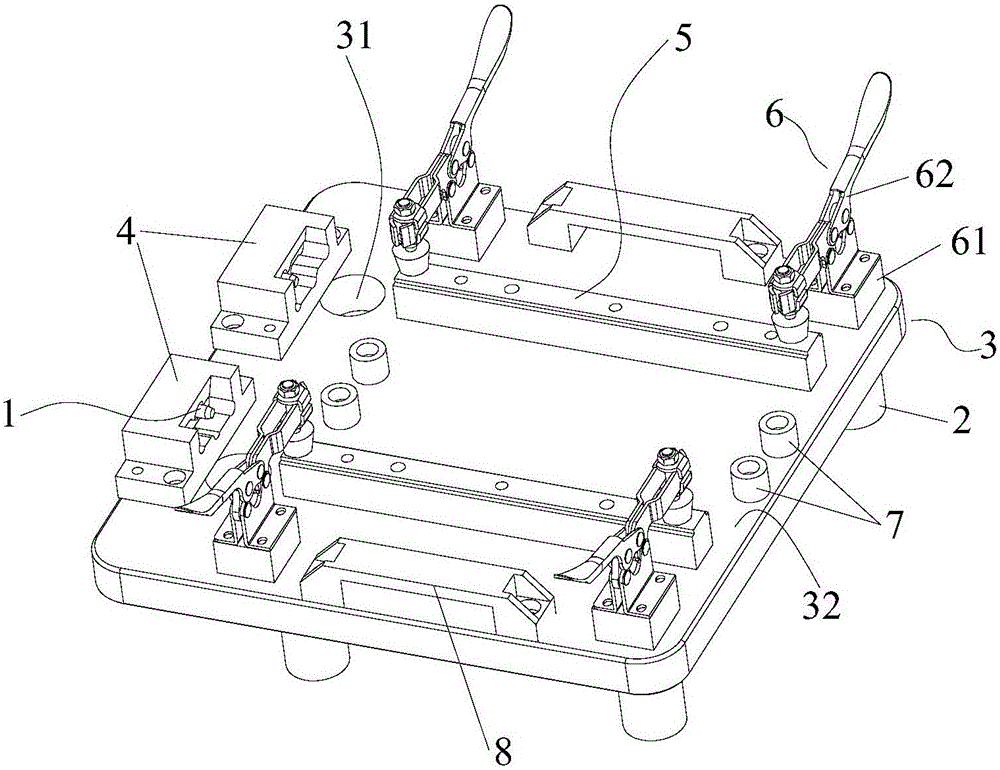

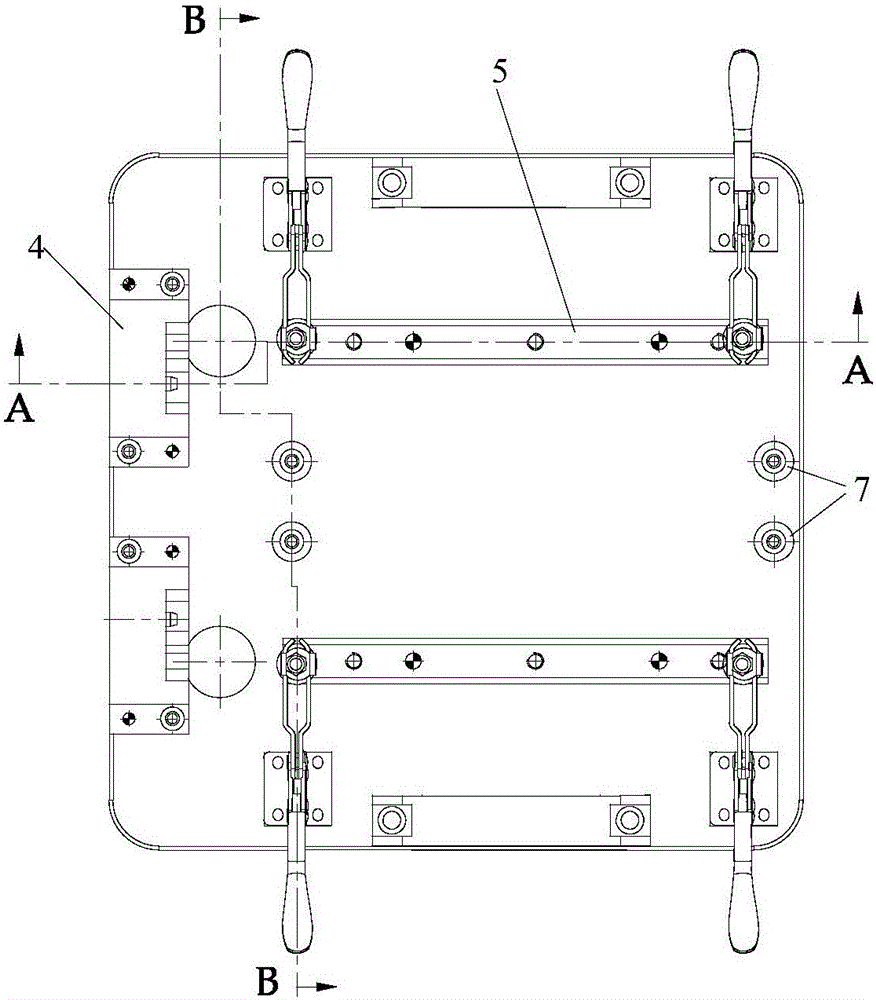

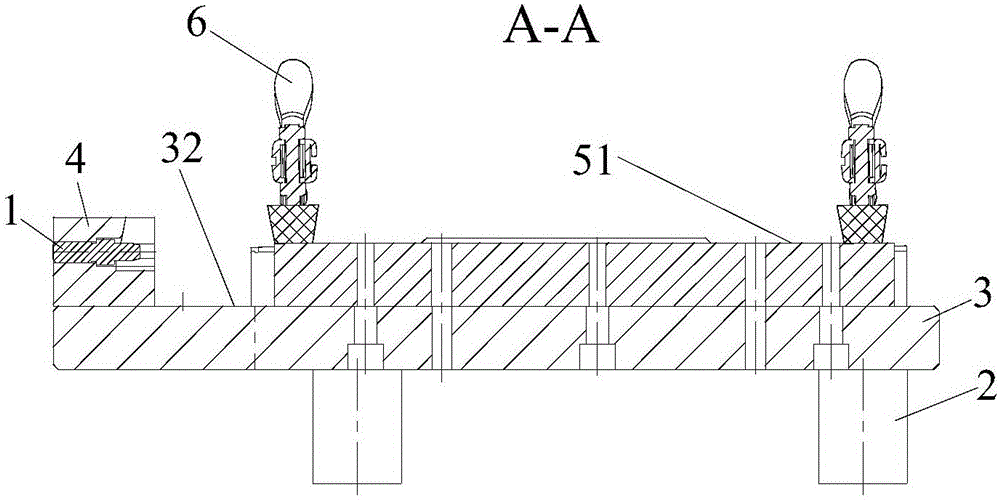

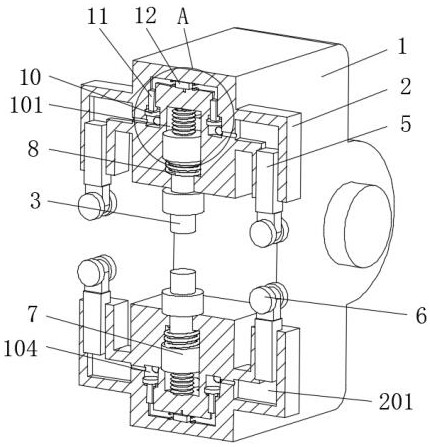

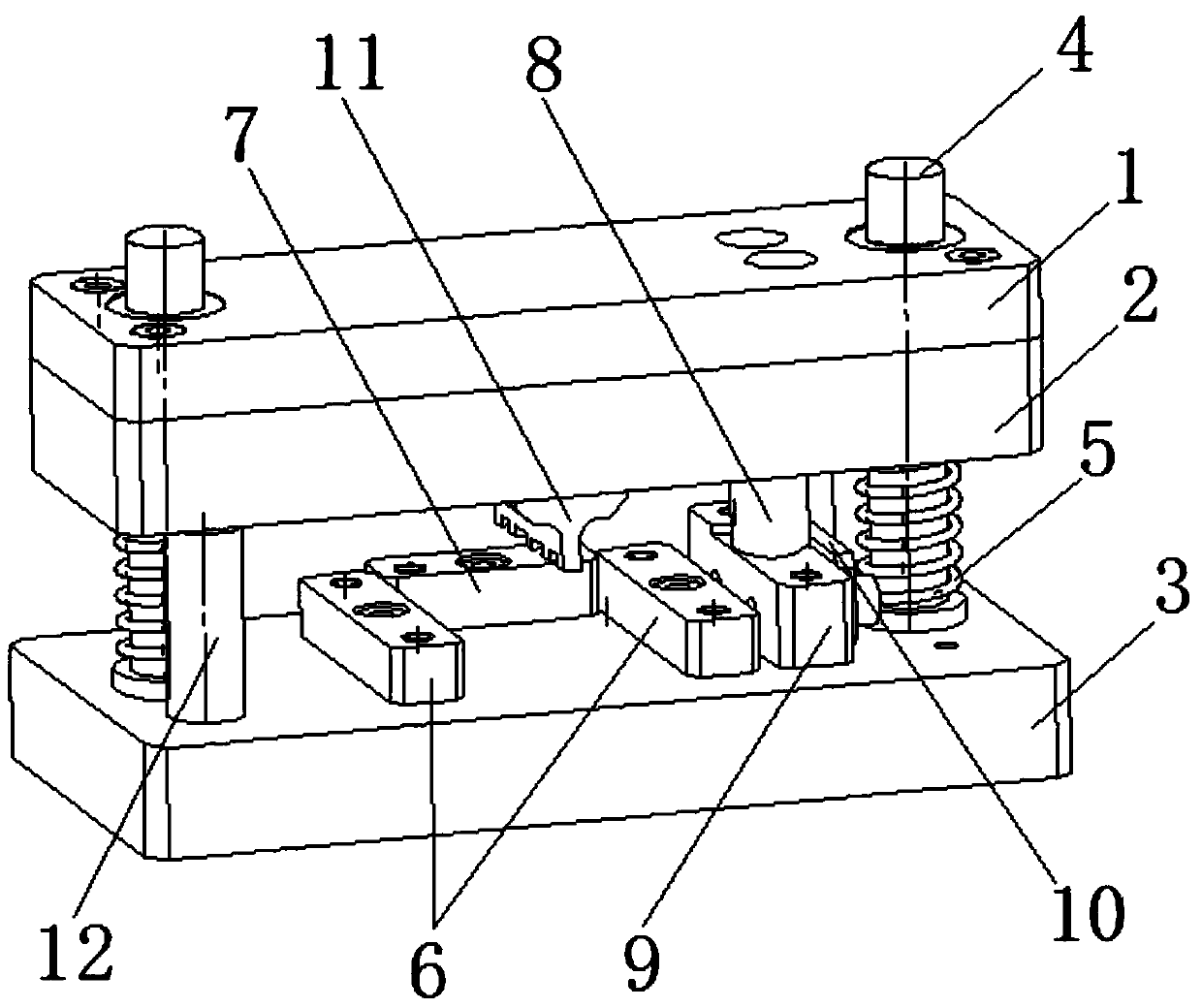

Jump catch clamp, integrated tool for jump catch riveting and flanging and machining method thereof

ActiveCN106653495AEasy to placeNot easy to scatterEmergency protective device manufactureEngineeringMechanical engineering

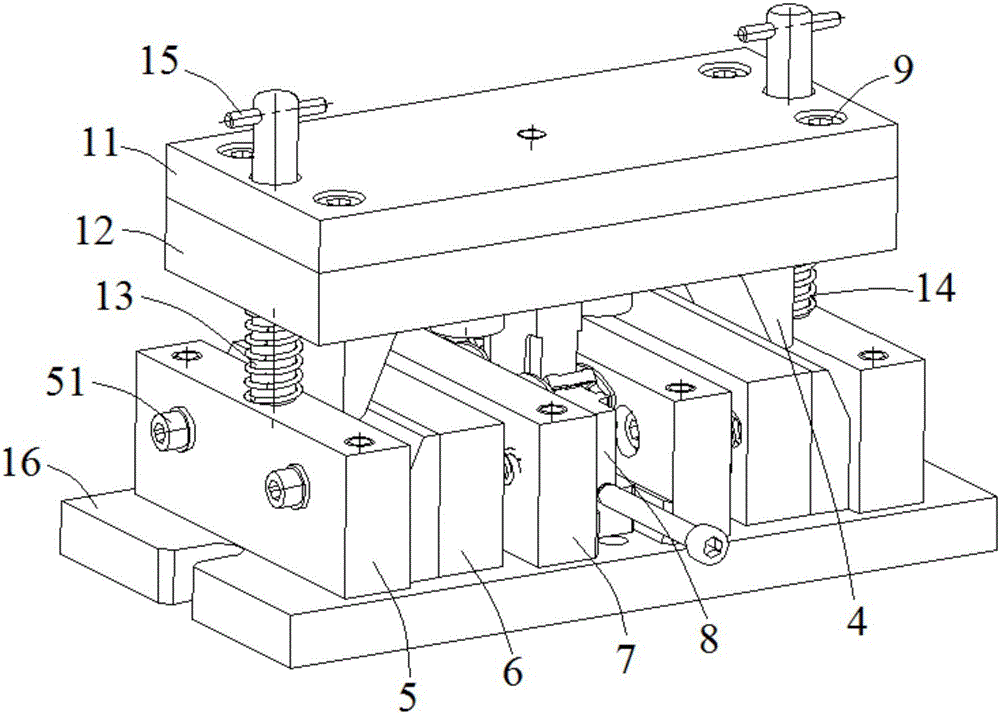

The invention discloses a jump catch clamp, an integrated tool for jump catch riveting and flanging and a machining method thereof, and the jump catch clamp is a special clamp. The tool disclosed by the invention comprises an upper die, a guide post, a guide post spring, a base plate, sliding block assemblies, a first lower die upright post plate and the jump catch clamp, wherein the guide post is serially connected to the upper die, the first lower die upright post plate and the base plate; the guide post spring is arranged on the guide post in a penetrating manner; the jump catch clamp can be inserted in a drawer groove in the middle part of the base plate; the sliding block assemblies capable of moving horizontally are arranged on the left side and the right side of the jump catch clamp; a riveting punch is arranged on the side, close to the jump catch clamp, of each sliding clock assembly, and an inclined wedge surface is arranged on the other side of each sliding block assembly; an inclined pressing block is arranged above each inclined wedge surface; the inclined pressing blocks are connected with the upper die; and the inclined pressing blocks are provided with inclined wedge surfaces matched with the inclined wedge surfaces of the sliding block assemblies. The jump catch can be assembled at a time, the riveting and flanging quality is reliable, and the production efficiency is improved.

Owner:JIANGSU DAQO KFINE ELECTRIC

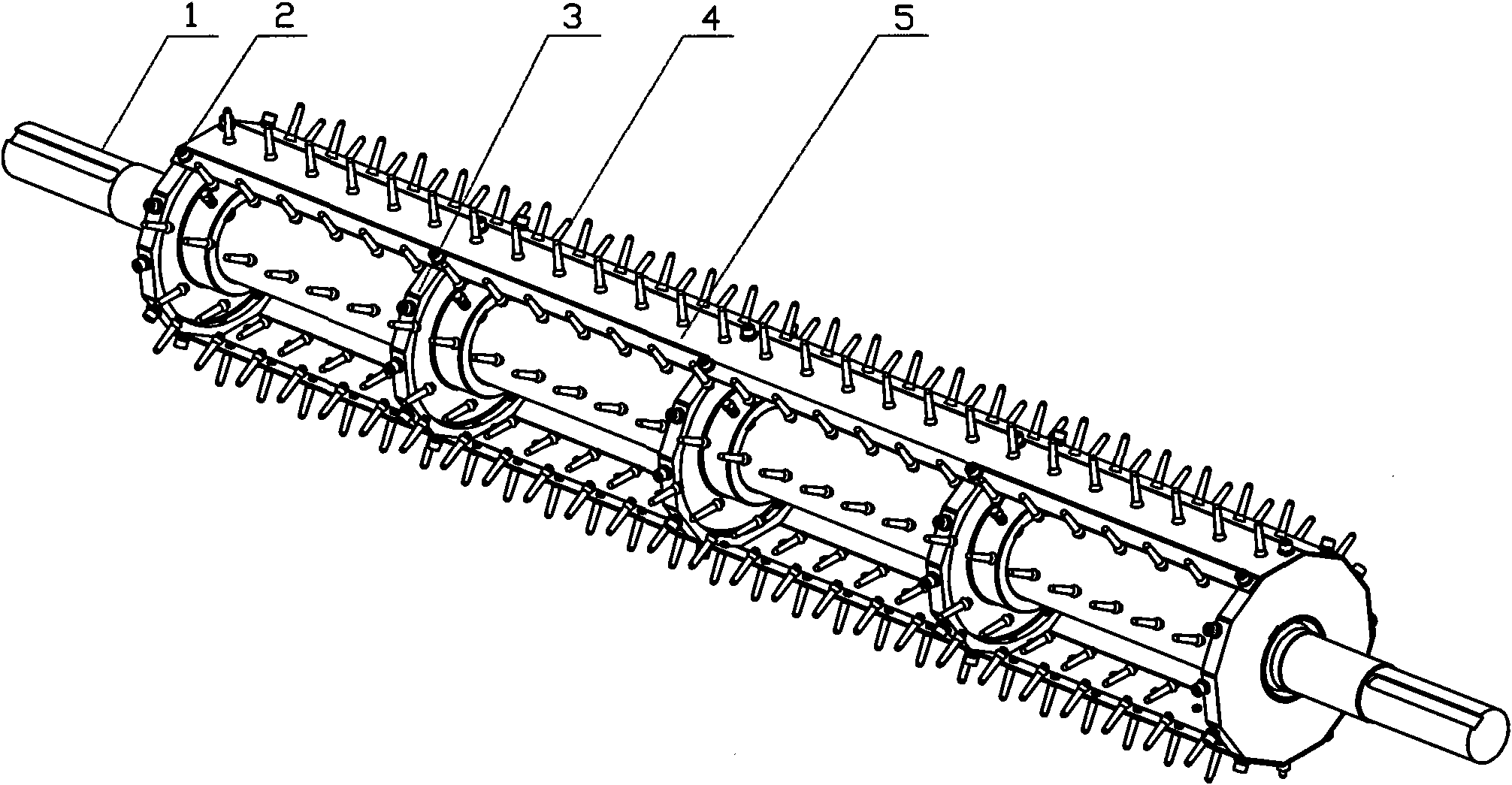

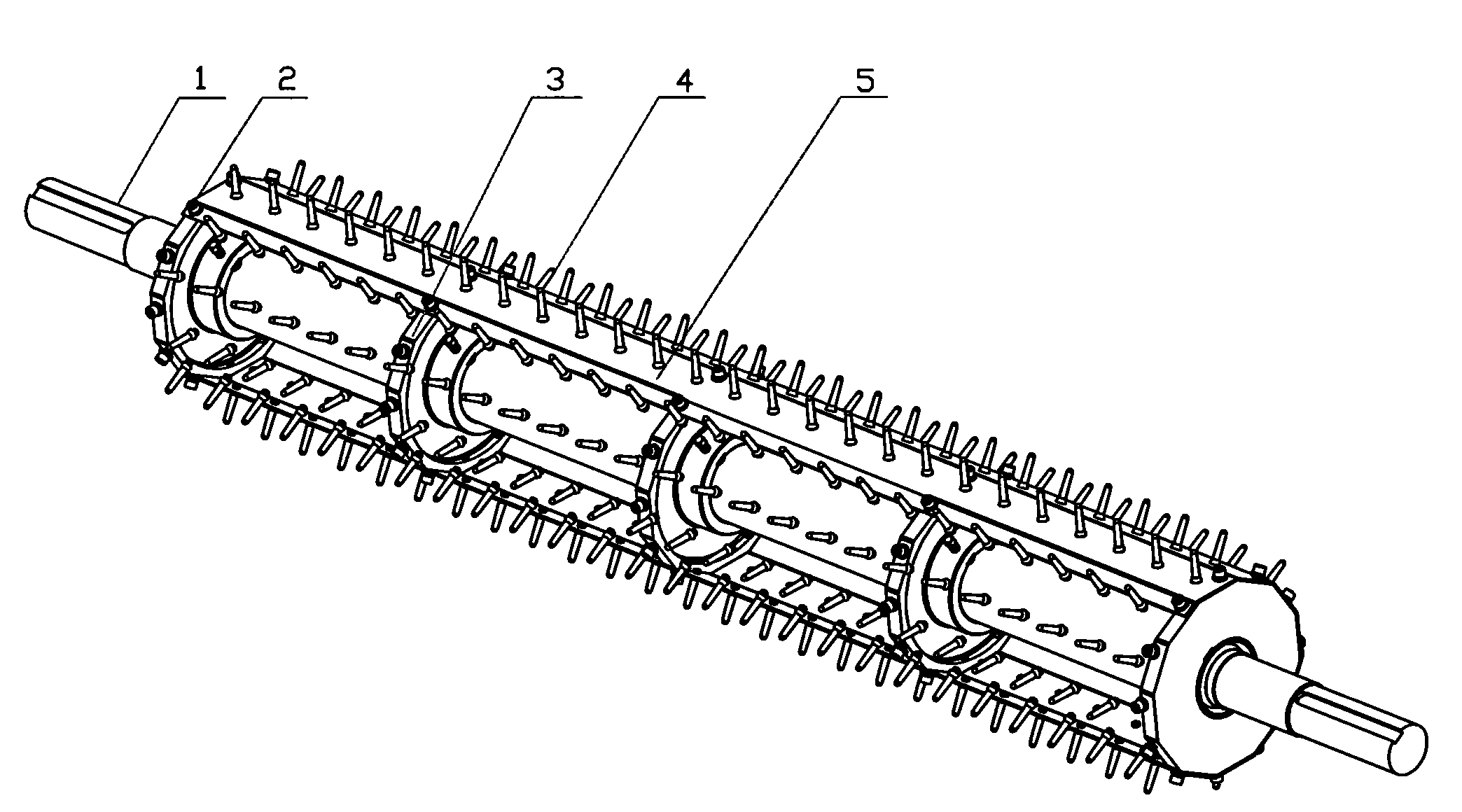

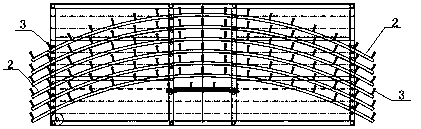

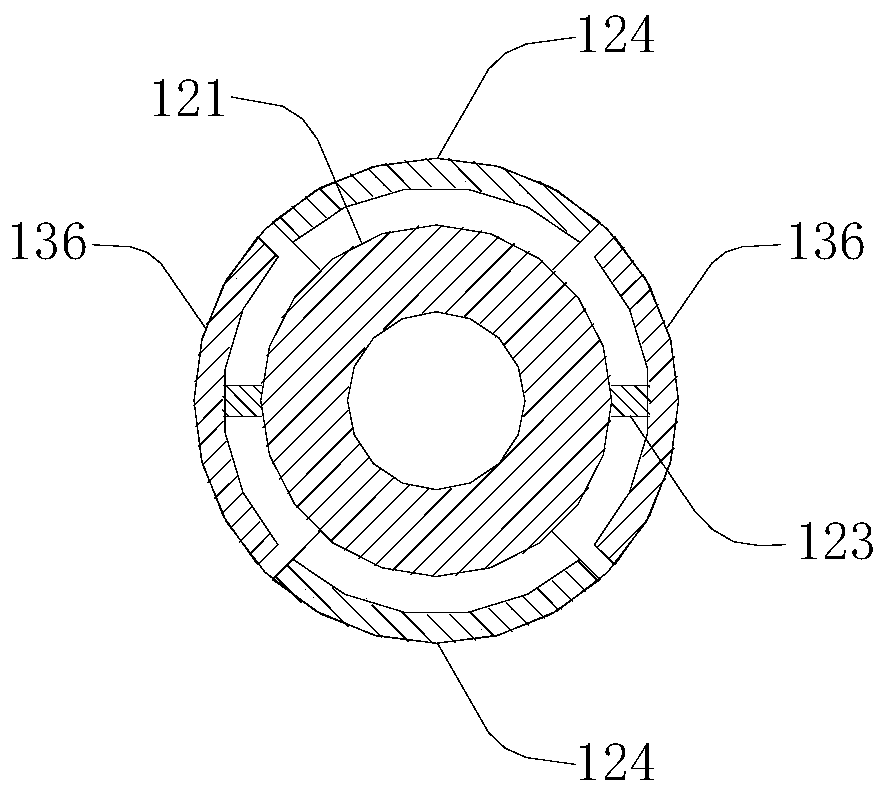

Barbed nail roller assembly

The invention discloses a barbed nail roller assembly which comprises a pipe shaft, a group of flanges and a wrapping plate, wherein the flanges are arranged along with axial direction of the pipe shaft and are coaxial with the pipe shaft; the wrapping plate is fixed on the flanges to form a cylinder; barbed nails are uniformly arranged on the wrapping plate; each flange has a regular pyramid structure; the wrapping plate comprises a plurality of split bodies which are exactly divided by the arris number of the regular pyramid; the split blocks are used for forming the side surface of the cylinder; and the barbed nails are spherical crown tapered barbed rivets. The barbed nail roller assembly has high motion precision, high reliability and long service life.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

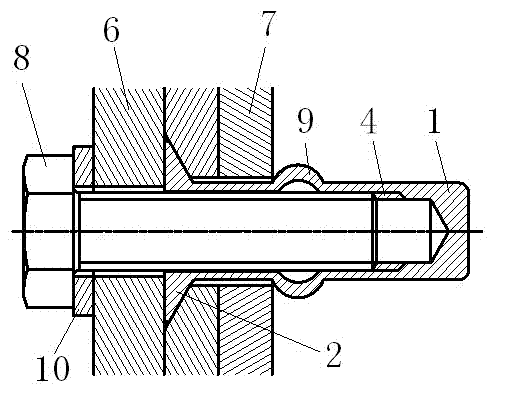

Method for automatically riveting multi-layer sheets in screw joint and screw nuts applied

ActiveCN103089765AGuarantee riveting qualityImproved sealing and reliabilityNutsSheet joiningScrew jointHigh speed train

The invention discloses a method for automatically riveting multi-layer sheets in screw joint and screw nuts applied. In the method, internal-thread blind-hole rivet nuts are used to automatically rivet the multi-layer sheets in screw joint; the method includes the following steps: inserting the internal-thread blind-hole rivet nuts into holes of to-be-riveted workpieces when operating; connecting the internal-thread blind-hole rivet nuts with internal threads arranged at the bottoms of the internal-thread blind-hole rivet nuts through bolts; riveting multi-layer sheets together by compressionally deforming the thin-wall portions of the internal-thread blind-hole rivet nuts to be distended outwards when the bolts are tightened and the internal-thread blind-hole rivet nuts are contracted axially inwards; and meanwhile, topping sheets are in screw joint with multi-layer sheets through the bolts. The method for automatically riveting multi-layer sheets in screw joint requires no extra installing tools when used, so that the technical problem that a riveter is difficult to be used for riveting in a narrow area is solved, riveting quality is well guaranteed, and reliability and tightness in riveting are improved. The method for automatically riveting multi-layer sheets in screw joint is suitable for aviation and aerospace, high speed trains and some high-demanding important situations with toxic-resistant or corrosive air or liquid.

Owner:AEROSPACE PRECISION PROD INC LTD

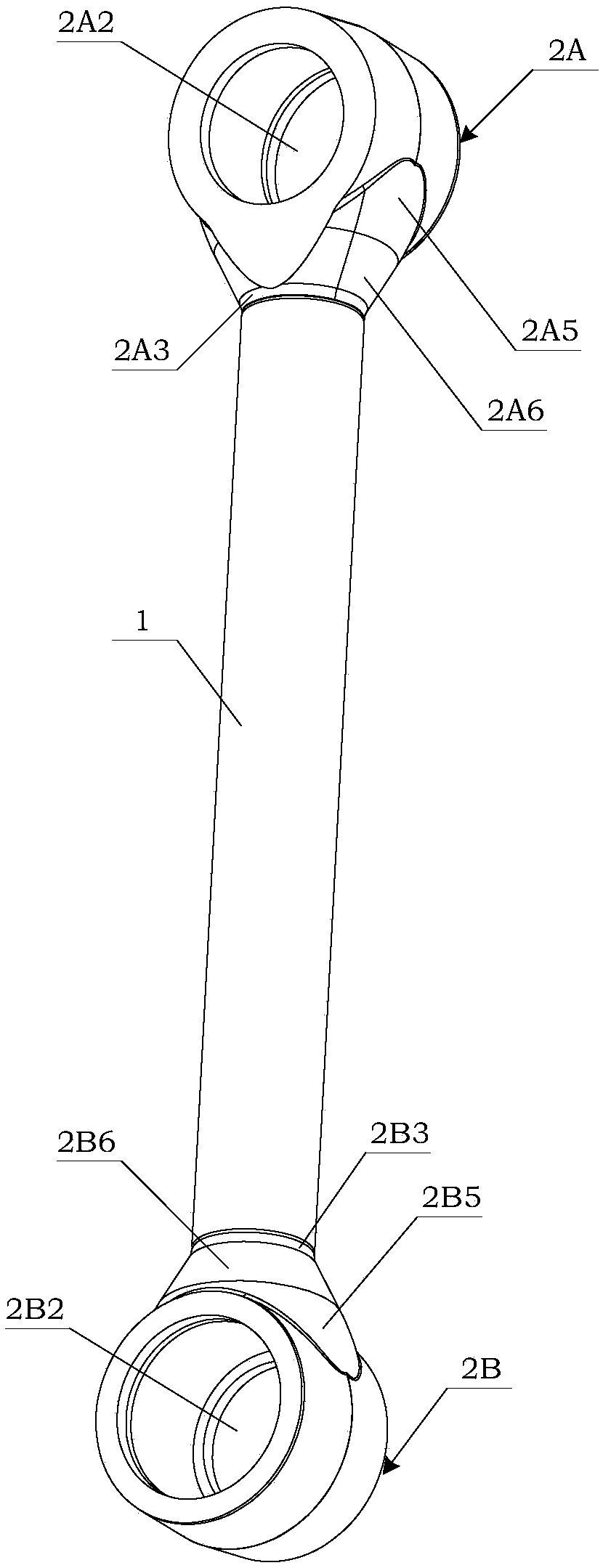

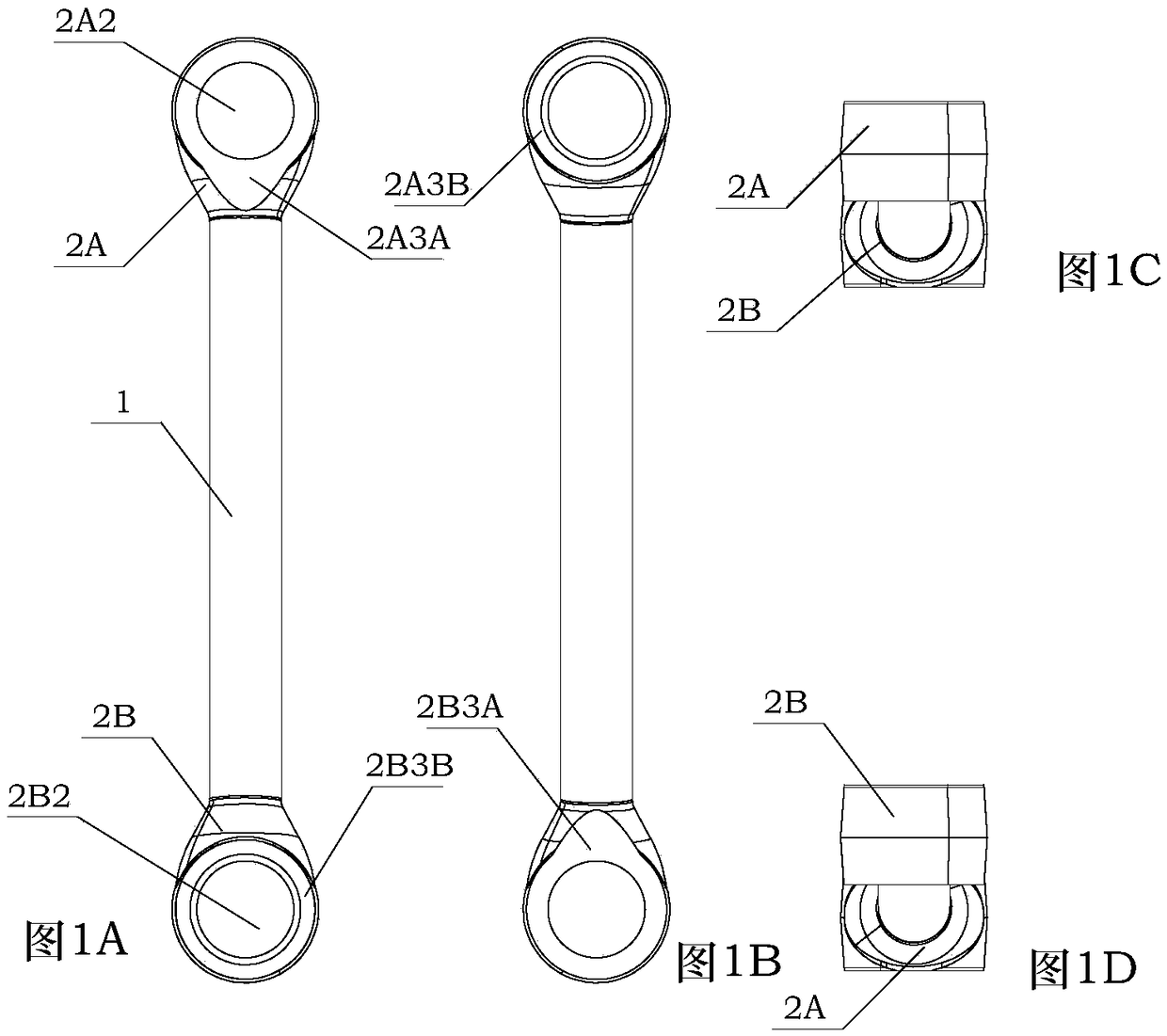

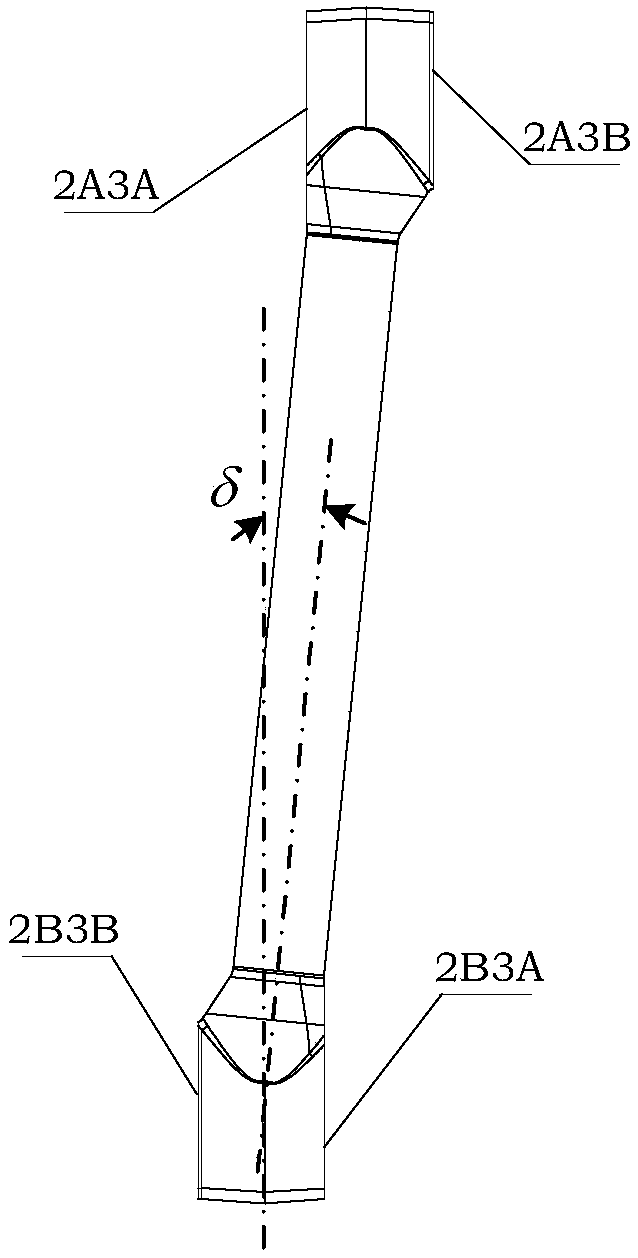

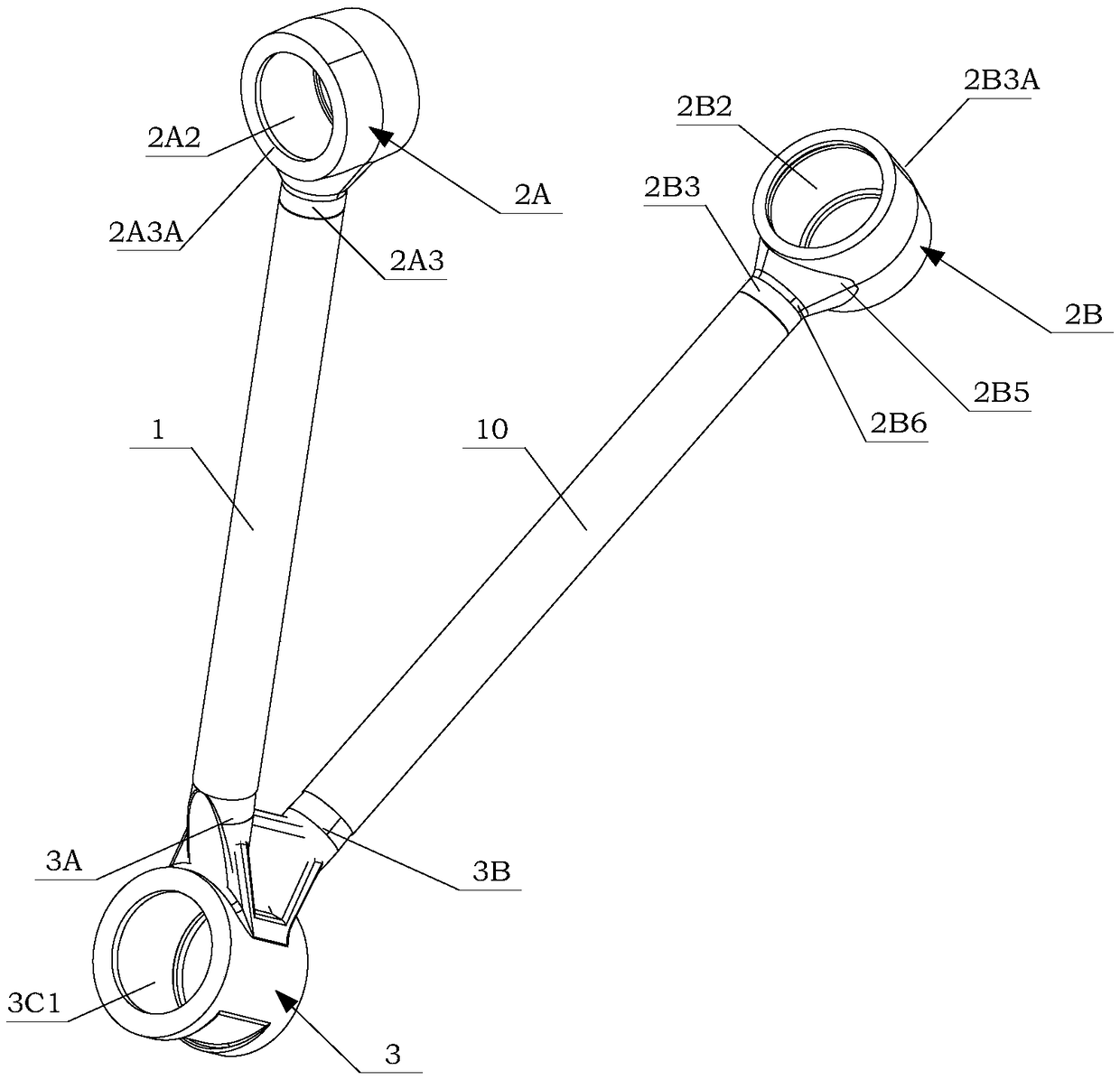

Aluminum alloy split-type I-type thrust rod and preparation process thereof and friction stir welding and fitting method thereof

InactiveCN108973567AHigh strengthImprove performancePivoted suspension armsNon-electric welding apparatusFriction weldingMaterials science

The invention discloses an aluminum alloy split-type I-type thrust rod, wherein the material of the thrust rod is aluminum alloy, and the preferred composition can be Al-Cu-based alloy, Al- Si-based alloys, Al-Mg-Si-based alloys, Al-Mg-Si- Cu-based alloy or Al-Mg-based alloys, and aluminum alloys in which trace alloying elements such as Sr, La, Ce, Y, Sc, Er, Nb, B, and Cr are added to the aluminum-based alloys. The aluminum alloy split-type I-type thrust rod sleeve is composed of a ball head and a ball hinge, two ends of the sleeve are respectively installed with a ball head, and the ball hinge is installed in a through hole of the ball head; The neck of the spherical head is a combination of an elliptical shape and an arc shape, which improves the bearing capacity. The aluminum alloy thrust rod sleeve and the ball head are prepared by a hot extrusion molding and / or a forging molding process. As that sleeve and the ball head are arrange by friction welding or friction stir welding, the thrust rod is obtained, and the weight reduction effect can reach 40 to 70 percent.

Owner:北京航大新材科技有限公司

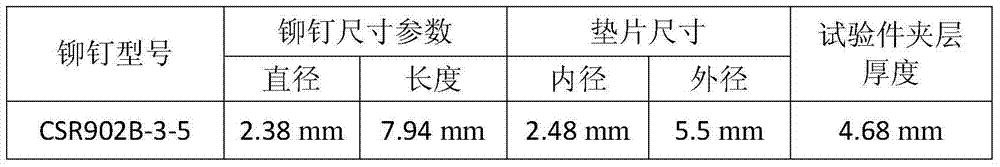

Process method of electromagnetic riveting composite material

The invention discloses a process method for achieving an electromagnetic riveting composite material. The method mainly resolves the problem that when riveting is carried out through a traditional riveting method at preset, the composite material is damaged easily. The process method for achieving the electromagnetic riveting composite material adopts the electromagnetic riveting technology, and largely reduces the installation damage to the structure of the composite material in the riveting process through a specially designed gasket and an appropriate tack hole interval and rivet overhang, thereby improving the quality of connectors.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

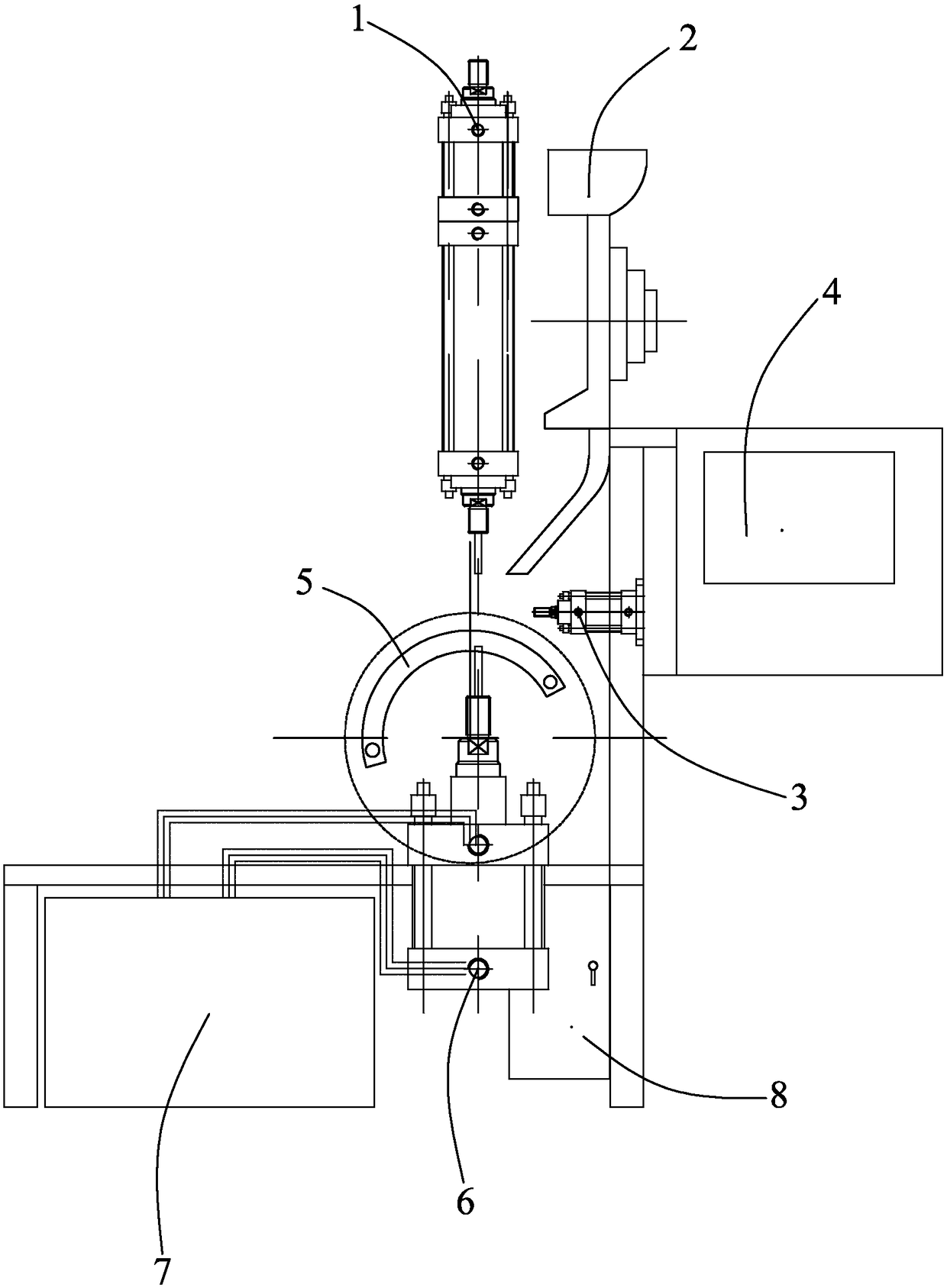

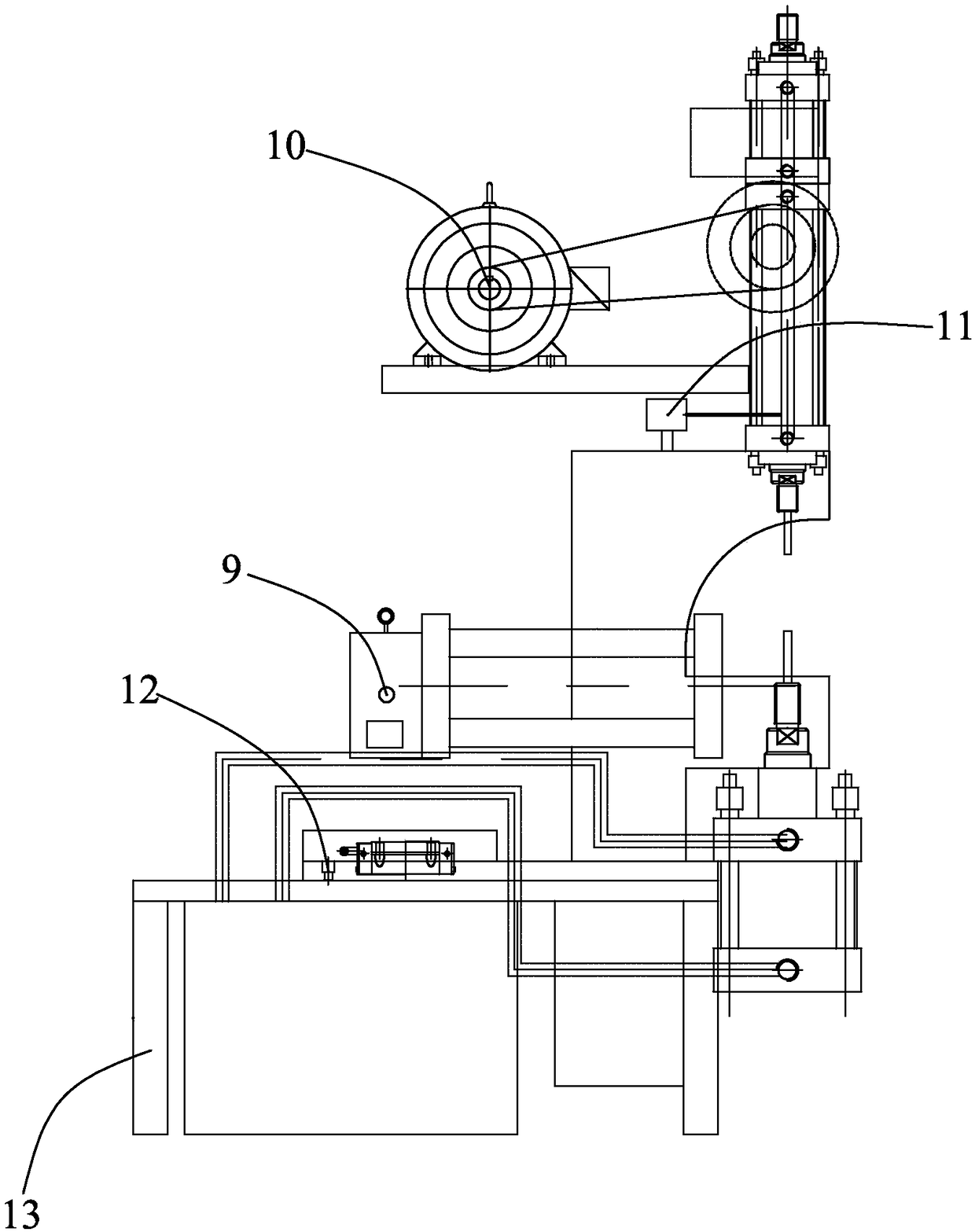

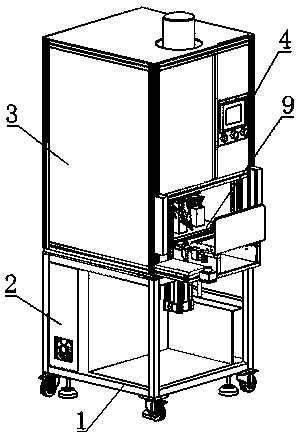

Full-automatic riveting machine

The invention discloses a full-automatic riveting machine. The machine comprises a pressurizing air cylinder, an automatic feeding mechanism, an auxiliary air cylinder, a PLC, a clamp, an upward jacking oil cylinder, a hydraulic station, an electric control box, an index plate, a motor, a pressure sensor, a rail line and a support table; the pressurizing air cylinder is arranged in the vertical direction, the automatic feeding mechanism is located on one side of the pressurizing air cylinder, the PLC and the auxiliary air cylinder are located on the lower side of the automatic feeding mechanism, the PLC is connected with the auxiliary air cylinder, the clamp is arranged on the lower side of the pressurizing air cylinder, the upward jacking oil cylinder is located on the lower side of the clamp, the hydraulic station and the electric control box are located on the two opposite sides of the upward jacking oil cylinder, the support table is located on the lower side of the index plate, and the rail line is supported on the support table. The full-automatic riveting machine is simple and reasonable in structure, easy and convenient to operate, and convenient to maintain, a worker can easily learn and know the machine, labor intensity of the worker is reduced, production efficiency is improved, the riveting quality is ensured, and production cost of an enterprise is saved.

Owner:靖江市恒大汽车部件制造有限公司

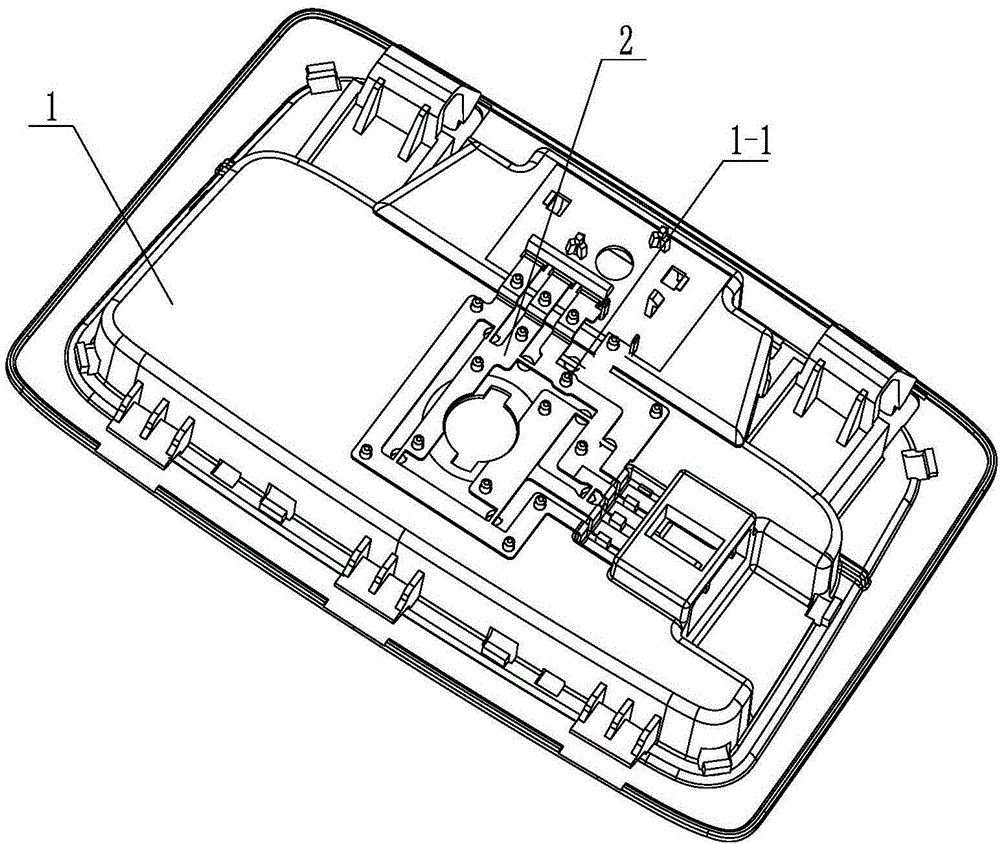

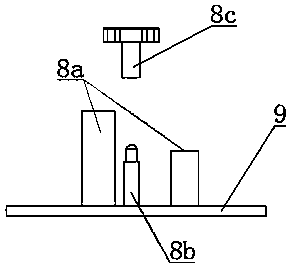

Plastic hot riveting device for automobile lamp

The invention relates to a plastic hot riveting device for an automobile lamp. A workbench is provided with a lamp body positioning mechanism, a press riveting mechanism, a rivet head grabbing mechanism and a heating mechanism. The lamp body positioning mechanism comprises a push air cylinder, a lamp body positioning base and a floating positioning base. The push air cylinder installed on the workbench is connected with the lamp body positioning base. The floating positioning base is connected with the lamp body positioning base and arranged at the upper portion of the lamp body positioning base. A rivet head positioning plate on the floating positioning base is borne on a lower elastic body. The press riveting mechanism comprises a rivet pressing air cylinder, guide columns and a rivet pressing mechanism, wherein the rivet pressing air cylinder is connected with the rivet pressing mechanism. A pressing base of the rivet pressing mechanism is provided with pressing columns and air blowing pipes, and elastic push rods connected to the pressing base are opposite to the rivet head positioning plate. The rivet head grabbing mechanism comprises a support, a lifting rod and a movable rod which are connected. The heating mechanism comprises a heating furnace and a rotary disc, and the heating furnace and the rotary disc are fixed to the workbench. The plastic hot riveting device is reasonable in structure, rapid hot riveting and cooling can be achieved during multi-point riveting, the riveting quality can be ensured, and the riveting efficiency can be improved as well.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

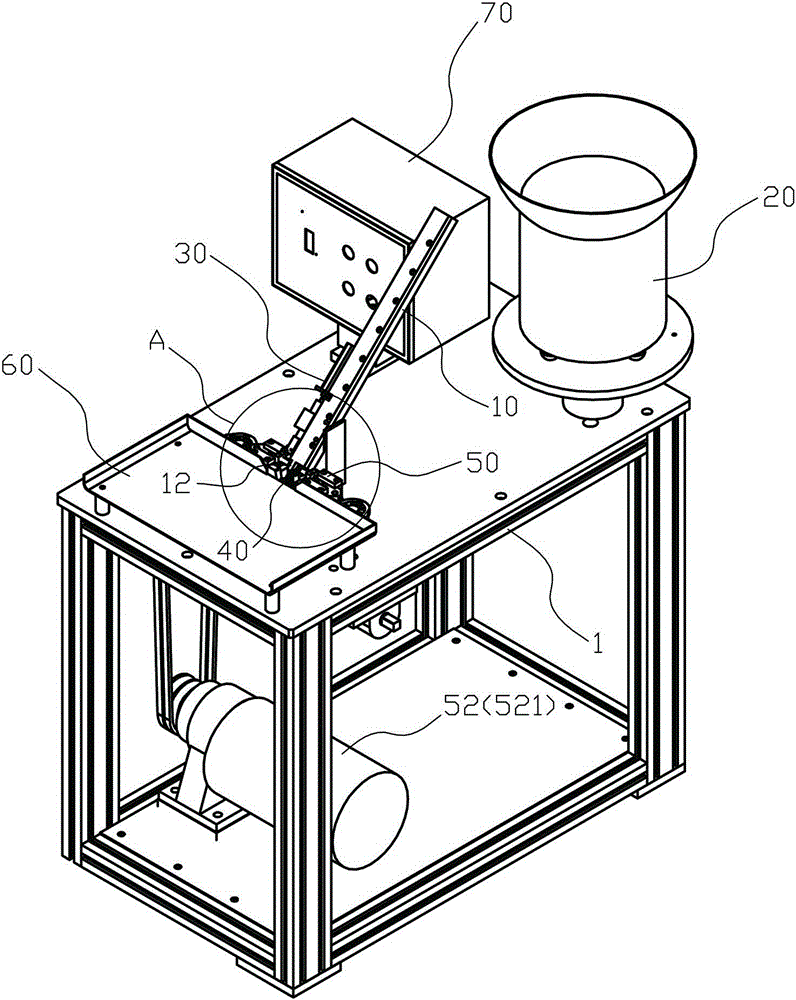

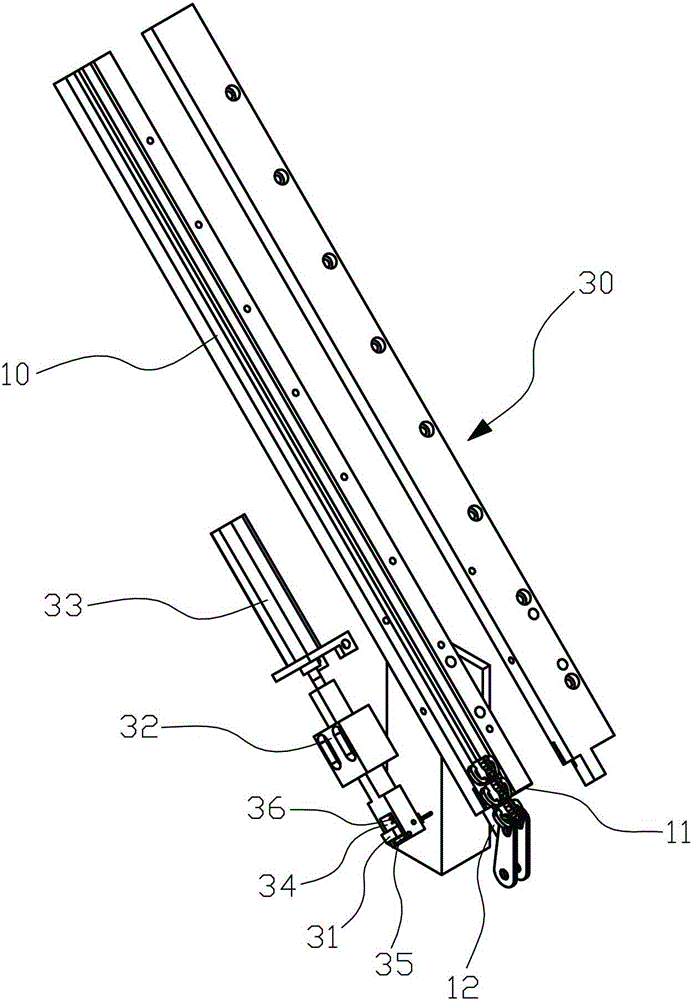

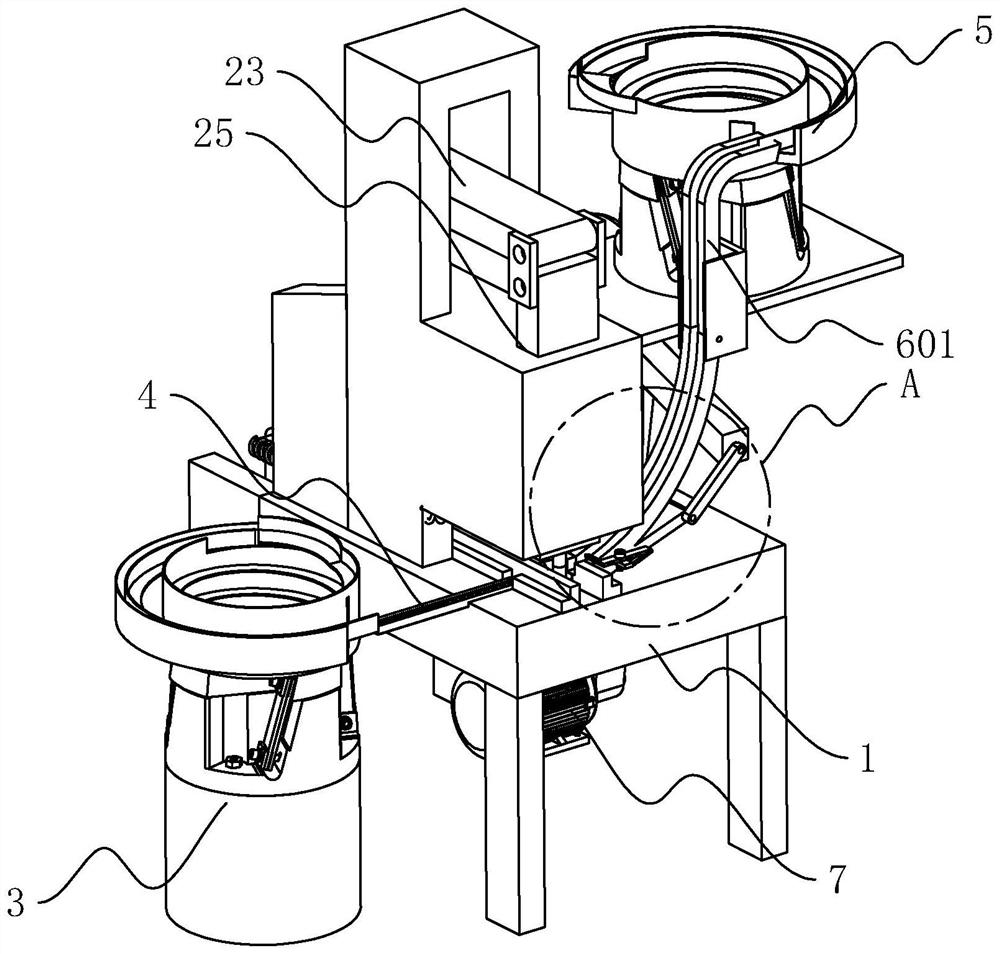

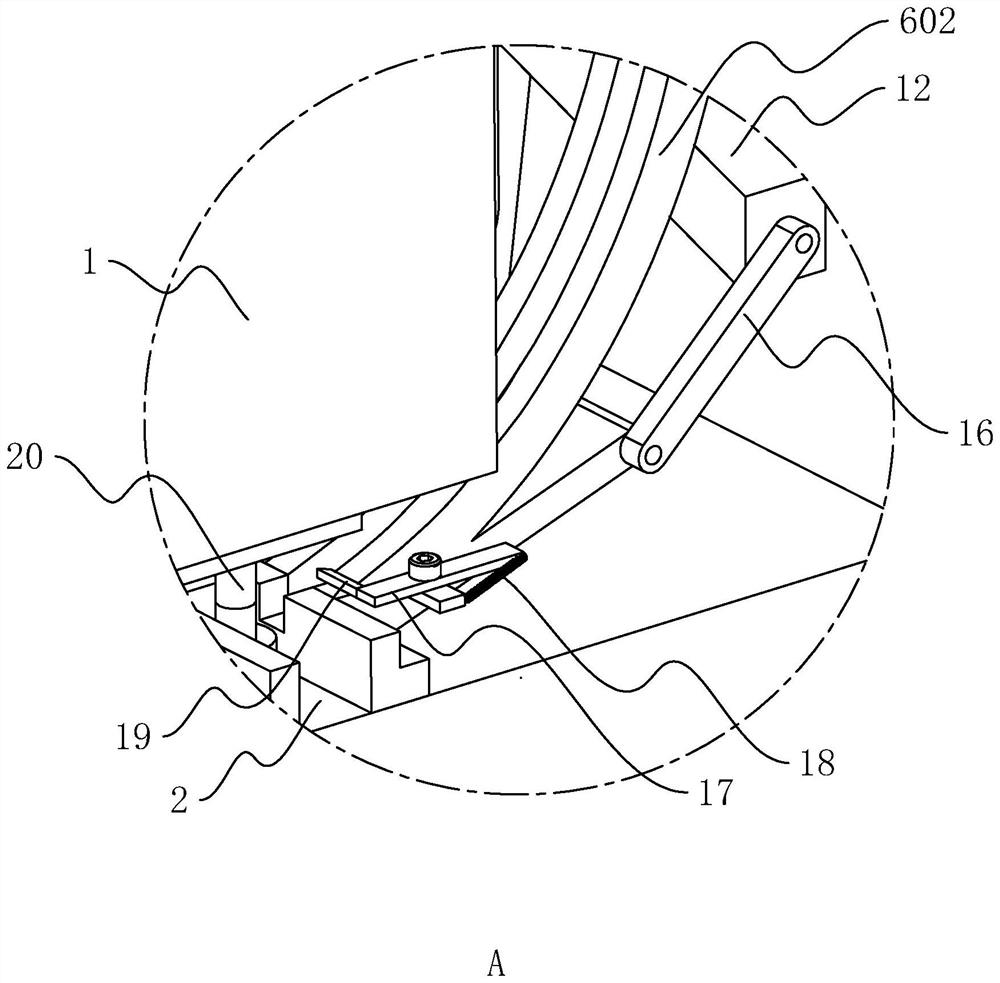

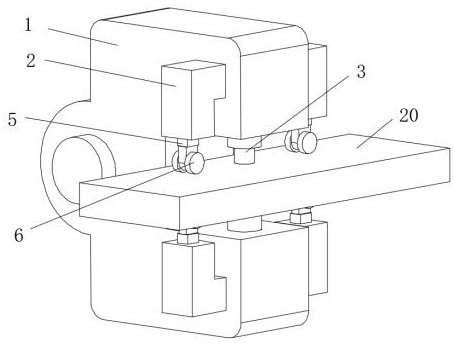

Device for riveting threaded cap plate and thin cover of full-automatic filter

InactiveCN106513522AGuarantee riveting qualityImprove processing efficiencyShaping toolsVehicle componentsEngineeringMechanical engineering

The invention relates to a riveting device, in particular to a device for riveting a threaded cap plate and a thin cover of a full-automatic filter. The invention provides the following technical scheme that the device for riveting the threaded cap plate and the thin cover of the full-automatic filter comprises a machine body, a rotatable rotary table arranged on the machine body, a plurality of positioning dies uniformly distributed on the rotary table, and at least two riveting die heads capable of being matched with the positioning dies and lifting up and down along the positioning dies in a reciprocating way. An extracting device for extracting riveted and formed products from the positioning dies is arranged on the machine body. By adopting the technical scheme, the invention provides the device for riveting the threaded cap plate and the thin cover of the full-automatic filter, which has no need for manual operation, and is high in riveting efficiency, guaranteed in quality, and simple in structure.

Owner:陈正江

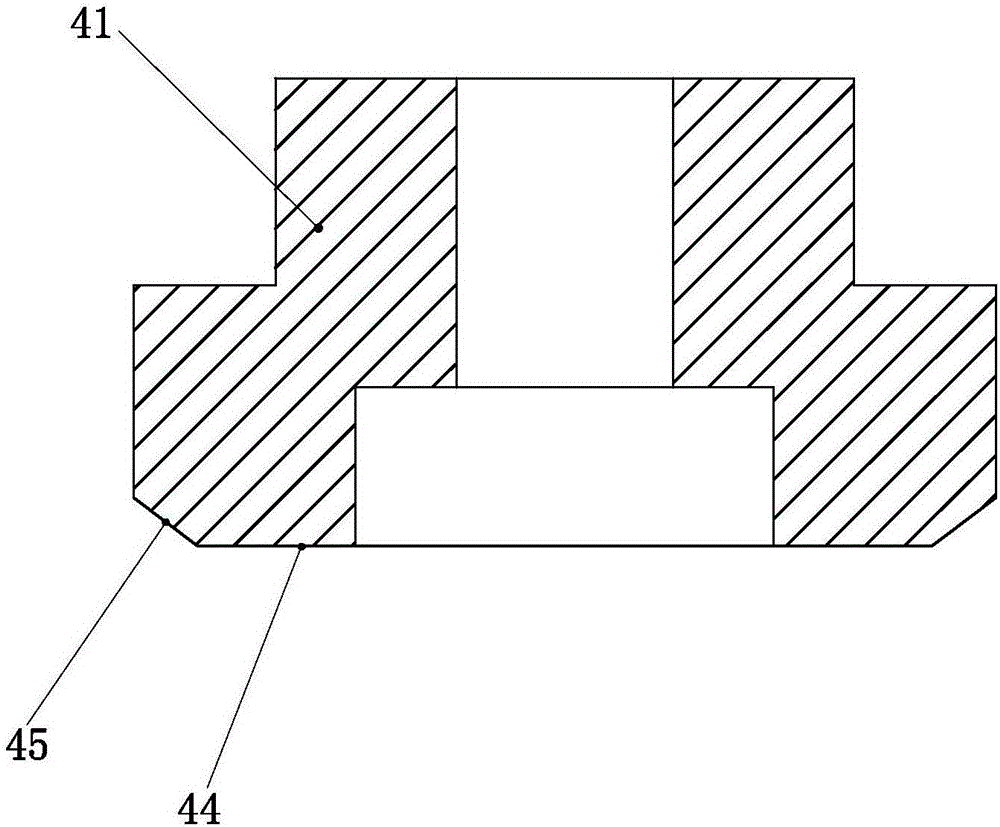

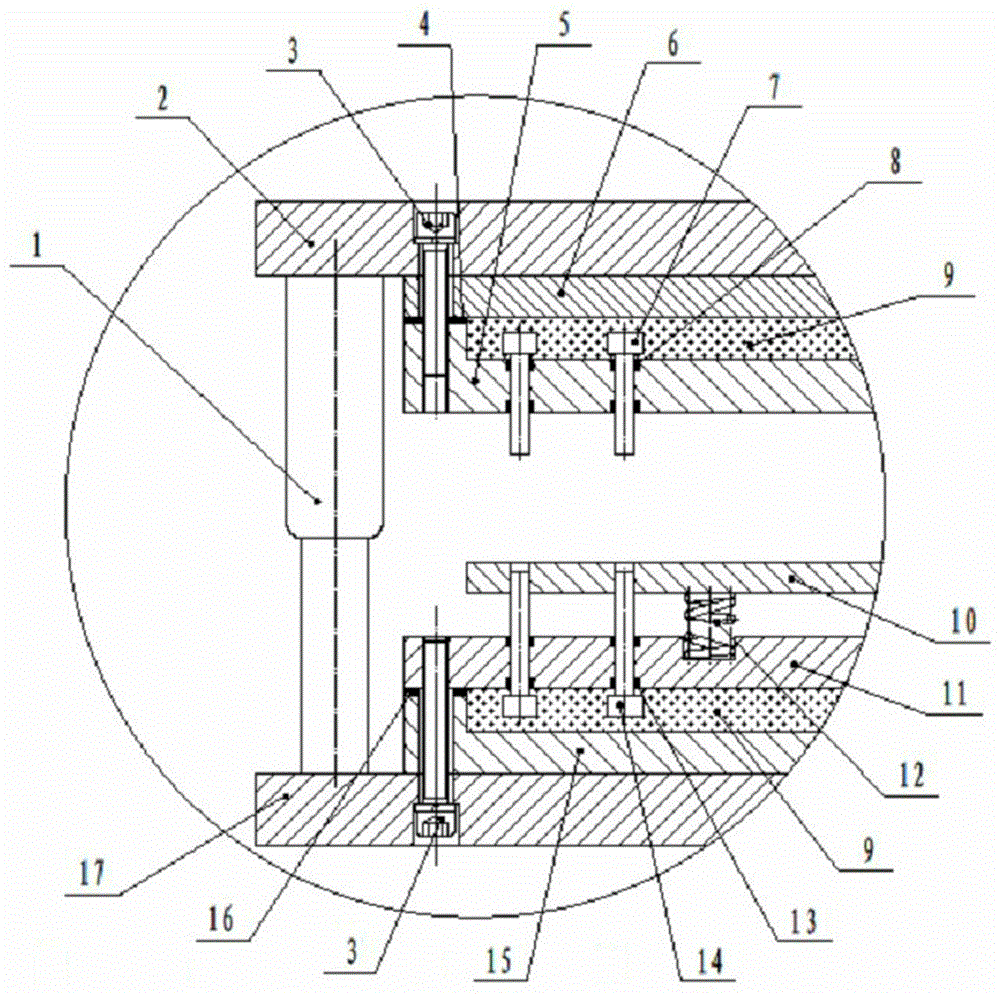

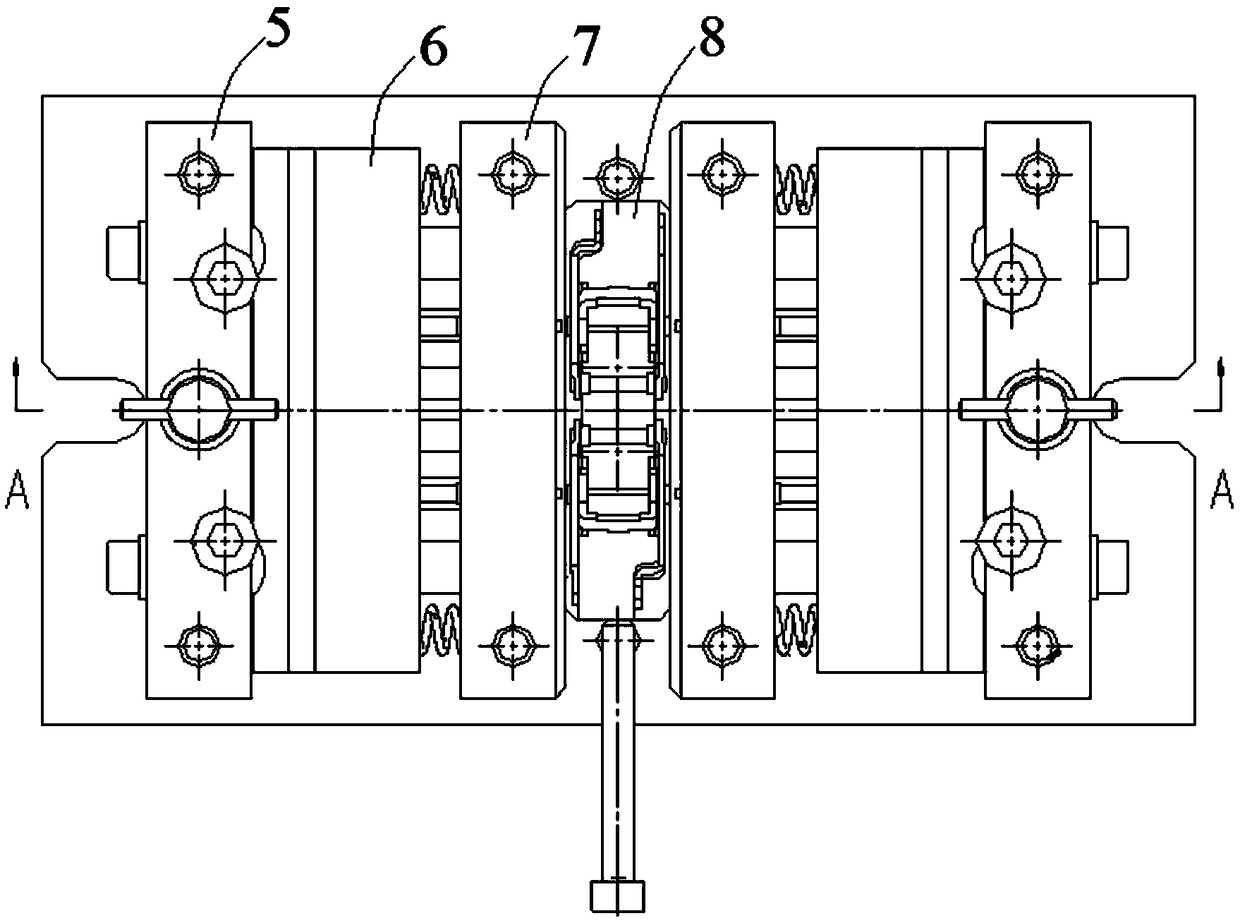

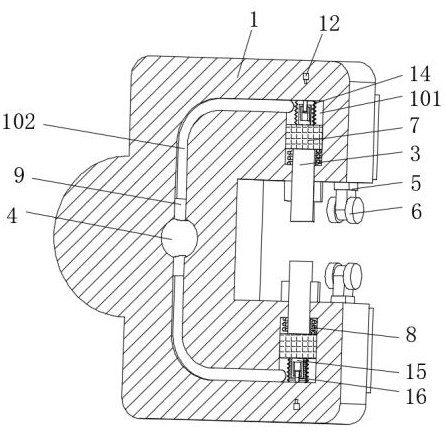

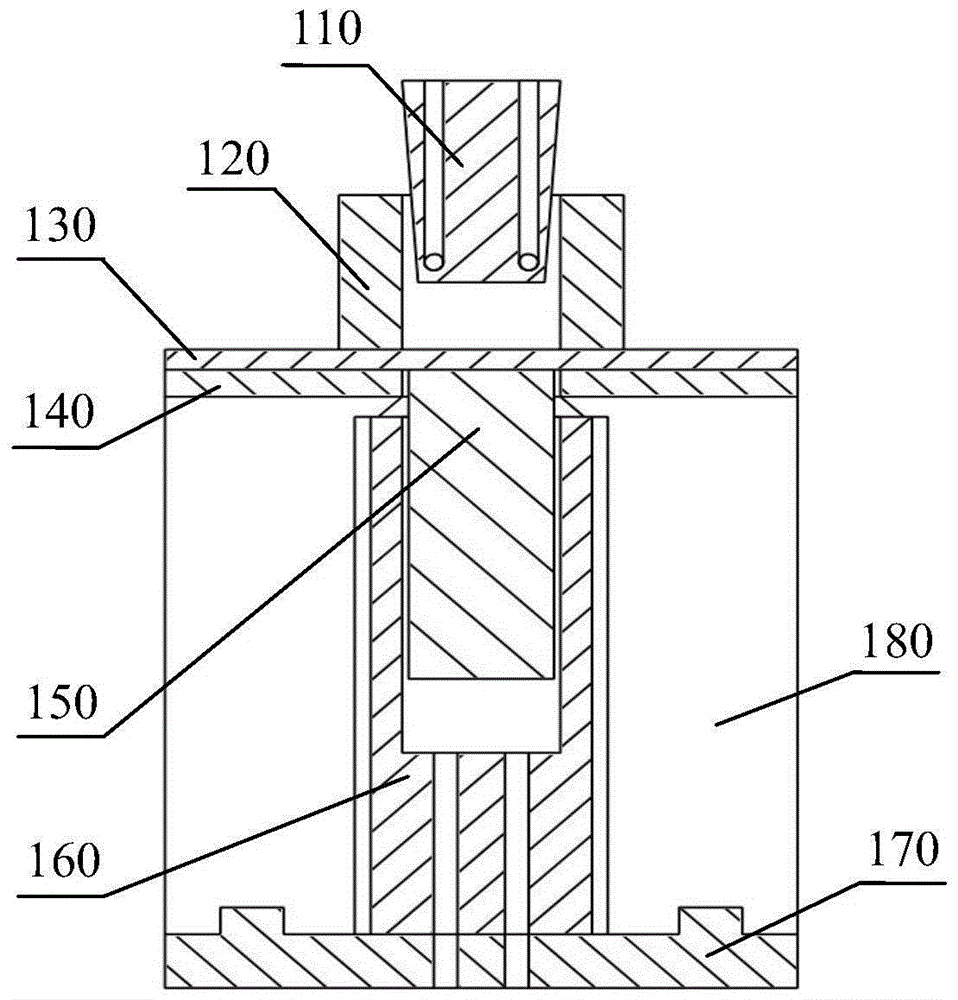

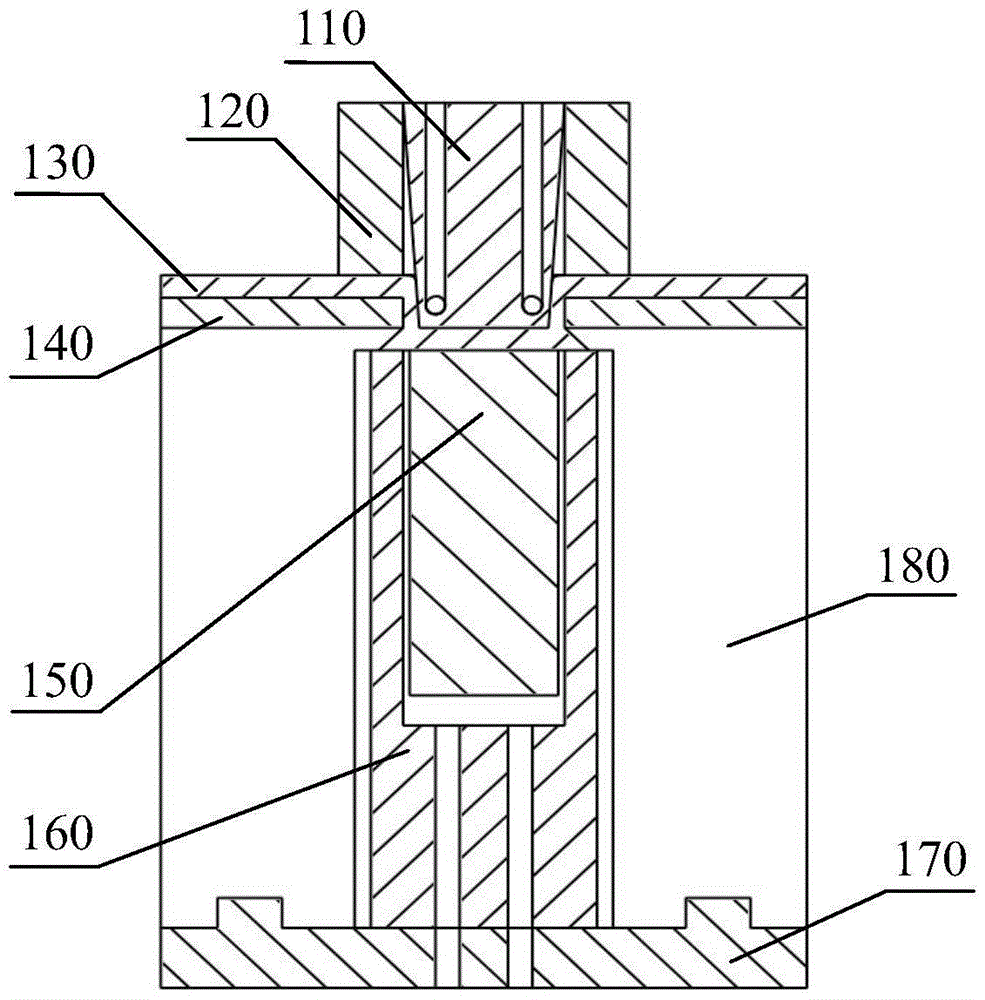

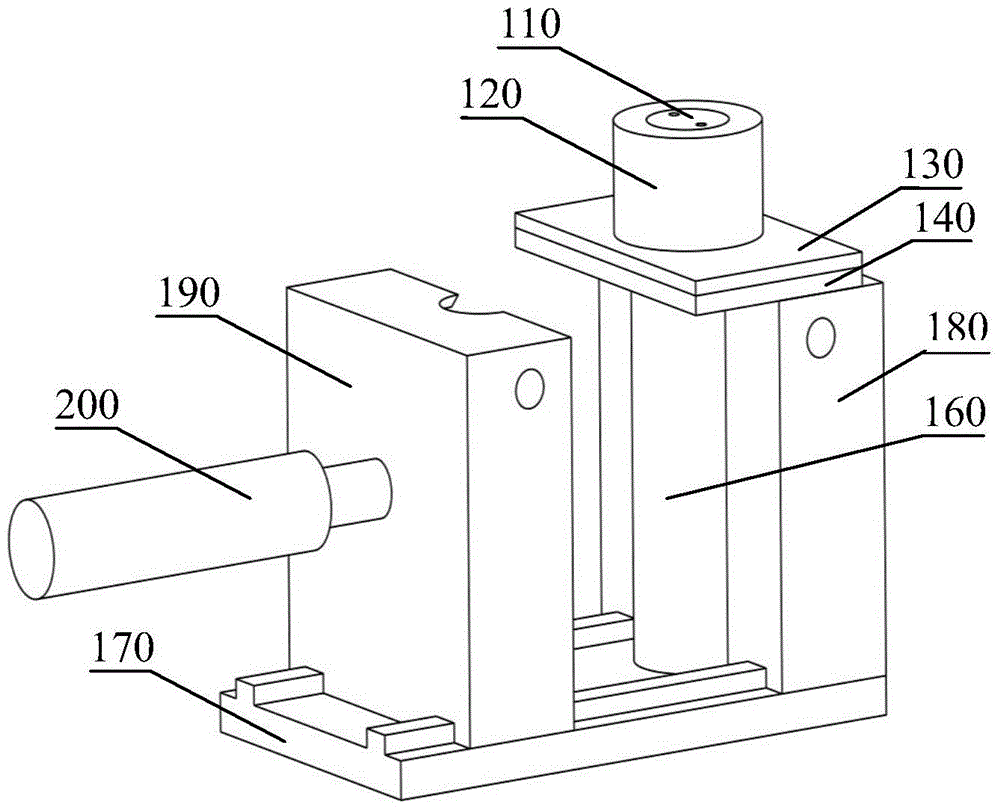

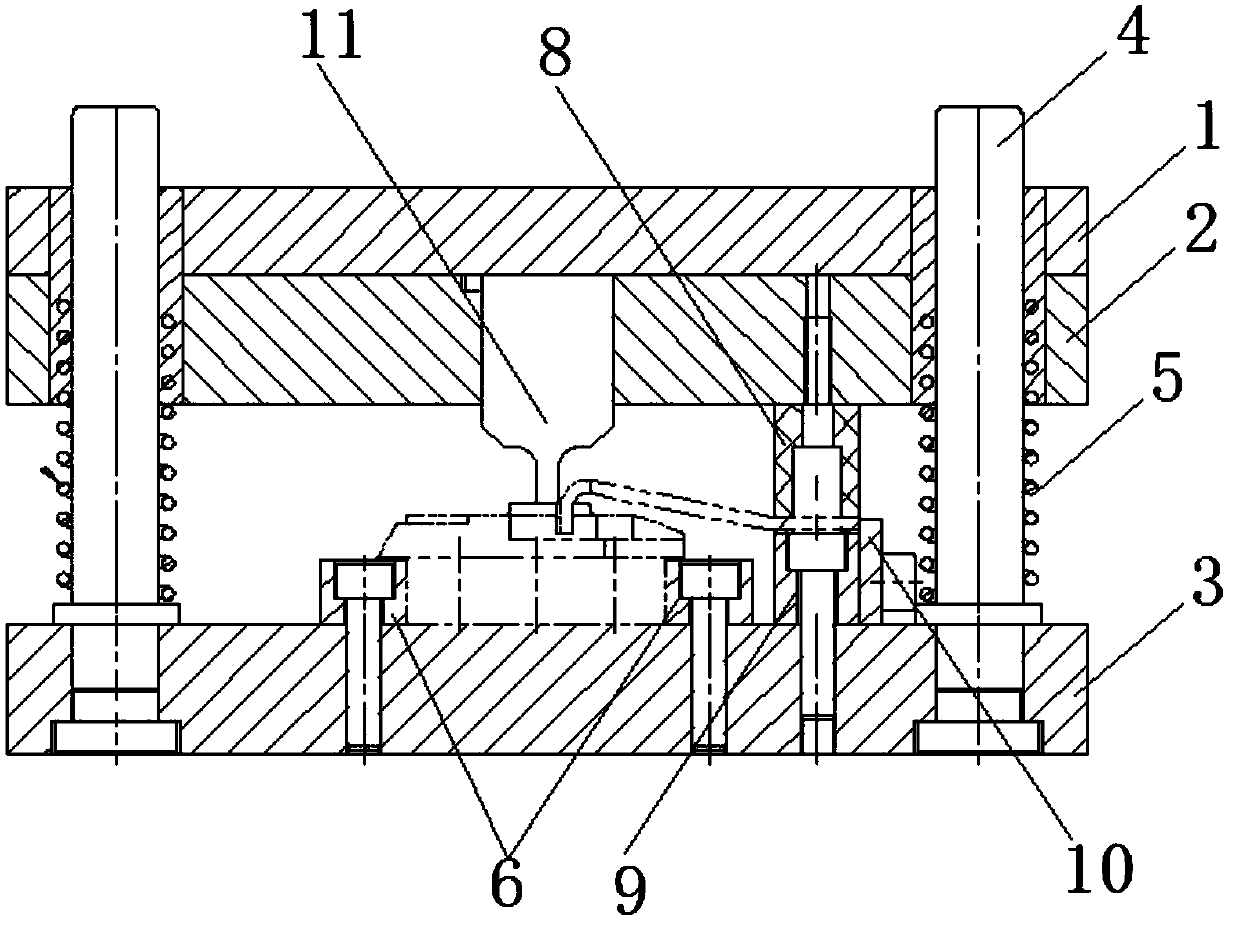

Riveting die of floating pressure head structure

The invention discloses a riveting die of a floating pressure head structure. An upper oil groove of the die is connected with an upper template of the die, an upper base plate is arranged between the upper template and the upper oil groove, and a closed space is formed between the upper base plate and the upper oil groove through a sealing gasket. The upper template is connected with a lower template through guide pillars and guide sleeves, upper pressure heads are arranged above the upper oil groove, and lower pressure heads are arranged below a pressure head fixing plate and connected with a prepressing plate. The upper pressure heads and the lower pressure heads are oppositely arranged, the pressure head fixing plate is connected with the lower template, a lower oil groove is formed between the pressure head fixing plate and the lower template, and a closed space is formed between the pressure head fixing plate and the lower oil groove through a sealing gasket. The closed space formed between the upper base plate and the upper oil groove and the closed space formed between the pressure head fixing plate and the lower template are filled with hydraulic oil. According to the hydraulic principle, it is ensured that equal pressure is exerted on both the pressure heads in the riveting process, the die technology can meet the machining requirement and the assembling requirement, all rivets can have high riveting quality in the riveting process, and the riveting die is suitable for all types of multi-pressure-head riveting dies.

Owner:GUILIN FUDA

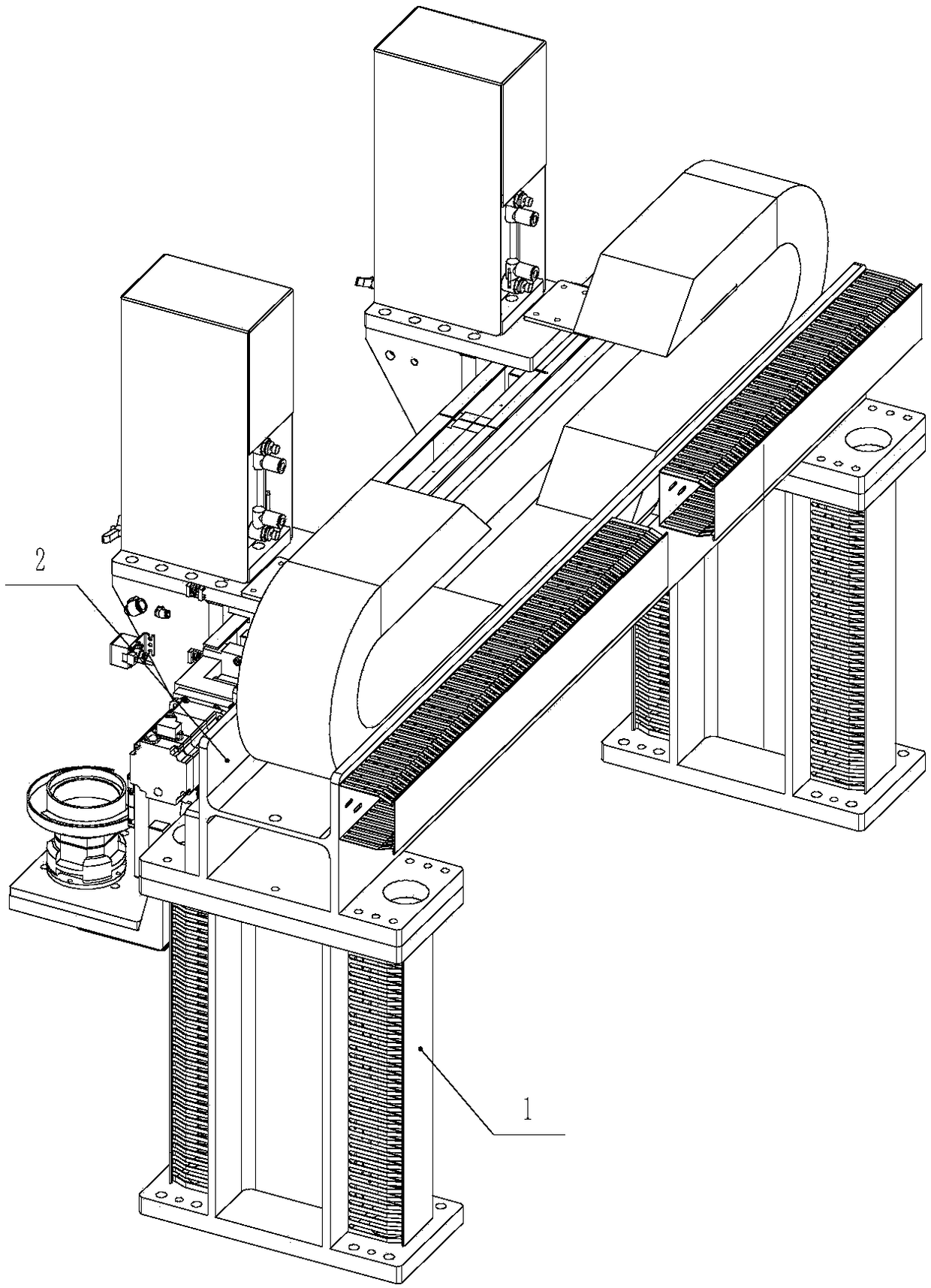

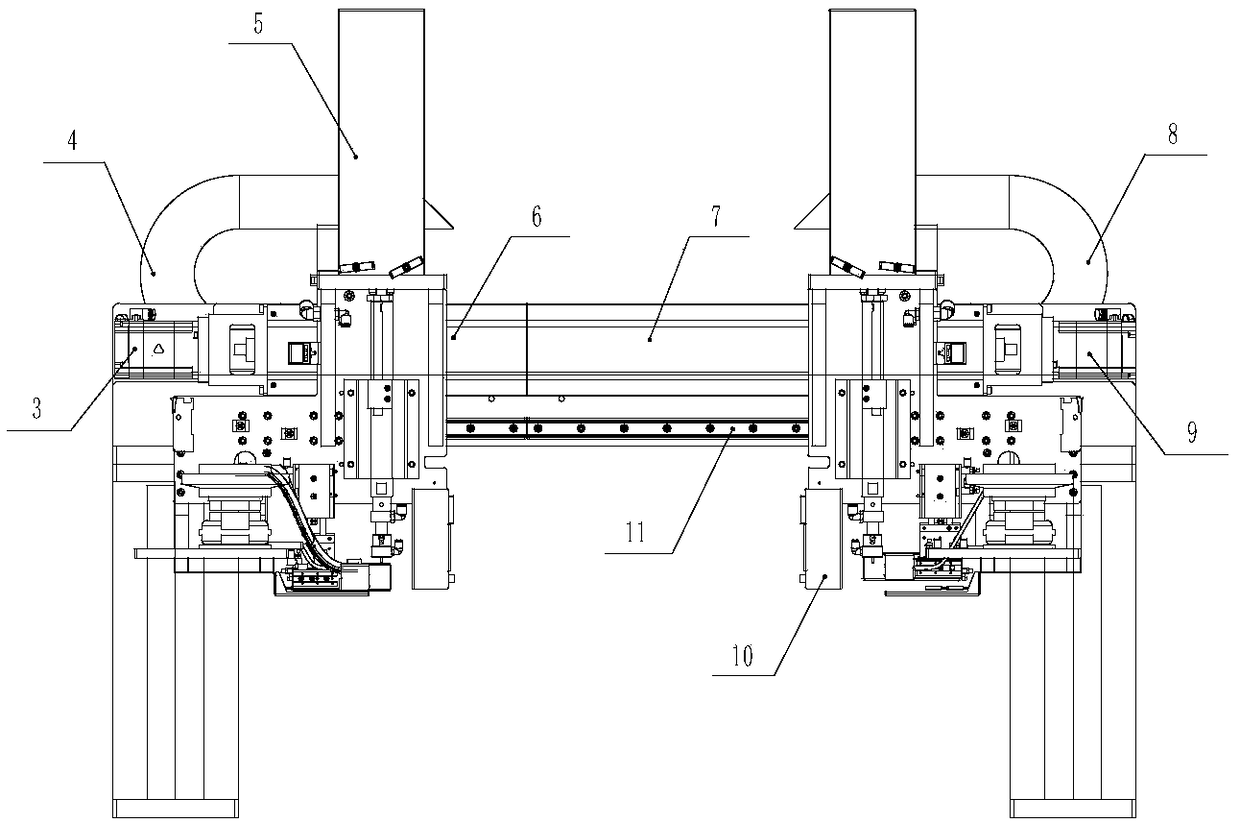

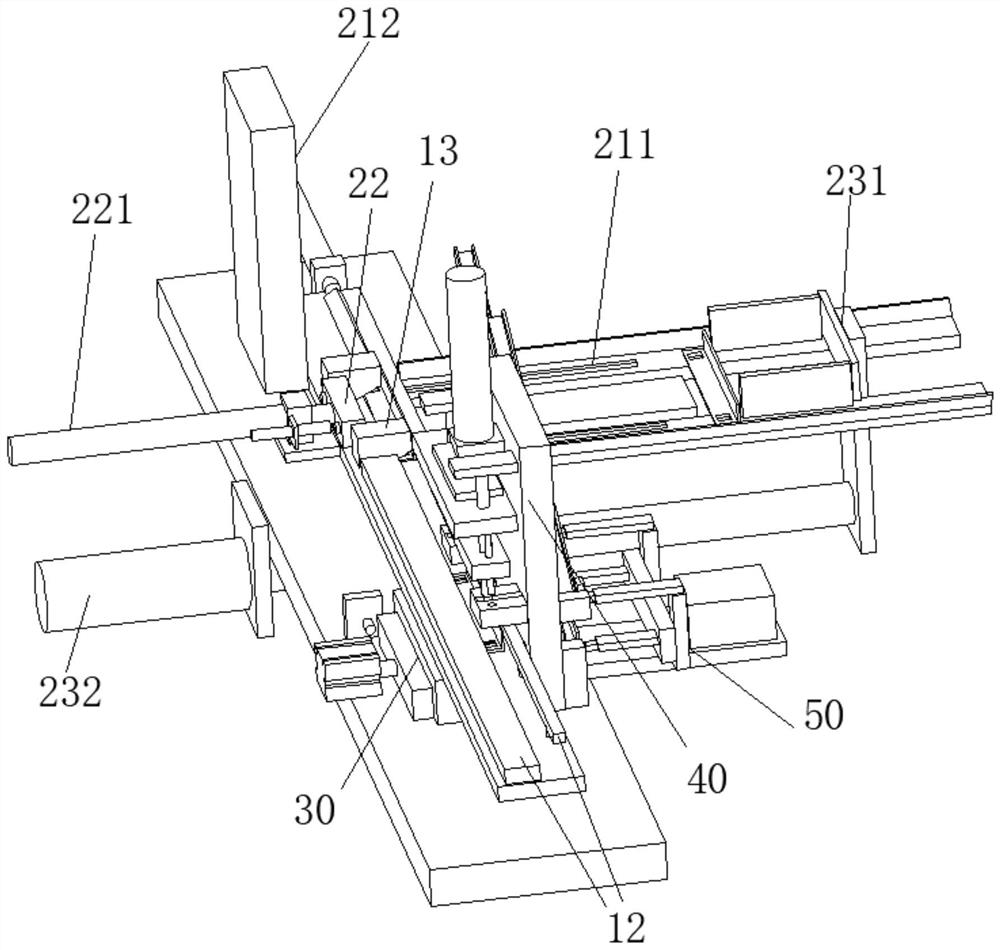

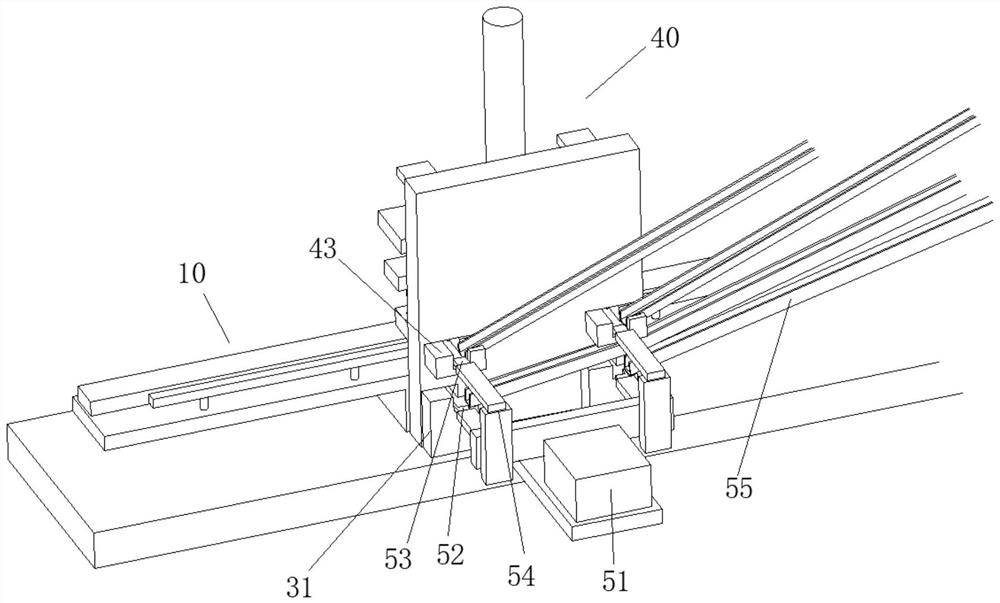

Riveting machine riveting device for circuit board riveting and operation method thereof

InactiveCN109501297AImprove riveting qualityIncrease productivitySheet joiningDomestic articlesEngineeringRiveting machines

The invention discloses a riveting machine riveting device for circuit board riveting and an operation method thereof. The riveting machine riveting device for circuit board riveting is characterizedin that a cross beam is fixedly installed on the top faces of stand columns; a back servo motor is installed on a back translation module, and a front servo motor is installed on a front translation module; a linear guide rail is fixedly installed on the cross beam; a sliding block is installed on the linear guide rail; a back-side automatic riveting device is installed on the back translation module and a back-side sliding block, and a front-side automatic riveting device is installed on the front translation module and a front-side sliding block; one end of a back dragging chain is installedon the cross beam, and the other end of the back dragging chain is installed on the back-side automatic riveting device; and one end of a front dragging chain is installed on the cross beam, and theother end of the front dragging chain is installed on the front-side automatic riveting device. The riveting machine riveting device for circuit board riveting has the advantages of being high in riveting quality and production efficiency and low in cost, the defects of being large in labor amount, poor in working efficiency and low in reliability in the prior art are overcome, and the effects ofbeing small in labor amount and high in working efficiency and reliability are achieved.

Owner:昆山敏欣电子有限公司

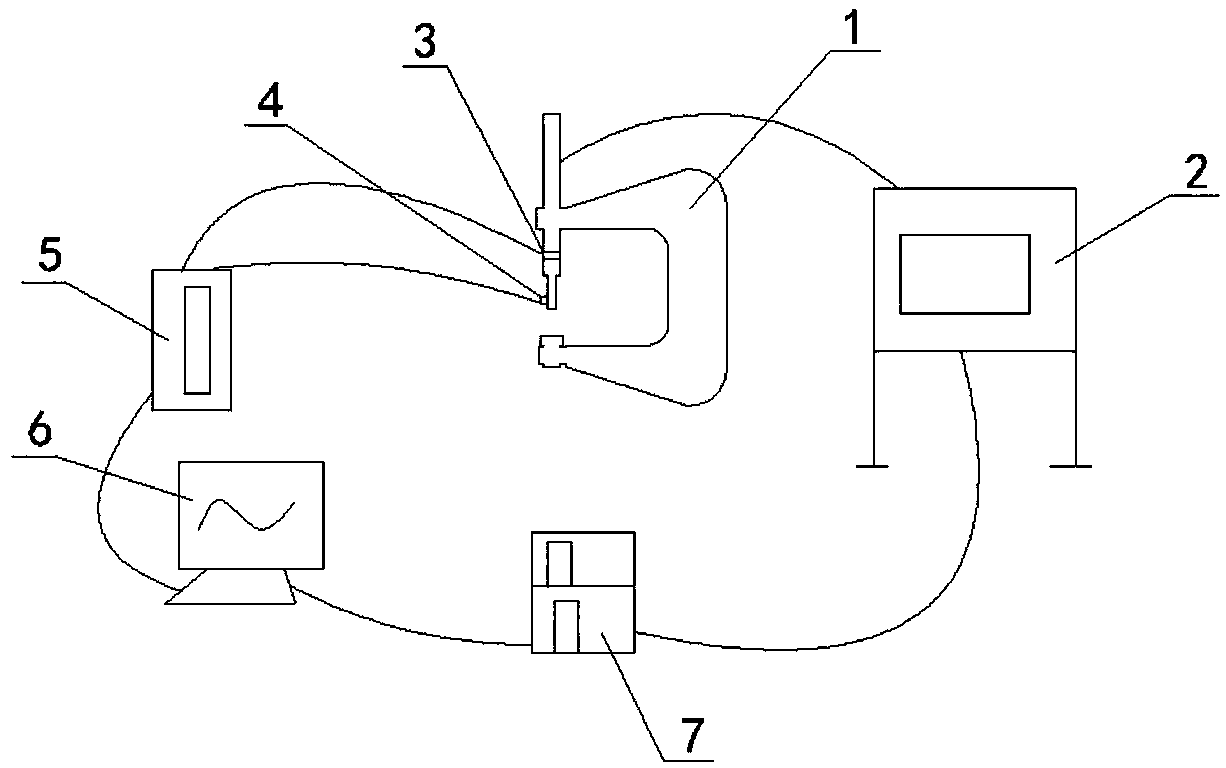

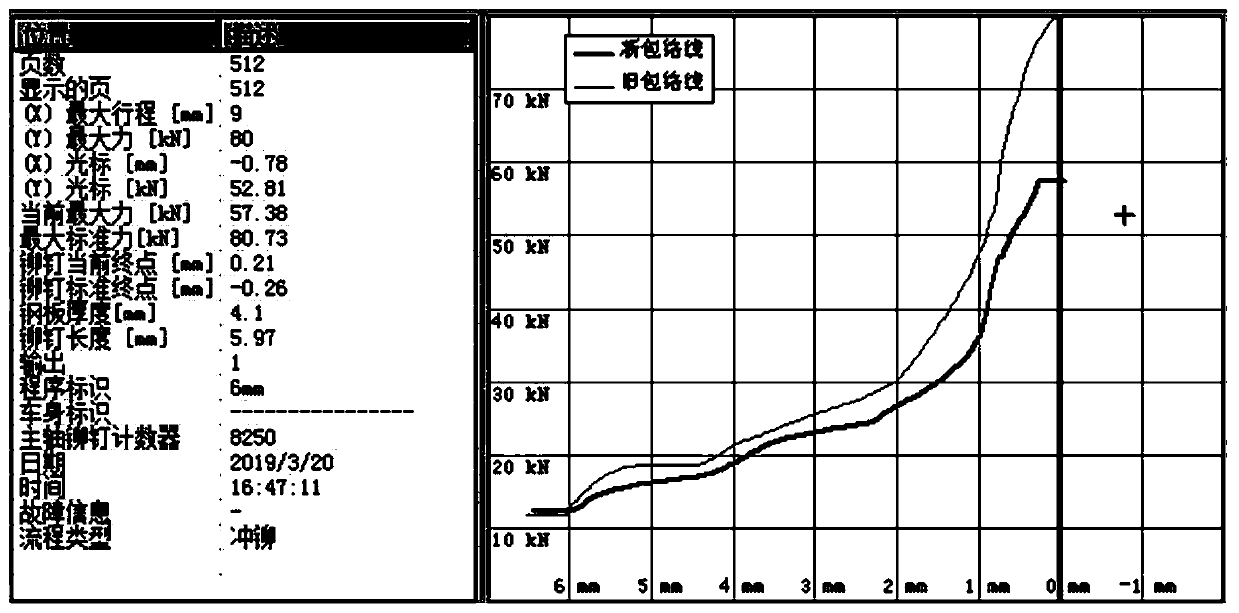

Aluminum body self-piercing riveting quality control method based on force and displacement curve

InactiveCN108971409AGuarantee riveting qualityEliminate self-piercing riveting defectsEngineeringState control

The invention discloses an aluminum body self-piercing riveting quality control method based on force and a displacement curve. A relationship standard curve of riveting force and punch displacement in the riveting process is built by experiments or simulation, and the variation trend of the riveting force corresponding to different riveting defects is acquired. Real-time detection is performed toobtain measured values of the punch displacement and the punch riveting force in the riveting process, and a current measured curve is drawn according to the measured values. The current measured curve is compared with the relationship standard curve, a riveting state is judged, and the punch riveting force of a riveting tool is controlled according to the riveting state. The force and displacement curve in the riveting process are monitored in real time, and riveting force values are controlled, so that the riveting force is kept within a reasonable range to ensure riveting quality.

Owner:HEFEI JEE INTELLIGENT EQUIP CO LTD

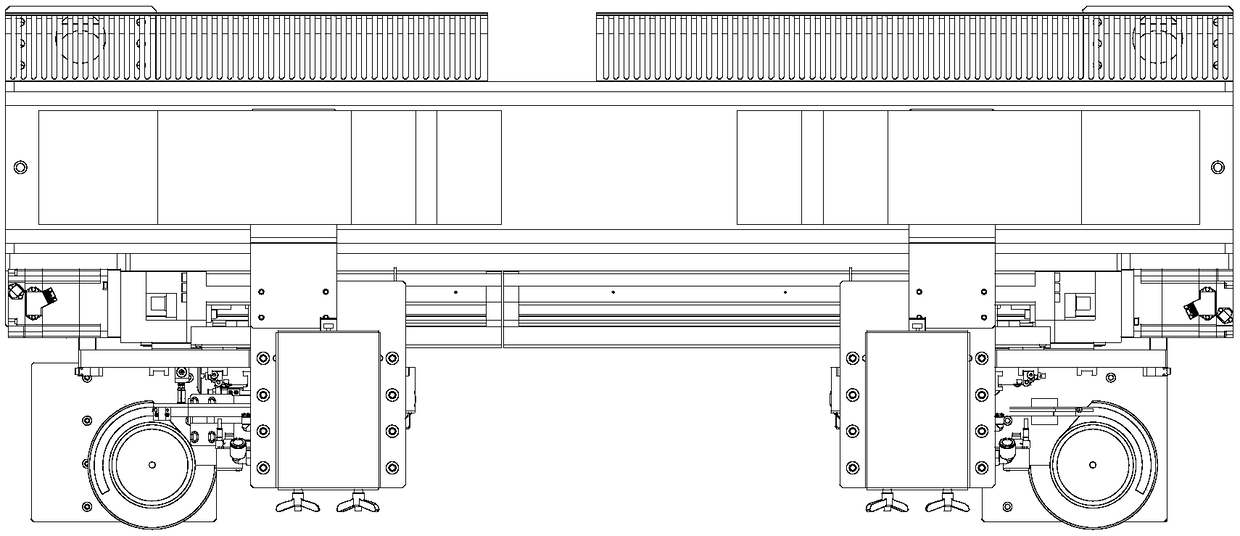

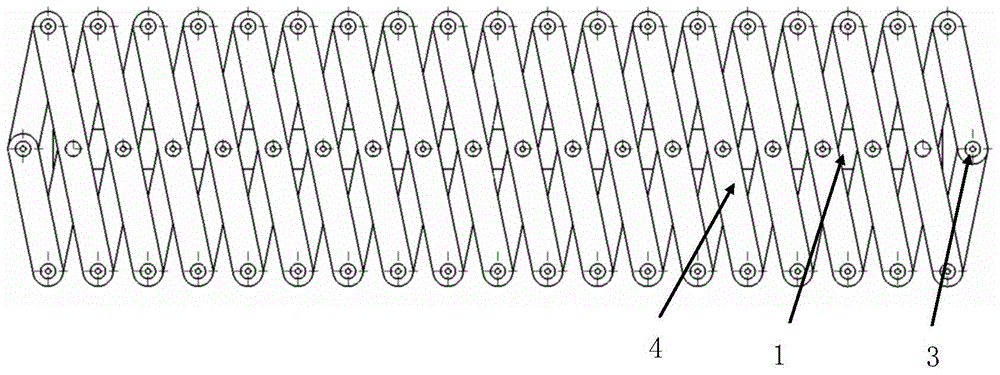

Dual-nose semi-automatic assembler

ActiveCN105249624AReduce labor intensityImprove assembly efficiencySlide fastenersSemi automaticEngineering

A dual-nose semi-automatic assembler comprises a rack, a puller rail, a vibration disc device, a puller pushing device, a puller supporting device and a riveting device; a thin steel sheet of a stop puller is arranged at the side surface of the end part of the puller rail; a puller guide rail in the length of a puller downwards extends from the middle of the lower end surface of the puller rail; a guide seat is arranged below the puller guide rail; the puller supporting device comprises a loose core and a cylinder driving the loose pulling core to move up and down; the loose core upwards penetrates through the guide seat and is inserted into the pushed puller of the puller guide rail; the loose core and the puller at the end part of the puller guide rail are fixed by the pushed puller; the riveting device comprises two riveting cutters positioned at the side surfaces of two notch slots of the puller guide rail, a power mechanism driving the two riveting cutters to move and rivet toward the direction of the puller guide rail, and a reset mechanism for resetting the riveting cutters. The semi-automatic assembler improves the efficiency during assembly of individualized zipper pulls of dual noses, relieves labor intensity of staff and improves the percent of pass of finished products assembled by the dual noses.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

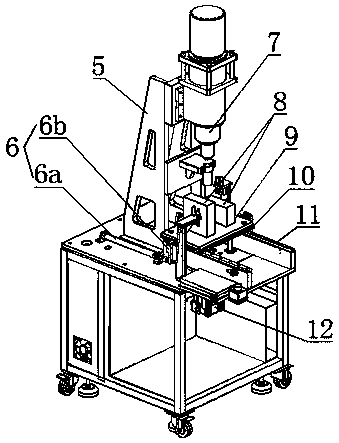

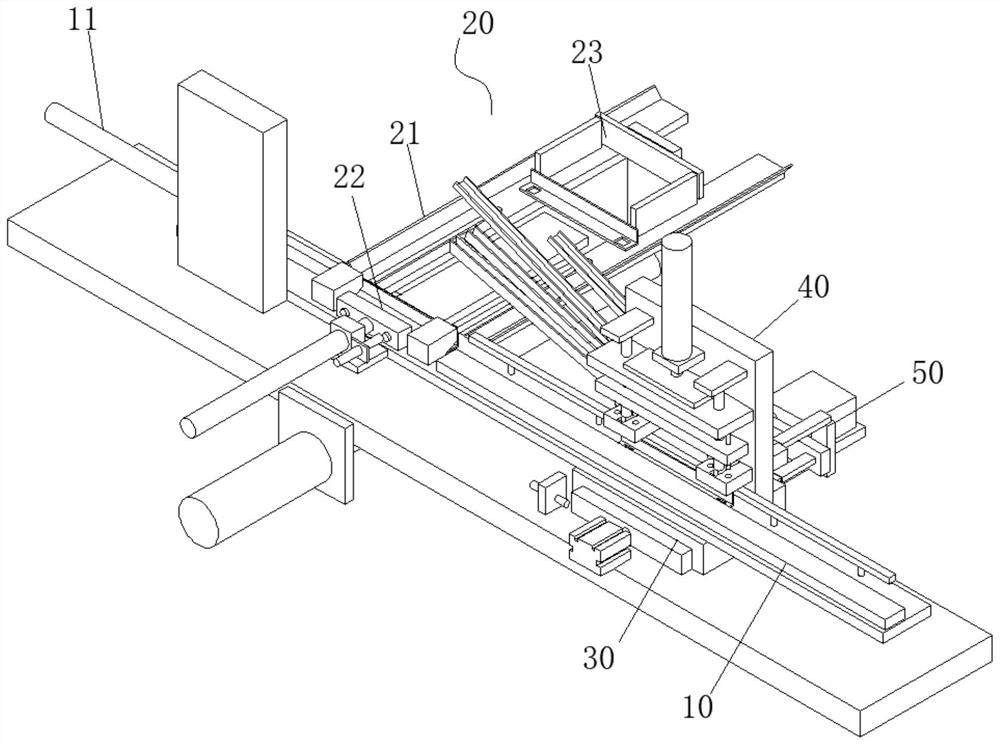

Automatic riveting equipment

PendingCN114309302ASimple and fast operationReduce labor intensityMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses automatic riveting equipment, and belongs to the technical field of workpiece riveting, the automatic riveting equipment comprises a frame body, the frame body is provided with a feeding mechanism, a pressing mechanism and a pushing mechanism, the frame body is provided with a material placing groove for placing materials, the feeding mechanism comprises a first feeding assembly and a second feeding assembly, and the first feeding assembly is provided with a clamping mechanism; the first feeding assembly comprises a first feeding disc and a first guide rail. The second feeding assembly comprises a second feeding disc and a second guide rail. The material pressing mechanism comprises a material pressing piece and a material pressing movement assembly, the material pressing movement assembly is used for driving the material pressing piece to move in the vertical direction, the material pressing piece is located at the top of the material containing groove, the material pushing mechanism comprises a material pushing rod and a material pushing movement assembly, and the material pushing movement assembly is used for driving the material pushing rod to move in the horizontal direction. The material pushing rod is arranged in the material containing groove in a sliding mode in the horizontal direction. The riveting device has the advantages that two to-be-riveted parts can be conveniently placed at the stamping position of the riveting device, the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:广东省润杰服饰有限公司

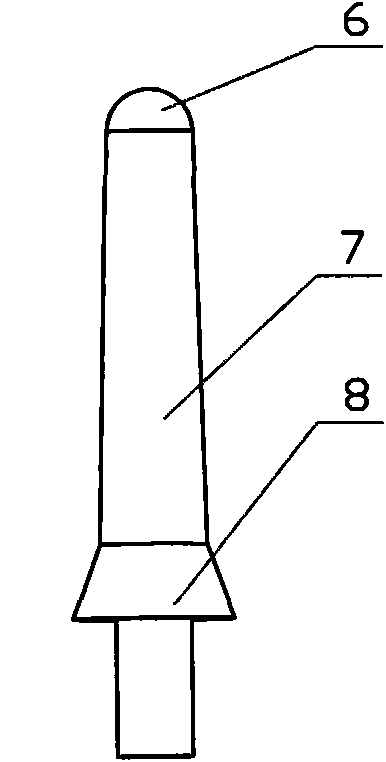

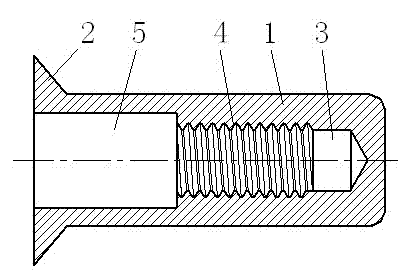

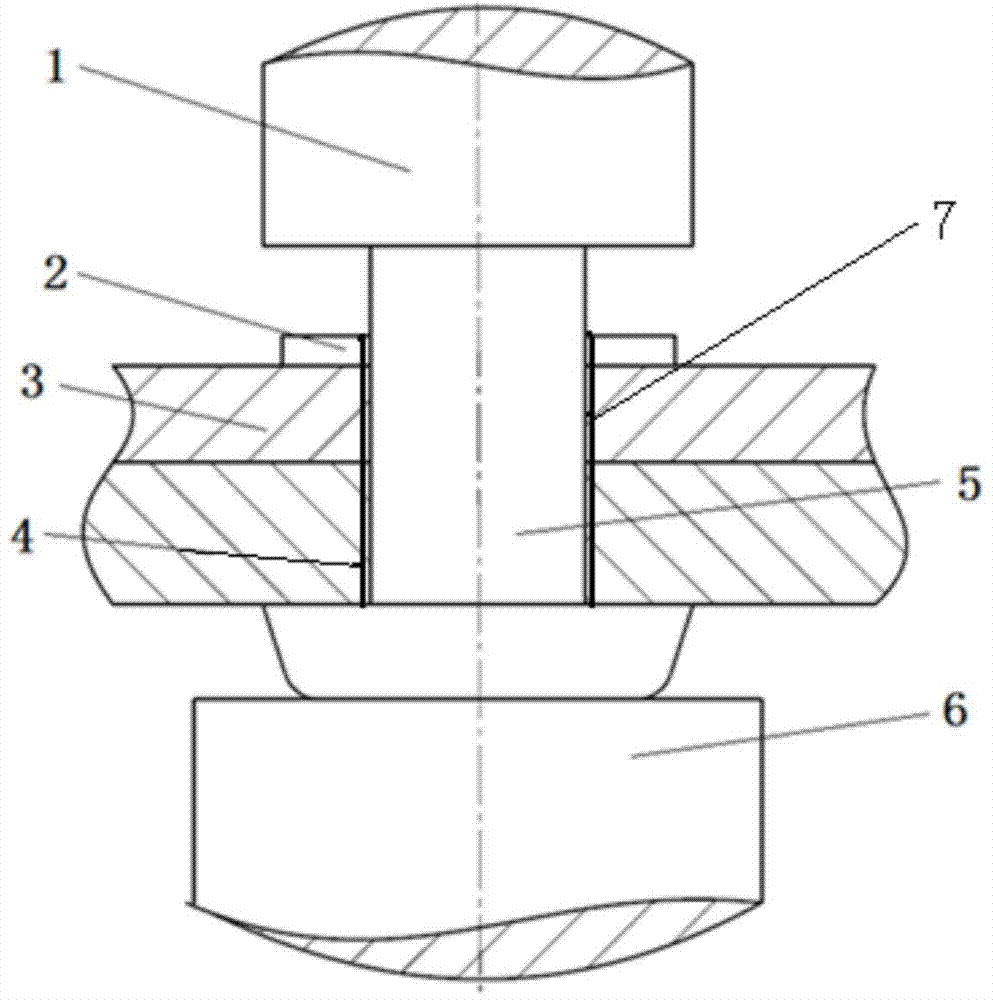

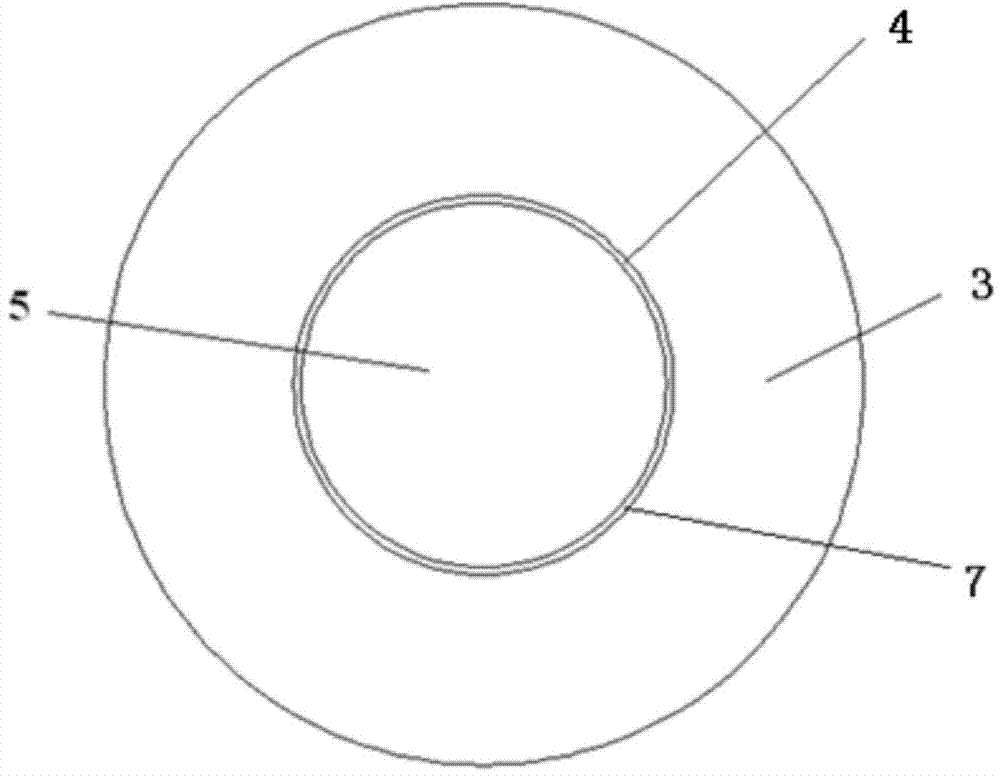

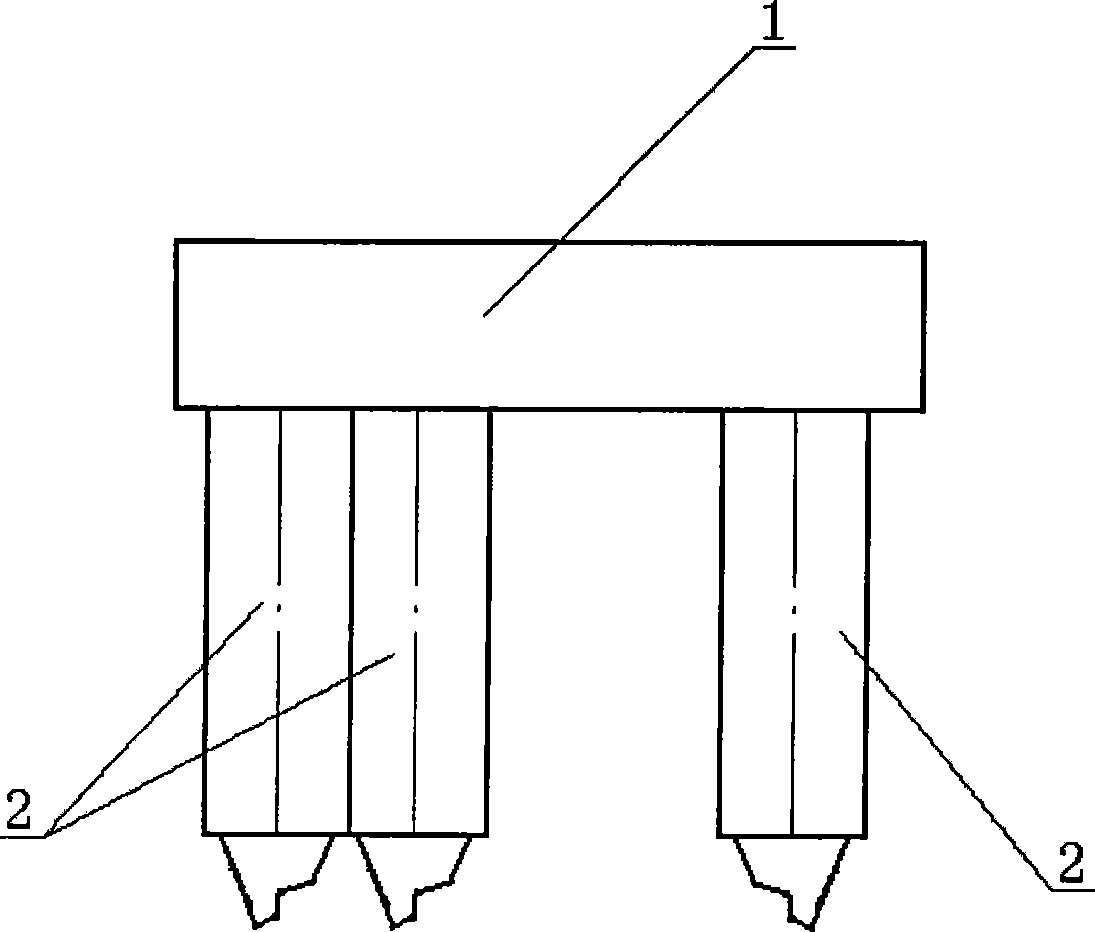

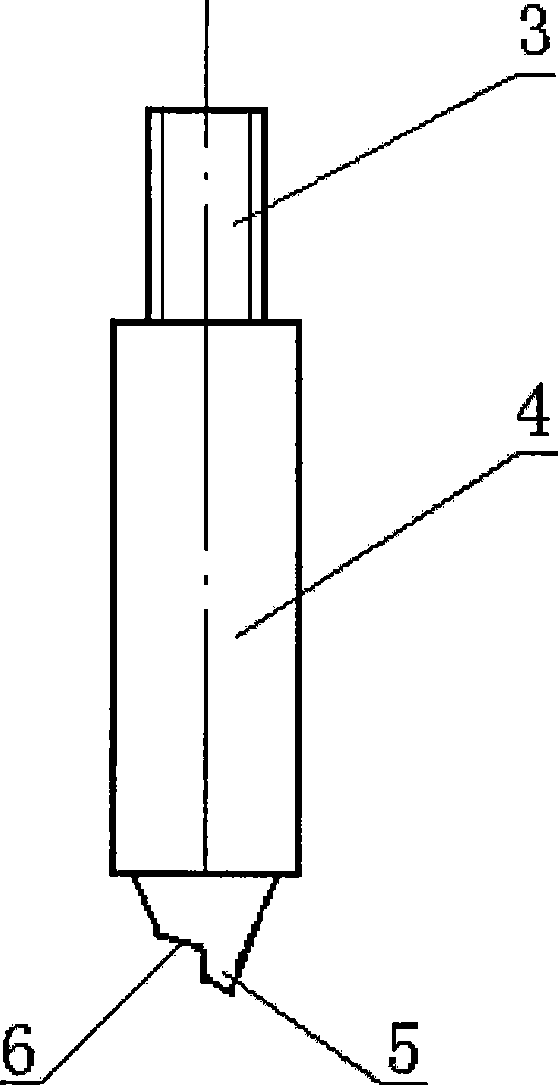

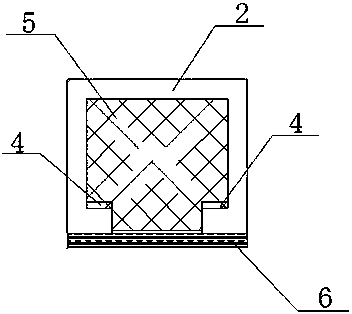

Riveting die of water pump shell with aluminum ring

The invention discloses a riveting die riveted by a water pump housing and an aluminum ring. The riveting die comprises an upper moulding board (1) and a plurality of riveting rods (2), wherein each riveting rod (2) consists of a rod body (4) and a pressing head at the lowest end of the rod body (4), the pressing head of each riveting rod (2) has a structure that a pressing wedge (5) is arranged on one side at the bottom of a cone frustum, and the bottom surface of the cone frustum at the root of the pressing wedge (5) is an inclined surface (6). The riveting die riveted by the water pump housing and the aluminum ring adopts the structure so that the pressing head of the riveting rod can be pressed into a pressing groove of the aluminum alloy water pump housing and extruded as well as deformed by applying a small riveting force, thereby guaranteeing the riveting quality and improving the production efficiency.

Owner:WUHU DONGDA MOTORCAR IND

Pre-buried groove channel

InactiveCN109931076AImprove anti-corrosion performanceExtended service lifeMining devicesUnderground chambersPunchingEngineering

The invention relates to a pre-buried groove channel. The pre-buried groove channel comprises a groove body, anchor rods and filling strips; the groove body comprises groove channels and T-shaped bolts; the anchor rods are uniformly distributed on the top ends of the groove channels; the filling strips are arranged inside the groove channels; the groove channels are arc C-shaped steel members withdownward openings; folding edges extend inwards from the two sides of the bottom ends of the groove channels; the folding edges are right angle folding edges, and form the parallel notches of the groove channels; the inner sides of the folding edges are provided with sawteeth; the tooth spacing of the sawteeth is 3 mm; punching holes are uniformly distributed in the top ends of the groove channels; the punching holes are matched with the anchor rods; the anchor rods are placed in the punching holes; the filling strips are matched with the groove channels; the filling strips are polyethylene foam strips and are charged into the groove channels; EV foam integrated tape with the width being 30 mm is arranged at the position of each of the parallel notches of the groove channels; gaps are left between the polyethylene foam strips and the EV foam integrated tape; and one ends of the T-shaped bolts are placed in the groove channels and are in occlusion with the sawteeth on the folding edges. The pre-buried groove channel according to the invention is simple in structure, convenient and fast to install and good in fatigue resistance and bearing capacity.

Owner:刘富全

Jump button riveting and flanging integrated tooling and processing method thereof

ActiveCN106653495BEasy to placeNot easy to scatterEmergency protective device manufactureFlangingEngineering

The invention discloses a jump catch clamp, an integrated tool for jump catch riveting and flanging and a machining method thereof, and the jump catch clamp is a special clamp. The tool disclosed by the invention comprises an upper die, a guide post, a guide post spring, a base plate, sliding block assemblies, a first lower die upright post plate and the jump catch clamp, wherein the guide post is serially connected to the upper die, the first lower die upright post plate and the base plate; the guide post spring is arranged on the guide post in a penetrating manner; the jump catch clamp can be inserted in a drawer groove in the middle part of the base plate; the sliding block assemblies capable of moving horizontally are arranged on the left side and the right side of the jump catch clamp; a riveting punch is arranged on the side, close to the jump catch clamp, of each sliding clock assembly, and an inclined wedge surface is arranged on the other side of each sliding block assembly; an inclined pressing block is arranged above each inclined wedge surface; the inclined pressing blocks are connected with the upper die; and the inclined pressing blocks are provided with inclined wedge surfaces matched with the inclined wedge surfaces of the sliding block assemblies. The jump catch can be assembled at a time, the riveting and flanging quality is reliable, and the production efficiency is improved.

Owner:JIANGSU DAQO KFINE ELECTRIC

Riveting method for skylight outer pipe pressing block and sliding rail

The invention discloses a riveting method for a skylight outer pipe pressing block and a sliding rail. A special riveting tool is adopted. The method comprises the steps that the outer pipe pressing block is positioned on the riveting tool; the sliding rail is positioned on the riveting tool and compressed; the outer pipe pressing block and the sliding rail are riveted. According to the riveting method for the skylight outer pipe pressing block and the sliding block, the special riveting tool is adopted, a positioning mechanism is arranged on the riveting tool for positioning the outer pipe pressing block and the sliding rail, and a compressing mechanism is used for compressing the sliding rail, so that it is ensured that the outer pipe pressing block and the sliding rail are reliably and precisely positioned so as to avoid the phenomenon that the outer pipe pressing block and the sliding rail move during riveting and affect the riveting quality, the outer pipe pressing block and the sliding rail can be rapidly positioned, the riveting efficiency is improved, and the riveting quality is ensured.

Owner:WUHU MOTIONTEC AUTOMOTIVE

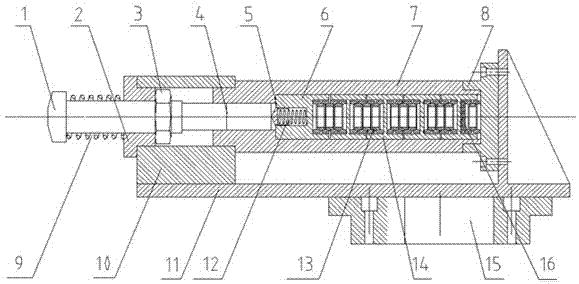

Portable stress wave riveting vibration attenuation reinforcing rod

InactiveCN103791024AStrong impact resistanceGuarantee riveting qualityNon-rotating vibration suppressionStress waveEngineering

The invention discloses a portable stress wave riveting vibration attenuation reinforcing rod. A cylinder body of a damping cylinder is connected with a front cylinder cover through an ejector rod supporting base, the ejector rod supporting base is fixedly connected to a connecting plate, the connecting plate is fixedly connected to a robot flange, and a hollow sleeve is arranged in the ejector rod supporting base; the two ends of an ejector rod are sleeved with an ejector rod positioning nut and an ejector rod pre-tightening spring respectively, and the ejector rod and an absorbing rod make coaxial contact; the absorbing rod is installed in the front end of the cylinder body, a sinking bar is installed in the rear end of the cylinder body, a spring hole is formed in the sinking bar, a reset spring is installed in the spring hole, the reset spring is sleeved with a spring sleeve, and the spring sleeve is pressed against the absorbing rod; the sinking bar is connected with a rear cylinder cover sequentially through a plurality of sets of spring damping components and adjusting elastic components, and the rear cylinder cover is fixedly connected to the connecting plate. The portable stress wave riveting vibration attenuation reinforcing rod is high in anti-impact performance, light in weight, convenient to fix and hold, simple in design and convenient to adjust; due to momentum conversion and buffering, the rigidity requirement for a reinforcing rod carrier is lowered; due to the fact that the portable stress wave riveting vibration attenuation reinforcing rod can automatically return to the original position, the repeated positioning accuracy is guaranteed; the portable stress wave riveting vibration attenuation reinforcing rod has the vibration isolation protection function on the reinforcing rod carrier.

Owner:ZHEJIANG UNIV

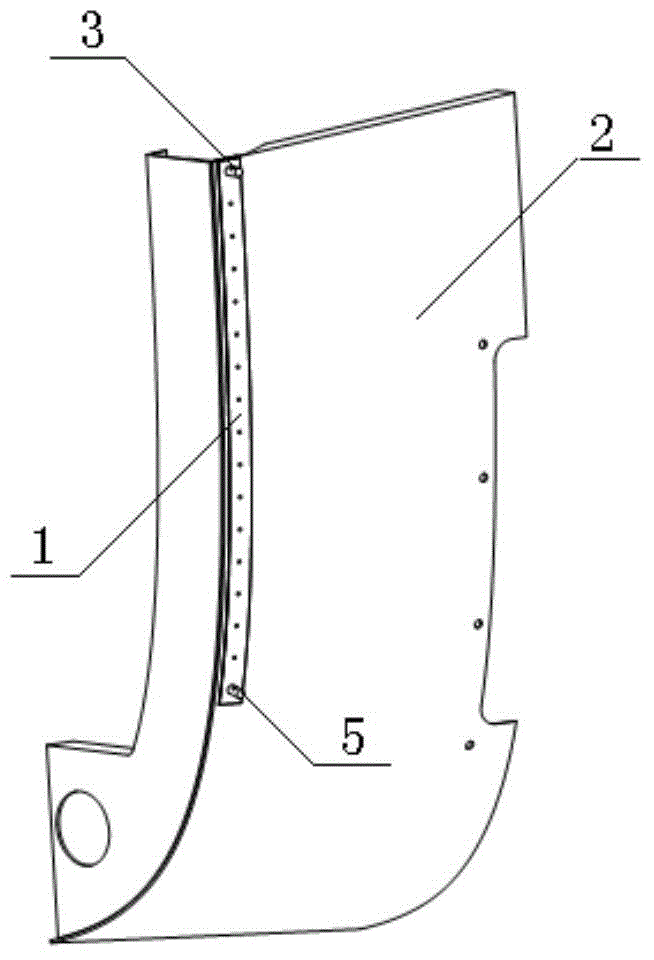

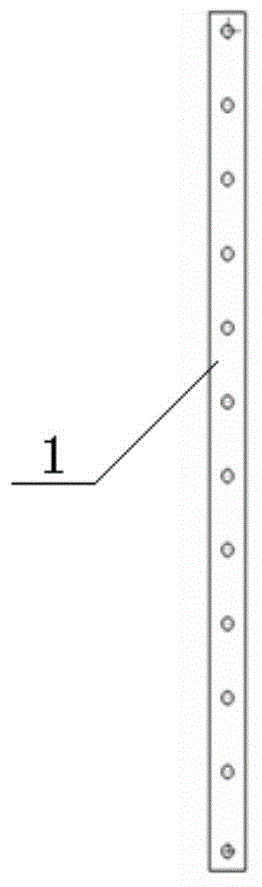

Method for rapidly drilling riveting holes in body structure of airplane

ActiveCN104827069ASmall spacing errorReduce labor intensityAircraft componentsDrill jigsImproved methodHole drilling method

The invention belongs to an airplane assembling technology, relating to an improved method for drilling riveting holes in a body structure of an air plane. The method is characterized by comprising the following drilling steps: manufacturing an elastic ruler; drilling process holes; drilling equidistant holes in the elastic ruler (1); drilling the riveting holes in the body structure of the airplane. According to the method for rapidly drilling the riveting holes of the body structure of the airplane, the labor intensity is greatly lightened, the working efficiency is improved, the interval error of the riveting holes is reduced, and the riveting quality is ensured.

Owner:HARBIN

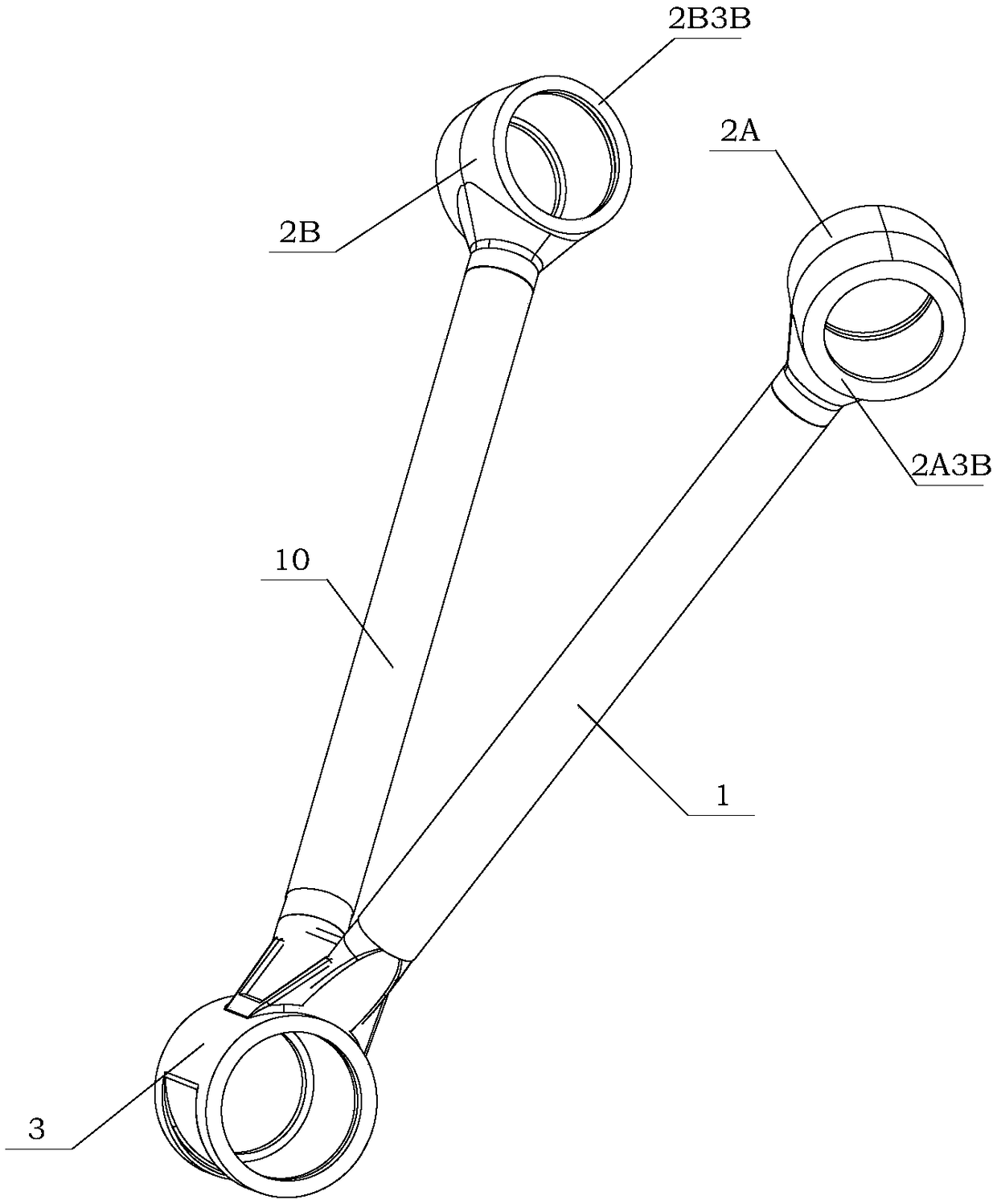

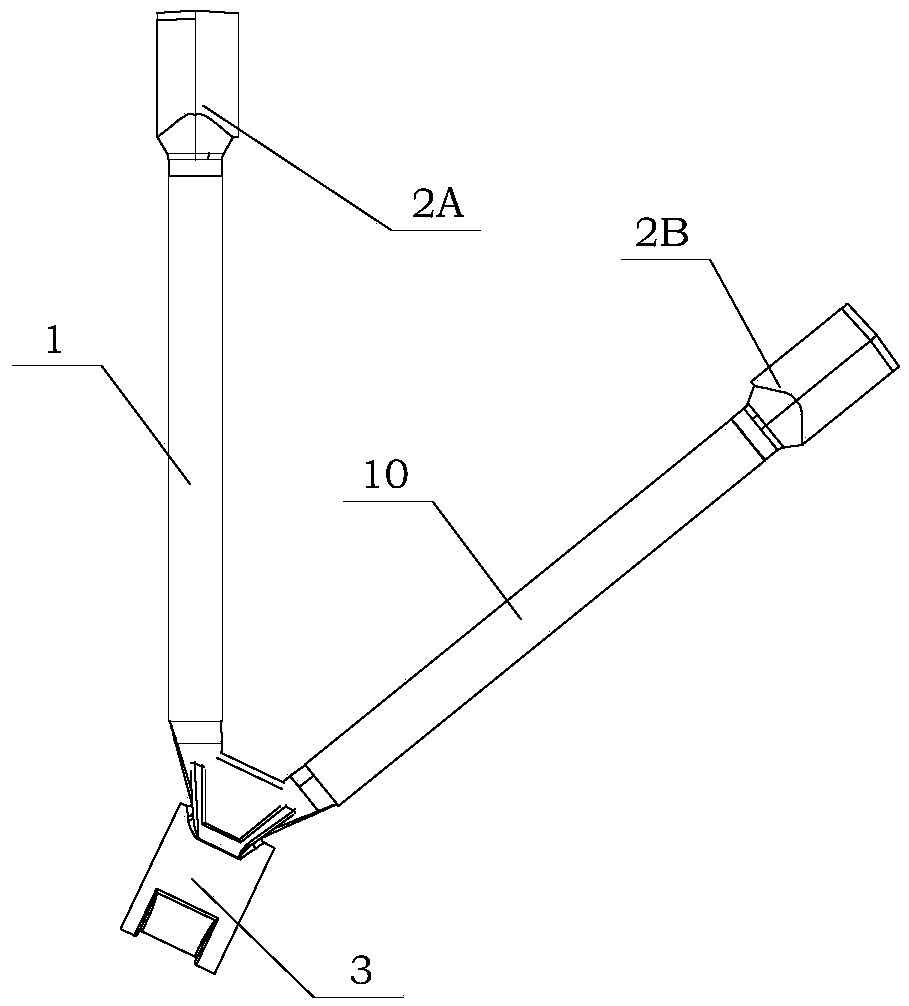

Aluminum alloy split V-shaped thrust rod and casting forming and friction stir welding matching method thereof

InactiveCN109017186AHigh strengthImprove performancePivoted suspension armsNon-electric welding apparatusFriction weldingFriction stir welding

The invention discloses an aluminum alloy split V-shaped thrust rod and a foundry forming and friction stir welding matching method thereof, wherein the material of the thrust rod is aluminum alloy, and the preferred composition is Al-Cu-based alloy, Al-Si-based alloys, Al-Mg-Si-based alloys, Al- Zn-Mg-Cu-based alloy or Al-Mg-based alloys, and aluminum alloys in which trace alloying elements suchas Sr, La, Ce, Y, Sc, Er, Nb, B, and Cr are added to the aluminum-based alloys. An aluminum alloy split V-shaped thrust rod is composed of a casing, a ball head and a ball hinge, wherein the V-shapedball head and the ball heads at both ends are connected by a casing, and the ball hinge is arranged in a through hole of the ball head; The neck of the spherical head is a combination of an ellipticalshape and an arc shape, which improves the bearing capacity. The aluminum alloy thrust rod ball head is prepared by a casting molding process. The aluminum alloy sleeve and ball head are assembled byfriction stir welding or friction welding process. 40 to 70 percent of weight reduction effect of that thrust rod obtain by the invention can be achieved compare with the traditional steel thrust rod.

Owner:北京航大新材科技有限公司

Hydraulic riveting machine for hardware machining

The invention relates to the technical field of riveting machines, and discloses a hydraulic riveting machine for hardware machining, a group of support arms are symmetrically and fixedly mounted on the two sides of a clamp body, a hydraulic balance groove is formed in the top of the clamp body and located between two second hydraulic cavities with the same height, and the middle of the top of the hydraulic balance groove is movably sleeved with a sliding block; a corrugated pipe sleeve is movably connected between the first piston and the inner wall of the first hydraulic cavity, a sliding barrel is fixedly installed at the top of the first piston, a fixing rod with the bottom end extending into the sliding barrel is fixedly installed on the top wall of the first hydraulic cavity, a resistor strip is fixedly installed on the inner wall of the sliding barrel, and a sliding piece in sliding contact with the resistor strip is fixedly installed at the bottom end of the fixing rod. Riveting heads are symmetrically designed at the upper end and the lower end of a clamp body, supporting arms are arranged on the outer sides of the riveting heads, rolling wheels are installed at the ends of the supporting arms in an interactive mode, a sliding block in a hydraulic balance groove is used for controlling on-off of a circuit, a hydraulic system is fed back for adjustment according to resistance changes, and the riveting quality and efficiency are improved.

Owner:扬州盛世模塑科技有限公司

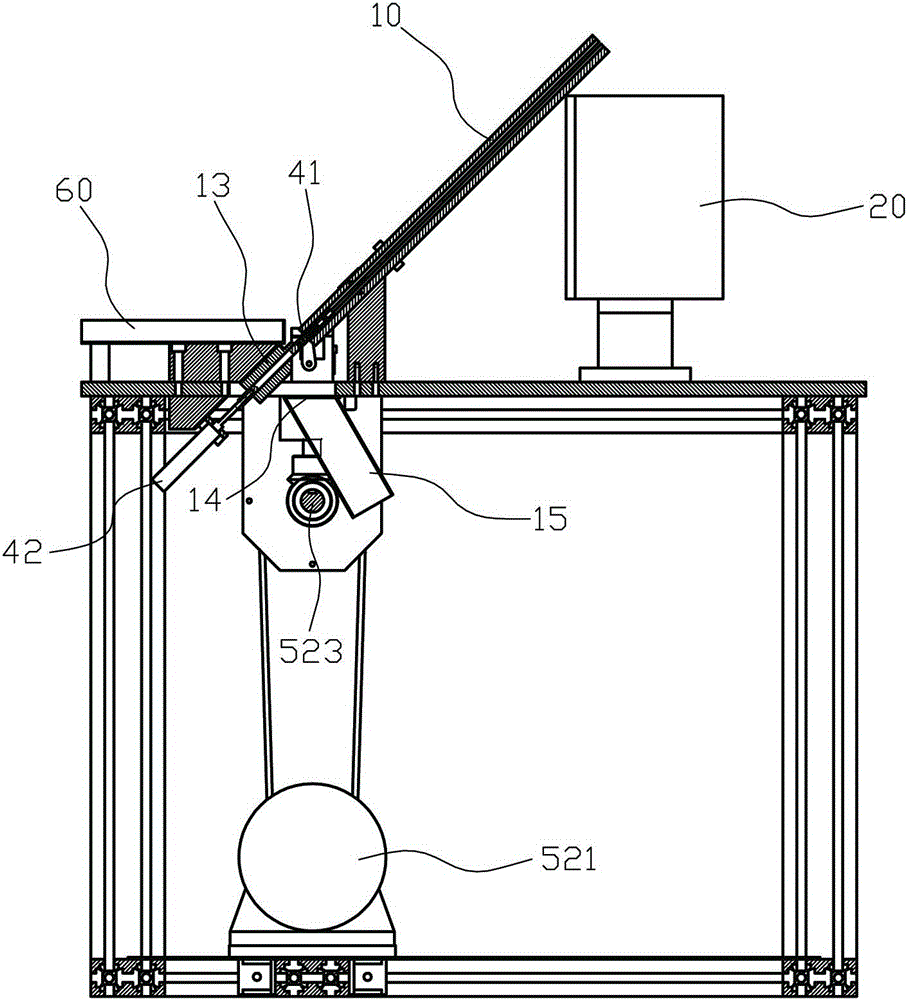

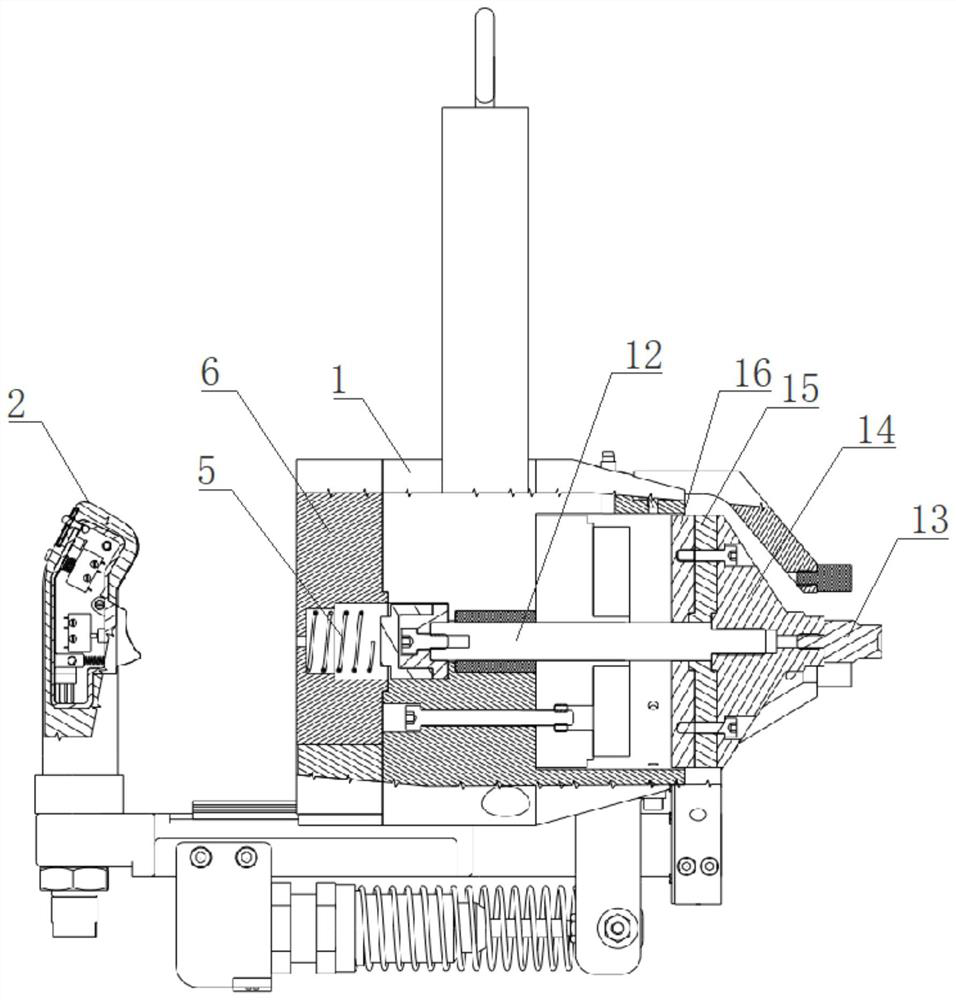

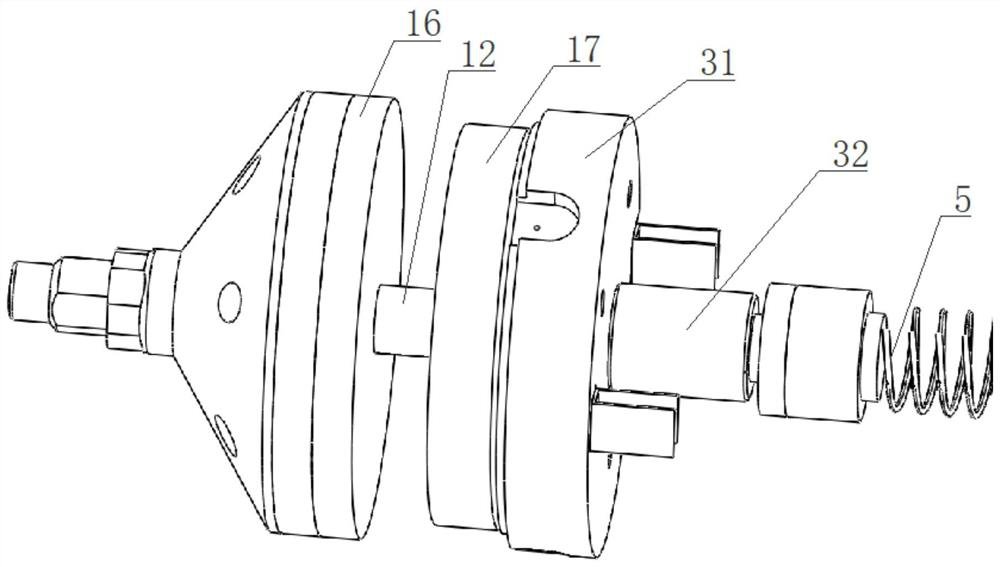

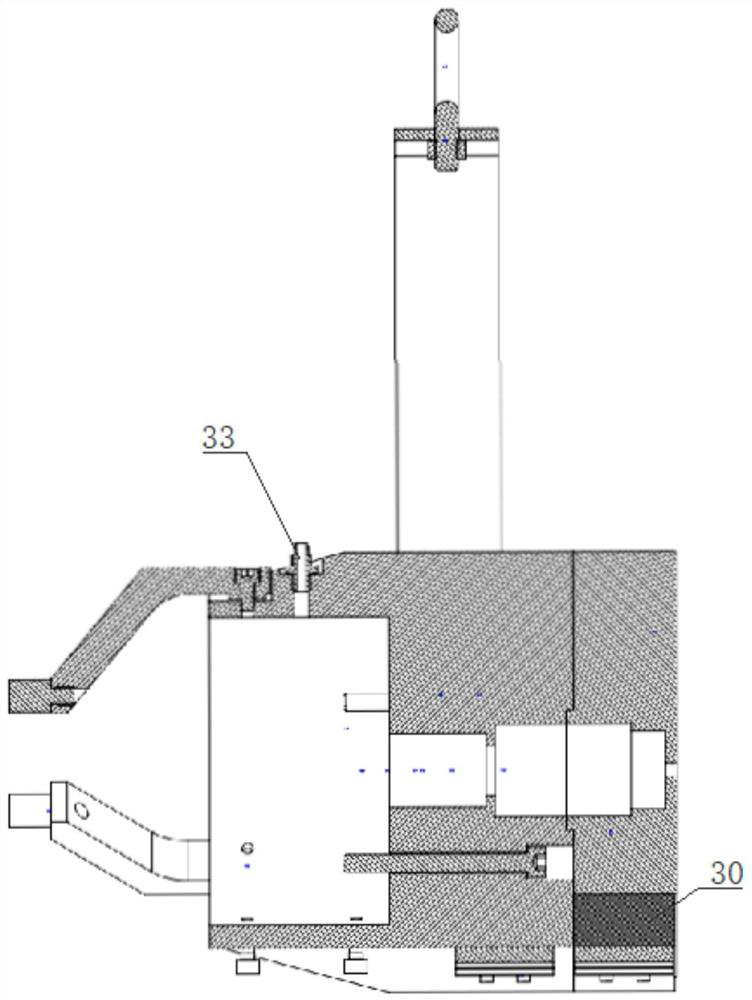

Automobile rearview mirror spin riveting device

PendingCN110180960AImprove efficiencyGuarantee riveting qualityMetal-working feeding devicesPositioning devicesRear-view mirrorEngineering

Owner:SUZHOU INST OF INDAL TECH

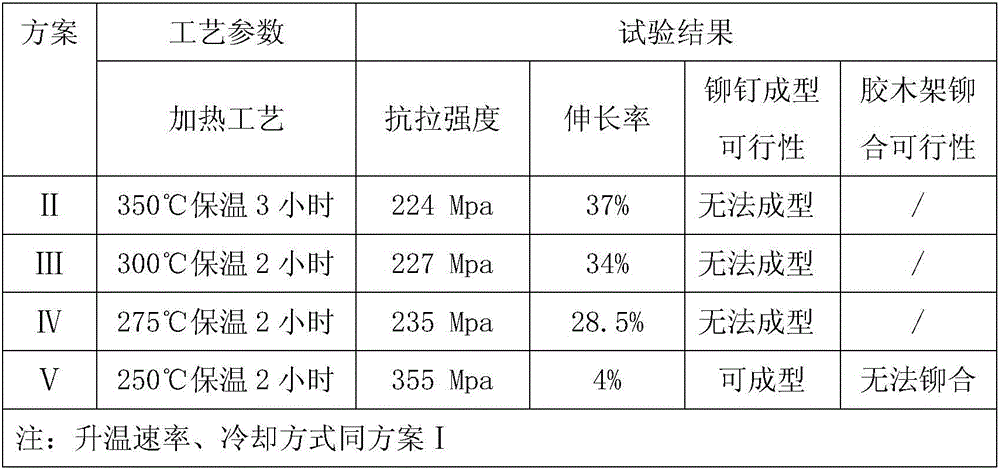

Red copper wire softening treatment process

InactiveCN105951005AGuarantee riveting qualityGuaranteed uptimeFurnace typesHeat treatment furnacesCopper wireTreatment parameters

The invention provides a red copper wire softening treatment process, which relates to a copper wire softening treatment process and aims at solving the problem that a red copper wire purchased according to the existing copper alloy wire material standard cannot meet the rivet forming and Bakelite retainer riveting performance requirements. According to the process, a Y2 state red copper wire is selected; the selected Y2 state red copper wire is cleaned and is naturally dried in the air; then, the cleaned and dried red copper wire is put in a vacuum heat treatment furnace to be subjected to heat treatment according to the following heat treatment parameters: the heating temperature rise value is 270 to 280 DEG C, and the heat insulation time is 43 min to 47 min; and inert gas is inflated into the furnace for cooling; and discharging is performed when the copper wire is cooled to a temperature being 43 DEG C or below. The process provided by the invention is used for softening the red copper wire.

Owner:AVIC HARBIN BEARING

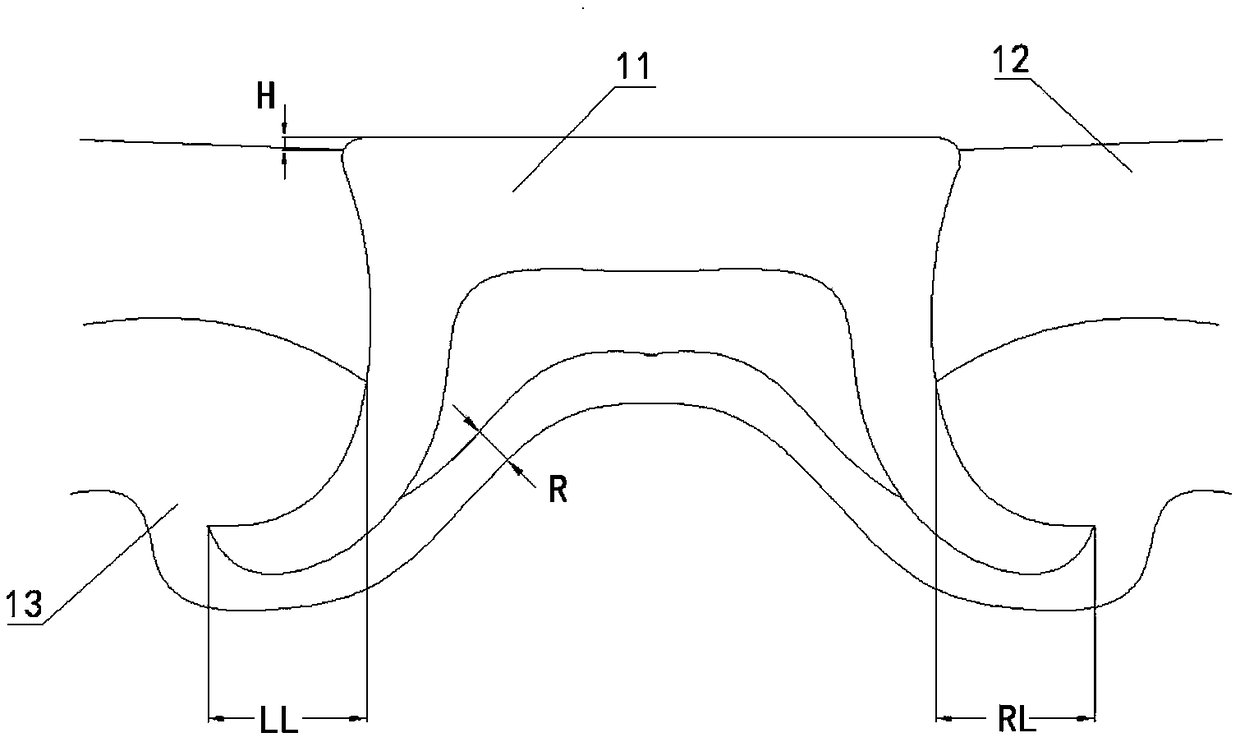

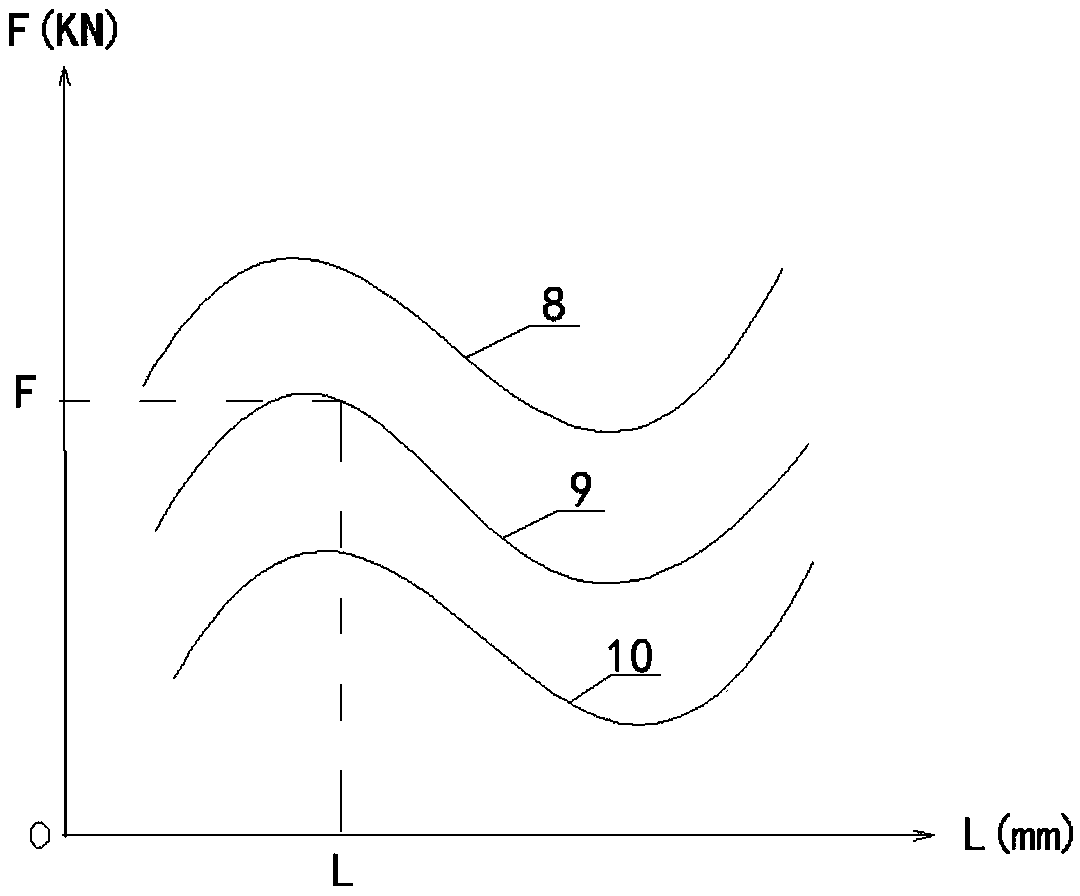

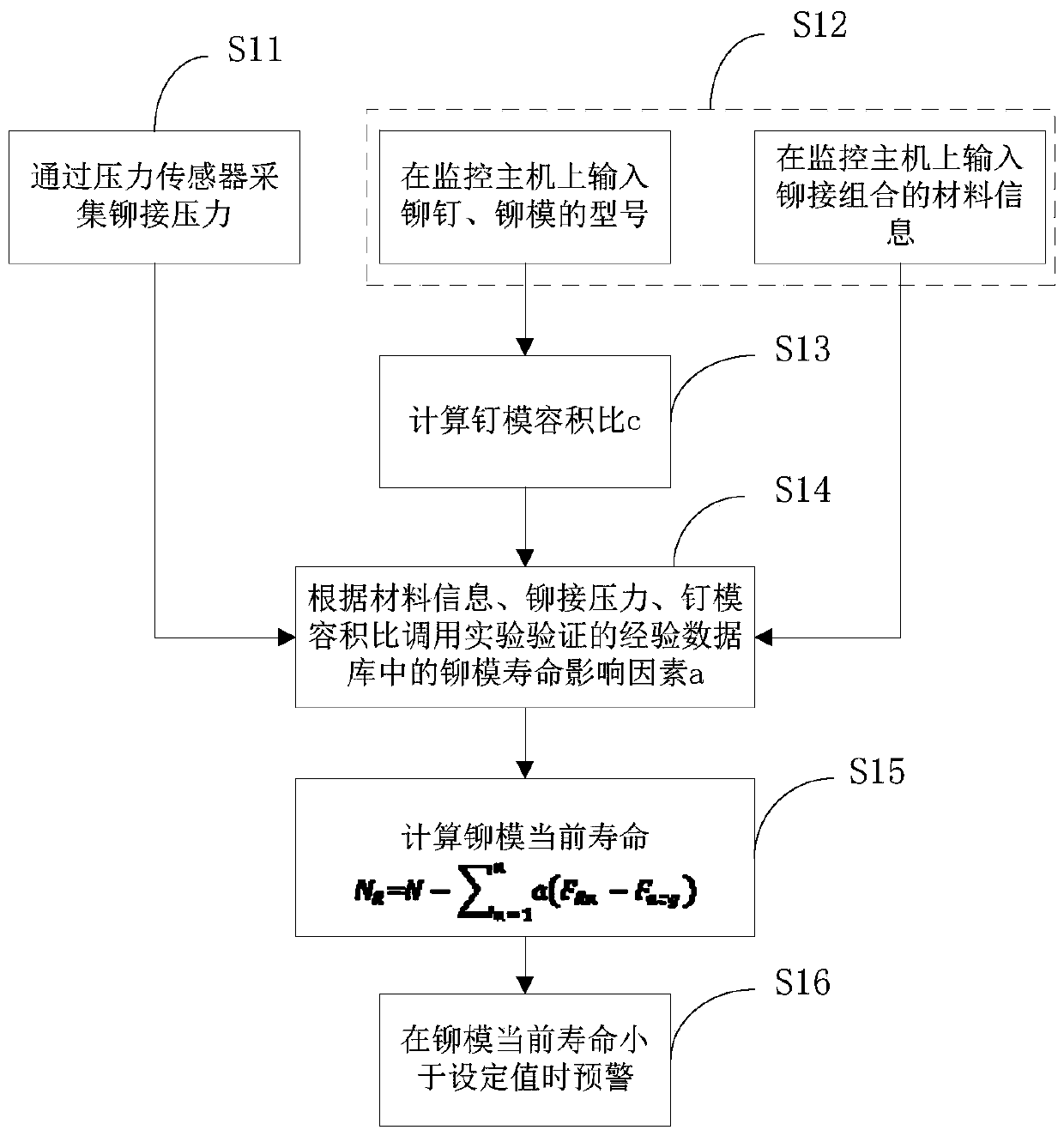

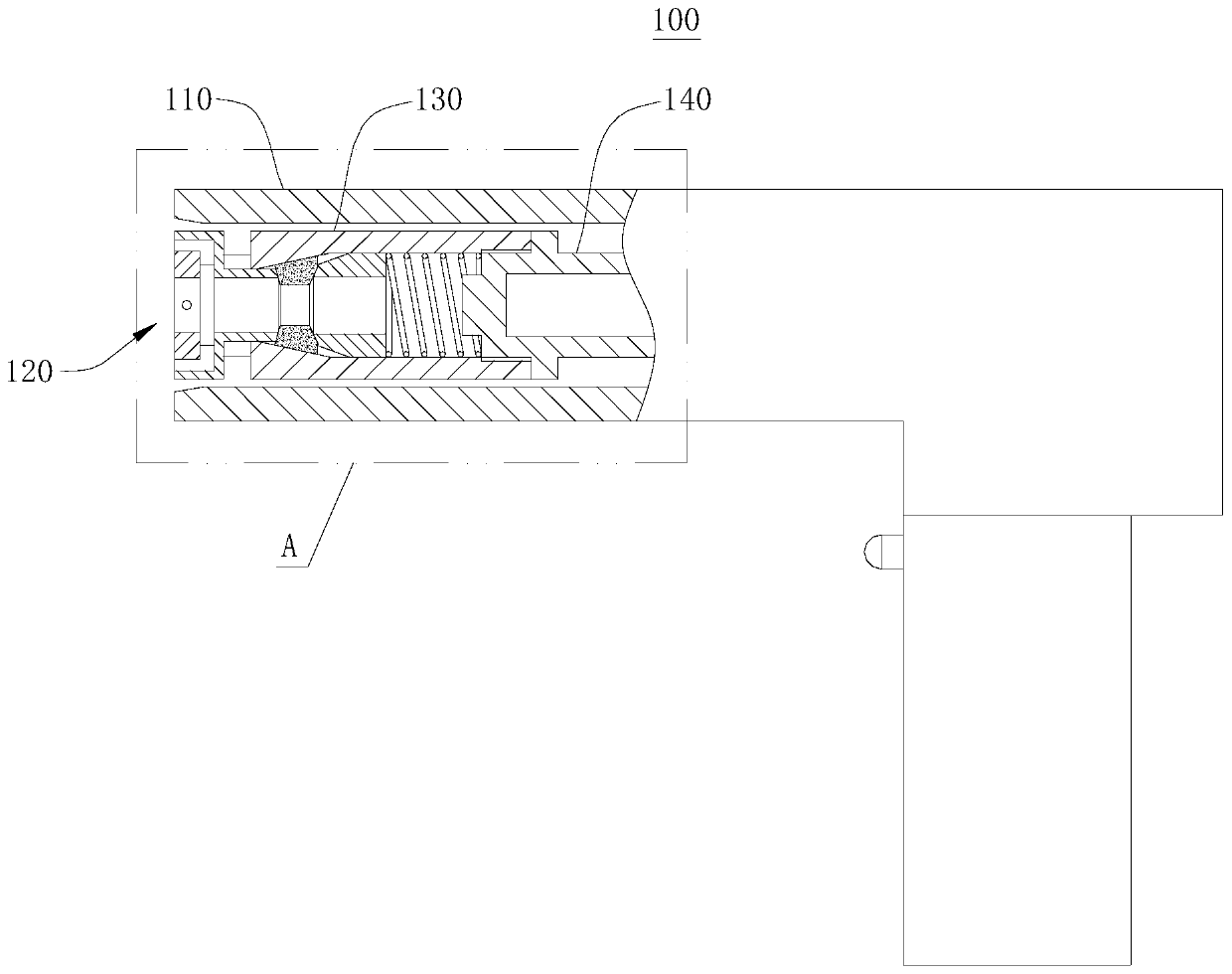

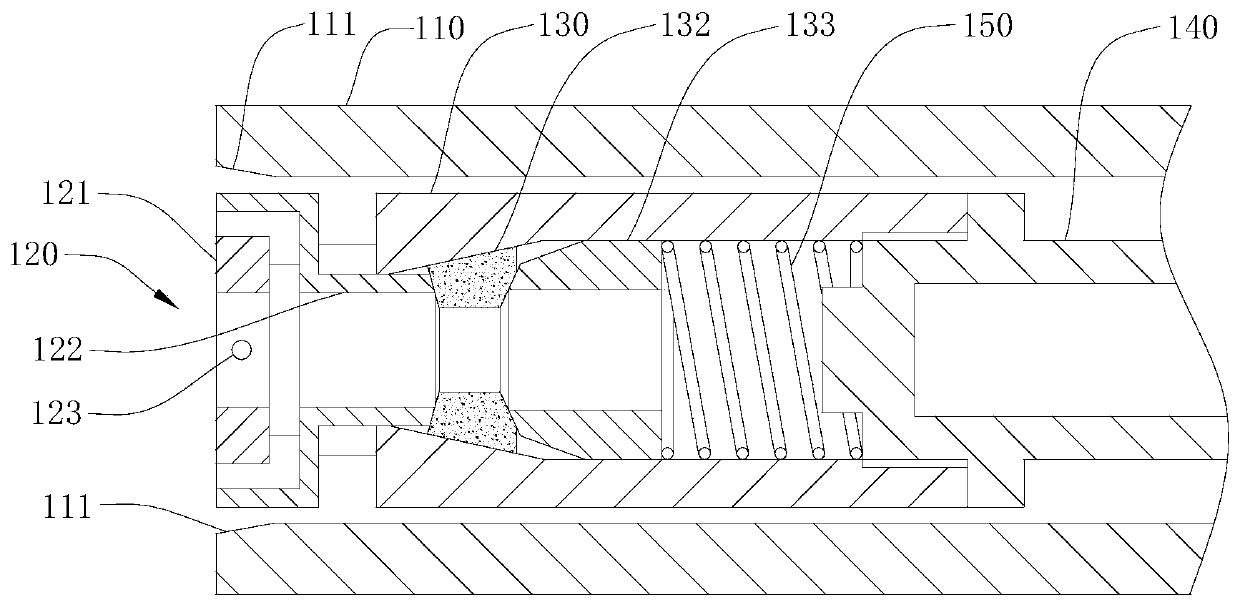

Method for monitoring service life of steel-aluminum hybrid vehicle body self-piercing riveting die based on riveting curve

The invention discloses a method for monitoring the service life of a steel-aluminum hybrid vehicle body self-piercing riveting die based on a riveting curve. The method comprises the following stepsthat a riveting pressure value is monitored in real time through a pressure sensor and is transmitted to a monitoring host; the material information, the rivet information and the riveting die information of the riveting combination are input in the monitoring host; the rivet-die volume ratio c is calculated according to the rivet information and the riveting die information; according to the material information, the riveting pressure and the rivet-die volume ratio c, the experience database is called to query the riveting die service life influence factor a; and the current service life NR of the riveting die is calculated by using a formula, and when NR is smaller than the set value, early warning of riveting die replacing is performed. According to the method, the change of the riveting pressure curve is monitored in real time, so that the factors influencing the riveting die are obtained, the current service life of the riveting die is calculated according to the riveting pressure, the rivet-die volume ratio and the plate information, early warning is conducted in advance, the situation that people can not realize the damage of the riveting die is avoided, and the riveting quality of the white body is guaranteed.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Cold-drawn rivet gun, cold-drawn rivet and cold-drawn riveting method

The invention discloses a cold-draw riveting gun, a cold-pull rivet and a cold-pull riveting method, and belongs to the technical field of riveting. The tail part of the cold-draw rivet is provided with a clamping ring groove, the riveting gun comprises a gun shell, a clamping shell and connecting seat which are both arranged in the gun shell, a sliding block is arranged in the clamping shell, thesliding block can be clamped in the clamping ring groove, one end of the sliding block is contacted with a limit device, and the other end is connected with the connecting seat through a first top block and an elastic piece. According to the invention, the clamping ring groove is arranged at the tail part of the cold-draw rivet, the cold-draw riveting gun is connected with the clamping ring groove in a clamping mode through the sliding block, the connection between the cold-draw riveting gun and the cold-draw rivet is not easy to damage, and the service life of the cold-draw riveting gun is prolonged. The cold-draw riveting gun and the cold-draw rivet cannot slip and separate from each other, so that the cold-draw rivet is easily and reliably fastened and tensioned tightly, the riveting quality is ensured, the problems in the prior art are solved, the structure is reasonable and novel, and the operation is convenient and safe.

Owner:成都浩益科技有限公司

Heavy electromagnetic riveter

The invention discloses a heavy electromagnetic riveter, and relates to the field of electromagnetic riveters. The heavy electromagnetic riveter comprises a riveter main body part, a driving part and a handle part, the riveter main body part comprises a shell, the driving part is arranged in the shell, the driving part comprises a first buffer mechanism, the handle part comprises an operation handle, the operation handle and the shell are of a split structure, and a second buffer mechanism is arranged between the operation handle and the shell. The heavy electromagnetic riveter is heavy in overall structure, a large primary coil can be installed, large electromagnetic force can be generated in the actual use process, the generated recoil force is small due to the large mass ratio, the operation handle and the shell are connected in a separated mode, the recoil force is prevented from directly acting on an operator in the operation process, meanwhile, a double-buffering structure is designed, 70%-90% of riveting recoil force can be consumed, and the operation safety is improved.

Owner:SHAANXI DAGONG XUHANG ELECTROMAGNETIC TECH CO LTD

Automatic riveting machine

PendingCN113145787AGuarantee riveting qualityAccurate and orderly pre-installationLanternIndustrial engineering

The invention relates to the technical field of riveting, in particular to an automatic riveting machine. The automatic riveting machine is characterized in that a material taking assembly is arranged on the side of a conveying plate, and the material taking assembly is used for transferring a workpiece to the conveying plate; a jacking assembly is arranged below the conveying plate, and the jacking assembly is used for jacking rivets to the workpiece on the conveying plate; a discharging assembly is suspended above the jacking assembly and the conveying plate, and the discharging assembly is used for pressing a lantern ring onto the workpiece; feeding assemblies are arranged on the side of the jacking assembly and the side of the discharging assembly and used for conveying the rivets and the lantern ring into the jacking assembly and the discharging assembly respectively. The workpiece, the rivets and the lantern ring are conveyed to be fed through the conveying plate and the feeding assemblies correspondingly, the rivets and the lantern ring are pre-installed on the corresponding positions of the workpiece through the jacking assembly and the discharging assembly, accurate and orderly pre-installation of the workpiece, the rivets and the lantern ring is achieved, the accuracy of the installation position is guaranteed, the production efficiency is greatly improved through automatic production, and the riveting quality of the workpiece is ensured.

Owner:惠州市海尚科技有限公司

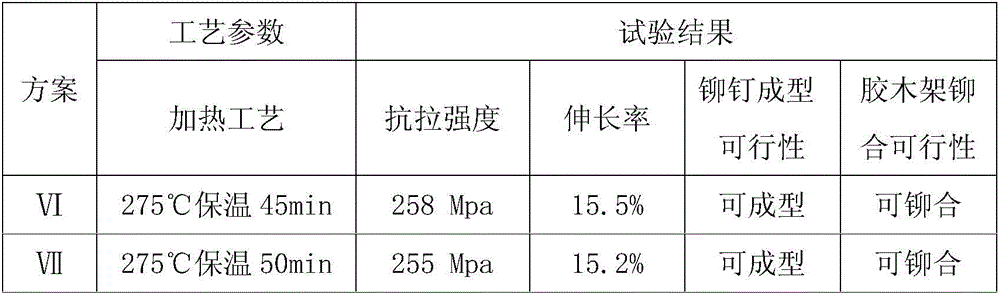

A positionable pre-punching rivetless constant temperature stamping die and its control method

InactiveCN105328045BAchieve connectionAccurately press inShaping toolsMetal working apparatusHydraulic cylinderEngineering

The invention discloses a pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning. The stamping die comprises a punch, a lower die holder and a hydraulic cylinder. The punch is of a circular truncated cone structure. The radius of the upper surface of the punch is larger than that of the lower surface of the punch. The center of the lower die holder is a containing cavity. The upper portion of the containing cavity is a regular circular truncated cone cavity, and the lower portion of the containing cavity is provided with a through hole. An upper end opening of the regular circular truncated cone cavity is formed in the upper plane of the lower die holder, and the lower end of the regular circular truncated cone cavity is communicated with the through hole. The hydraulic cylinder is located in the through hole. A piston of the hydraulic cylinder stretches out of the upper end opening of the regular circular truncated cone cavity in the non-stamping process. The punch and the lower die holder are both provided with a cooling channel and are provided with a temperature sensor and a controller. The invention further discloses a control method of the pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning. The pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning achieves connection between high-strength steel and aluminum alloy without rivets and has the advantages that accurate positioning can be achieved, and meanwhile riveting accuracy is not affected due to the cooling punch and the die.

Owner:JILIN UNIV

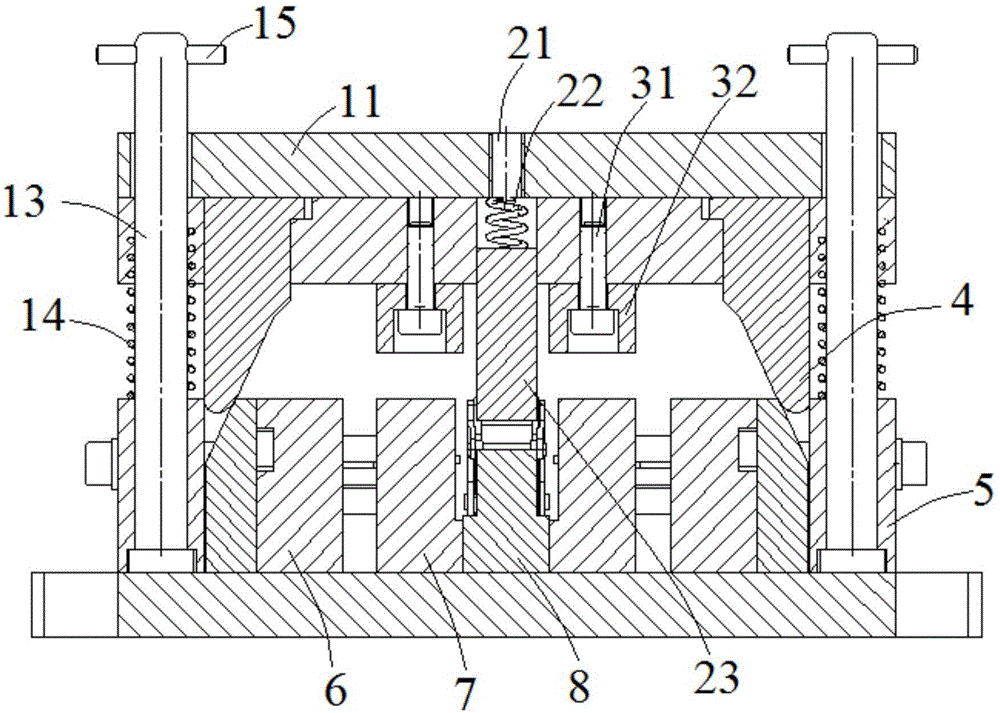

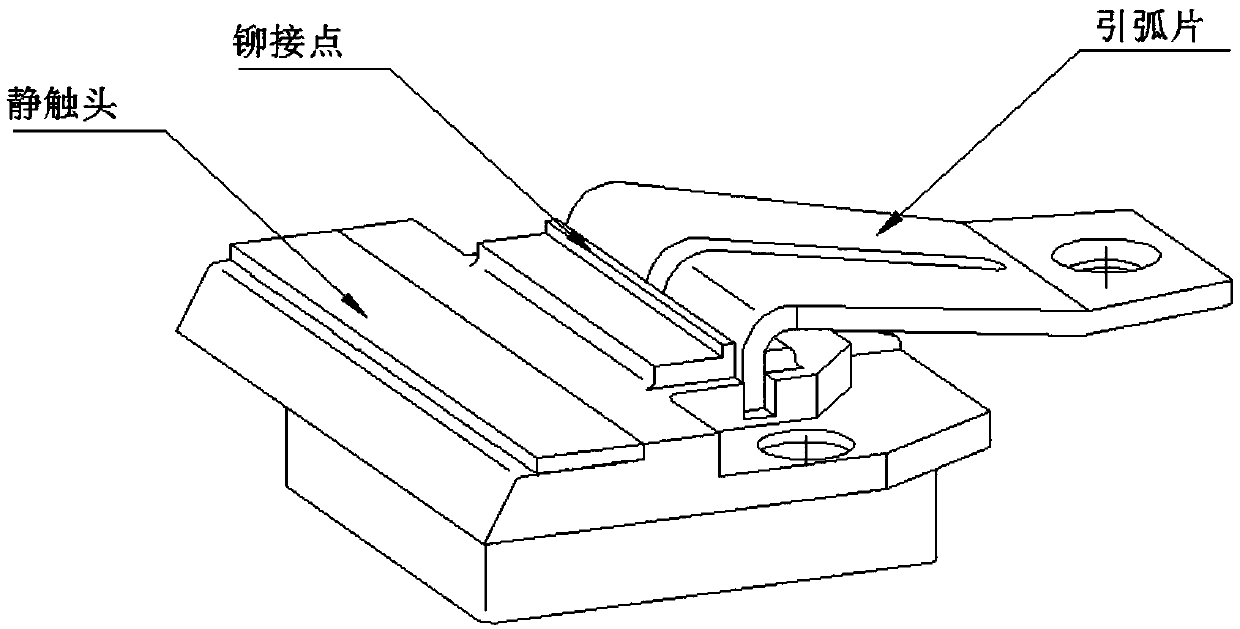

Riveting clamp of arc striking piece of frame type circuit breaker

InactiveCN109647994AEasy and fast changeoverCompact structureShaping toolsMetal-working feeding devicesEngineeringCircuit breaker

The invention relates to a riveting clamp of an arc striking piece of a frame type circuit breaker. The riveting clamp comprises a static contact and the arc striking piece. The clamp comprises a power mechanism, a positioning and fixing mechanism and an upper punch. The power mechanism comprises an upper baffle, an upper fixing plate, a lower bottom plate, guide posts and springs. The positioningand fixing mechanism comprises limiting plates, a rear baffle, an arc striking piece pressing column, an arc striking piece cushion plate and an arc striking piece baffle. The upper punch is fixed below the upper fixing plate. The riveting clamp is small in size, ingenious in structure, attractive in appearance, easy to operate and low in cost.

Owner:JIANGSU DAQO KFINE ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com