Method for monitoring service life of steel-aluminum hybrid vehicle body self-piercing riveting die based on riveting curve

A technology for self-piercing and riveting dies, which is applied in the field of monitoring the life of self-piercing riveting dies for steel-aluminum mixed car bodies. found effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

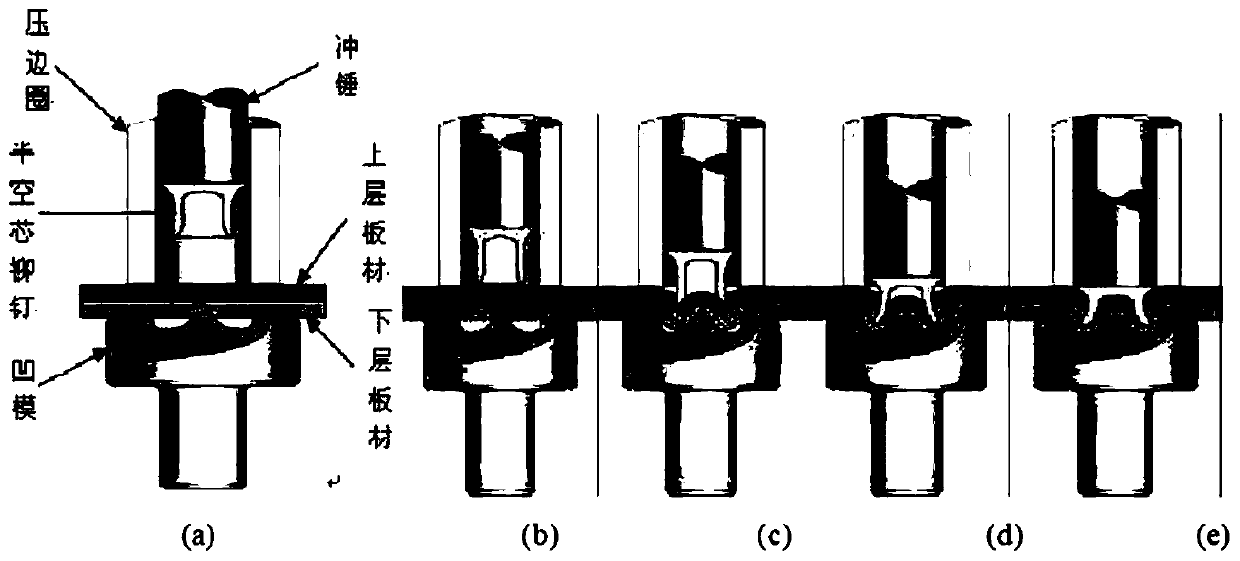

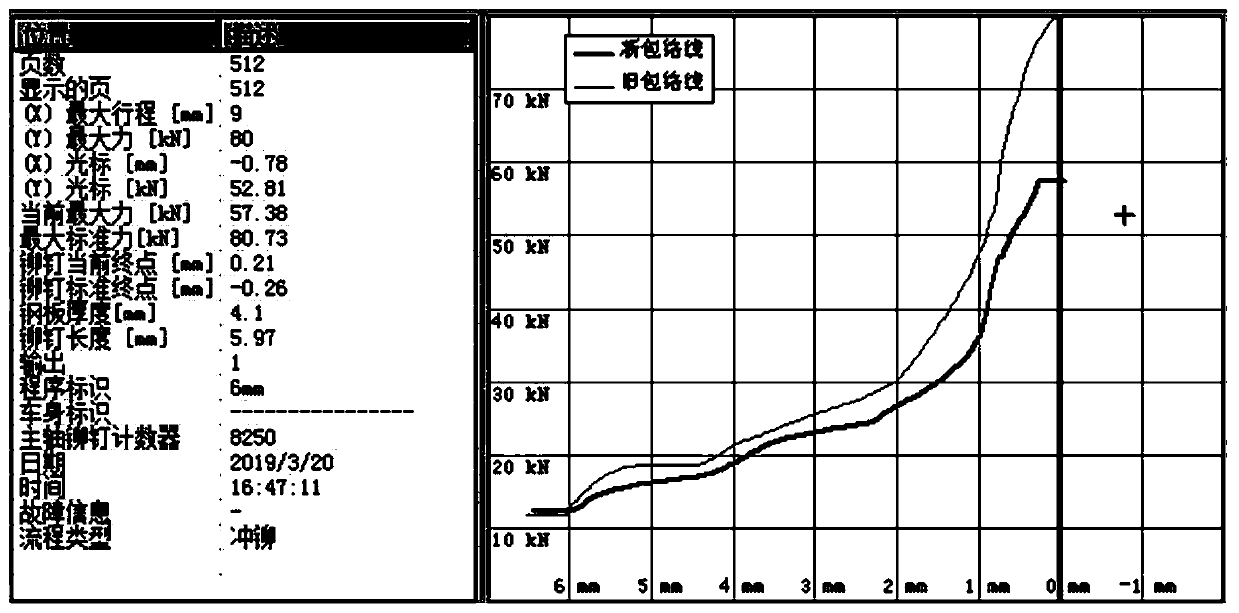

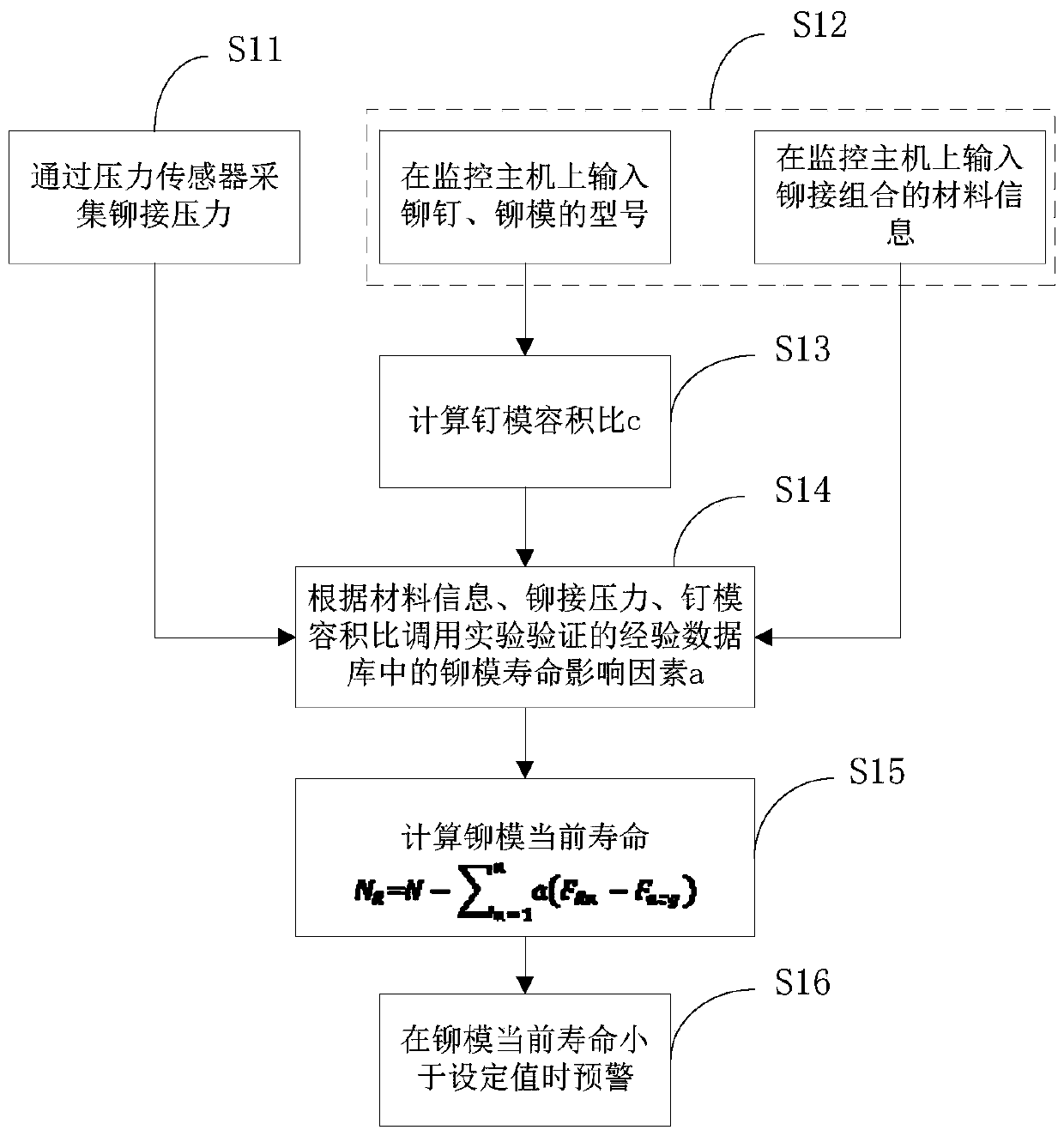

Method used

Image

Examples

Embodiment

[0038] 1. In the ES8 project, the UB station riveting mold was only used more than 50,000 times in the production process, and the riveting mold cracked. The theoretical lifespan is 200,000 times.

[0039] 2. In the ES6 project, during the production process of the riveting mold at the MFS station, the riveting mold cracked after using more than 80,000 times. The theoretical lifespan is 200,000 times.

[0040] In the above example 1, the theoretical life of the riveting die is 200,000 times, and the actual life of the riveting die is 50,000 times. In the above example 2, the actual life of the riveting die is 80,000 times, which is far less than the theoretical life. Monitor the remaining life of the riveting die or the time to scrap under different working conditions.

[0041] The present invention takes the influence of the riveting work place on the life of the riveting die into consideration, repeats the working conditions of the riveting die in the first working place a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com