Dual-nose semi-automatic assembler

A semi-automatic, double-nose technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of inability to assemble personalized pull tabs, and achieve the effects of improving assembly efficiency, reducing labor intensity, and quickly starting and stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

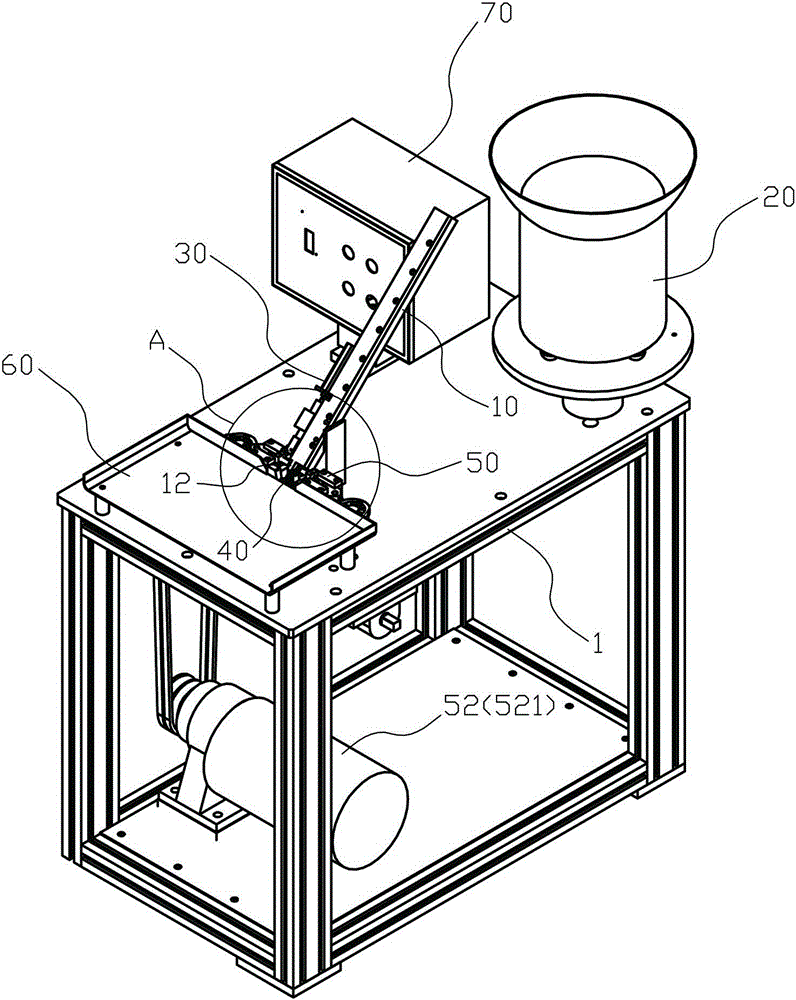

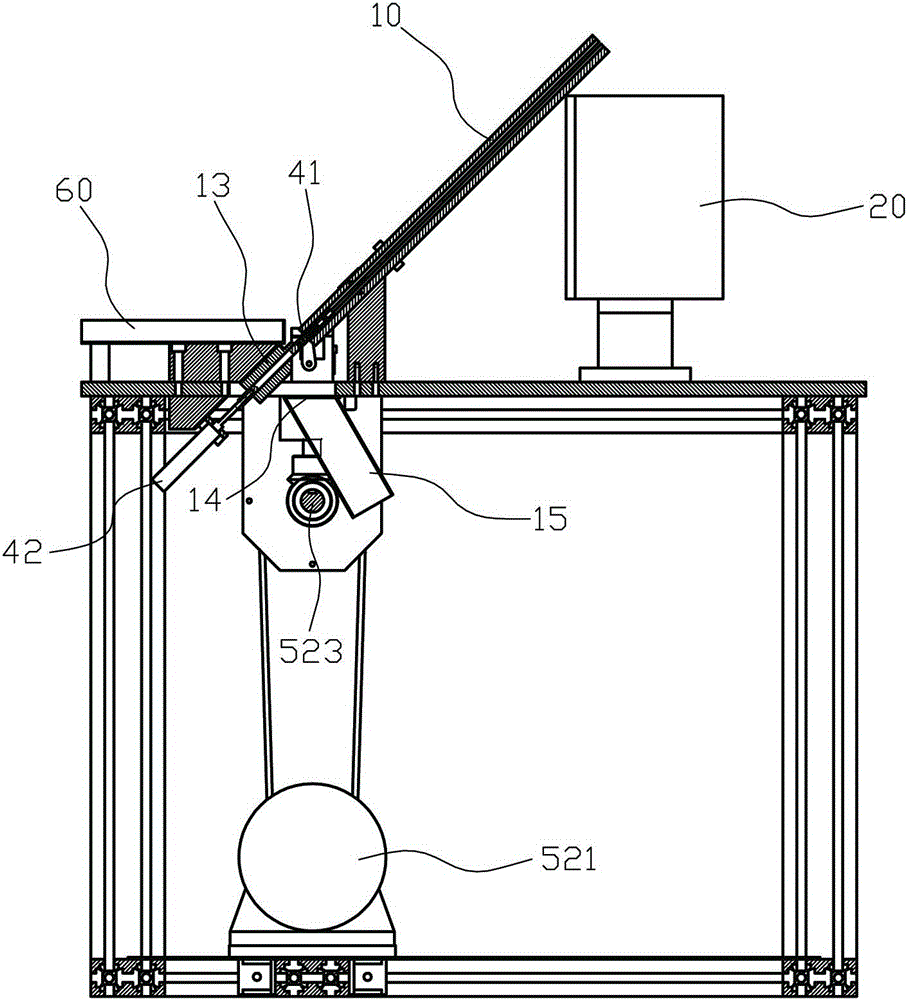

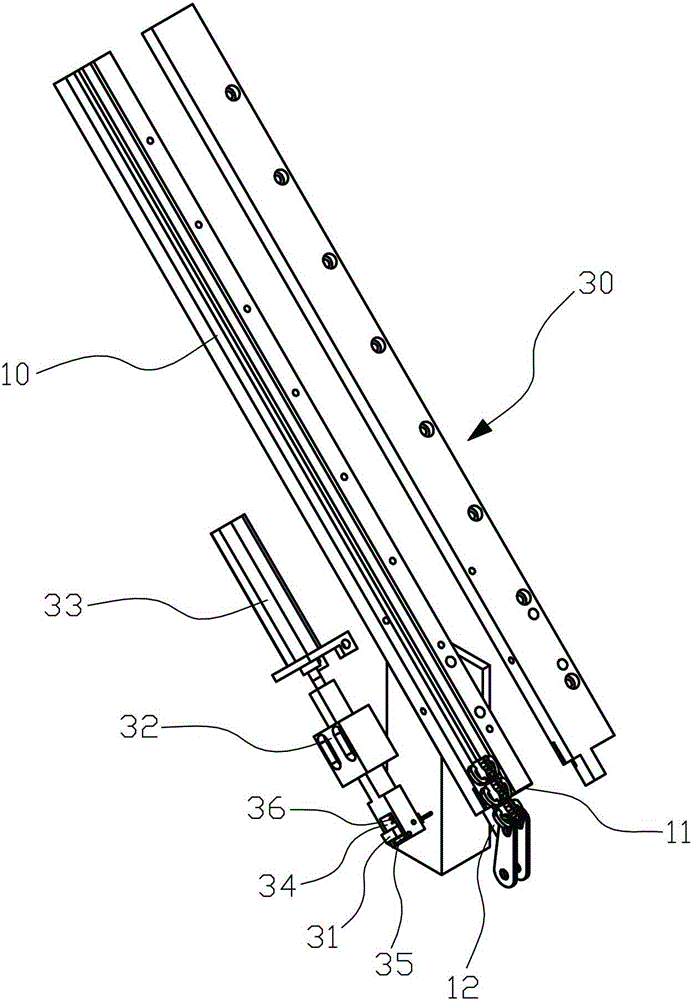

[0025] A double nose semi-automatic assembly machine, refer to figure 1 and figure 2 , including a frame 1 , a slider track 10 , a vibrating plate device 20 , a slider pushing device 30 , a slider supporting device 40 , a riveting device 50 , a tab tray 60 and an electric control device 70 . Wherein, the slider track 10, the vibrating plate device 20, the riveting device 50, the tab tray 60 and the electric control device 70 are arranged on the upper surface of the frame 1, and the electric control device 70 is connected with the vibrating plate devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com