Aluminum body self-piercing riveting quality control method based on force and displacement curve

A technology of self-piercing riveting and displacement curve, which is applied in the field of self-piercing riveting quality control of aluminum body, which can solve the problems that destructive testing cannot be applied to real-time monitoring of riveting quality, the internal quality defects of riveting cannot be identified, and real-time monitoring of riveting quality cannot be used. Achieve the effect of eliminating self-piercing riveting defects, reducing manual intervention, and ensuring riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

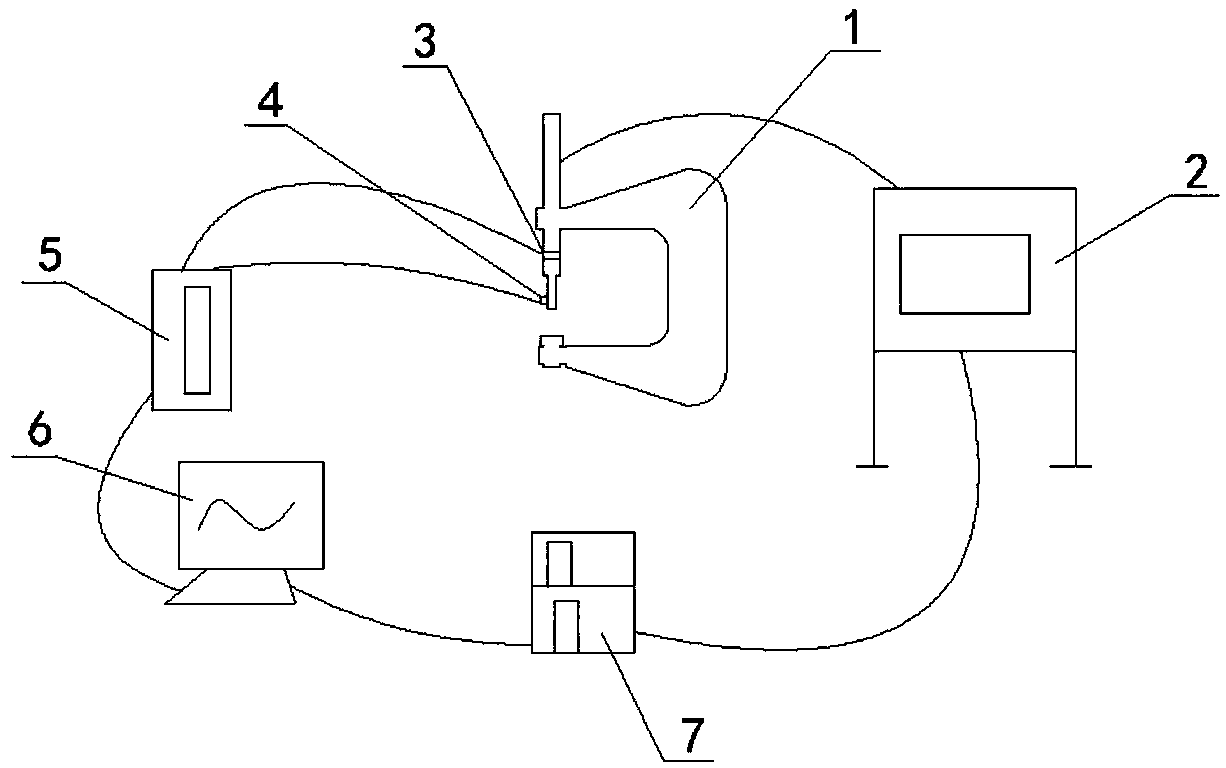

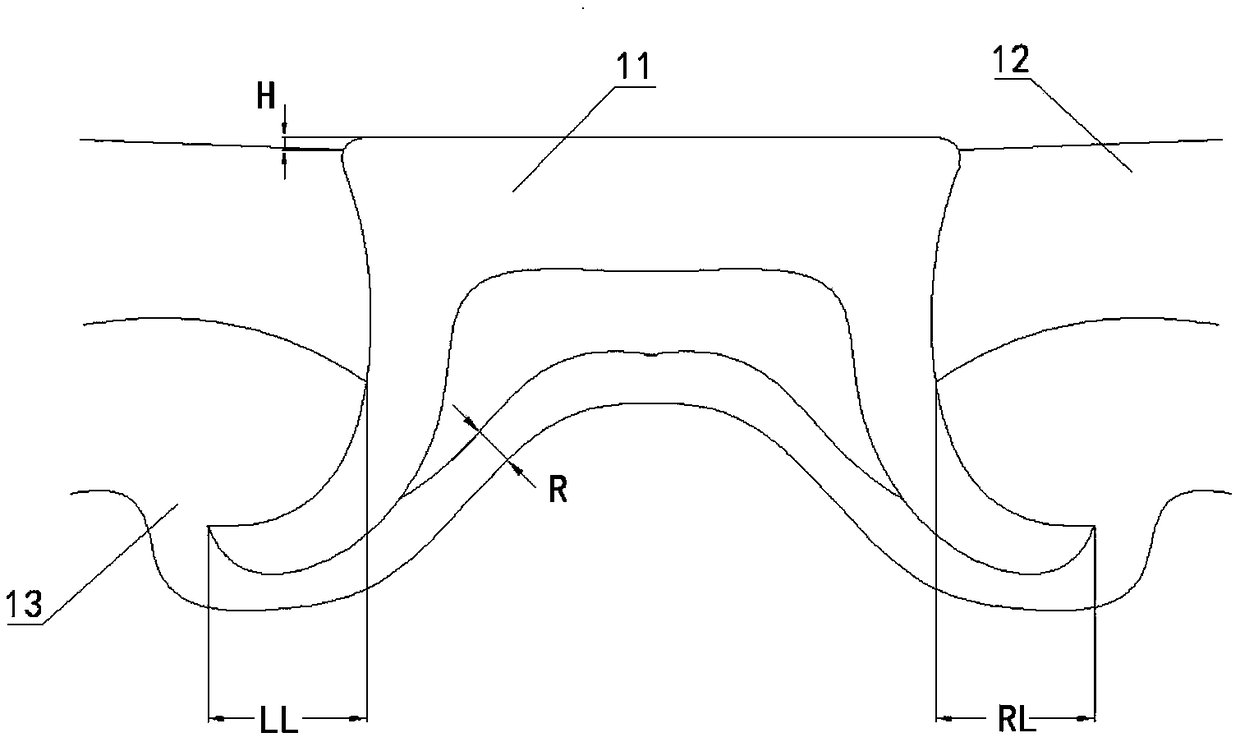

[0032] The quality control method of aluminum body self-piercing riveting based on force and displacement curve in this embodiment is:

[0033] Establish the standard curve of the relationship between the riveting force and the punch displacement during the riveting process through experiments or simulations, and obtain the change trend of the riveting force corresponding to different riveting defects; obtain the punch displacement and punch riveting during the riveting process through real-time detection According to the measured value of the force, the current measured curve is drawn according to the measured value; by comparing the current measured curve with the relationship standard curve, the riveting state is judged, and the punch riveting force of the riveting tool is controlled according to the riveting state.

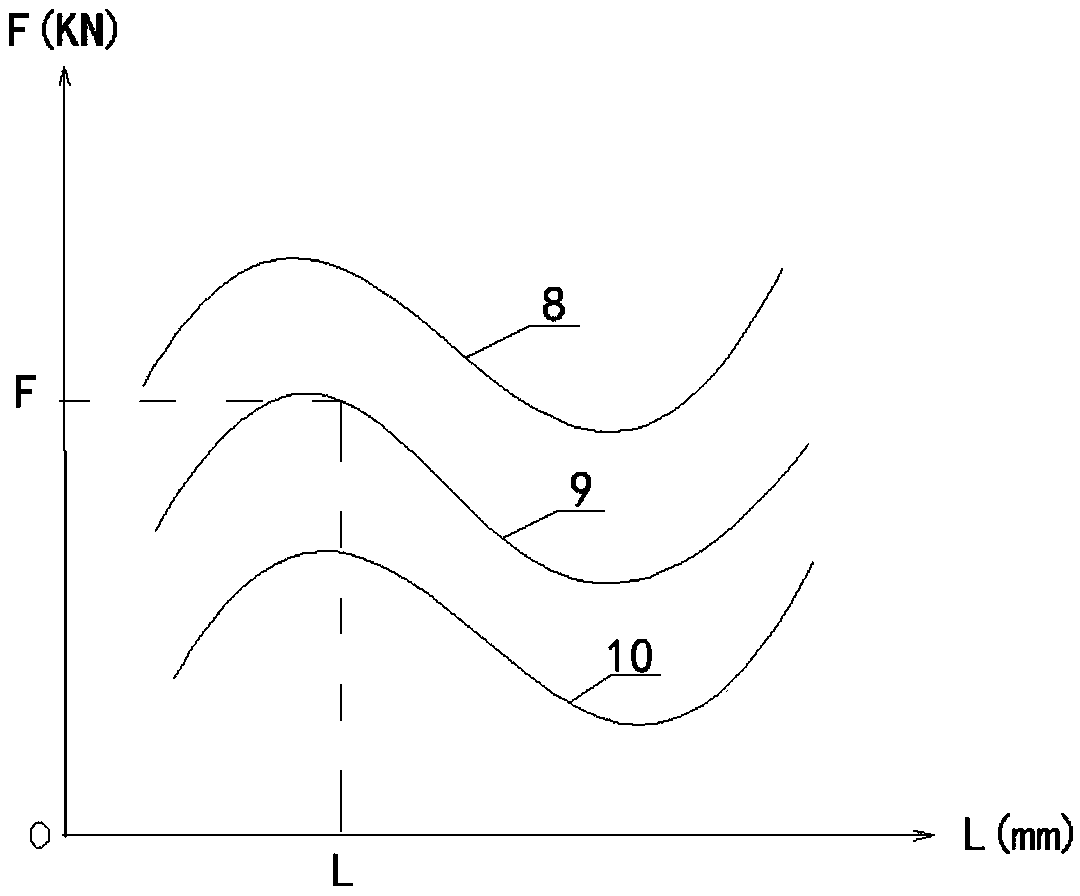

[0034] see image 3 , the force and displacement relationship standard curve in the present embodiment includes an upper limit standard curve 8 and a lower li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com