Heavy electromagnetic riveter

An electromagnetic riveting gun, heavy-duty technology, applied in the field of heavy-duty electromagnetic riveting guns, can solve the problems of unfriendly riveting operation, low riveting efficiency, and inability to solve the overturning moment of the riveting gun in horizontal centering, so as to improve the joint quality and use Longer life, improved safety, and improved alignment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

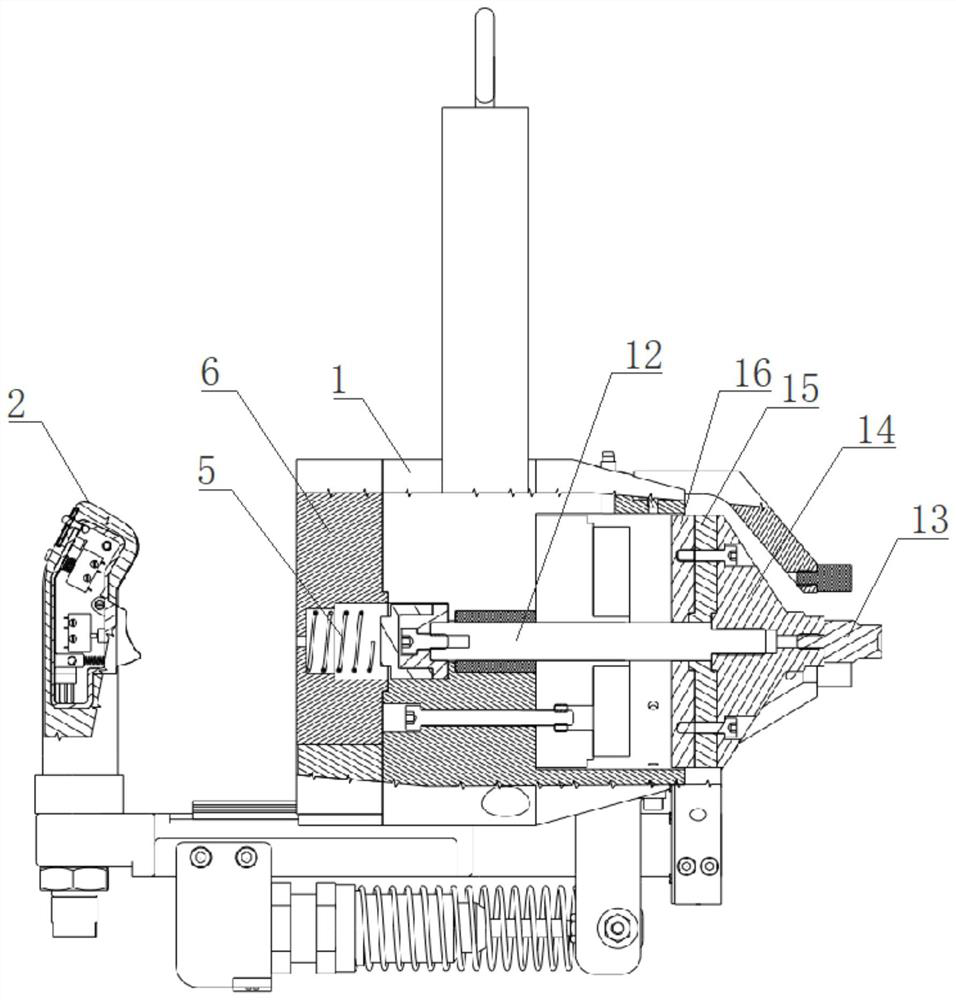

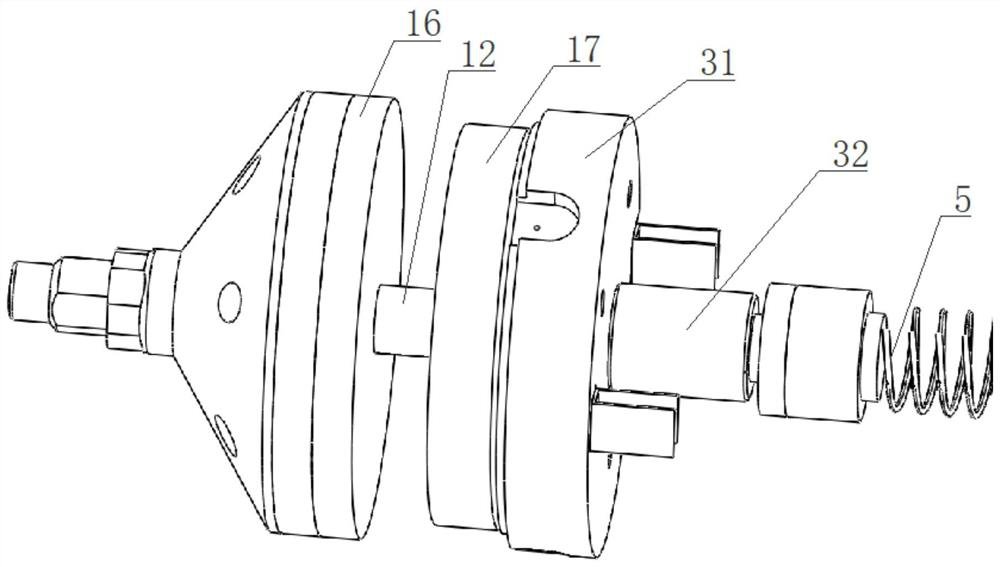

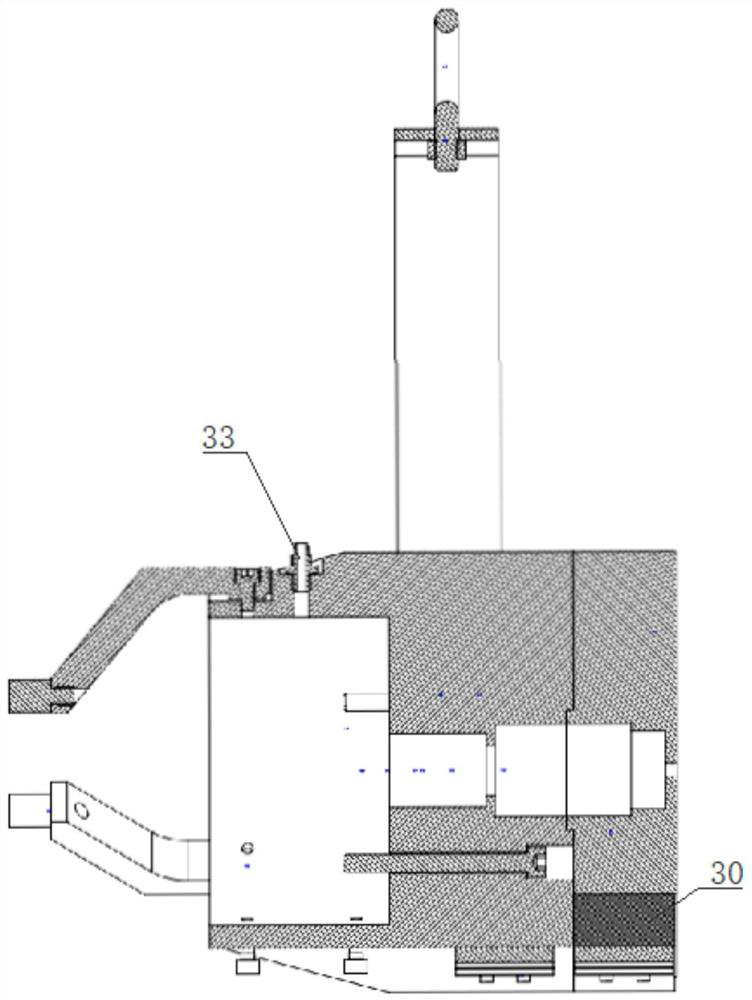

[0032] Such as Figure 1-8 As shown, it is a heavy-duty electromagnetic riveting gun according to the present invention, which includes a riveting gun main body, a driving part and a handle part. The riveting gun main body includes a casing 1, and the driving part is arranged in the casing 1. The driving part includes a first buffer mechanism, the handle part includes the operating handle 2, the operating handle 2 and the housing 1 adopt a split structure, and a second buffer mechanism is arranged therebetween.

[0033] Such as figure 1 As shown, the riveting gun adopts the separate connection mode of the operating handle and the shell to avoid the recoil force directly acting on the operator during the operation process. At the same time, a double buffer structure is designed to consume 70%-90% of the riveting recoil force and improve the safety of the operation. sex.

[0034] Specifically, such as figure 1 and Figure 5 As shown, the first buffer mechanism includes a buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com