Cold-drawn rivet gun, cold-drawn rivet and cold-drawn riveting method

A technology for pulling rivets and rivet guns, which is applied in the field of cold-drawing rivets, cold-drawing riveting, and cold-drawing rivet guns. It can solve problems such as ring teeth or threads that are easily damaged, and achieve improved service life, uniform force, and good transmission effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

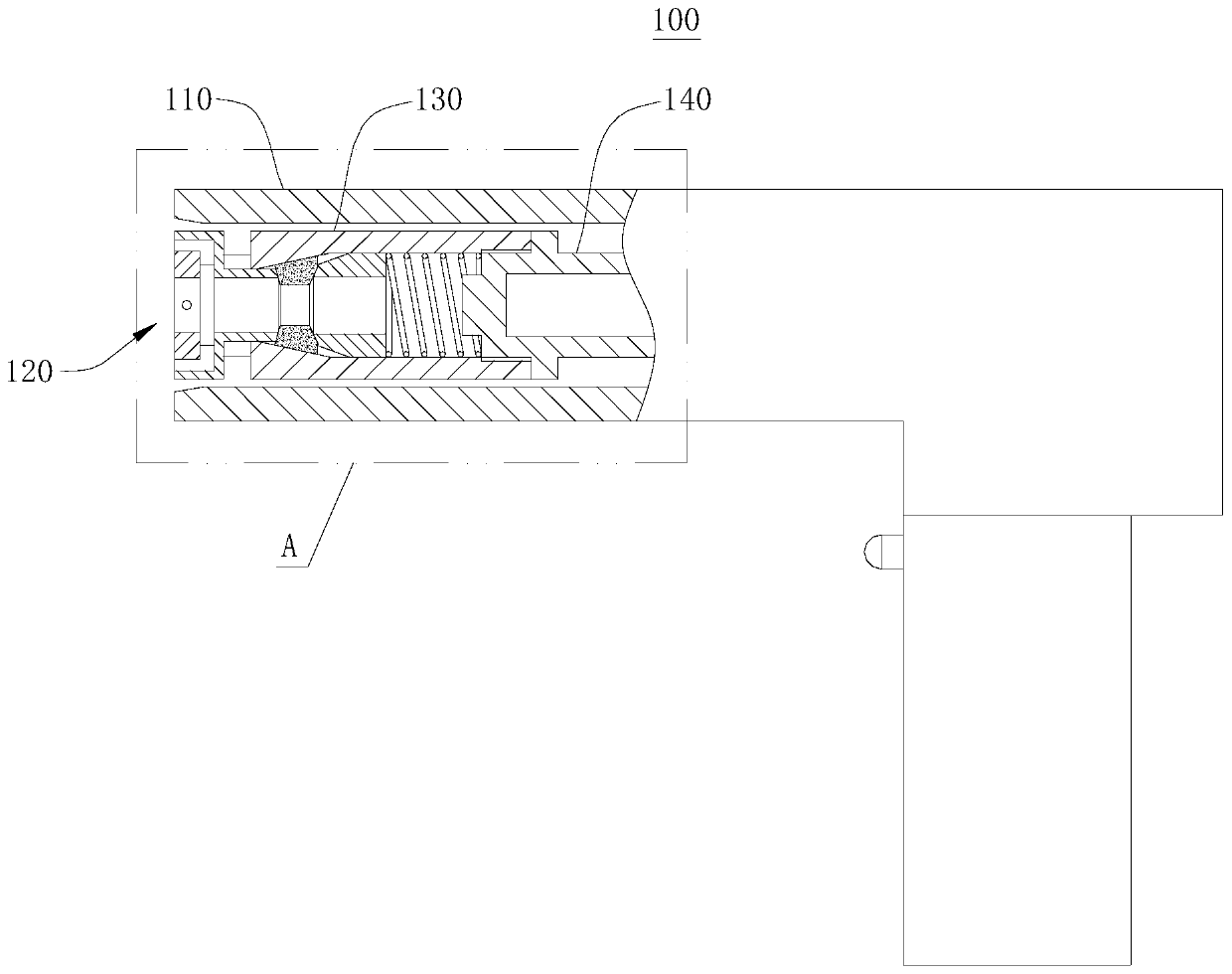

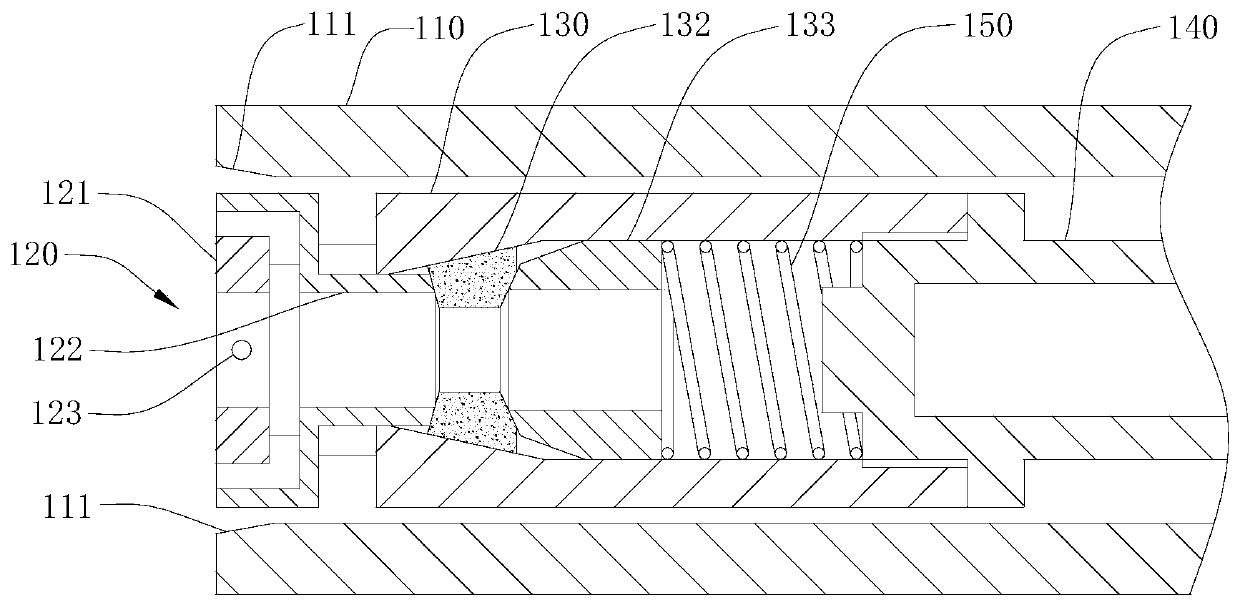

[0050] Please refer to figure 1 , a cold-drawn rivet gun 100, including a gun casing 110, a power unit, a gun handle, a start button, a reversing valve and other components; the middle cavity of the gun casing 110 is sequentially provided with a limit device 120, The clamping shell 130, the connecting seat 140 and the power device, and the limiting device 120, the clamping shell 130, the connecting seat 140 and the power device are connected in sequence. The limiting device 120 is located at the muzzle of the gun, the power unit is connected to the gun shell 110 , and the movement direction of the connecting seat 140 is opposite to that of the gun shell 110 . In this embodiment, the power device is a hydraulic drive device, obviously, the power device may also be an electric drive device or a manual drive device.

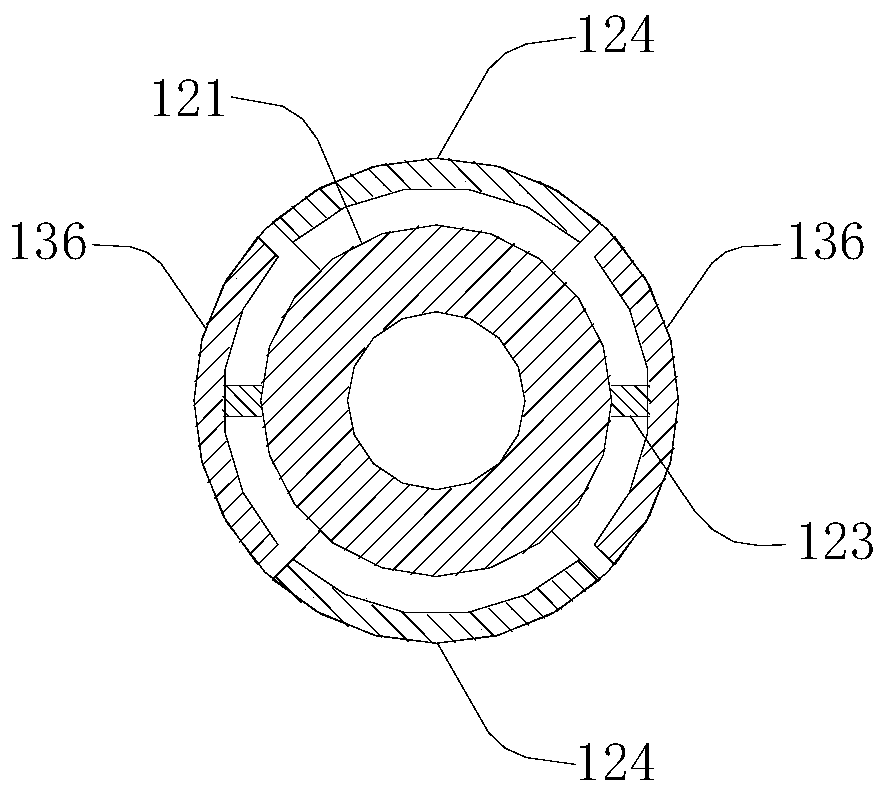

[0051] Please refer to figure 2 , The inner surface of the gun shell 110 close to the muzzle is provided with an extruding slope 111 . The extrusion slope 111 o...

Embodiment 2

[0069] Please refer to Figure 17 and Figure 18The difference between this embodiment and Embodiment 1 is that the cold-drawn rivet 200 is not provided with a breaking groove 216, and a connecting section 217 is provided between the riveting section 212 and the clamping section 213, and the axes of the connecting section 217 and the riveting section 212 coincide. And the diameter of the connecting section 217 is consistent with the diameter of the riveting section 212, and the diameter of the connecting section 217 is greater than the diameter of the clamping section 213, so that the cold-drawn rivet 200 is stepped. At this time, the cold-drawn rivet 200 is a short-tail cold-drawn rivet. The connection method between the cold-drawn rivet 200 and the cold-drawn rivet gun 100 of the present invention is applied to short-tailed rivets.

[0070] The method and principle of riveting the cold-drawn rivet 200 with the cold-drawn rivet gun 100 of this embodiment are the same as thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com