A positionable pre-punching rivetless constant temperature stamping die and its control method

A stamping die and control method technology, applied in the field of pre-punching rivetless constant temperature stamping die and its control, can solve the problems of large differences in melting point and thermal expansion coefficient, difficult precise positioning of punches and pre-punching holes, and difficult welding joints, etc. , to achieve the effect of unaffected riveting accuracy, simple implementation and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

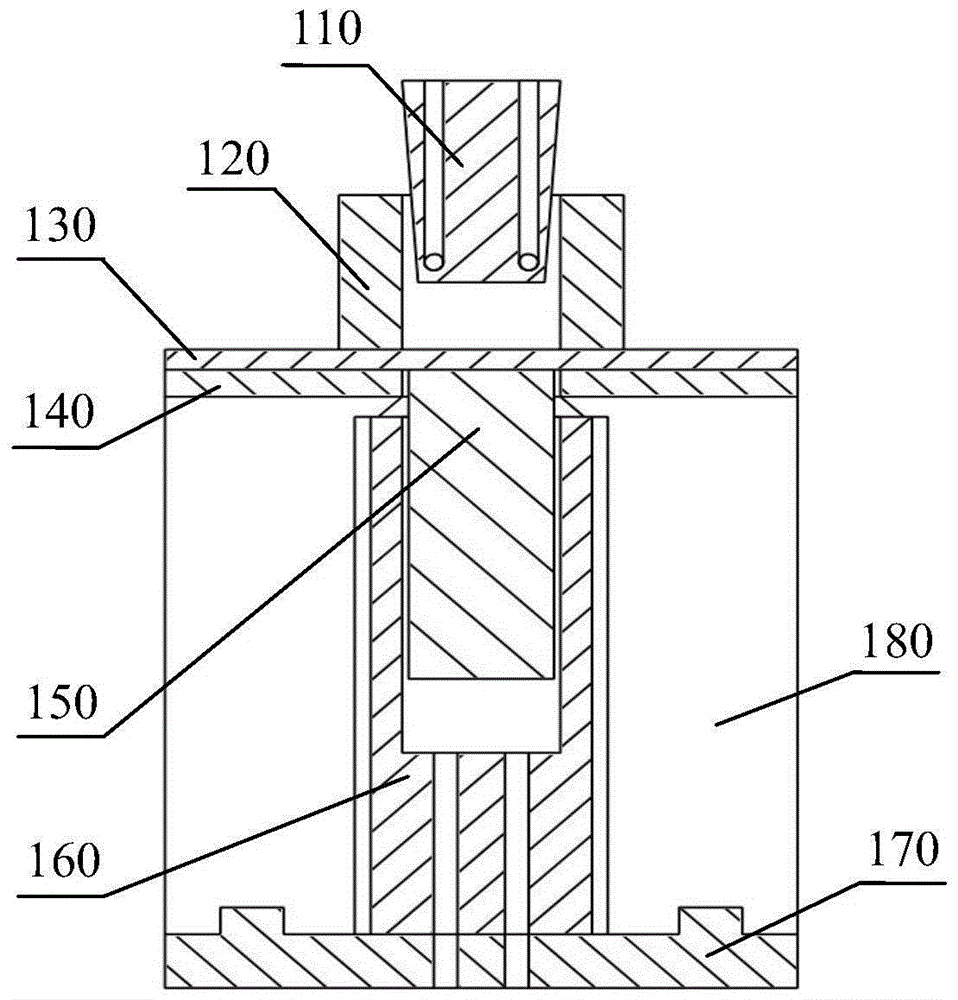

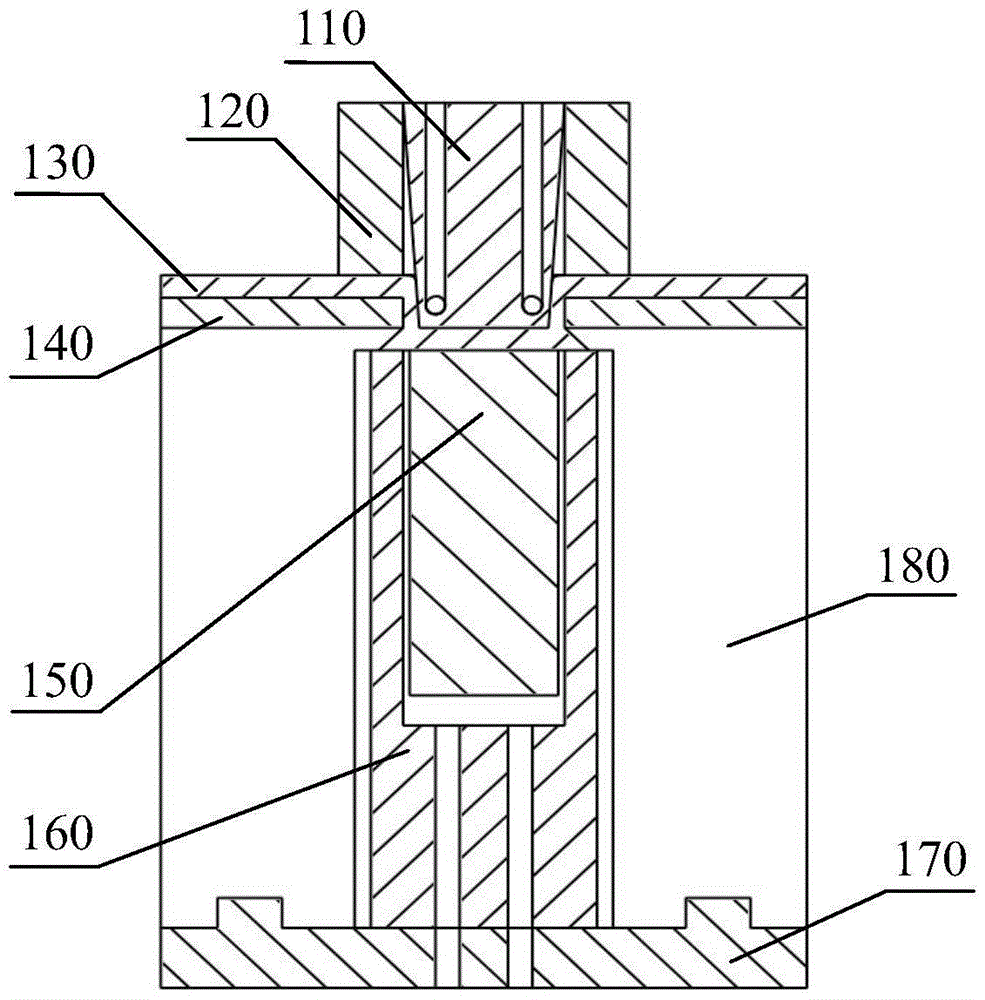

[0050] During the hot forming process of the high-strength steel plate 140, a circular through hole with a diameter of 10mm is punched out at the riveting position of the steel plate.

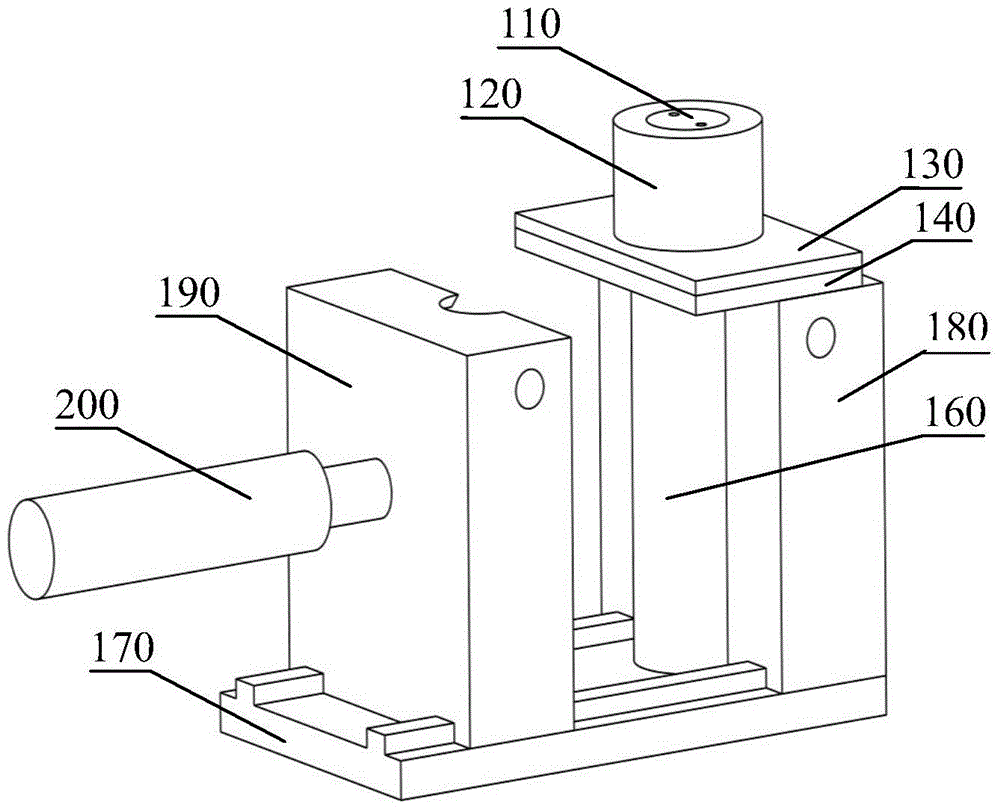

[0051] like figure 1 As shown, the punch 110, the positioning hydraulic cylinder and the integral lower die base are coaxially arranged, and the positions of the hydraulic cylinder and the fixed lower die base 180 are fixed; The diameter of the small circle on the surface is 8mm, the inclination angle of the bus bar is 45°, the height is 15mm, the diameter of the internal cooling liquid channel is 2.5mm, and the distance between the axis plane and the lower surface of the punch is 3mm. The punch 110 is placed in the center hole of the blank holder 120 for sliding connection. The blank holder 120 is a ring-shaped structural member with a height of 15mm, an outer diameter of 20mm, an inner diameter of 10mm, and a piston 150 with a diameter of 10mm. The cylinder 160 has a diameter of 14 mm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com