Device for riveting threaded cap plate and thin cover of full-automatic filter

A threaded cover plate and filter technology, which is applied in the direction of ejection equipment, metal processing equipment, forming tools, etc., can solve the problems of dislocation riveting between riveting blocks and riveting grooves, low efficiency of manual riveting, and injuries to operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

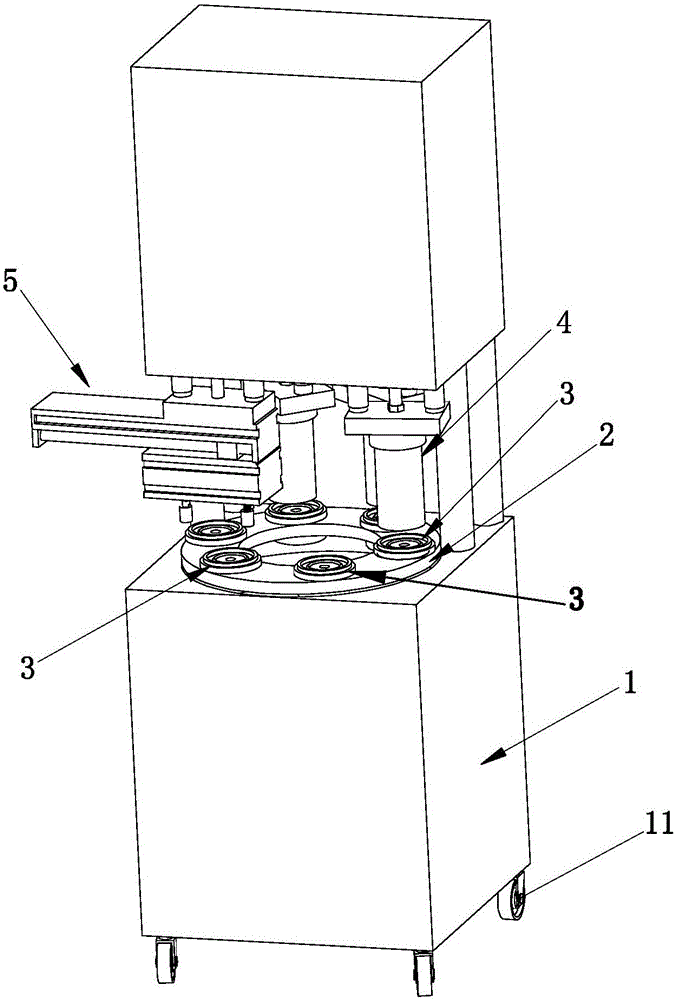

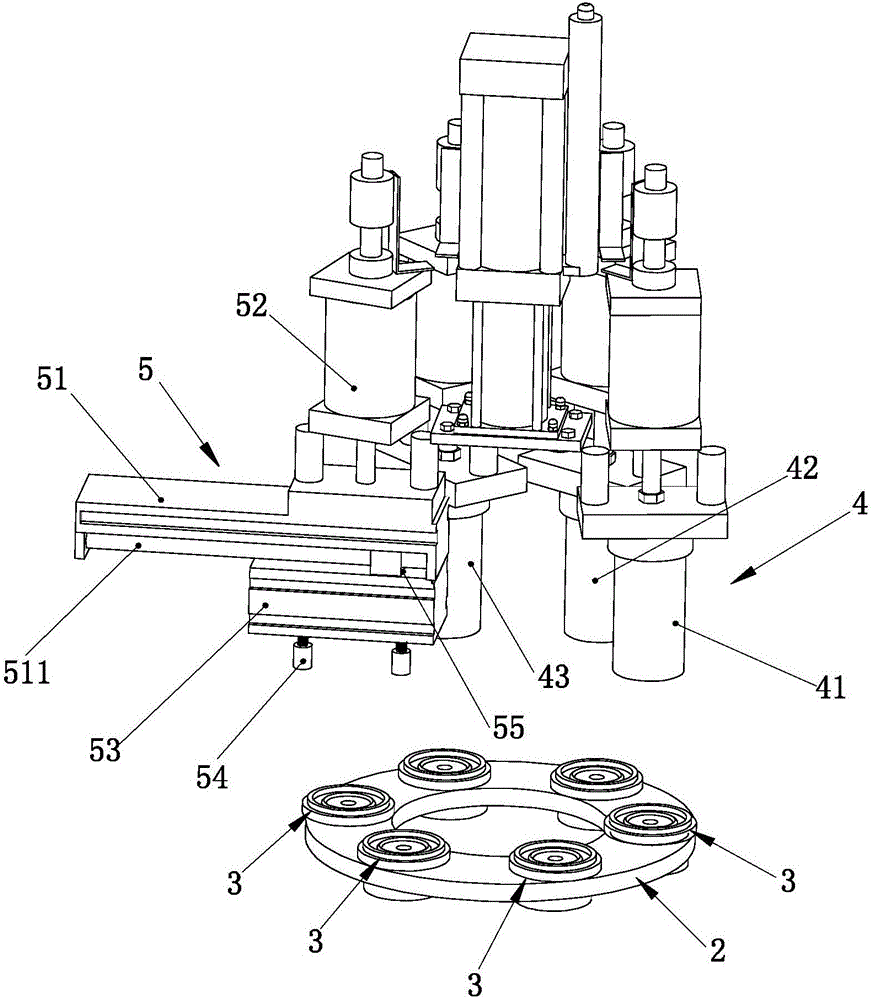

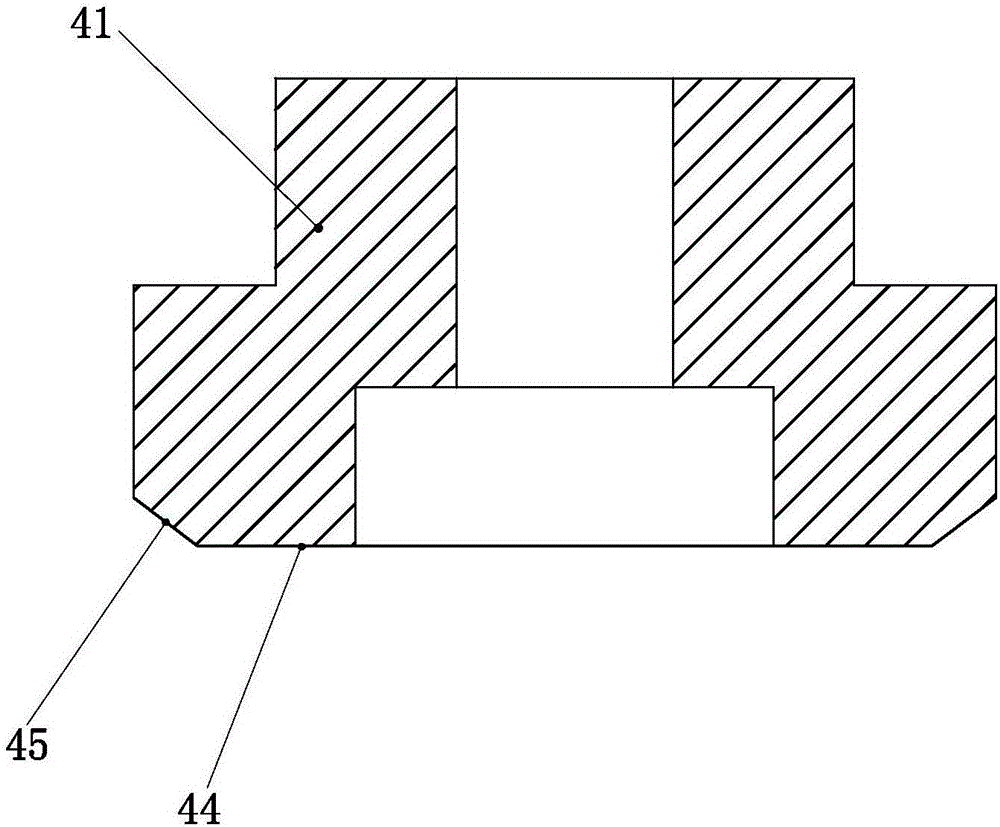

[0019] Such as figure 1 — Figure 5 The shown riveting equipment for threaded cover plate and thin cover of a fully automatic filter includes an organic body 1, a rotatable turntable 2 erected on the body 1, several positioning molds 3 evenly distributed on the turntable 2 and At least two riveting die heads 4 erected on the machine body 1 and compatible with the positioning mold 3 that can be reciprocated and lifted along the positioning mold 3. The machine body 1 is equipped with an extraction device for extracting riveted products in the positioning mold 3 5. During the assembly process of the above solution, the thin cover to be riveted and the threaded cover laminated with the thin cover can be placed on the positioning mold 3, and the positioning mold 3 with the thin cover and the threaded cover can be transported by the rotation of the turntable 2 To the riveting die 4, and riveting it through the riveting die 4, the riveted thin cover and threaded cover can be remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com