Red copper wire softening treatment process

A technology of softening treatment and copper wire, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems that cannot meet the performance requirements of rivet forming and bakelite cage at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

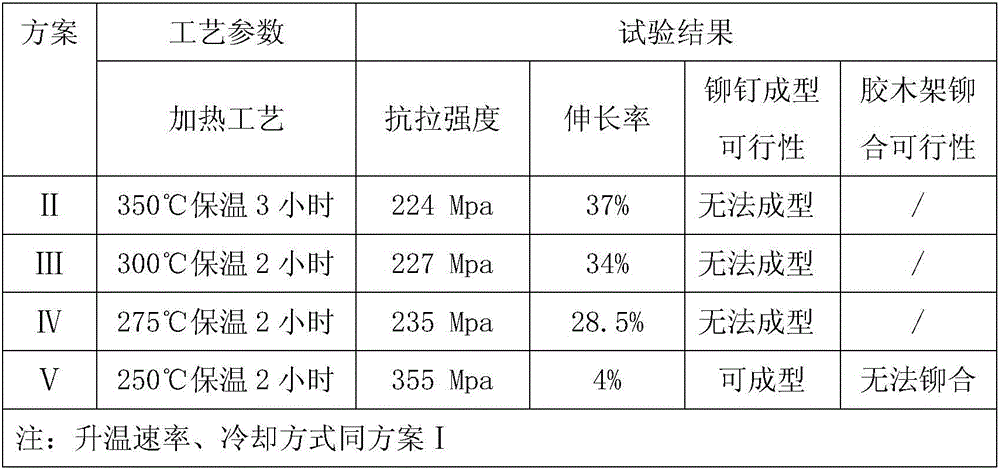

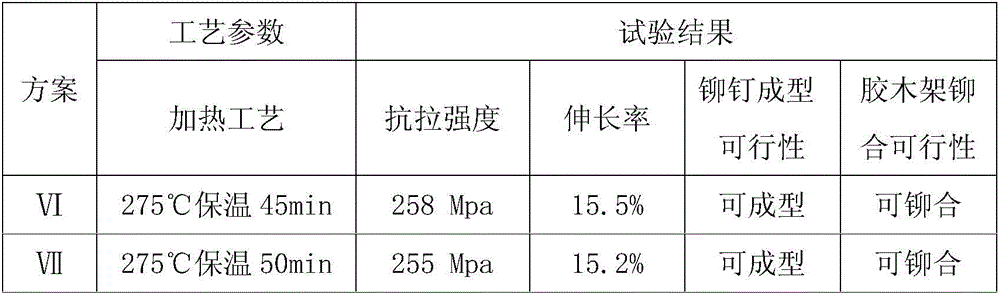

Examples

specific Embodiment approach 1

[0008] Specific implementation mode one: the copper wire softening treatment process of the present embodiment, selects Y 2 state copper wire; the selected Y 2 Clean the state copper wire and dry it naturally; then place the cleaned and dried copper wire in a vacuum heat treatment furnace for heat treatment. Cool with inert gas, cool to below 43°C and leave the furnace.

specific Embodiment approach 2

[0009] Specific Embodiment 2: This embodiment differs from Specific Embodiment 1 in that: the heating method adopts atmosphere convection heating.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the rate of heating to 270° C. to 280° C. is 7° C. to 12° C. / min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com