Pre-buried groove channel

A technology for pre-embedding channels and channels, applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of general fatigue resistance, non-compliance with requirements, slow pre-embedding speed, etc., so as to improve the installation speed and quality. Anti-corrosion ability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

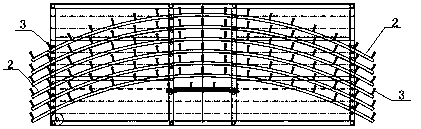

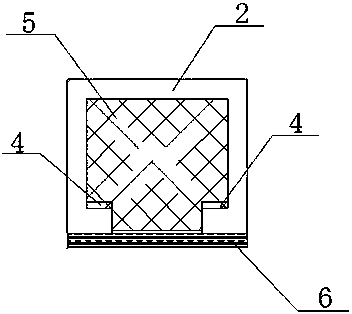

[0040] A pre-buried channel provided by this embodiment has a structure such as Figure 1-2 As shown, it includes the tank body, the anchor rod 1 and the filling strip. The tank body includes the channel 2 and the T-shaped bolt 3. The anchor rods 1 are evenly distributed on the top of the channel 2. The thickness of the end of the channel 2 provided with the anchor rod 1 is 2.5-3.0mm, the inner and outer surfaces of the channel 2 are coated with a zinc layer, the thickness of the zinc layer is 80μm-120μm, the surface of the zinc layer is coated with a water-soluble sealing paint layer, and the surface of the anchor rod 1 is a threaded structure , and the anchor rod 1 is riveted in the punching hole at the top of the channel 2 through a riveting machine, and the filling strip is set inside the channel 2, wherein:

[0041] Channel 2 is a C-shaped steel member with an arc-shaped opening facing downwards. Flanges 4 extend inward on both sides of the bottom of channel 2. Flanges 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com