Riveting die of water pump shell with aluminum ring

A shell and aluminum ring technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high riveting pressure, difficulty in maintaining stable riveting quality, and aluminum ring falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

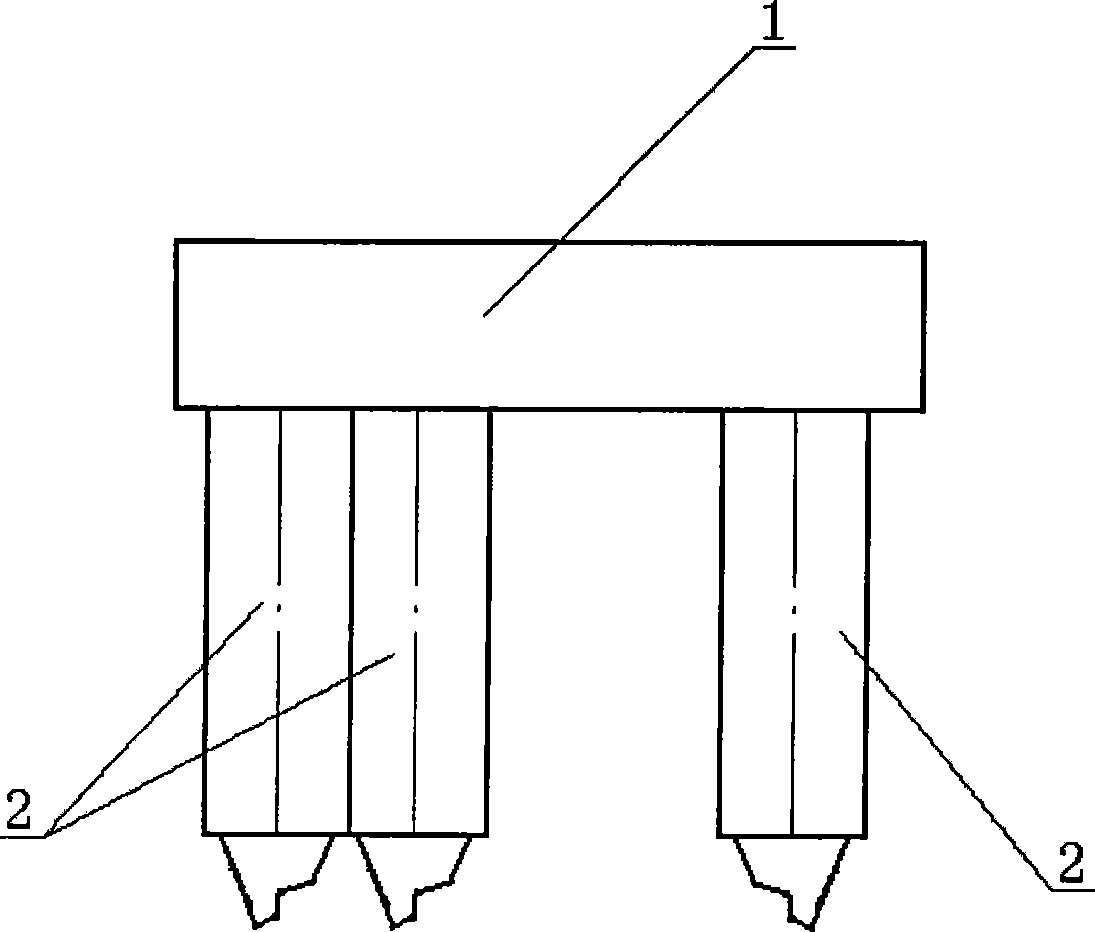

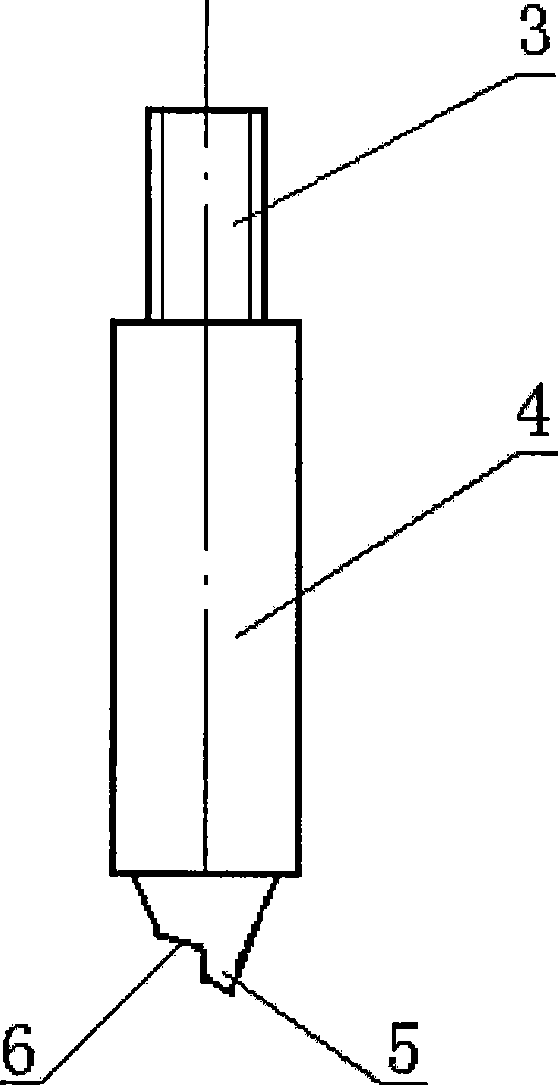

[0011] Such as figure 1 , figure 2 As shown, the riveting mold for riveting the water pump casing and the aluminum ring of the present invention includes an upper template 1 and a plurality of riveting rods 2, and each riveting rod 2 is composed of a rod body 4 and a pressing head at the lowermost end of the rod body 4. The structure of the pressing head of each riveting rod 2 described is that the bottom end of the truncated cone has a pressing wedge 5, and the bottom surface of the frustum of the frustum of the pressing wedge 5 is a slope 6, and the upper end of each riveting rod 2 is a The threaded section 3 of the threaded connection of the upper formwork 1. With such a structure, the pressing head of the riveting rod can be pressed into the pressure groove of the aluminum alloy water pump shell to be deformed by applying a small riveting force, thereby ensuring the riveting quality and improving the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com