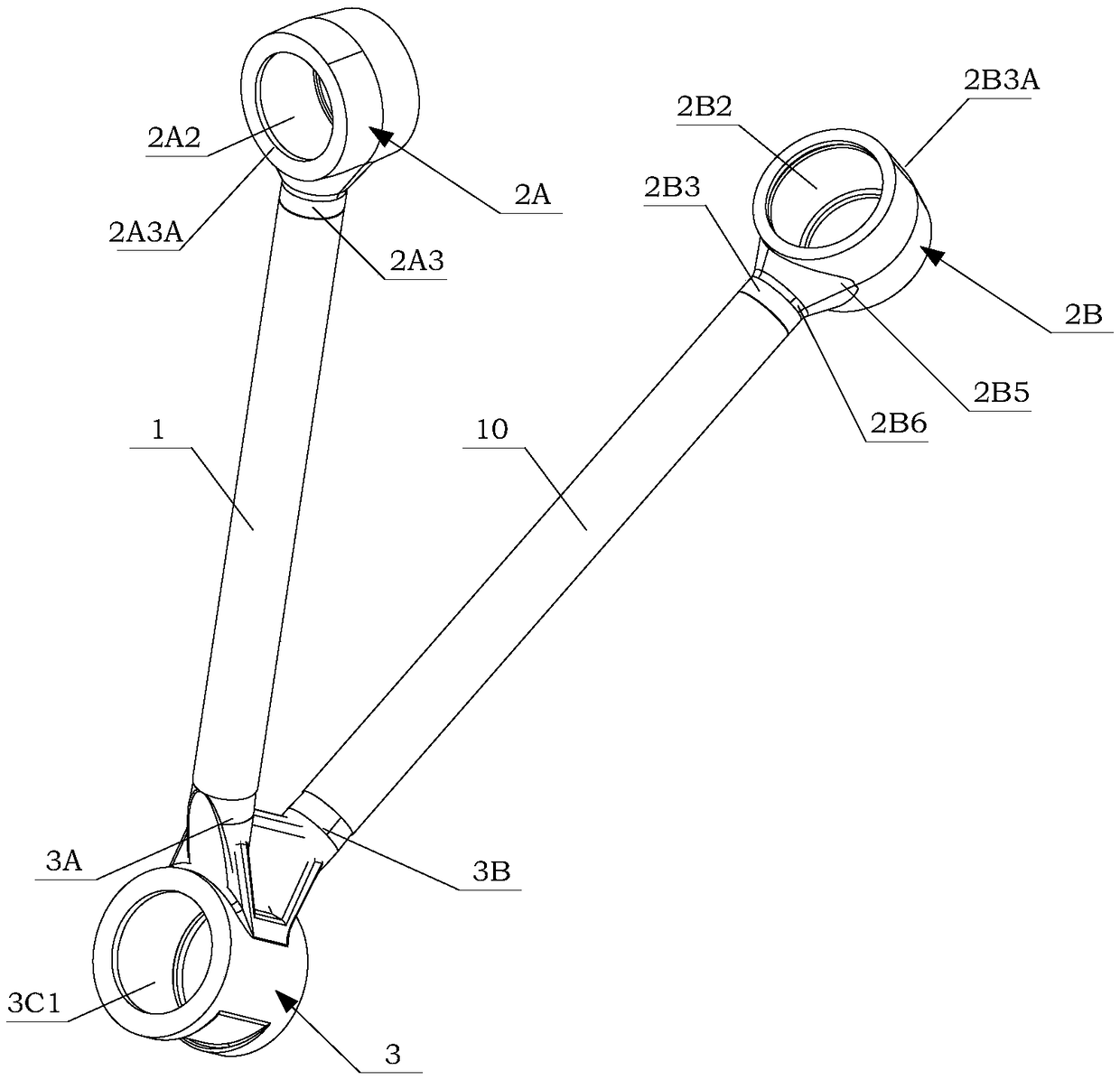

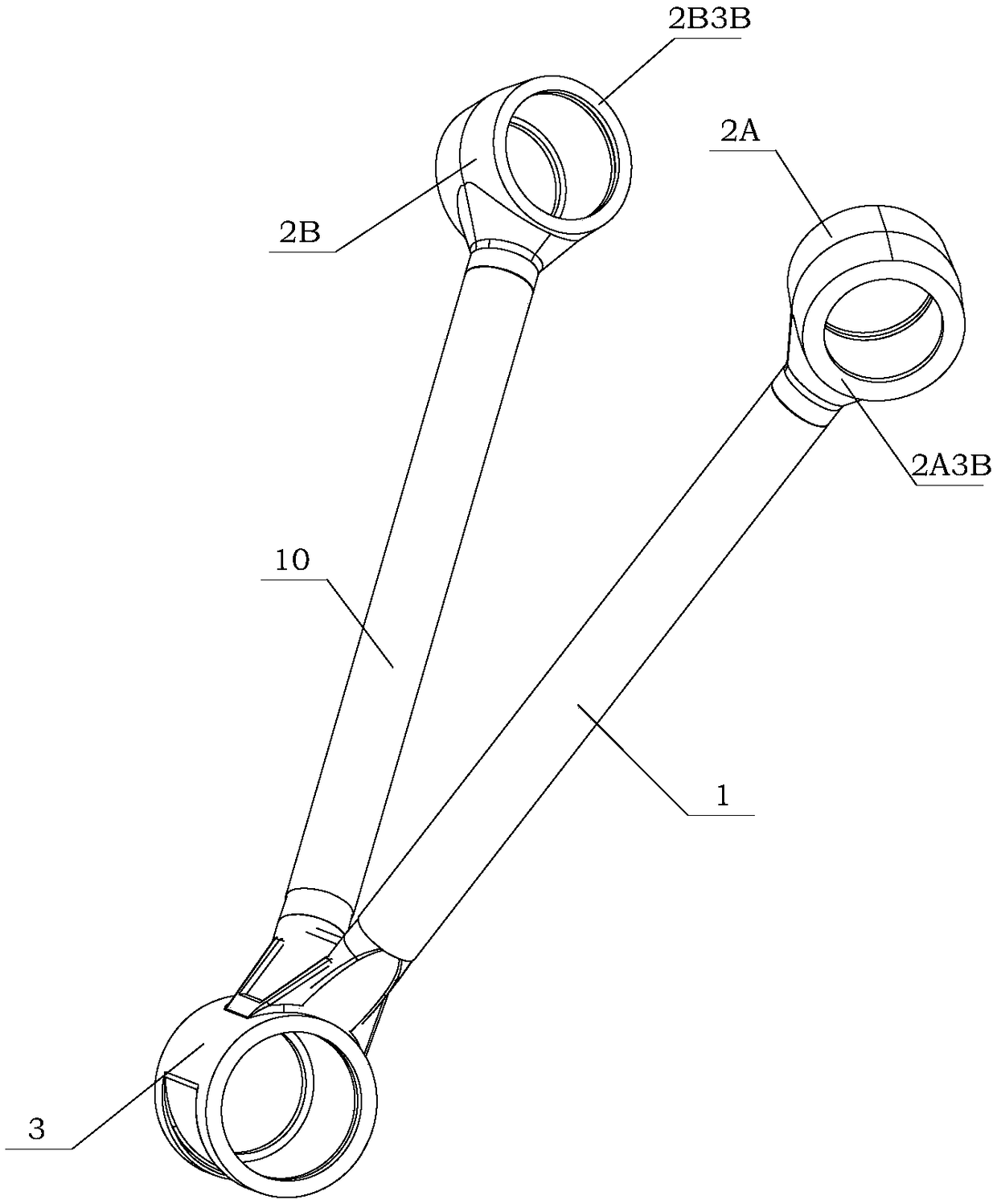

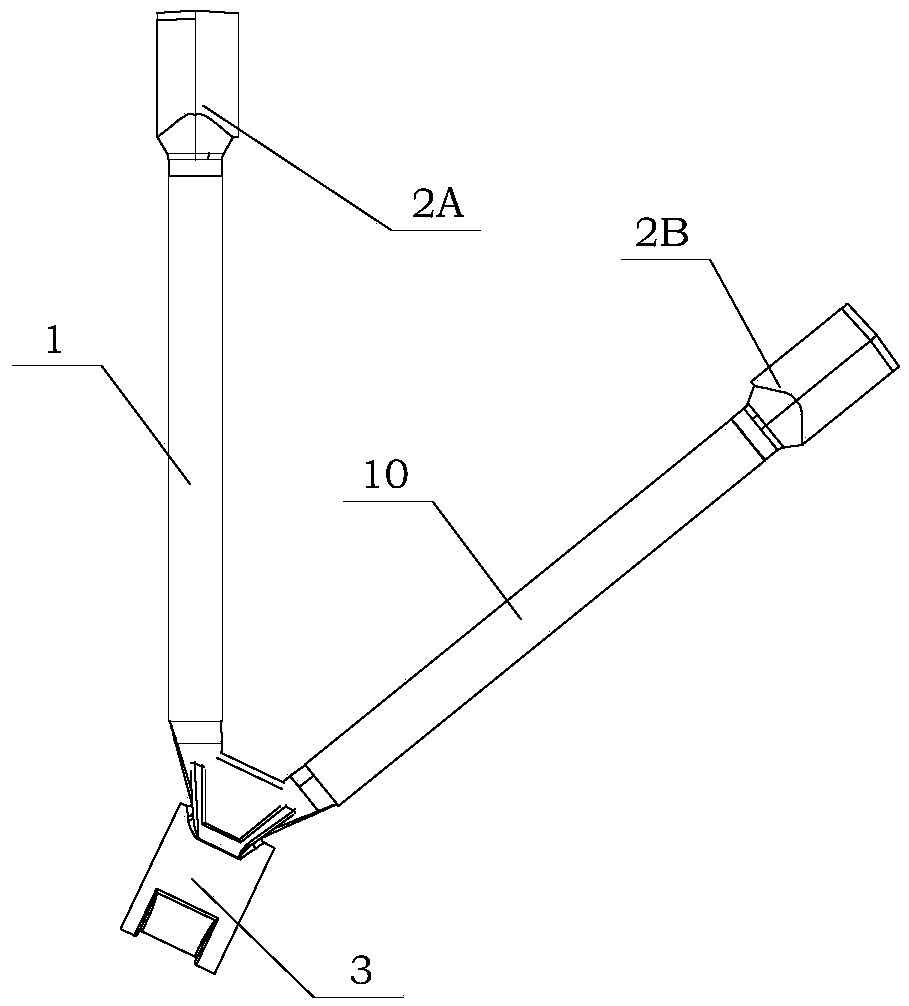

Aluminum alloy split V-shaped thrust rod and casting forming and friction stir welding matching method thereof

A technology of friction stir and thrust rod, which is applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problems of heavy thrust rod and poor lightweight effect, and achieve riveting quality assurance, easy structure, and high controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] The composition of ball head and V-shaped ball head in embodiment one is:

[0124] element

Amount (mass percentage, wt%)

Si

8.0

Mg

0.6

Fe

0.2

Cu

1.5

mn

0.4

Cr

0.08

Ni

0.01

Zn

0.2

Ti

0.16

Zr

0.03

Sr

0.15

Y

0.02

Ce

0.02

Al

balance, and unavoidable impurities.

[0125] The composition of sleeve pipe among the embodiment one is:

[0126] element

Amount (mass percentage, wt%)

Si

1.0

Mg

1.8

Fe

0.5

Cu

6.0

mn

0.9

Cr

0.1

Ni

0.1

Zn

0.1

Ti

0.15

Zr

0.05

Sr

0.01

Al

balance, and unavoidable impurities.

[0127] Overall length L of casing 1 1 =810mm, inner radius r of casing 1 1A =30mm; Radius r of connecting section of ball head 2A 2A1 =30mm; the radius of the arc section (2A6, 2B6) of the ball he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com