Semi-automatic rotary riveting fixture and riveting method thereof

A riveting tooling and semi-automatic technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive production efficiency and low degree of automation, and achieve the effects of reducing labor intensity, improving production efficiency, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In order to cope with the increasing output and rising labor costs, this embodiment provides a semi-automatic rotary riveting tool according to the characteristics of many types of riveting parts in circuit breaker products. The ultimate goal of this embodiment is to simplify the riveting process. It only needs to load the material, and the rest of the actions are automatically completed by the equipment, and the finished product can be obtained directly, and the riveting quality is reliable.

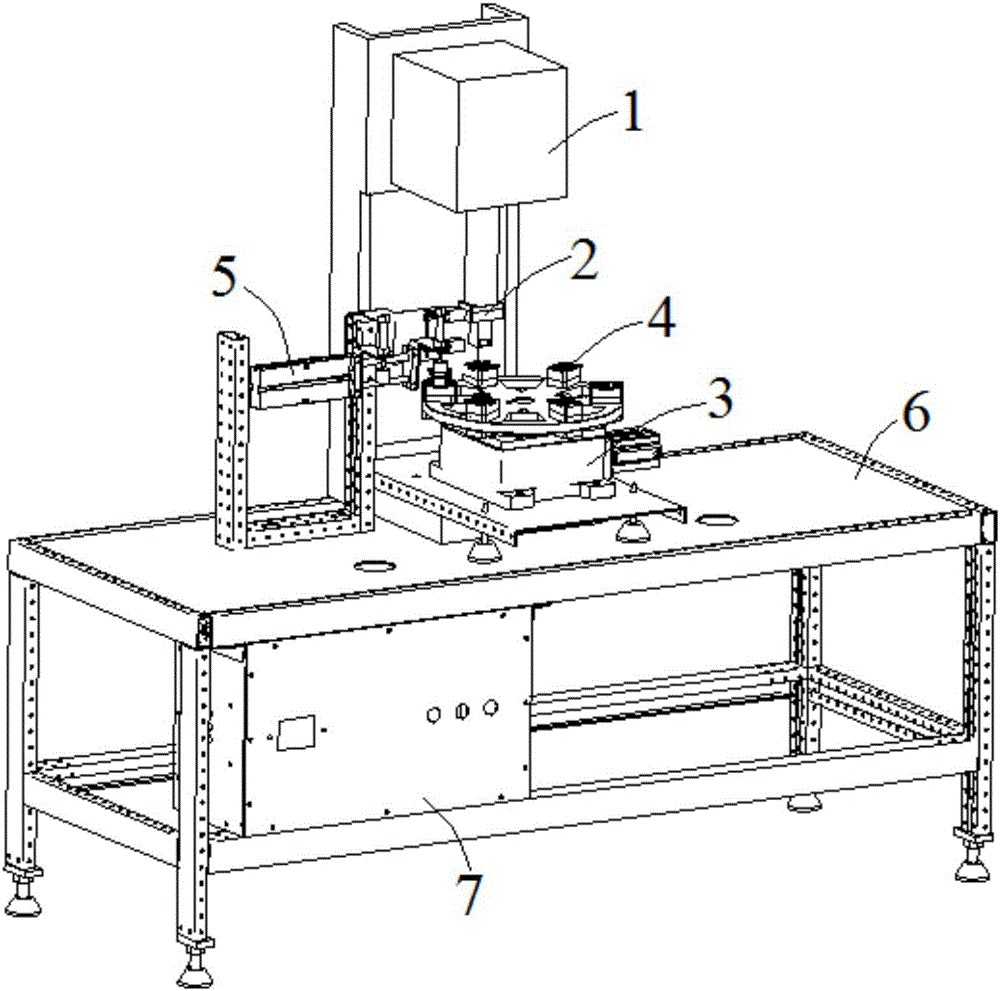

[0045] see figure 1 , the rotary riveting tooling of this embodiment adopts parametric modeling and modular design. It mainly includes a press 1, an upper die 2, an indexing unit 3, a lower die 4, a reclaiming unit 5, a tooling frame 6 and an electric control unit 7. The tooling frame 6 is a sheet metal frame structure, which is formed by standard C-shaped folding columns and corner braces, which is convenient for construction and low in cost. The height of the tooling frame 6 ...

Embodiment 2

[0053] A semi-automatic rotary riveting tool of this embodiment is mainly suitable for such as Figure 6 Processing of riveted parts shown in (b). Figure 6 The (a) in the figure shows the core component of a circuit breaker --- the trip unit. Both sides of the connecting plate of the trip unit are provided with a yoke 81. The yoke 81 and the stainless steel bracket 82 need to be joined together by riveting, and from Figure 6 It can be seen from (a) that the magnetic yokes 81 on both sides of the connecting plate and the stainless steel bracket 82 are mirror images. In this embodiment, the riveting processing of the magnetic yoke 81 and the stainless steel bracket 82 on both sides of the connecting plate is completed on the same set of moulds. For this reason, a set of upper and lower molds are specially designed in this embodiment, and the specific structure is as follows:

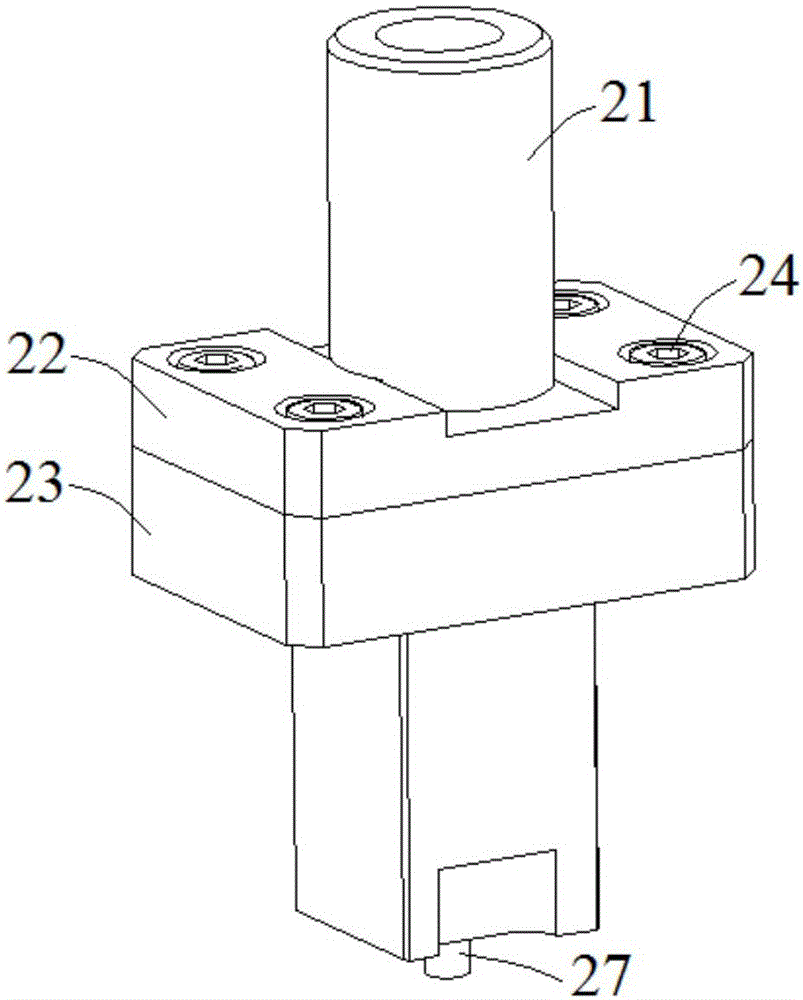

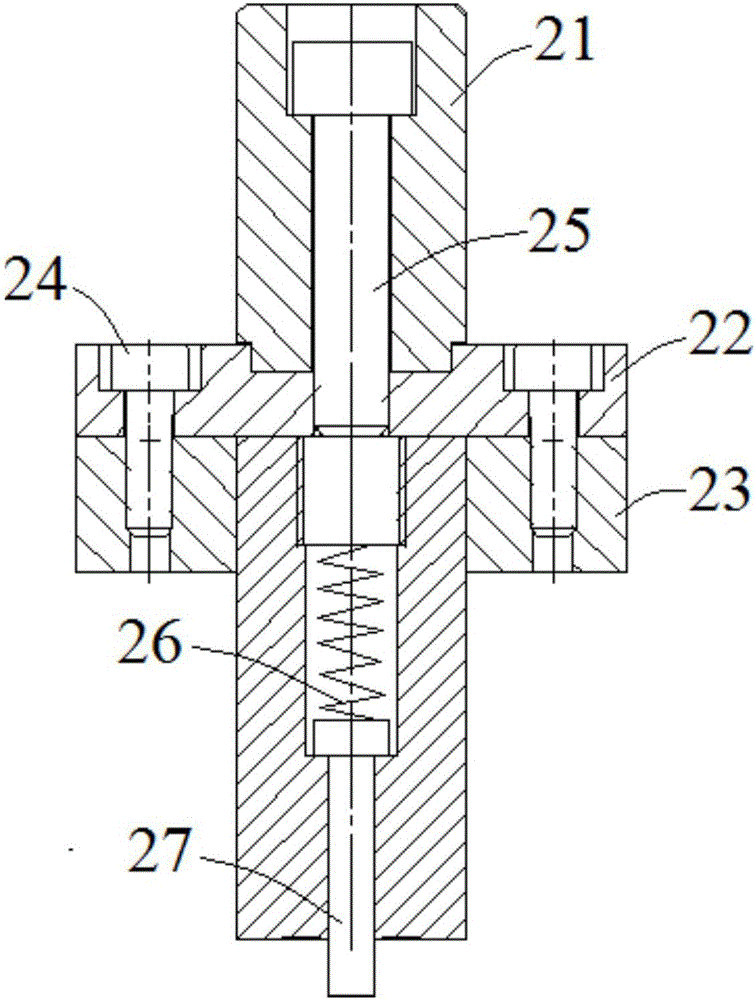

[0054] see Figure 7 and Figure 8 , the lower mold 4 of the present embodiment comprises a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com