Aluminum alloy split-type I-type thrust rod and preparation process thereof and friction stir welding and fitting method thereof

An aluminum alloy and thrust rod technology, which is used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of poor lightweight effect and large thrust rod weight, and achieve high yield, ensure riveting quality, and high performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The thrust rod composition in embodiment one is:

[0129] element

Amount (mass percentage, wt%)

Si

0.5

Mg

1.6

Fe

0.6

Cu

4.4

mn

0.6

Cr

0.1

Ni

0.008

Zn

0.25

Ti

0.15

Zr

0.01

Sr

0.01

La

0.01

Ce

0.005

Al

balance, and unavoidable impurities.

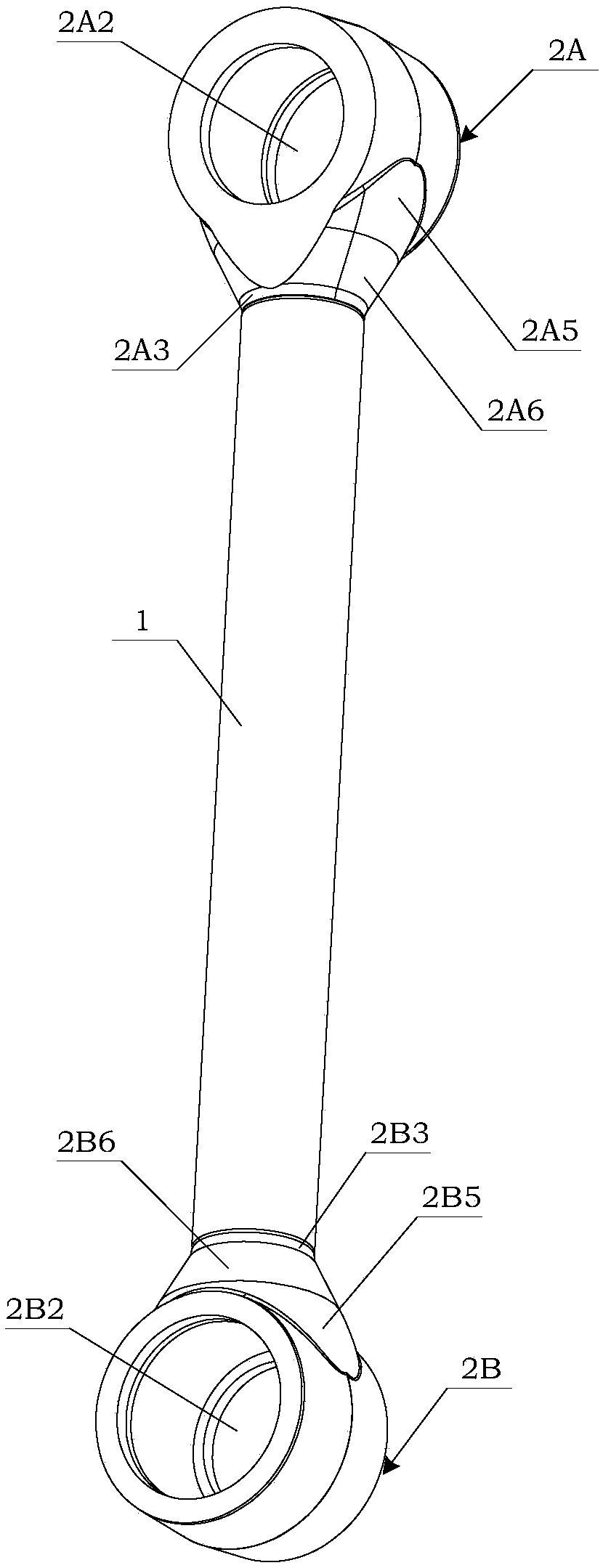

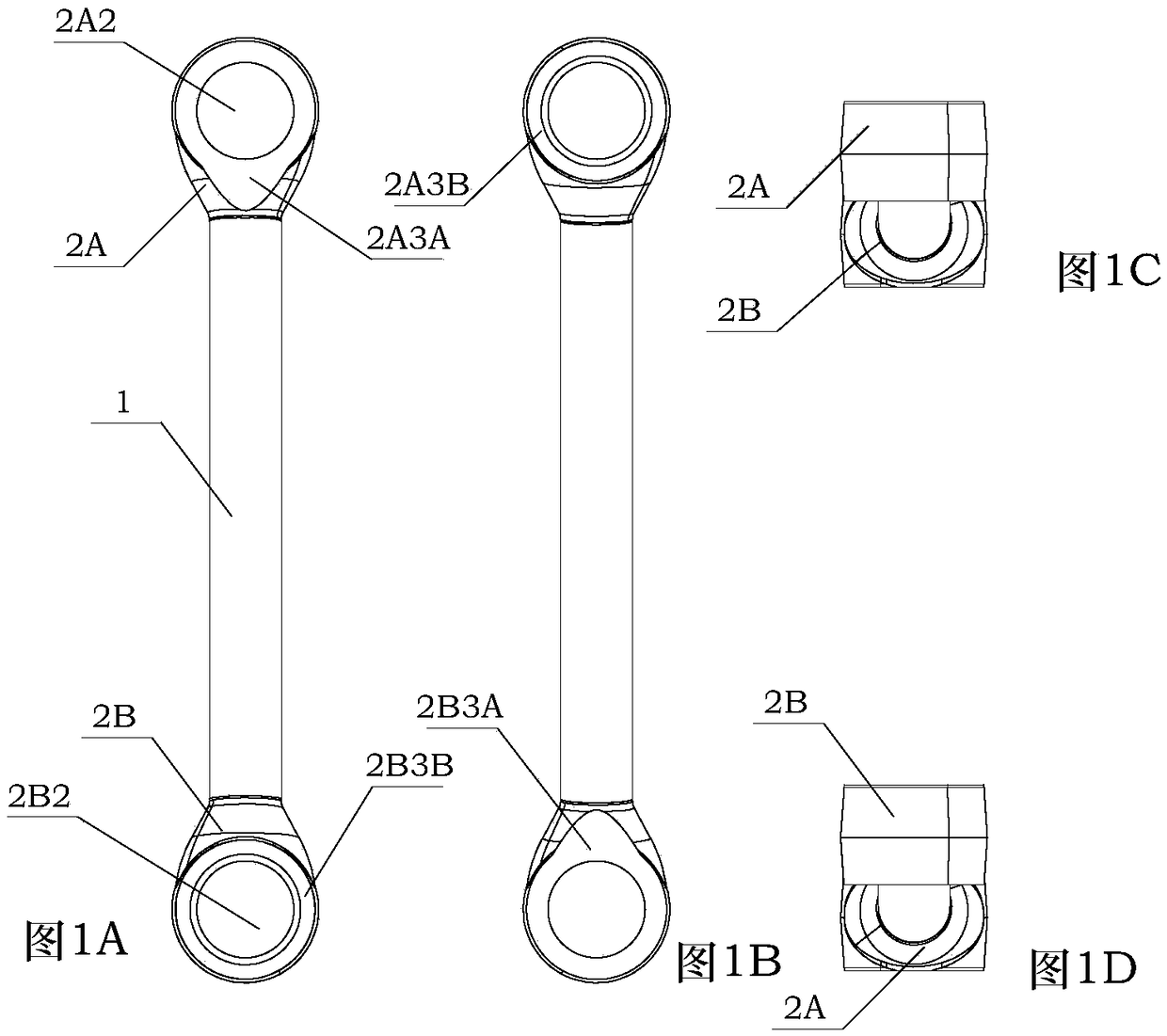

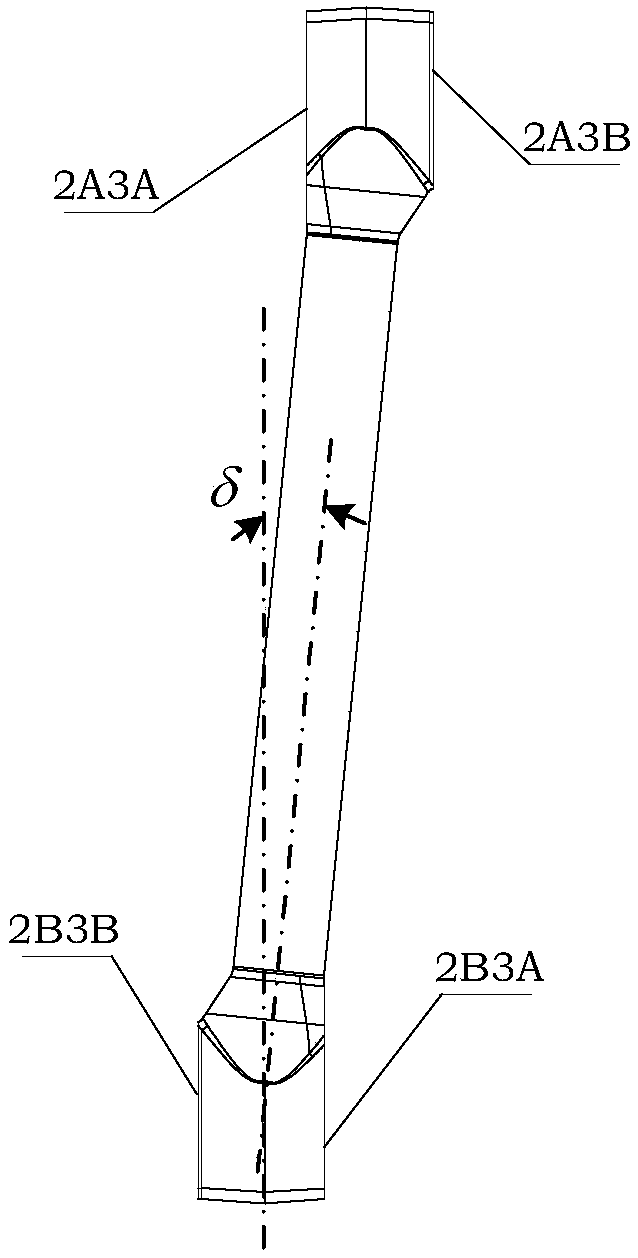

[0130] The total length of casing 1 is denoted as L 1 =810mm, the inner radius of casing 1 is denoted as r 1A =30mm; the end radius of the ball head 2A is denoted as r 2A1 = 30mm; the size of the joint between the sleeve and the ball head is r 2 (r 2 = r 1A = r 2A1 =30mm), the stop radius of the arc segment (2A6, 2B6) is r 4 The lower major radius of the oval segment (2A5, 2B5) is O 3 a 3 = 2r 1A =60mm, the lower short radius is upper long radius and the upper short radius O 4 b 4 = r 1A = 30mm.

[0131] The sleeve preparation process is hot extrusion molding, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com