Method for rapidly drilling riveting holes in body structure of airplane

A technology of aircraft fuselage and drilling method, which is applied to aircraft parts, drilling molds for workpieces, transportation and packaging, etc. It can solve the problems of large riveting hole spacing error, high labor intensity, poor riveting quality, etc., and achieve reduction Space error, reduce labor intensity, and ensure the effect of riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

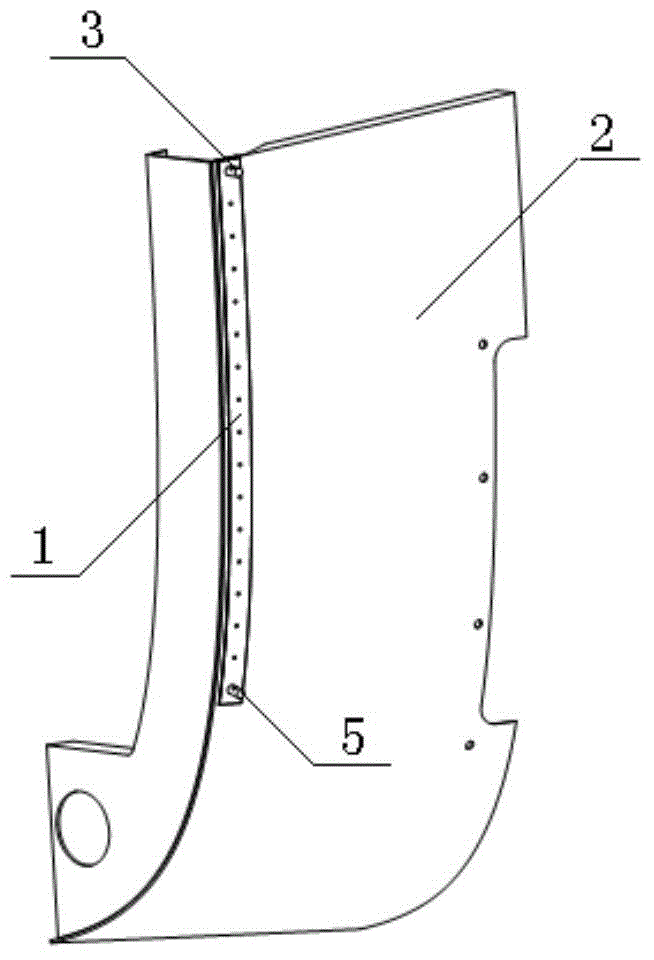

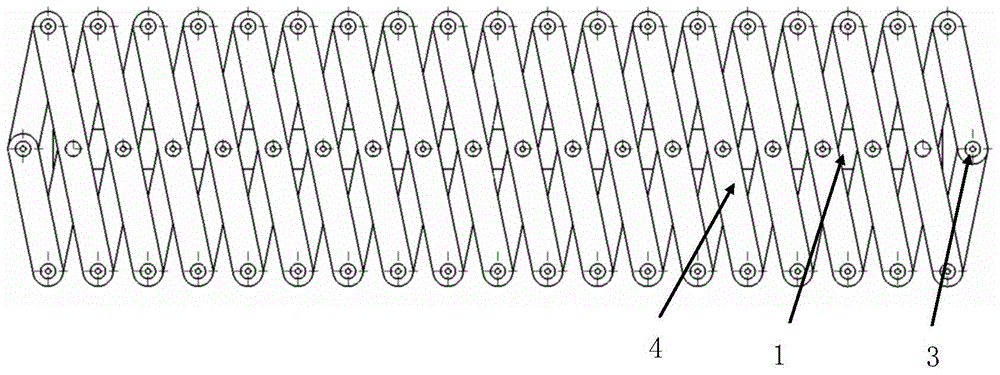

[0024] Embodiment 1, drilling riveting holes on the outer surface of frame 4 of the aircraft fuselage.

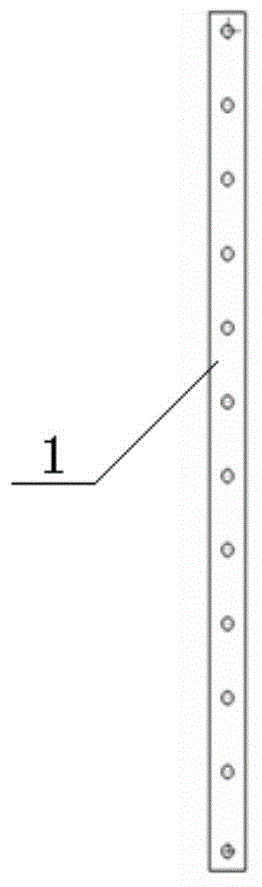

[0025] 1. Manufacture the elastic ruler: use spring steel to make the elastic ruler. The length of the elastic ruler is 450mm, the width is 20mm, and the thickness of the elastic ruler is 1mm;

[0026] 2. Drilling process holes: Drill 2 process holes on the aircraft fuselage structure 2, the aperture of the positioning hole is 3mm, use the marking method to determine the position of the process holes, and drill the process holes with a hand-held drilling machine;

[0027] 3. Drill equidistant holes on the elastic ruler 1:

[0028] 3.1. Drilling the elastic ruler process hole: the diameter of the elastic ruler process hole is 3mm;

[0029] 3.2. Drilling equidistant guide holes of the elastic ruler: According to the structural drawings of the aircraft fuselage, the number of riveting holes between the two process holes is determined to be 20, and the distance between the two...

Embodiment 2

[0032] Embodiment 2, drilling riveting holes on the outer surface of frame 4 of the aircraft fuselage.

[0033] 1. Manufacture the elastic ruler: use spring steel to make the elastic ruler. The length of the elastic ruler is 650mm, the width is 20mm, and the thickness of the elastic ruler is 1mm;

[0034] 2. Drilling process holes: Drill 2 process holes on the aircraft fuselage structure 2, the aperture of the positioning hole is 3mm, use the marking method to determine the position of the process holes, and drill the process holes with a hand-held drilling machine;

[0035] 3. Drill equidistant holes on the elastic ruler 1:

[0036] 3.1. Drilling the elastic ruler process hole: the diameter of the elastic ruler process hole is 3mm;

[0037] 3.2. Drilling equidistant guide holes for the elastic ruler: According to the structural drawings of the aircraft fuselage, the number of riveting holes between the two process holes is determined to be 30, and the distance between the tw...

Embodiment 3

[0040] Embodiment 3, drilling riveting holes on the outer surface of the Y45O beam of the aircraft fuselage.

[0041] 1. Manufacture the elastic ruler: use spring steel to make the elastic ruler. The length of the elastic ruler is 650mm, the width is 20mm, and the thickness of the elastic ruler is 1mm;

[0042]2. Drilling process holes: Drill 2 process holes on the aircraft fuselage structure 2, the aperture of the positioning hole is 3mm, use the marking method to determine the position of the process holes, and drill the process holes with a hand-held drilling machine;

[0043] 3. Drill equidistant holes on the elastic ruler 1:

[0044] 3.1. Drilling the elastic ruler process hole: the diameter of the elastic ruler process hole is 3mm;

[0045] 3.2. Drilling equidistant guide holes for the elastic ruler: According to the structural drawings of the aircraft fuselage, the number of riveting holes between the two process holes is determined to be 30, and the distance between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com