Improved structure of single mail separating device

A separation device and improved structure technology, which is applied in the postal field, can solve the problems of inability to accurately control the spacing and low efficiency of separation and delivery of mail single envelopes, and achieve the effect of improving the separation efficiency of mail single envelopes, reducing spacing errors, and reducing mail spacing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

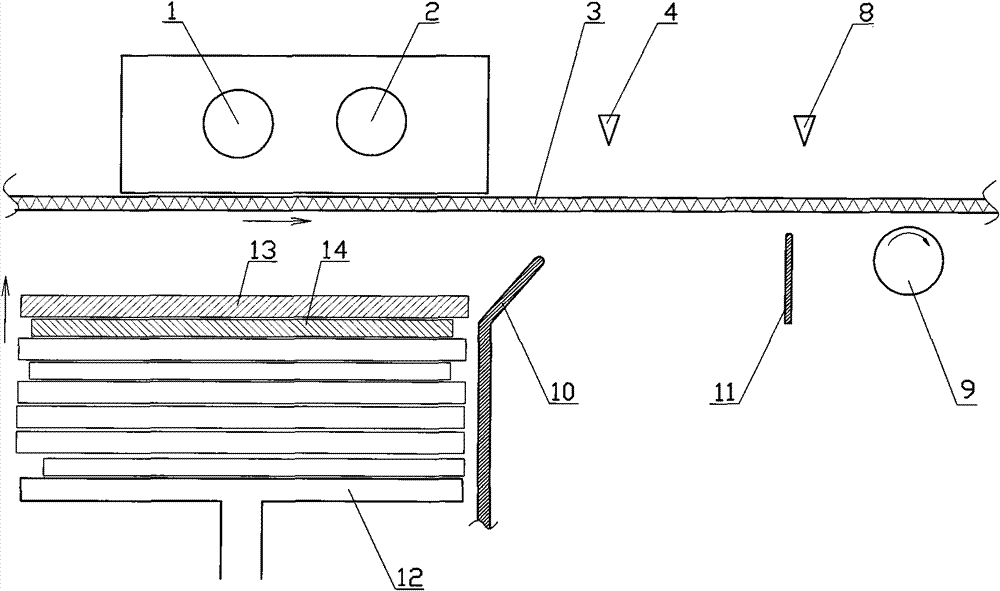

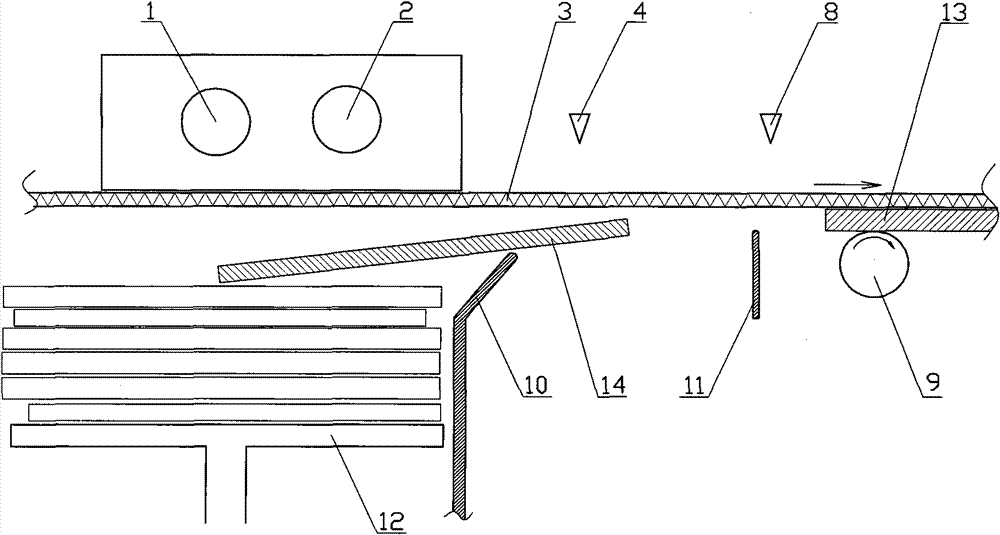

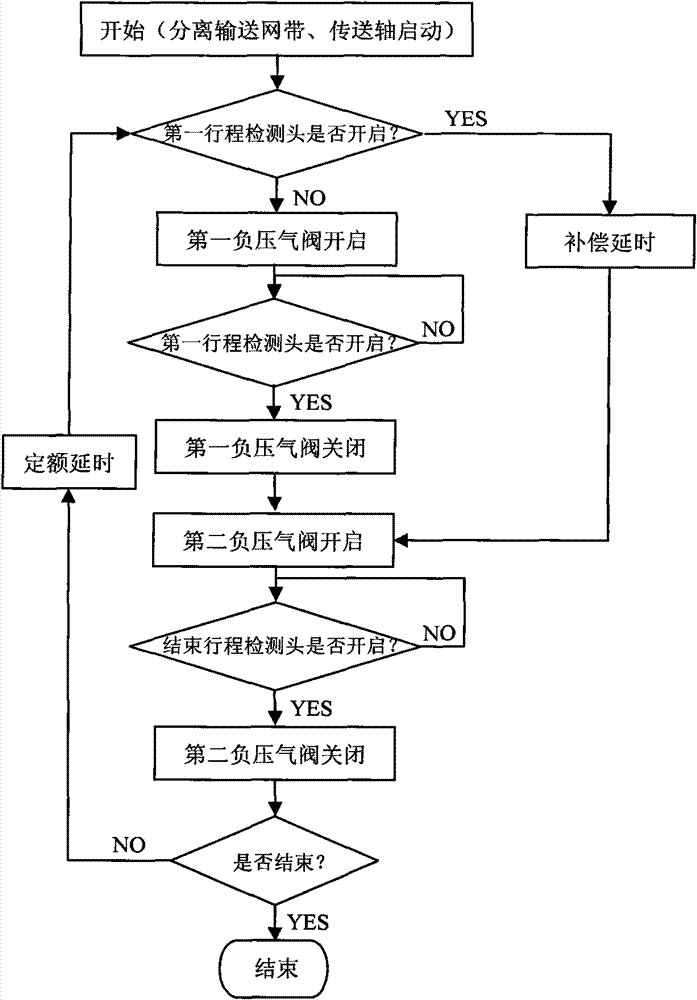

[0026] The existing mail single-envelope separation device includes a horizontally arranged separation conveying mesh belt 3, and one side of the separating conveying mesh belt 3 is sequentially arranged with a first negative pressure air valve 1, a second negative pressure air valve 2, and a first stroke along the conveying direction. Detection head 4 and end stroke detection head 8; on the other side of the separation conveying mesh belt 3, an automatic letter supply mechanism 12 is configured opposite to the first negative pressure valve 1 and the second negative pressure valve 2, and the automatic letter supply mechanism 12 A baffle 10 is arranged near the side of the first stroke detection head 4, a limit stopper 11 is arranged between the first stroke detection head 4 and the end stroke detection head 8, and close to the end stroke detection head 8, after the end strok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com