a washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve problems such as troubles, and achieve the effects of improving utilization rate, fast response speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

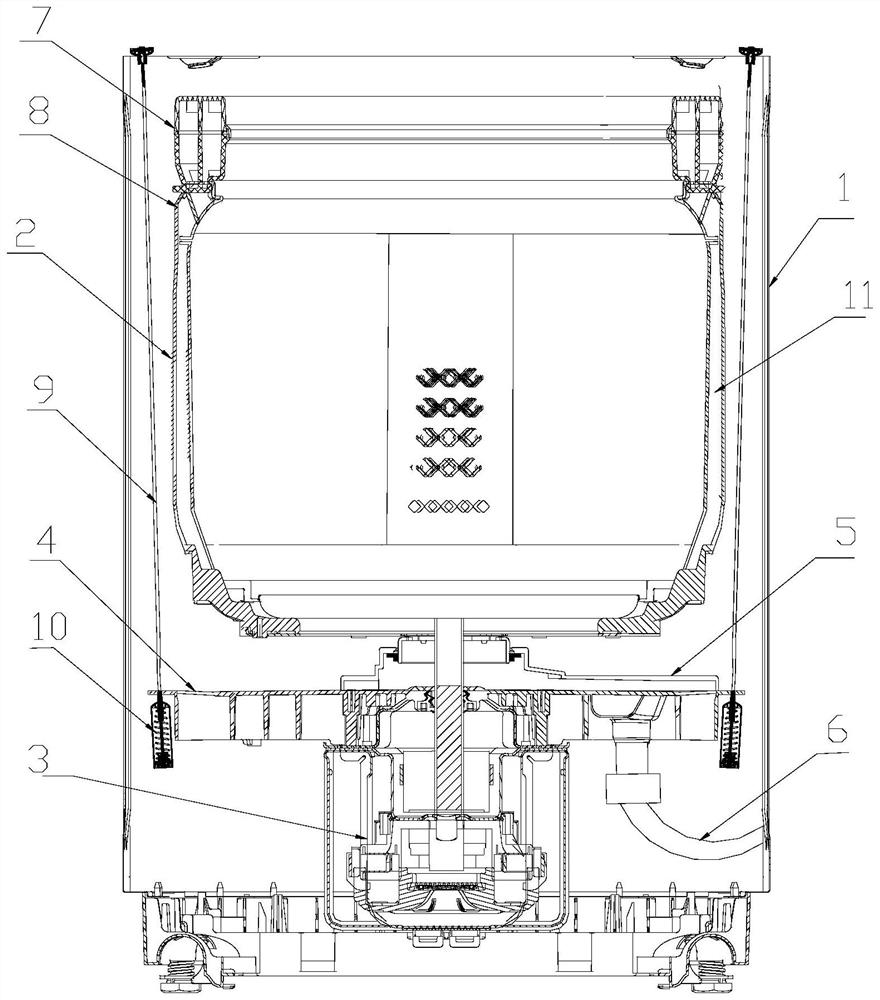

[0046] Such as Figure 7 As shown, in the washing machine according to the present invention, the anti-collision bucket switch 100, when the washing machine rotates stably, when the heavy ball 102 presses the pressure transmission device by its own gravity, or the heavy ball 102 is under the influence of external force, the heavy ball 102 When rolling down in the limited space to apply pressure to the pressure transmission device, the pressure transmission device receives the downward force given by the heavy ball 102, and the pressure transmission device moves downward after receiving the force, and exerts pressure on the pressure transmission device arranged below the pressure transmission device. The supporting spring 104 is deformed after receiving the pressure, and at the same time, when the pressure transmission device moves downward, the pressure will be transmitted to the contact switch 105 which is closed after receiving the pressure. At this time, the contact switch ...

Embodiment 2

[0048] Such as Figure 9 As shown, in the washing machine according to the present invention, the anti-collision bucket switch 100, when the washing machine fluctuates, the heavy ball 102 is under the influence of an external force, the heavy ball 102 rolls in the limited space, and when the heavy ball 102 rolls upwards , the heavy ball 102 reduces the pressure applied to the pressure transmission device, and the support spring 104 starts to restore its original shape from the compressed deformation state. While restoring the original shape, the support spring 104 will give the pressure transmission device an upward supporting force, driving the support The upper pressure transmission device moves upward, and the pressure transmission device moving upward releases the pressure on the contact switch 105. At this time, the contact switch 105 is in an open state, and the contact switch 105 transmits the disconnection signal to the circuit control device of the washing machine.

Embodiment 3

[0050] Such as Figure 7 to Figure 9 As shown, in the washing machine according to the present invention, the anti-collision bucket switch 100, the pressure transmission device can be a lever 103, the lever 103 includes a hinge point 1033 at one end, a fulcrum 1032 and a pressure point 1031 at the other end, and the hinge point 1033 is arranged on At the right end of the housing 101, the fulcrum 1032 is located above the contact switch 105 that is closed after being pressed, and the pressure receiving point 1031 is located below the pressure providing device. It is used to transmit signals to the washing machine circuit control device.

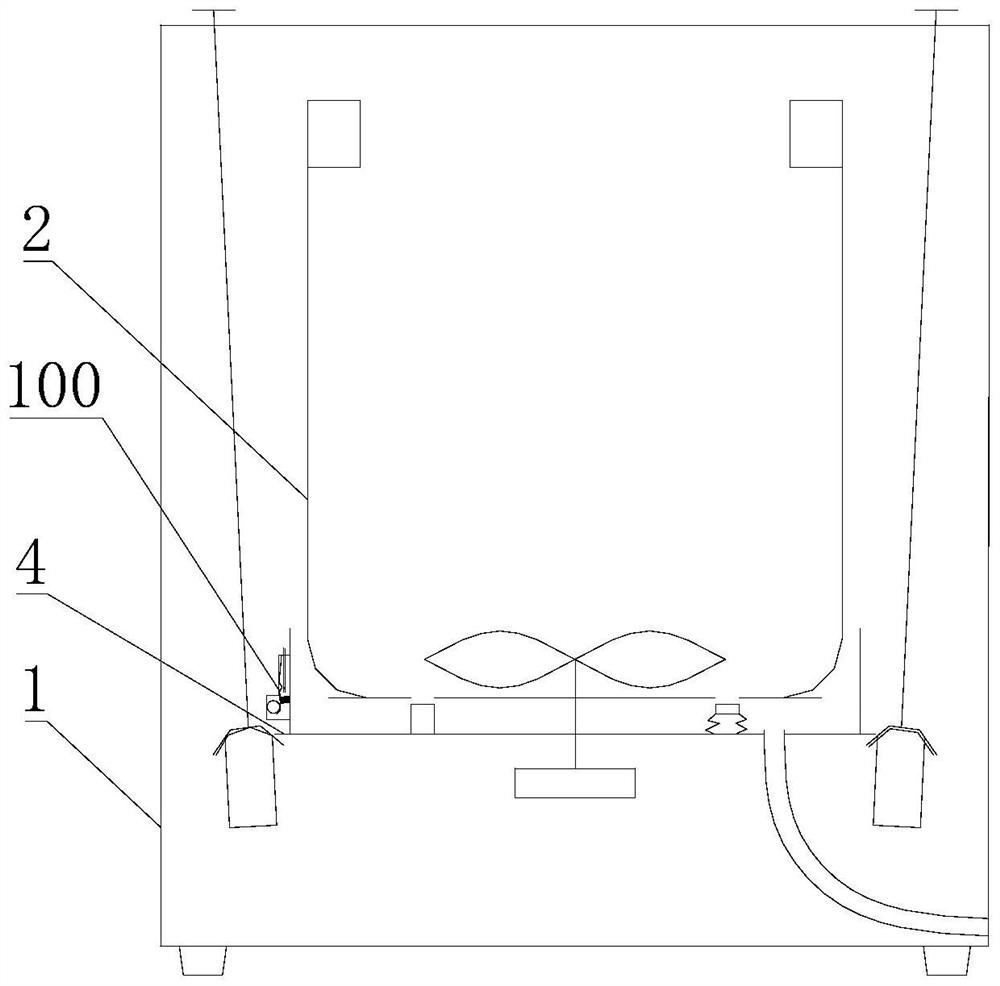

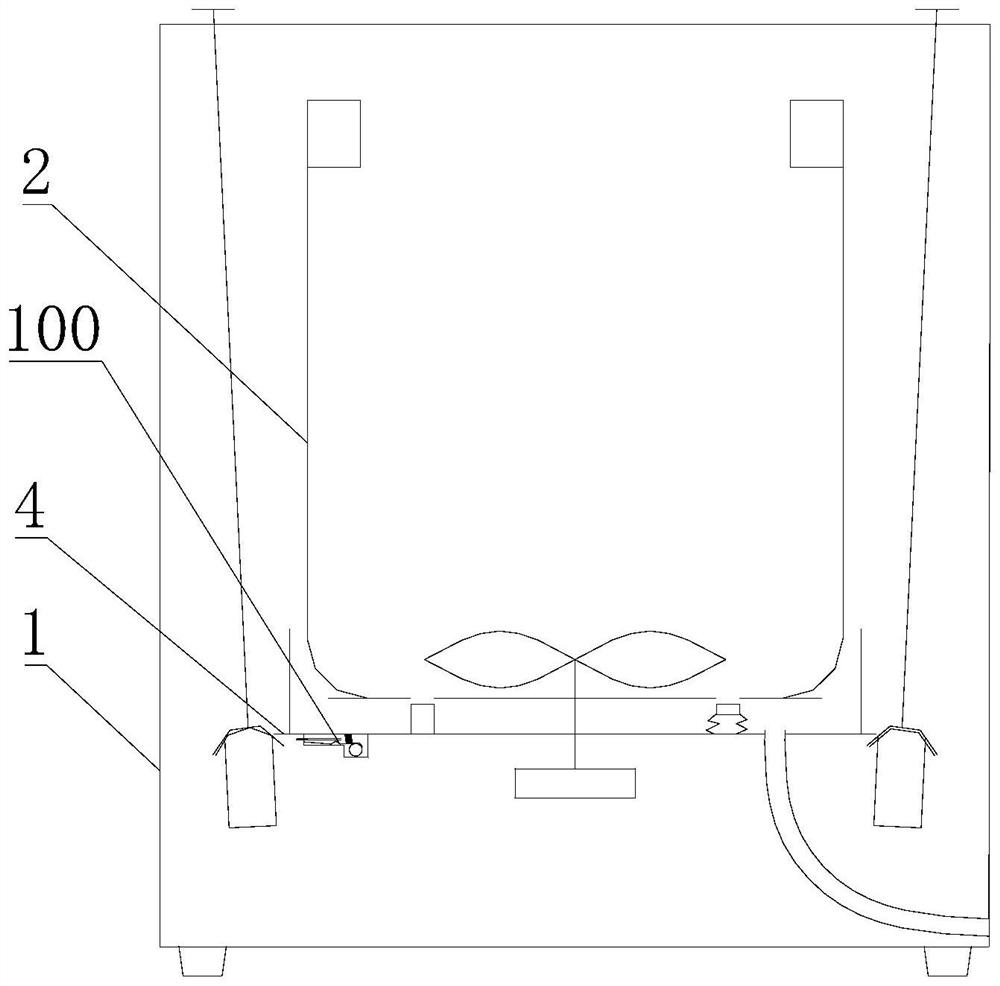

[0051] Further, the fulcrum 1032 in the middle of the lever 103 is a convex point where the lever 103 bends downward, and is used for pressing down the contact switch 105 . The structure can be as figure 1 with figure 2 The shown lever 103 has a downward convex bending structure. Since the lever 103 is under stress for a long time, the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com