A laser cleaning optical path

A laser cleaning and optical path technology, applied in the field of laser cleaning, can solve the problems of residual pollutants on the surface, affecting the cleaning effect, and large spacing, so as to avoid the residual pollutants, increase the coverage area, and improve the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

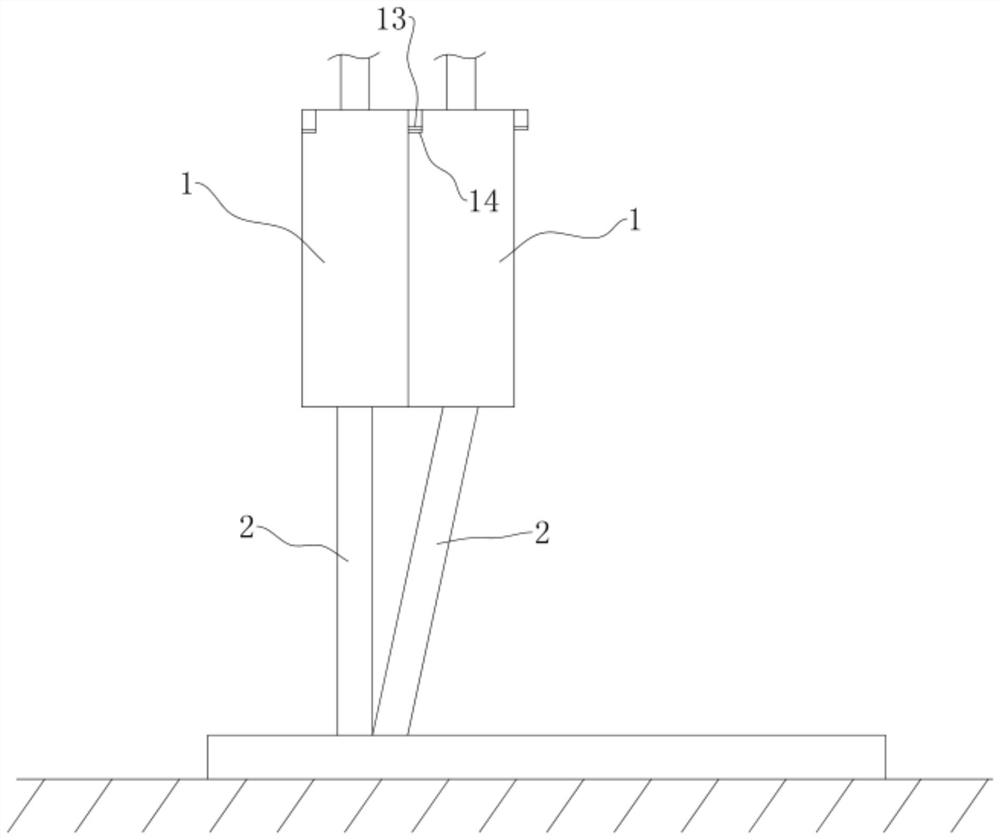

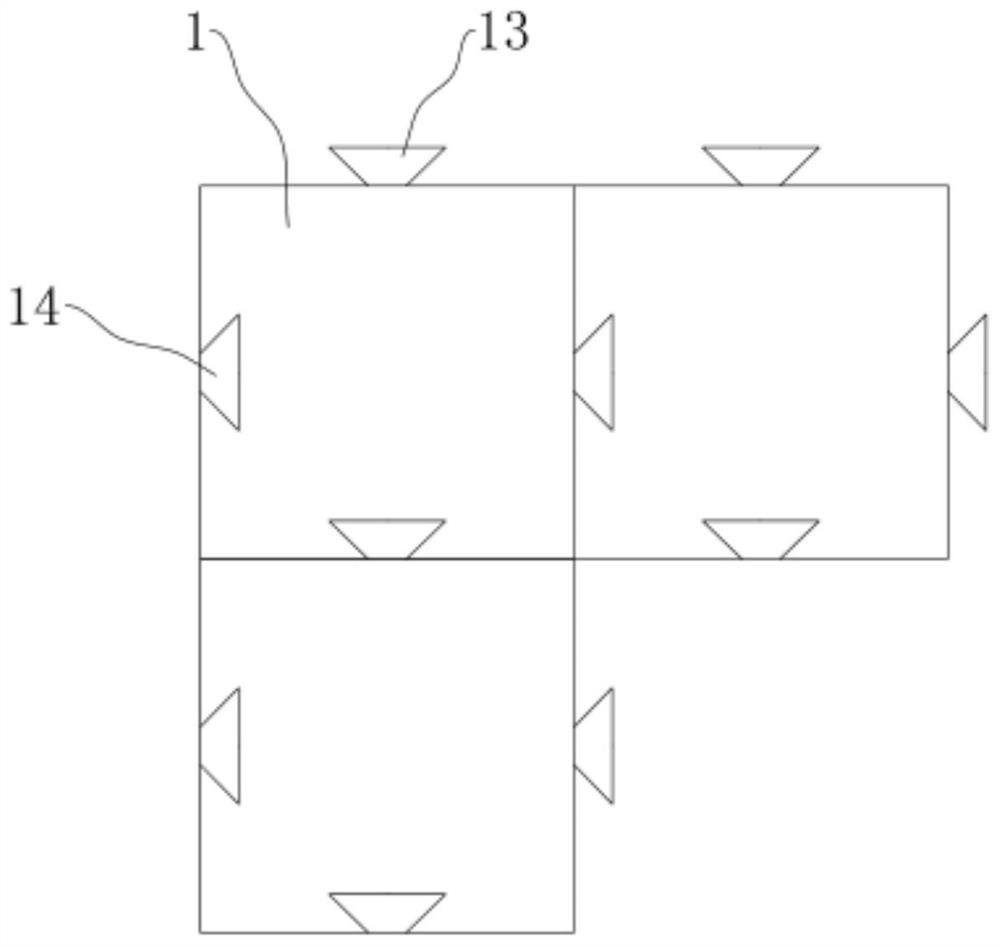

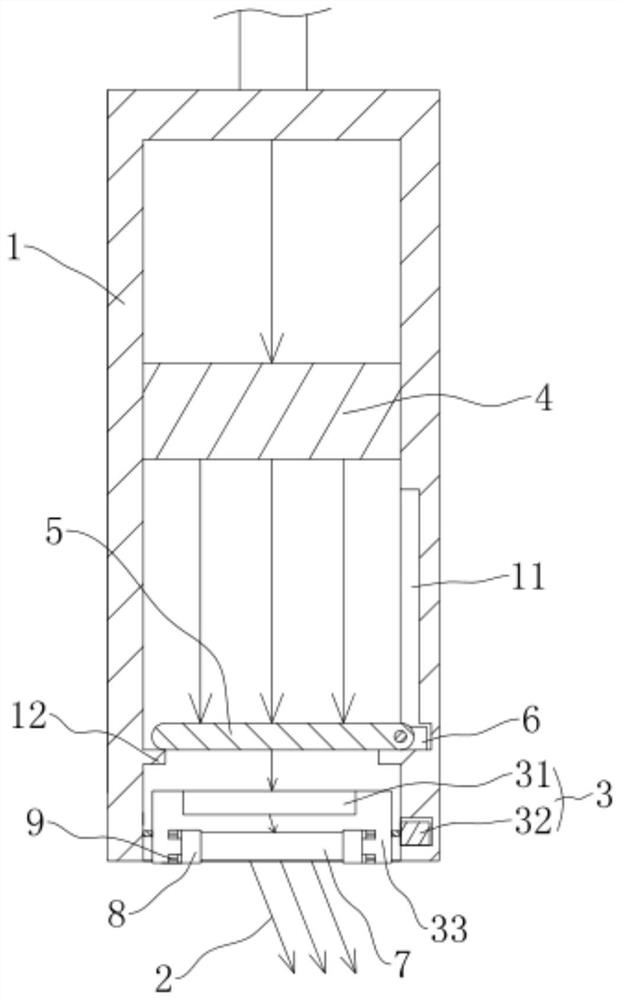

[0027] refer to Figure 1 to Figure 4 Further explain the optical path of laser cleaning.

[0028] A laser cleaning optical path, such as figure 1 As shown, including the housing 1 that has just been spliced together and the laser cleaning beam 2 disposed in the housing 1, the cross section of the housing 1 is set to a square shape, that is, it is formed into a square body, so that it can be spliced along the front, rear, left, and right. Several shells 1 are sequentially spliced in the X-axis or Y-axis direction, so that according to the cleaning surface requirements of the workpiece to be cleaned, they are sequentially spliced to cover the width direction of the cleaning surface, and you can directly move multiple shells 1 along the length of the cleaning surface Direction movement does not need to form a "zigzag" movement, reducing the occurrence of spot switching, that is, no spacing error, avoiding residues of pollutants, and has the advantage of improving its la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com