Transparent electrode manufacturing method, mask plate and equipment

A technology for transparent electrodes and manufacturing methods, applied in the fields of transparent electrode manufacturing methods, mask plates, and equipment, capable of solving problems such as uneven spacing and affecting display effects, achieving the effect of reducing spacing errors and improving display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description will be made in conjunction with the accompanying drawings and specific implementation manners.

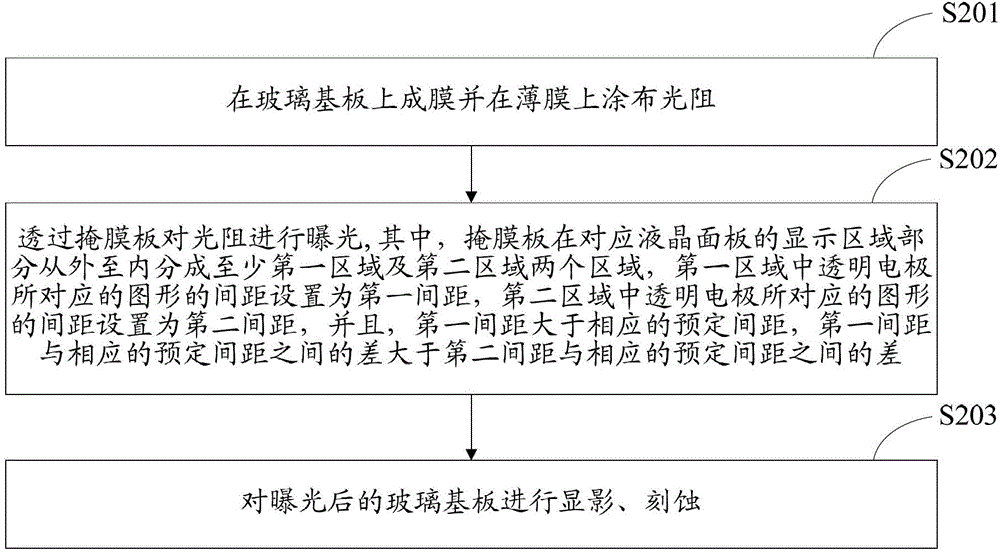

[0022] refer to figure 1 , figure 1 It is a flowchart of an embodiment of the transparent electrode manufacturing method of the present invention. The transparent electrode manufacturing method includes:

[0023] Step 201: forming a film on a glass substrate and coating a photoresist on the film.

[0024] A thin film is formed on a glass substrate by methods such as vacuum evaporation, sputtering, molecular beam evaporation or chemical evaporation, and then a photoresist is coated on the film by a photoresist coating machine.

[0025] Step 202: Exposing the photoresist through a mask.

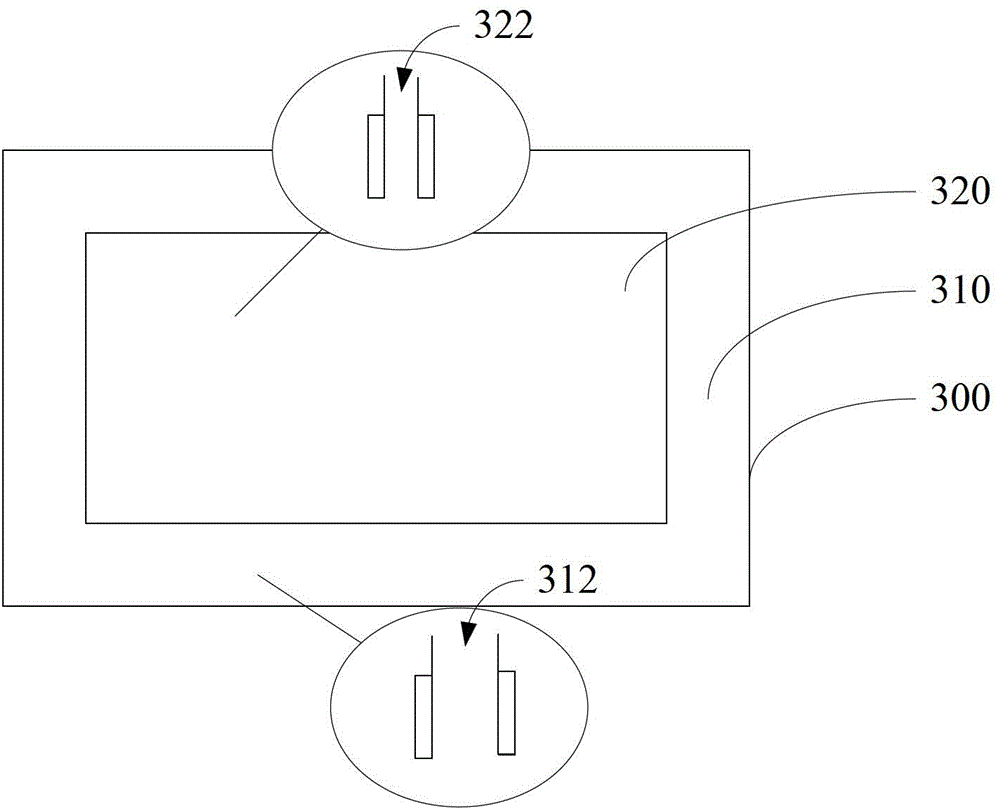

[0026] The glass substrate coated with the resistor is transported to the developing device, and the developing light source exposes the photoresist through the mask plate. Please also refer to image 3 , the mask plate is divided into at least two regions, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com