Magnetic path structure of outer rotor permanent magnet brushless motor and assembly method of outer rotor permanent magnet brushless motor

A permanent magnet brushless motor and outer rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, manufacturing stator/rotor body, etc., can solve the problem of large electrical deviation, affecting control accuracy and system performance, Problems such as mechanical strength and processability are not very good, to achieve the effect of small spacing error, lower requirements, and ensure control accuracy and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

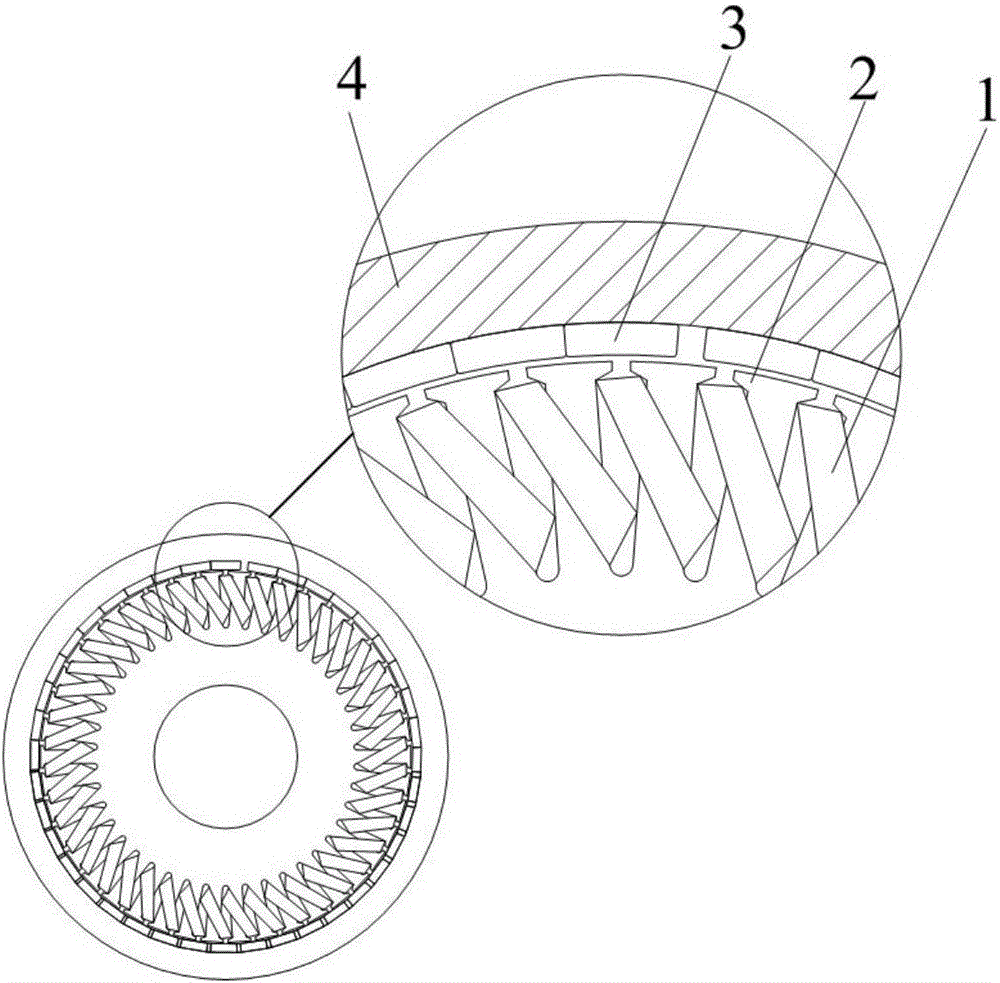

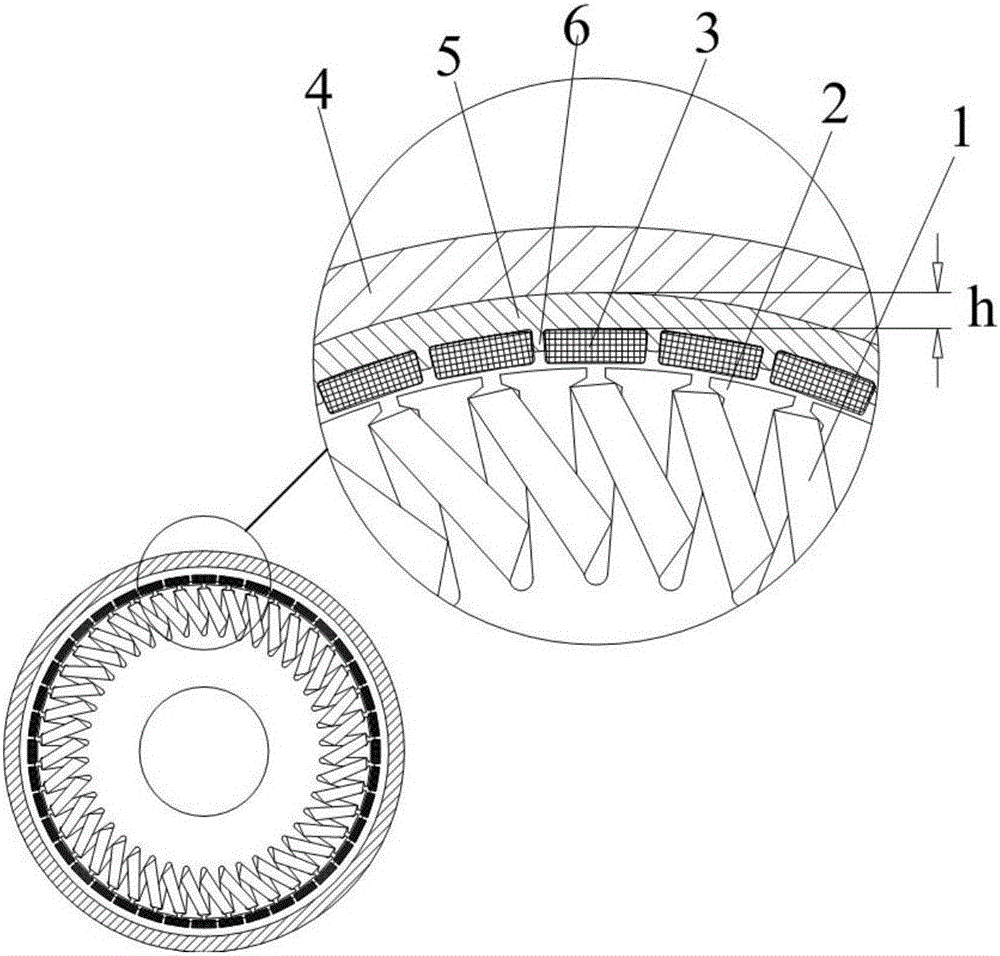

[0028] Such as figure 1 Shown is a schematic diagram of the magnetic circuit structure of the existing outer rotor permanent magnet brushless motor, wherein 1 is the stator winding, 2 is the stator core, 3 is the magnetic steel, and 4 is the casing. The stator core 2 is closely matched with the motor shaft. The entire motor body is supported by the motor shaft. Due to the limitation of the processing technology, the size of each magnet will have a certain tolerance. Since the magnetic poles of the adjacent magnets are opposite, the adjacent magnets will be attracted together during assembly. , which will result in a large distance between the last magnet and the first magnet (such as figure 1 The gap in the middle), and the uneven assembly of the magnetic steel will lead to uneven force on the motor during operation and low control accuracy. For motors that require high control accuracy (such as stepping motors and servo motors that require precise rotation) ), the uneven ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com