Method for automatically riveting multi-layer sheets in screw joint and screw nuts applied

A technology of riveting nuts and multi-layer boards, applied in the direction of thin plate connection, nuts, connecting components, etc., can solve problems such as difficult riveting, and achieve the effects of easy processing, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0017] Example.

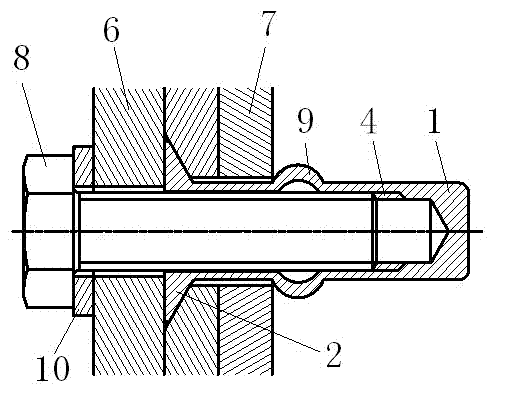

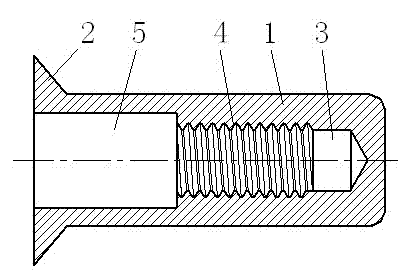

[0018] A method for screwing and self-riveting multilayer sheets, such as figure 1 shown. It is characterized in that: the method adopts an internally threaded blind hole rivet nut 1 to screw and self-rivet multi-layer sheet materials; before riveting, a group of sheet materials are stacked, and through-hole processing is completed on the stacked sheet materials at one time , the diameter of the through hole corresponds to the outer diameter of the internally threaded blind hole rivet nut; Insert the rest of the stacked sheets except the surface sheet and protrude from the bottom sheet 7, so that the rivet head 2 on the internally threaded blind rivet nut is completely immersed in the counterbore, and determine the size of the internally threaded blind rivet nut. Aperture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com