Grinding method of circular tooth cutter CNC grinding machine

A grinding machine and circular tooth cutter technology, which is applied in the field of grinding machines, can solve the problems of difficult processing of circular tooth cutter blades, etc., and achieve the effects of high grinding precision, increased strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a circular gear cutter CNC grinding machine, its overall shape is as follows Figure 4 As shown, it includes a host and a casing, and a control panel is arranged on the casing. Such as Figure 5 As shown, the main machine includes a machine base, an X-axis part 1, a Y-axis part 2 and a grinding wheel dressing device 4 arranged on the machine base; wherein, the X-axis part 1 includes an X-axis slide table 110 and a The grinding wheel driving device 120 on the platform 110 is used to drive the grinding wheel 122 to rotate in the XZ plane to grind the blade, and the slide table 110 can move in the X-axis direction along the X-axis to adjust the X-axis of the grinding wheel 122 Coordinates; the Z-axis part 3 is set on the Y-axis part 2, and the Z-axis part 3 includes a Z-axis slide table 310 and a workpiece driving device 320 arranged on the Z-axis slide table 310. The workpiece driving device 320 is used for clamping and Drive the blade to rotate...

Embodiment 2

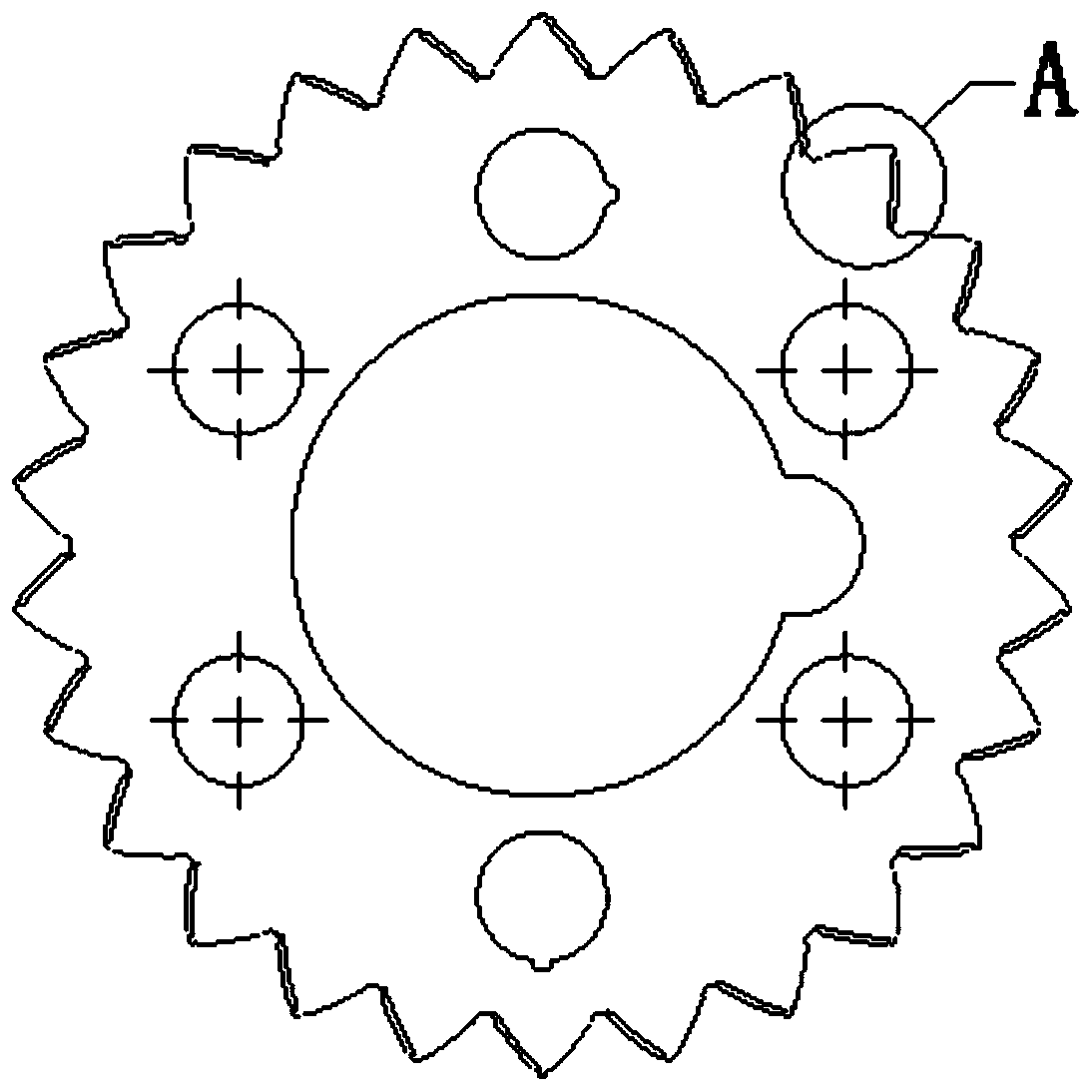

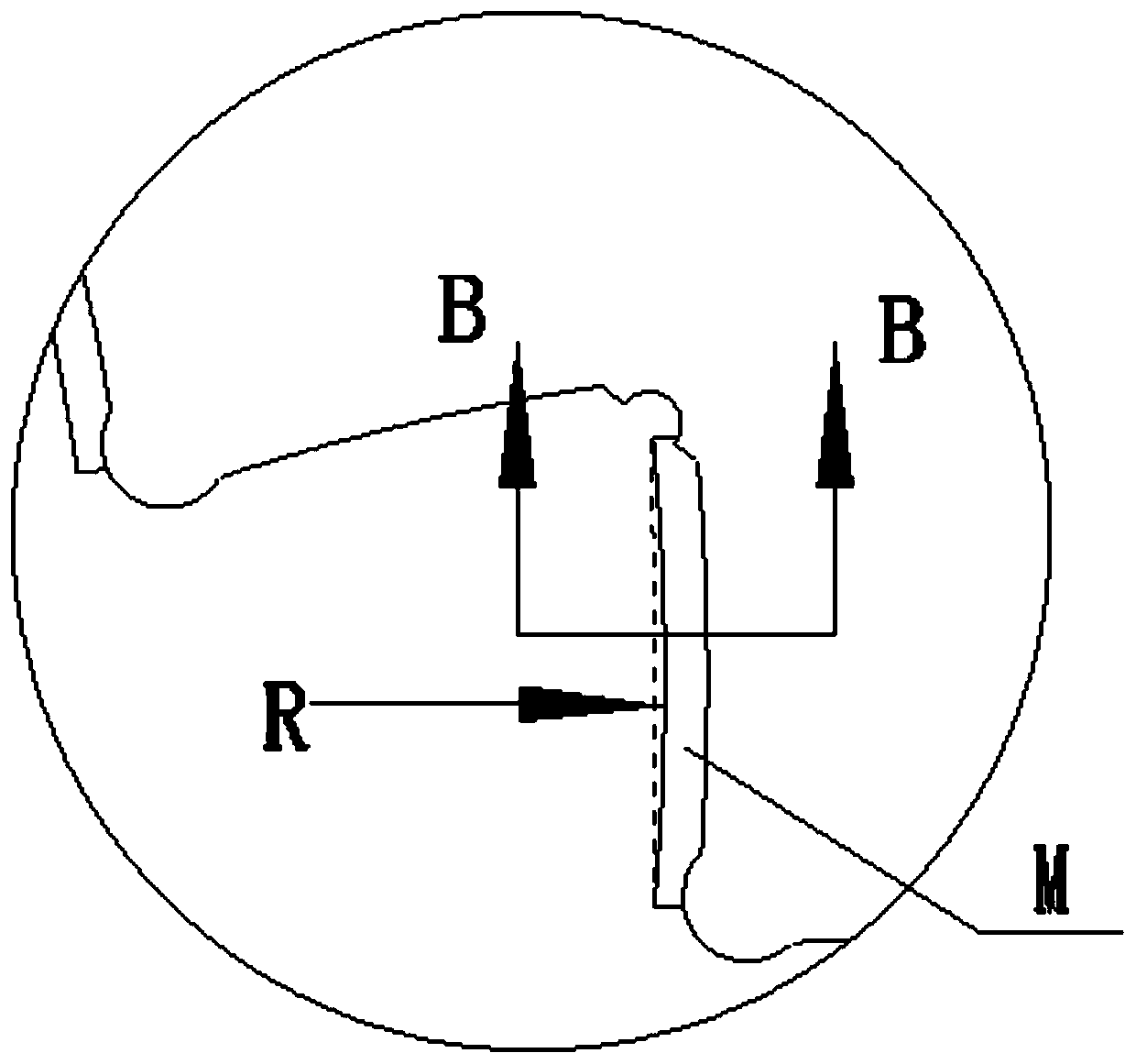

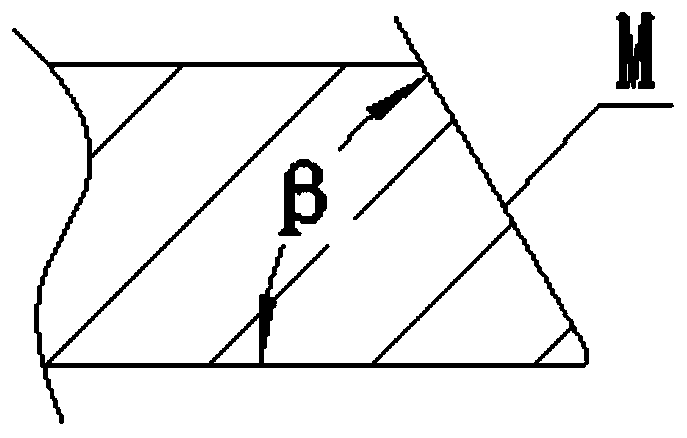

[0069] This embodiment provides a grinding method for a crenated cutter, using the numerically controlled grinder for a crested cutter in Embodiment 1 to grind the edge of the crested cutter, and the processed crested cutter is as follows figure 1 , figure 2 with image 3 As shown, it is necessary to process the blade surface M on the tooth side. The blade surface M is a circular arc surface with a radius of R, and the cutting surface of the blade surface M forms an angle β with the blade surface. In this embodiment, R=37.5mm, β =55°, and the thickness of the circular tooth cutter is b=2mm. The specific operation steps are as follows:

[0070] ① First, install the scalloped cutter to be processed on the fixture of the workpiece driving device 320 to ensure that the surface of the scalloped cutter is level, and drive the scalloped cutter to rotate through the workpiece motor 322 to measure the radial runout and ensure that the radial runout is not greater than 0.02mm; then ...

Embodiment 3

[0079] This embodiment provides a grinding method for a crenated cutter, using the numerically controlled grinder for a crested cutter in Embodiment 1 to grind the edge of the crested cutter, and the processed crested cutter is as follows figure 1 , figure 2 with image 3 As shown, it is necessary to process the blade surface M on the tooth side. The blade surface M is a circular arc surface with a radius of R, and the cut surface at the middle position of the blade surface M forms an angle β with the blade surface. In this embodiment, R=40mm, β=60°, and the thickness of the circular tooth cutter is b=2.5mm. The specific operation steps are as follows:

[0080] ① First, install the scalloped cutter to be processed on the fixture of the workpiece driving device 320 to ensure that the surface of the scalloped cutter is level, and drive the scalloped cutter to rotate through the workpiece motor 322 to measure the radial runout and ensure that the radial runout is not greater t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com