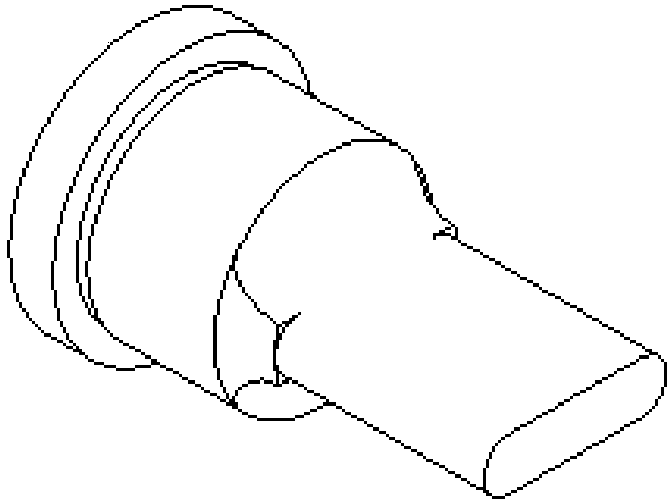

Grinding method for kidney-shaped punch

A waist-shaped and punch technology is applied to the waist-shaped punch profiling grinder and its grinding field, which can solve the problems of difficult grinding, low efficiency, poor quality, etc. Accuracy and wear resistance, the effect of less surface grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

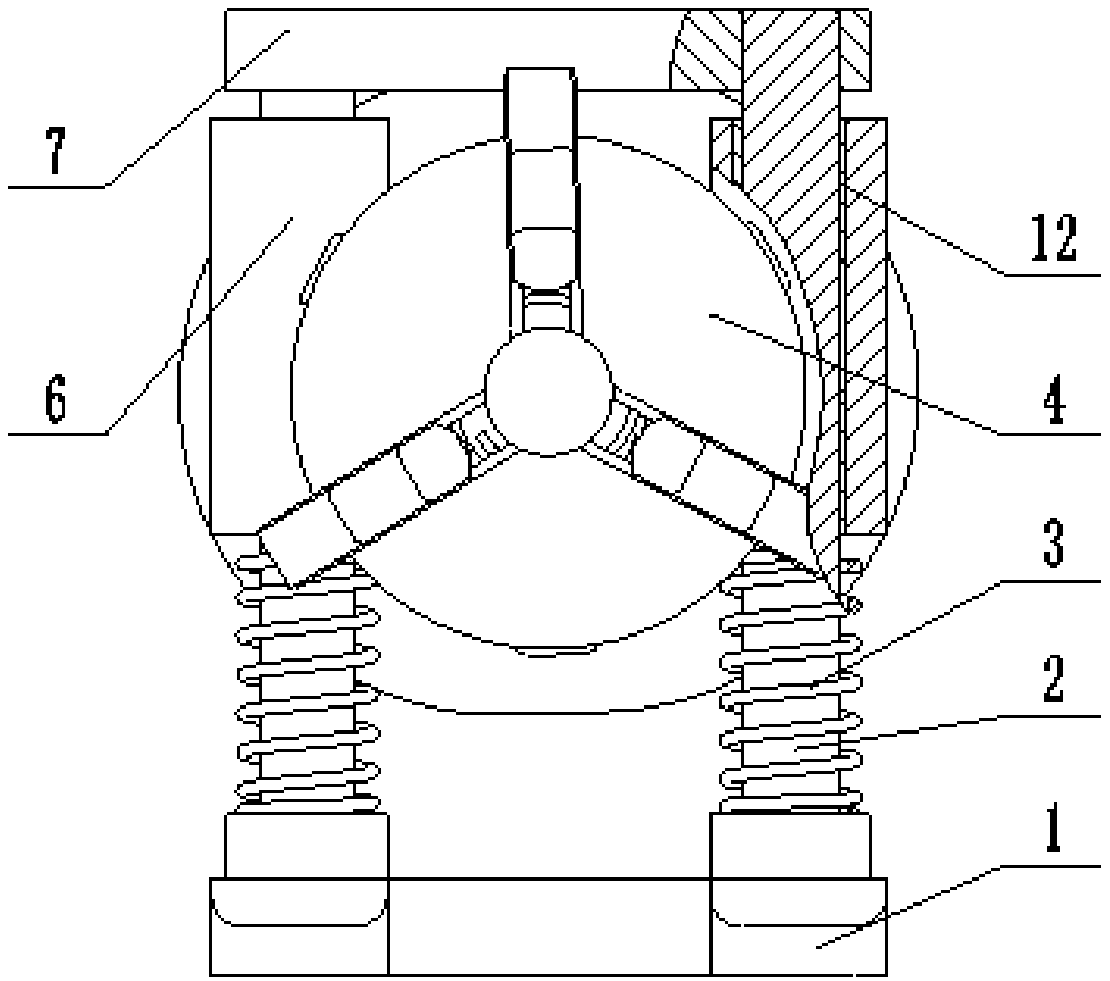

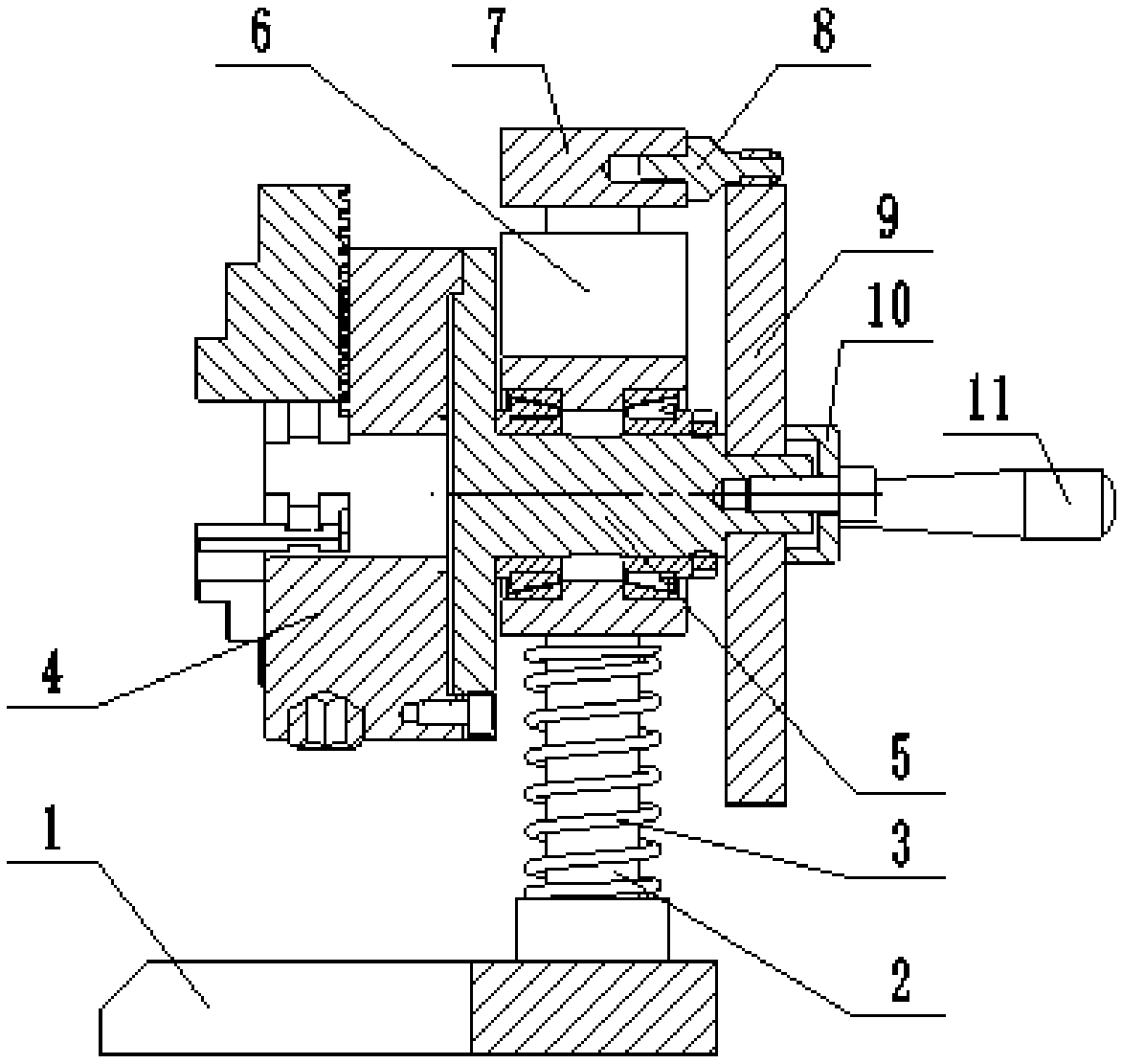

[0048] Such as figure 2 , image 3 and Figure 4 As shown, a waist-shaped punch profiling grinder of this embodiment includes a bottom plate 1, a spring 3, a chuck 4 and a main shaft 5; wherein, the bottom plate 1 is a "U"-shaped plate structure, and the While reducing the weight of the whole device, the support stability is ensured. Two vertical guide rods 2 are arranged in parallel and spaced apart on the bottom plate 1, and a sliding block 6 is sleeved on the two guide rods 2 . combine Figure 6 Specifically, in this embodiment, the sliding block 6 is provided with two guide holes 603 respectively matched with the two guide rods 2, and the two guide rods 2 respectively pass through the two guide holes 603, and each guide hole 603 Two guide sleeves 12 are arranged inside, and the guide sleeve 12 adopts a wear-resistant copper sleeve, which reduces the frictional resistance of the sliding block 6 moving on the guide rod 2, and improves the grinding quality of the waist-sh...

Embodiment 2

[0061] A waist-shaped punch profiling grinder of this embodiment has the same structure as that of Embodiment 1.

[0062] The waist-shaped punch is ground by the above-mentioned waist-shaped punch profiling grinder, and the steps are:

[0063] 1) Before installing the master form 9, use the chuck 4 to clamp the waist-shaped punch, turn the chuck 4, and measure the radial runout of the waist-shaped punch with a dial gauge to ensure that the radial circular runout of the waist-shaped punch is Proceed to the next step after not greater than 0.05mm;

[0064] 2) Install the former 9 on the main shaft 5, so that the upper side of the former 9 is in close contact with the guide wheel 802 of the guide wheel mechanism 8;

[0065] 3) Adjust the position of the limit plate 7 on the guide rod 2, so that the sliding block 6 compresses the spring 3, and the precompression of the spring 3 is ξ, ξ=βF / k; where β is 1-1.2, and F is 60 -100N, k is the elastic coefficient of spring; In the pres...

Embodiment 3

[0071] A waist-shaped punch profiling grinder of this embodiment has the same structure as that of Embodiment 1.

[0072] The waist-shaped punch is ground by the above-mentioned waist-shaped punch profiling grinder, and the steps are:

[0073] 1) Before installing the master form 9, use the chuck 4 to clamp the waist-shaped punch, turn the chuck 4, and measure the radial runout of the waist-shaped punch with a dial gauge to ensure that the radial circular runout of the waist-shaped punch is Proceed to the next step after not greater than 0.05mm;

[0074] 2) Install the former 9 on the main shaft 5, so that the upper side of the former 9 is in close contact with the guide wheel 802 of the guide wheel mechanism 8;

[0075] 3) Adjust the position of the limit plate 7 on the guide rod 2, so that the sliding block 6 compresses the spring 3, and the precompression of the spring 3 is ξ, ξ=βF / k; where β is 1-1.2, and F is 60 -100N, k is the elastic coefficient of spring; In the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com