Integrated device and method for forming of carbon fiber composite material and sticky-riveting of carbon fiber composite material and metal sheet piece

A composite material and carbon fiber technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of gaps between composite materials and metal materials, composite materials and adhesive layer damage process, complexity, etc., to save production The effect of occupying an area, reducing the production process, and improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

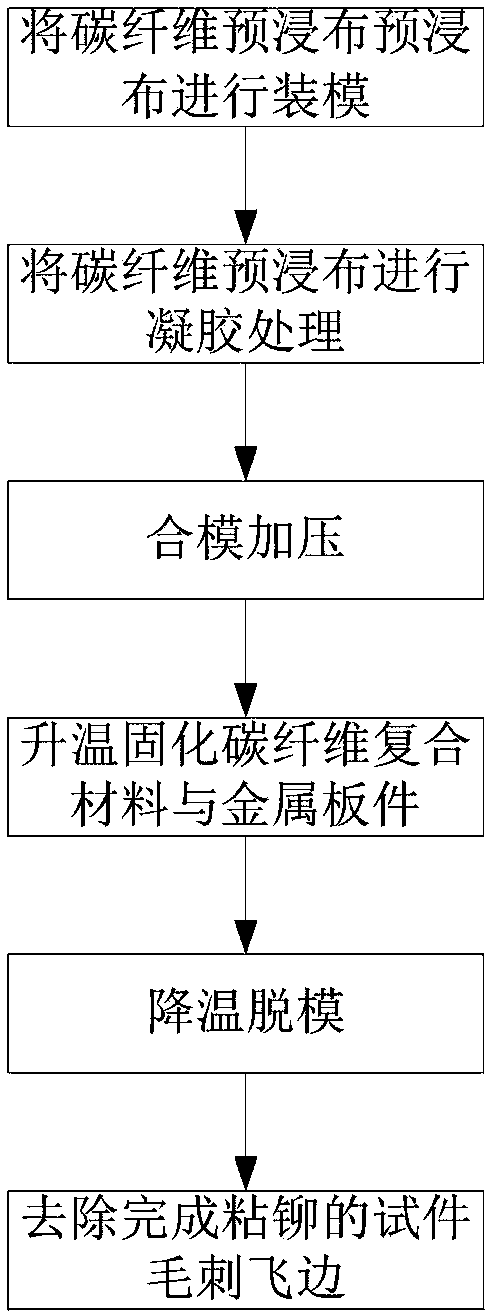

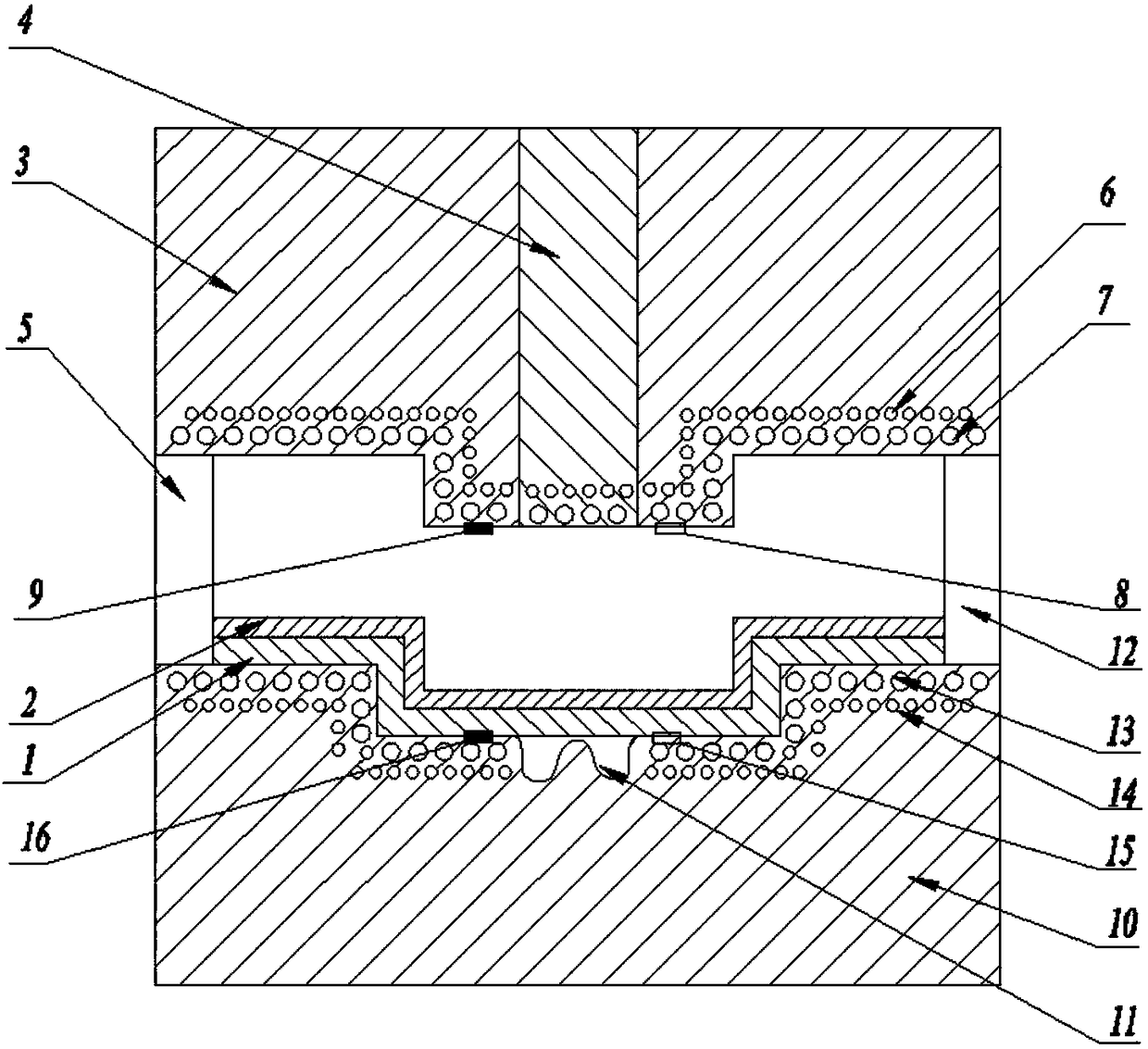

[0053] See attached Figure 1-8 The device for forming carbon fiber composite material and integrating riveting with metal plate parts of the present invention includes an upper mechanism, a lower mechanism, a driving mechanism, an upper temperature sensor 8, a lower temperature sensor 15, an upper heating channel 6, a lower heating channel 13, and an upper cooling channel. Water channel 6, lower cooling water channel 7, upper pressure sensor 9, lower pressure sensor 16 and control box;

[0054] The driving mechanism, upper temperature sensor 8, lower temperature sensor 15, upper heating channel 6, lower heating channel 13, upper cooling water channel 6, lower cooling water channel 7, upper pressure sensor 9 and lower pressure sensor 16 are all controlled by the control box;

[0055] The upper mechanism includes an upper punch 3, a punch, four guide sleeves 5 with the same structure, an upper heating channel 6, an upper cooling water channel 7, an upper temperature sensor 8, a...

Embodiment 2

[0078]Apply the carbon fiber composite material molding of the present invention and the integrated device for bonding and riveting with metal plate parts to prepare a carbon fiber composite material plate of 400mm * 400mm * 2mm and a thickness of 2mm aluminum alloy plate bonding riveting parts, select 3k carbon fiber as the main body of the carbon fiber composite material, Resin matrix selects phenolic epoxy modified resin;

[0079] The specific method includes the following steps:

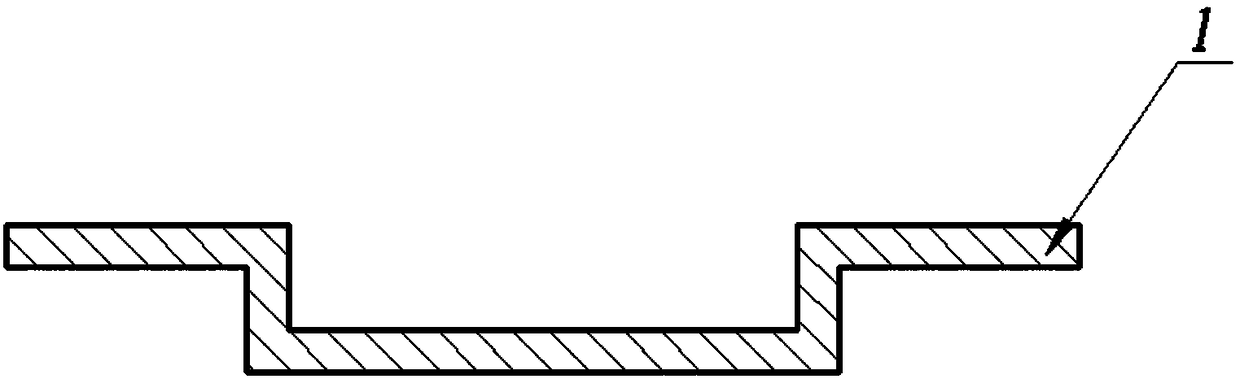

[0080] Step 1: mold the carbon fiber prepreg 2;

[0081] Operate the driving mechanism to raise the upper mechanism to the highest position, place the formed aluminum alloy plate 1 in the lower die 10; coat the aluminum alloy plate with a layer of resin adhesive with a thickness of 1 mm and then spread the carbon fiber prepreg 2, Carbon fiber prepreg 2 is a carbon fiber prepreg cloth with a length of 400 mm, a width of 400 mm, and a thickness of 0.24 to 0.26 mm. Since the thickness of the test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com