Patents

Literature

45results about How to "Reduced production footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

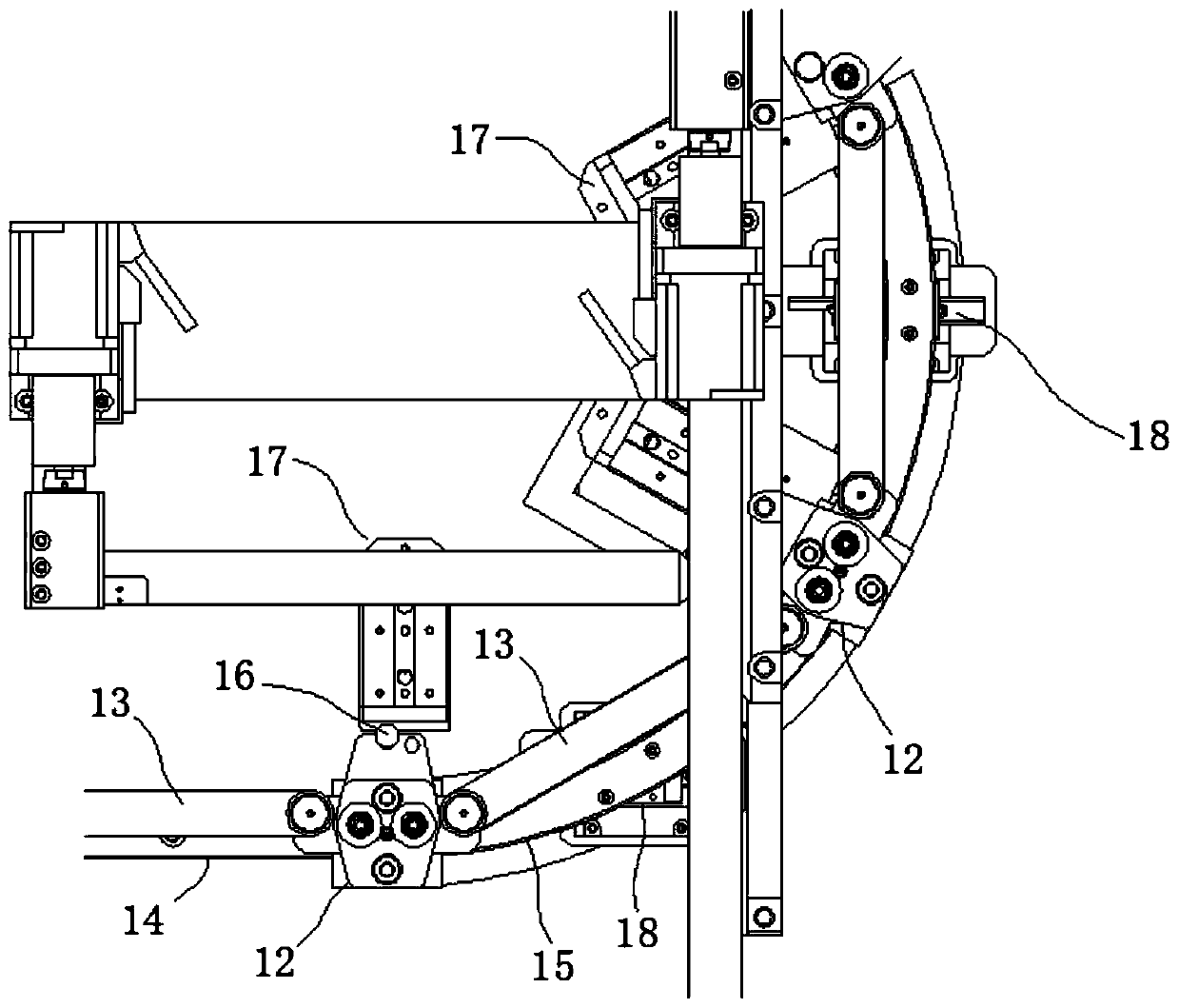

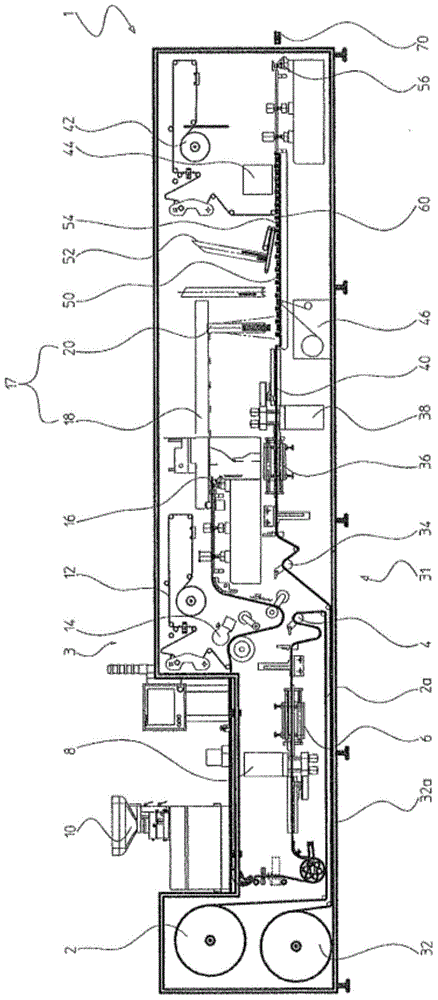

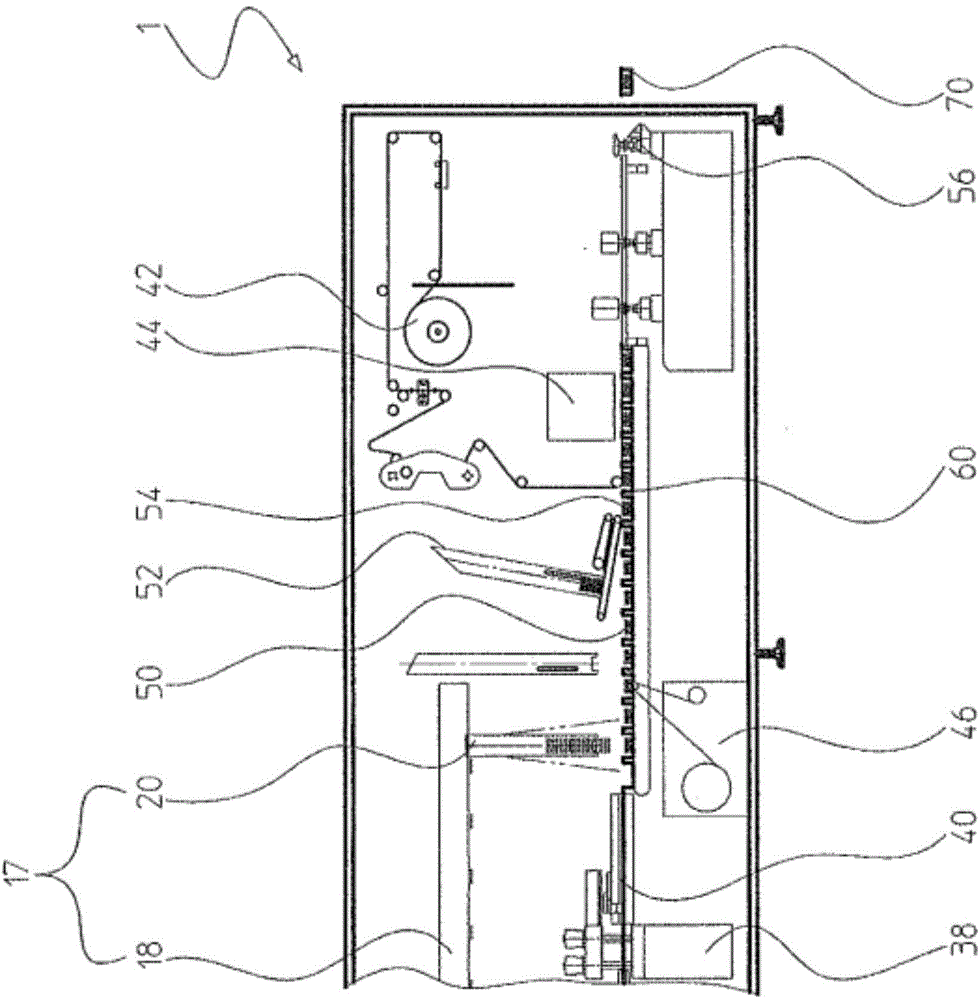

Vacuum liquid filling equipment for soft-package battery

InactiveCN102496691AShorten the soaking timeShorten the production cycleCell component detailsElectrical batteryEngineering

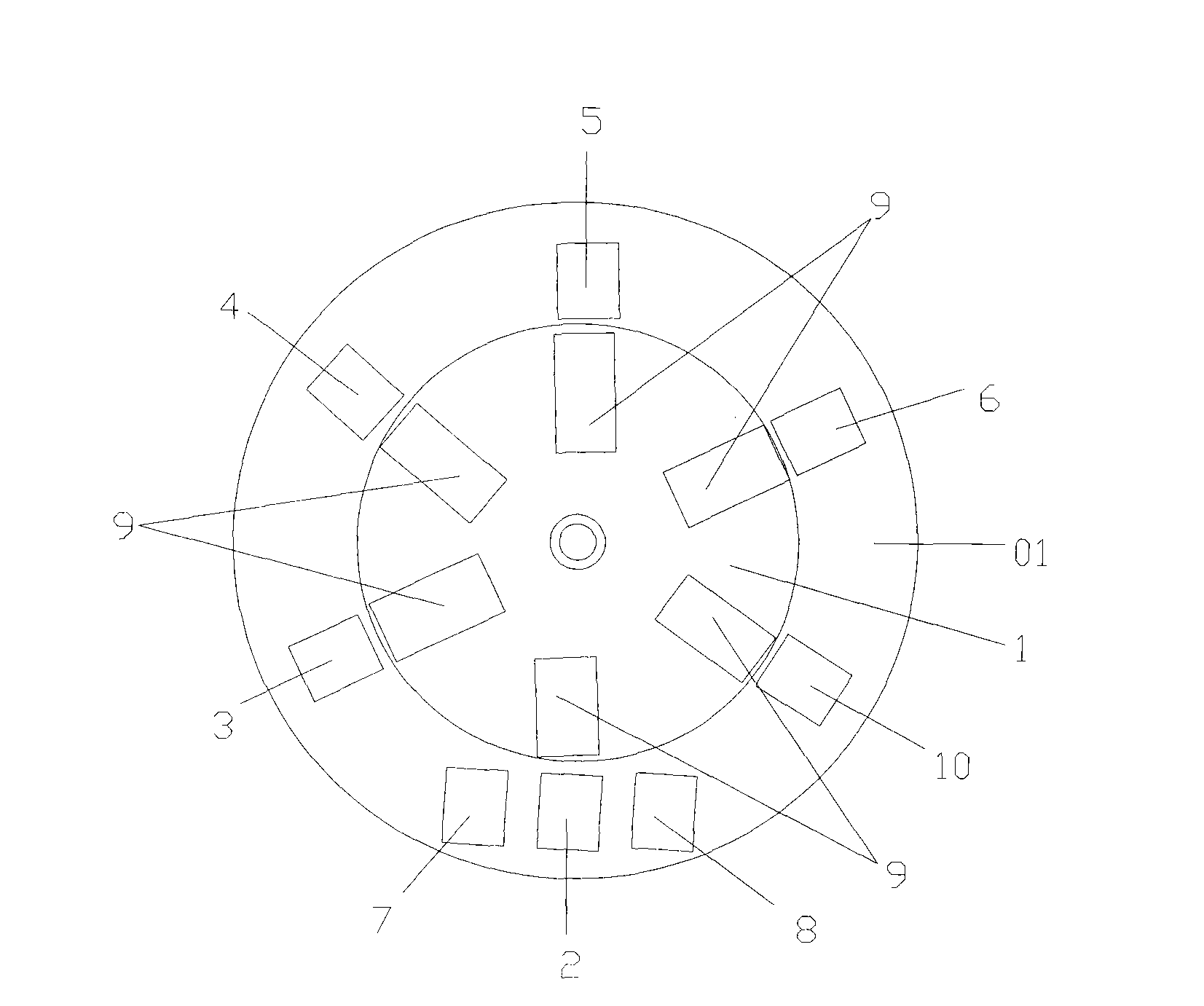

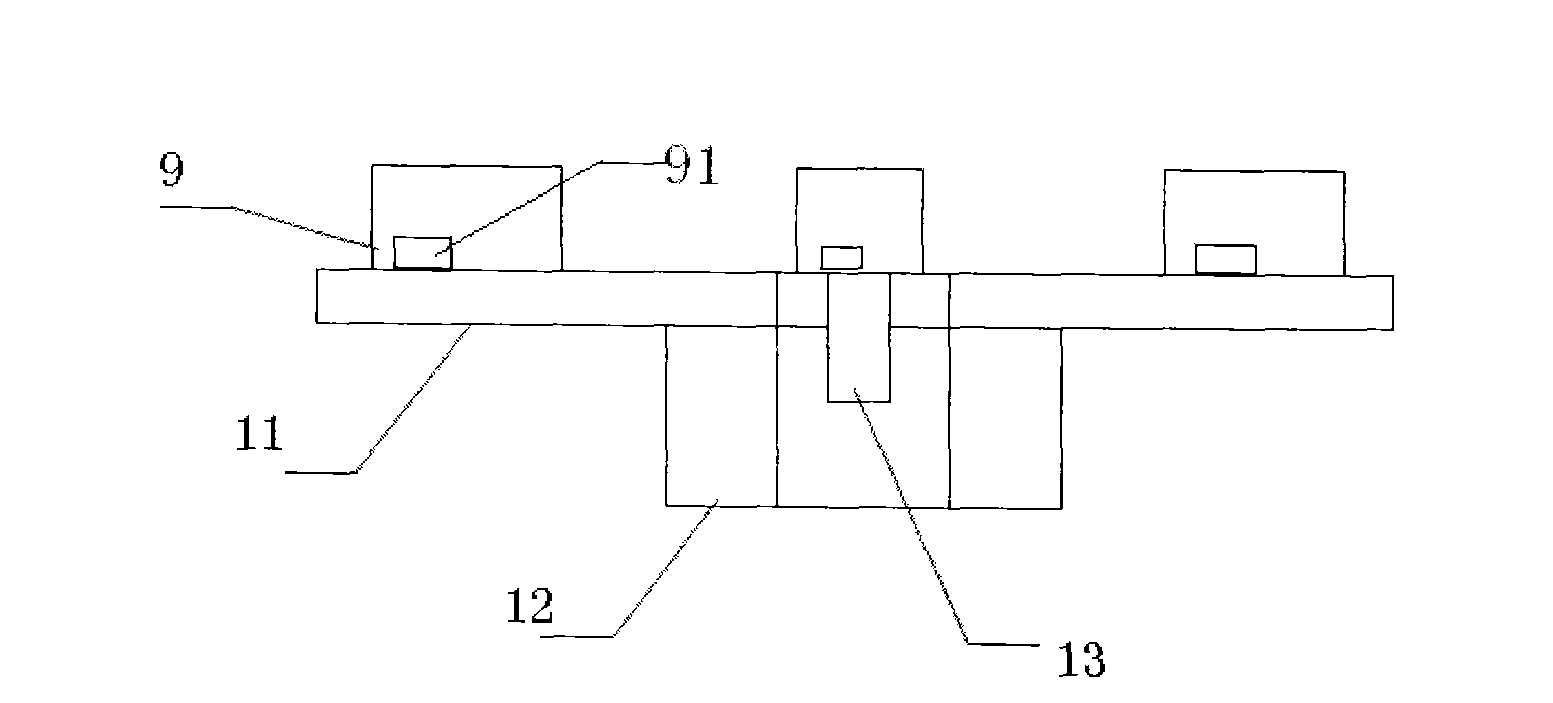

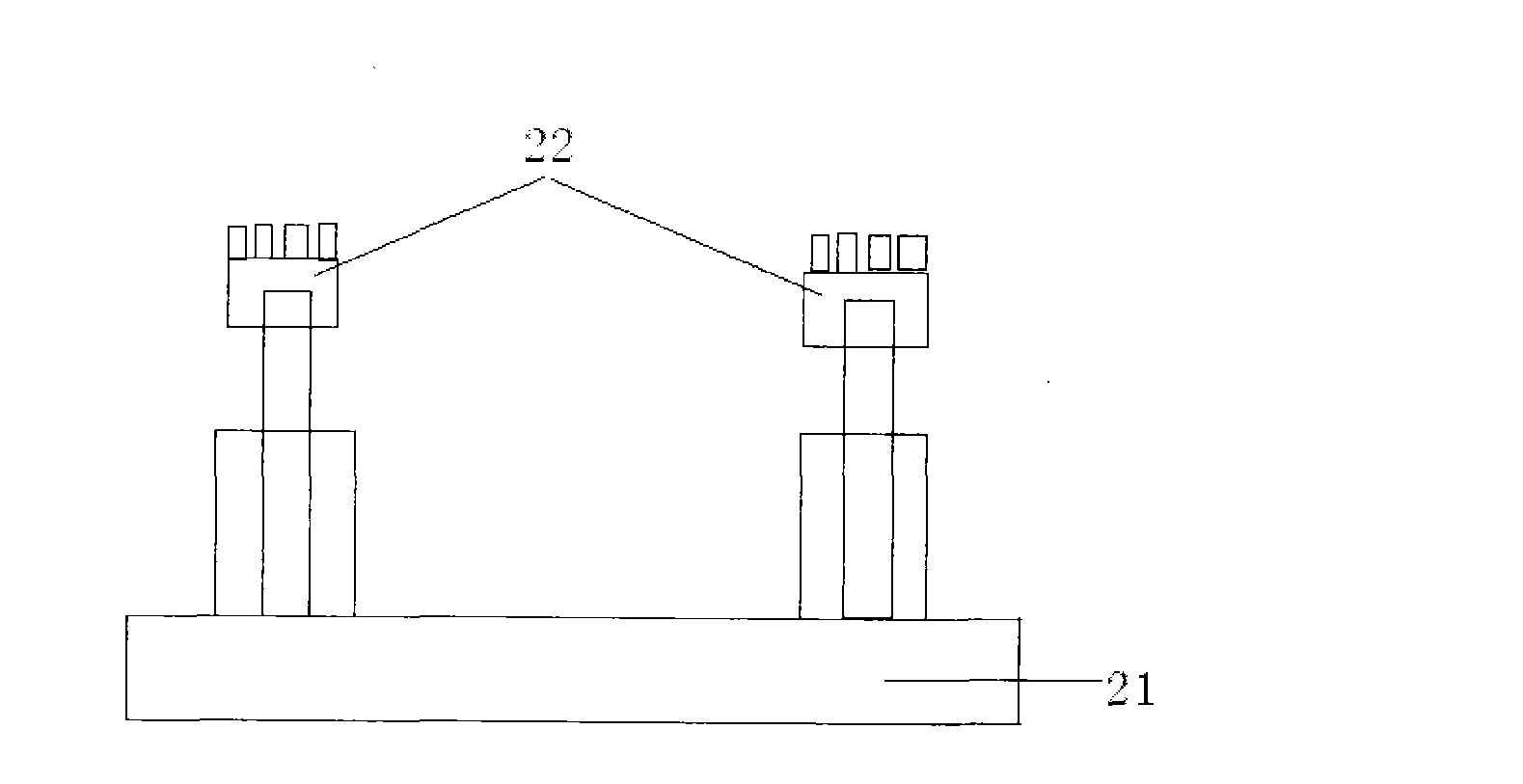

The invention belongs to the field of production equipment for lithium ion batteries, and particularly relates to vacuum liquid filling equipment for a soft-package battery. The vacuum liquid filling equipment for the soft-package battery comprises a machine frame and a multi-workstation turnplate which is arranged on the machine frame, wherein a drawer-type sealed box body is installed on any workstation of the multi-workstation turnplate; a battery fixing clamp is fixedly installed inside the drawer-type sealed box body; a battery loading and unloading unit, a battery packaging bag sucking-open unit, a vacuumizing unit, a liquid filling unit and a sealing unit which correspond to the workstations of the multi-workstation turnplate are fixedly arranged on the periphery of the multi-workstation turnplate sequentially; two sides of the battery loading and unloading unit are fixedly connected with a front filled liquid weighing unit and a back filled liquid weighing unit respectively; and each unit is fixedly connected on the machine frame. Compared with the prior art, the vacuum liquid filling equipment for the soft-package battery has the advantages that the electrolyte soaking time can be reduced, the space occupied by the equipment can be reduced, a surplus liquid filling pump can be saved, the investment cost of the equipment can be reduced, the liquid filling precision and the stability can be improved and the waste of the electrolyte can be reduced.

Owner:DONGGUAN AMPEREX TECH +1

Method for producing ferrovanadium

The invention relates to a method for producing ferrovanadium, belonging to the technical field of metallurgy and aiming at solving the technical problem of providing a method which has lower production cost and is used for producing the ferrovanadium. The method for producing the ferrovanadium comprises the following steps of: a, mixing materials: uniformly mixing vanadium-containing raw materials, iron red powder, aluminum powder and CaO to obtain a mixed material, wherein the vanadium-containing raw material is at least one of ammonium poly-vanadate and ammonium metavanadate, the proportion by weight of the vanadium-containing raw materials in terms of vanadium to the iron red powder in terms of iron is 1: (0.16-0.26), the coefficient of mixed aluminum is 1.05-1.15, and the coefficientof the mixed CaO is 0.35-0.47; b, pelletizing: pelletizing the obtained mixed material, and drying pellets; and c, placing into a furnace for smelting: placing the dried pellets into the furnace, andsmelting till the mixed material is completely reacted; and d, taking out of the furnace to obtain the ferrovanadium.

Owner:PANZHIHUA UNIV

Automatic production method of PCB

InactiveCN109587959AQuality improvementImprove organ functionPrinted circuit manufactureEtchingEngineering

The invention discloses an automatic production method of a PCB. The automatic production method comprises the steps of material cutting, film drying at an inner layer, browning, inner-layer board lamination, copper deposition, board electroplating, film drying at an outer layer, gold electroplating, green oil wetting, goldfinger plating, tin spraying and gold deposition. In the step of material opening, a large material is cut to various fine materials by an automatic cutting machine according to specifications, a tip end of a round board is grinded by a round angle grinding machine, the board is placed in an oven for heating after the board is washed and dried by a board washing machine, the board is taken out after cooling and then is labeled as a mark; and in the step of film drying atthe inner layer, the board is placed in a chemical cleaning machine by a carrying device, and the cleaning is completed sequentially by washing, micro etching, high-pressure washing, cycle washing, water suction, strong wind blowing and hot-air secondary drying. The automatic production method is high in automation, the whole PCB production efficiency is high, and the damage to the PCB is low during the production process.

Owner:刘夏冰

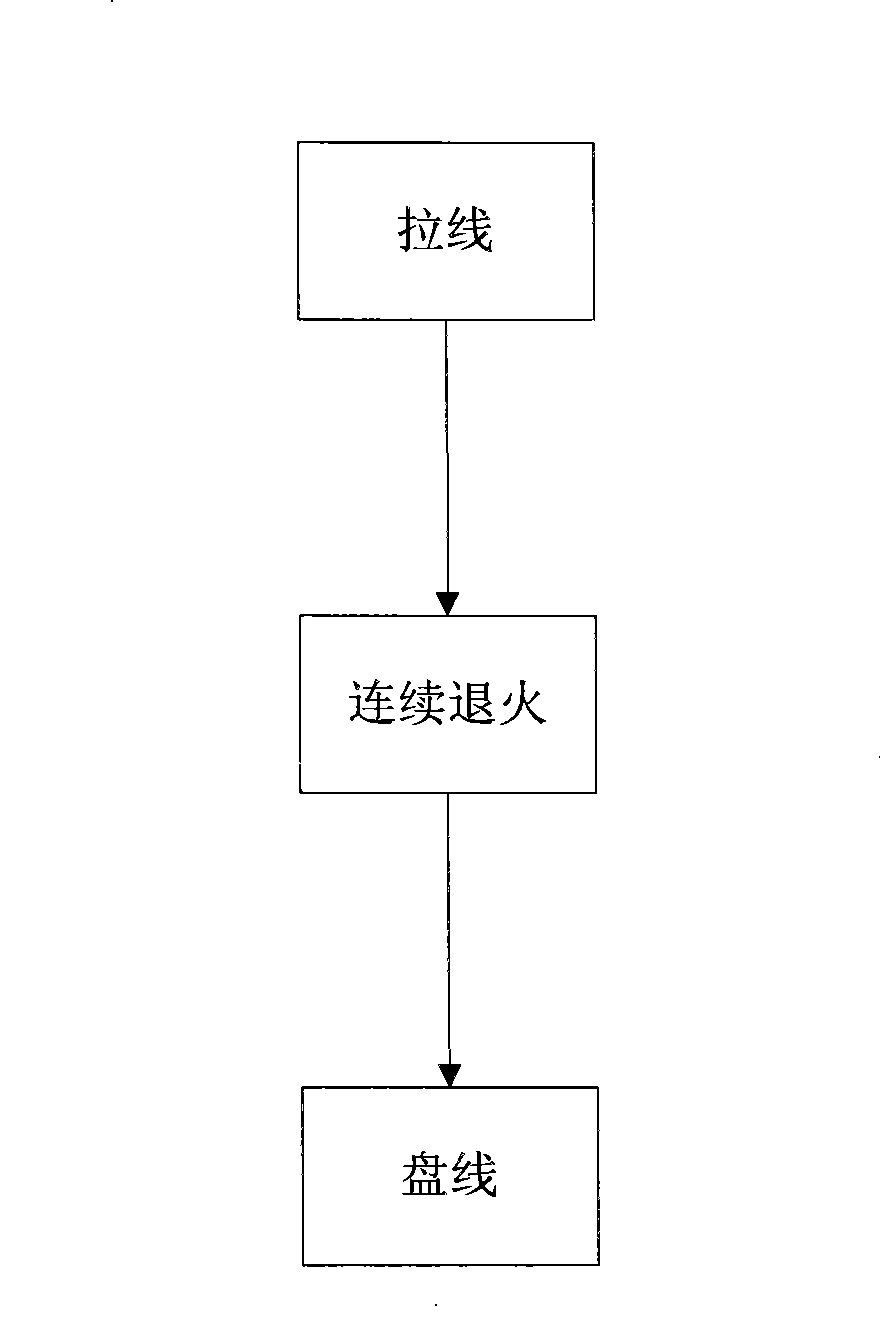

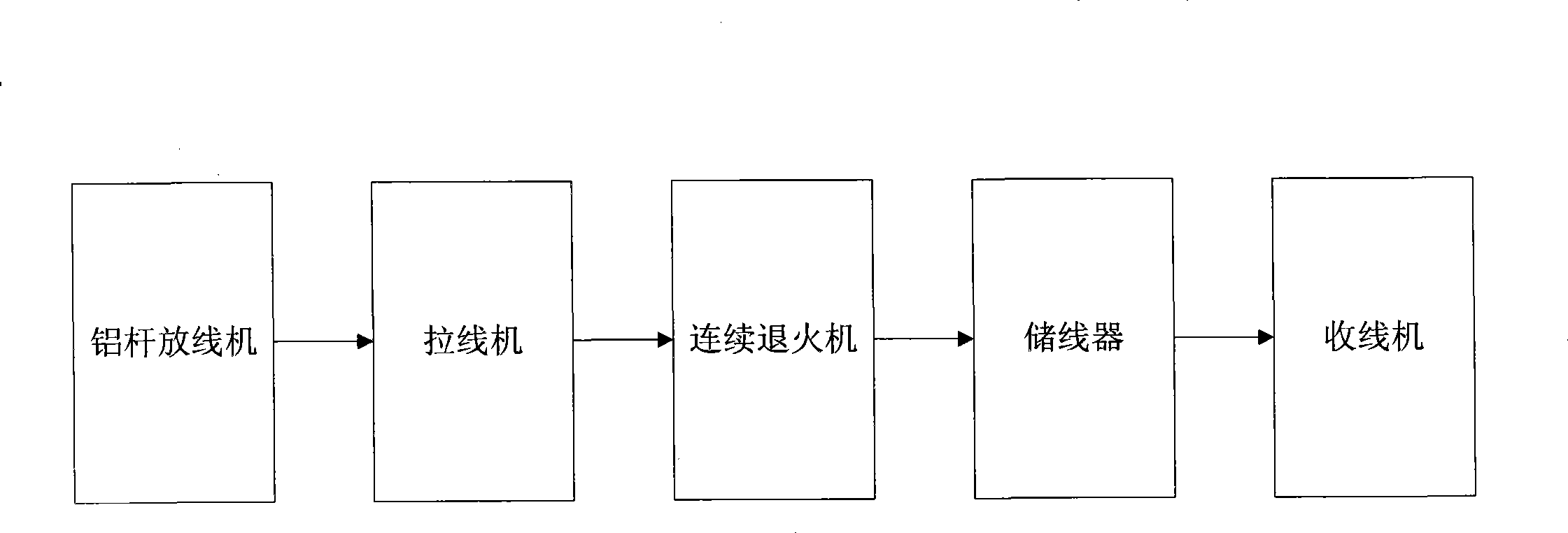

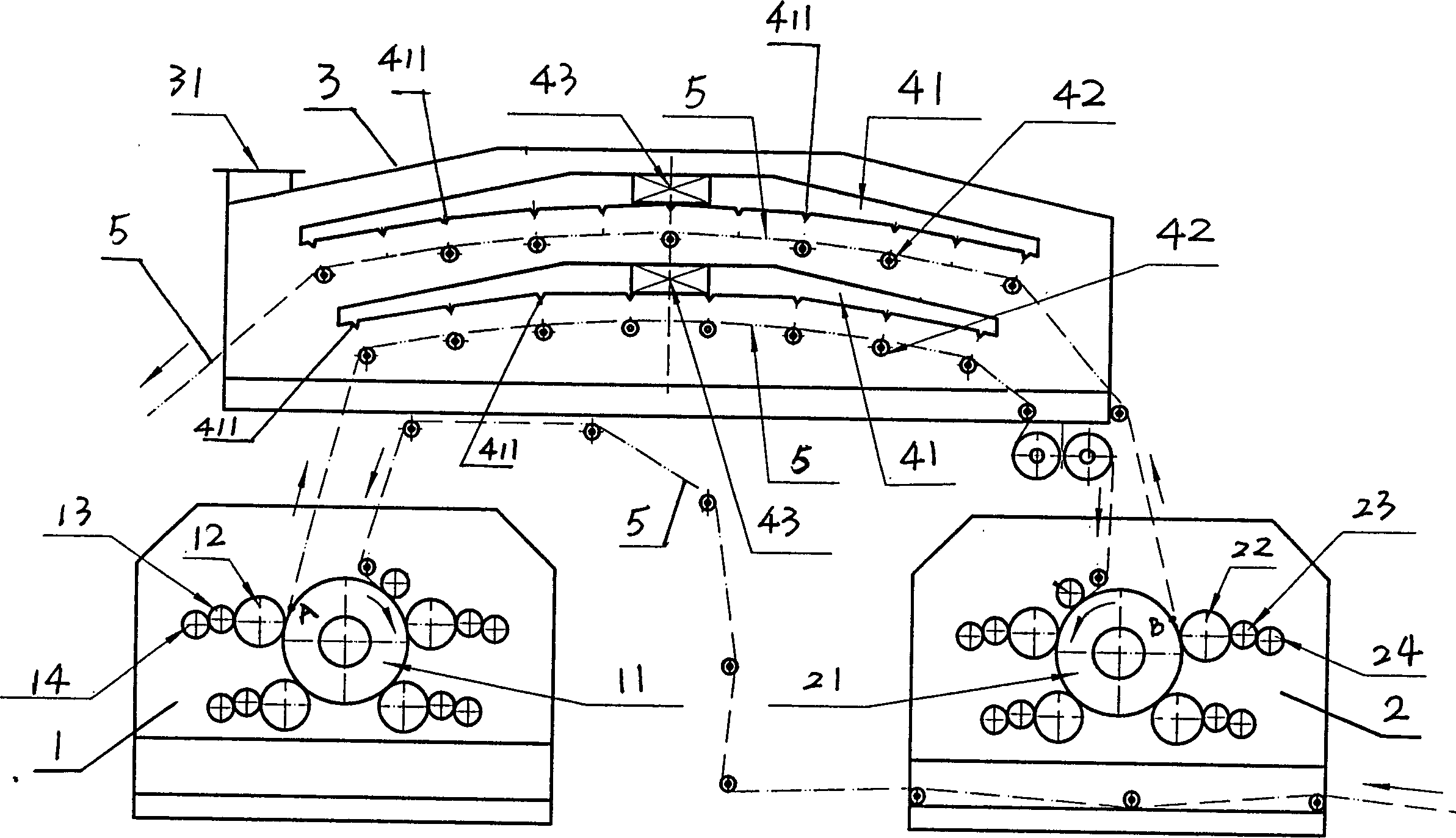

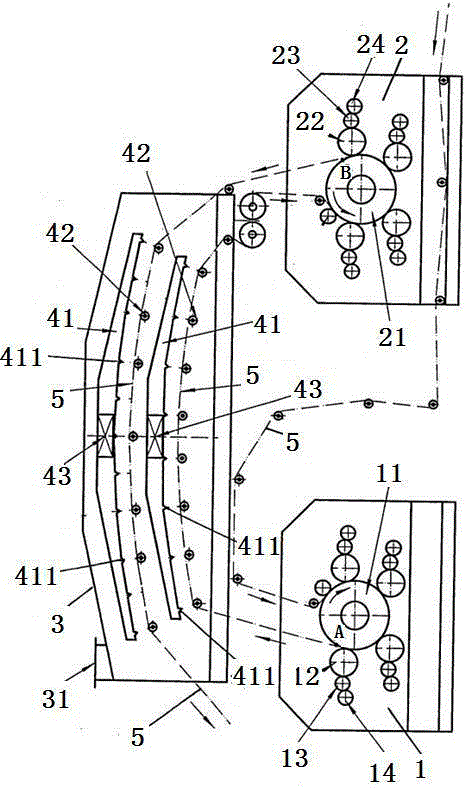

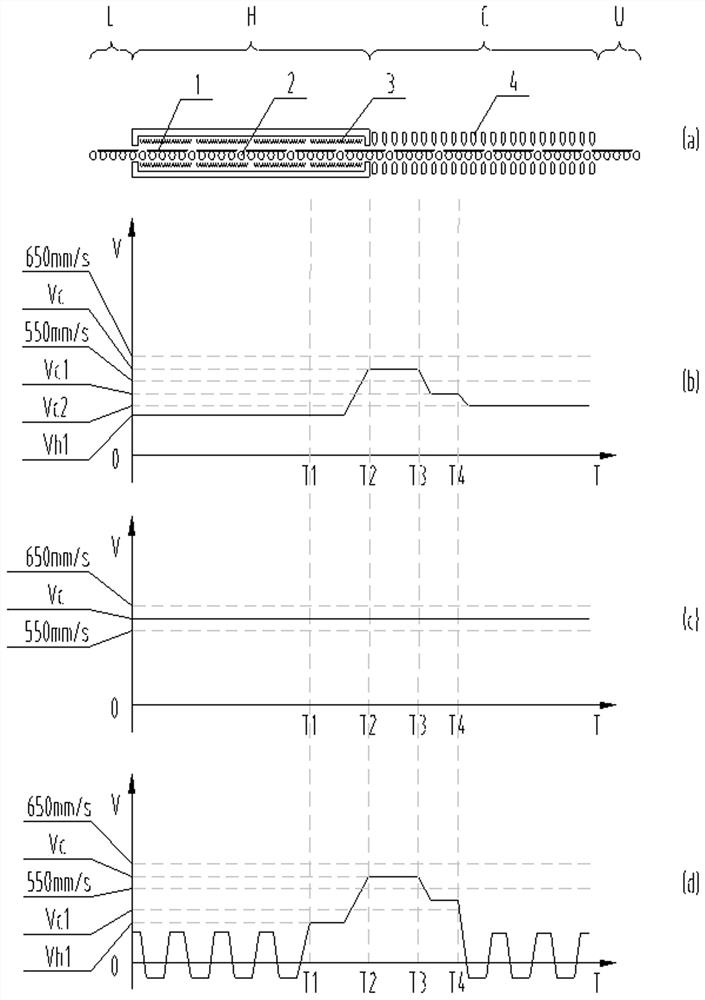

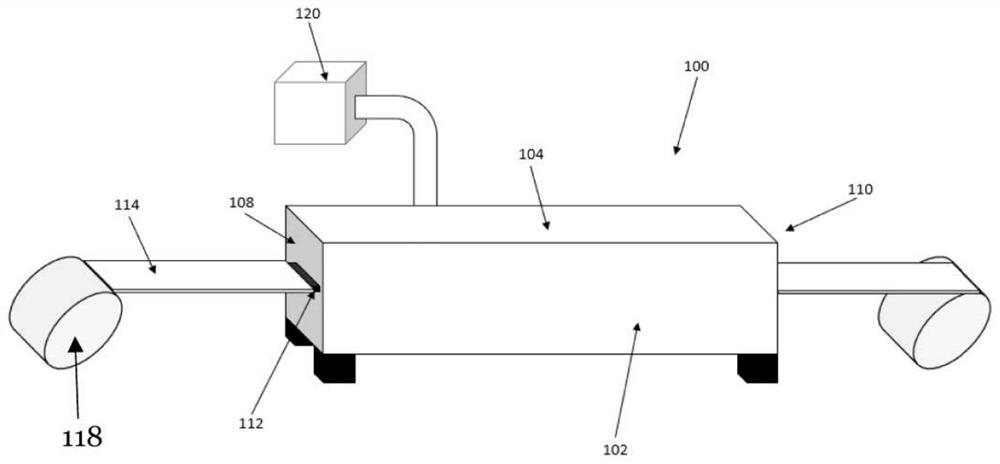

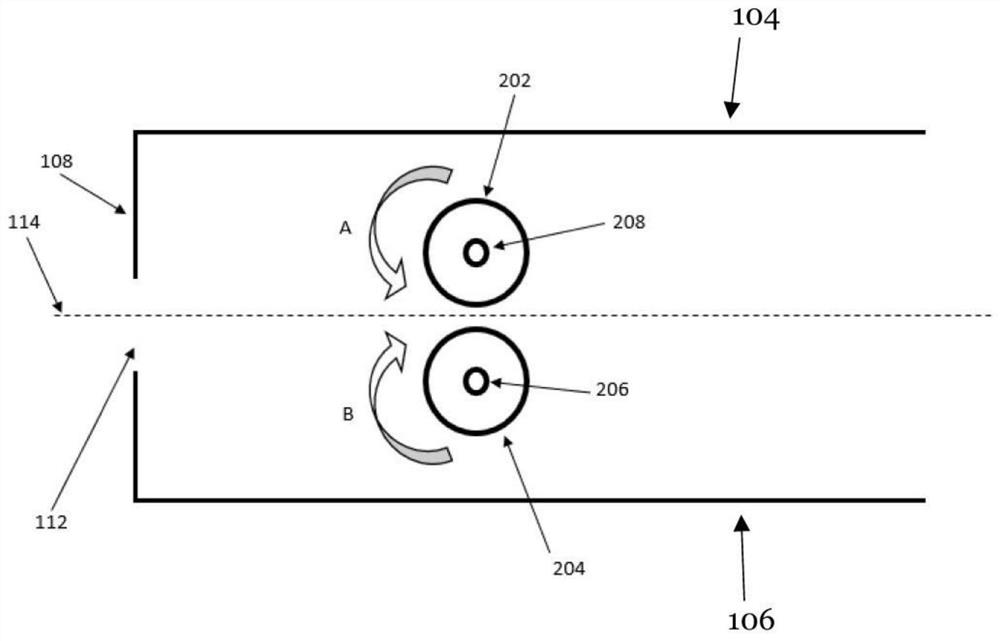

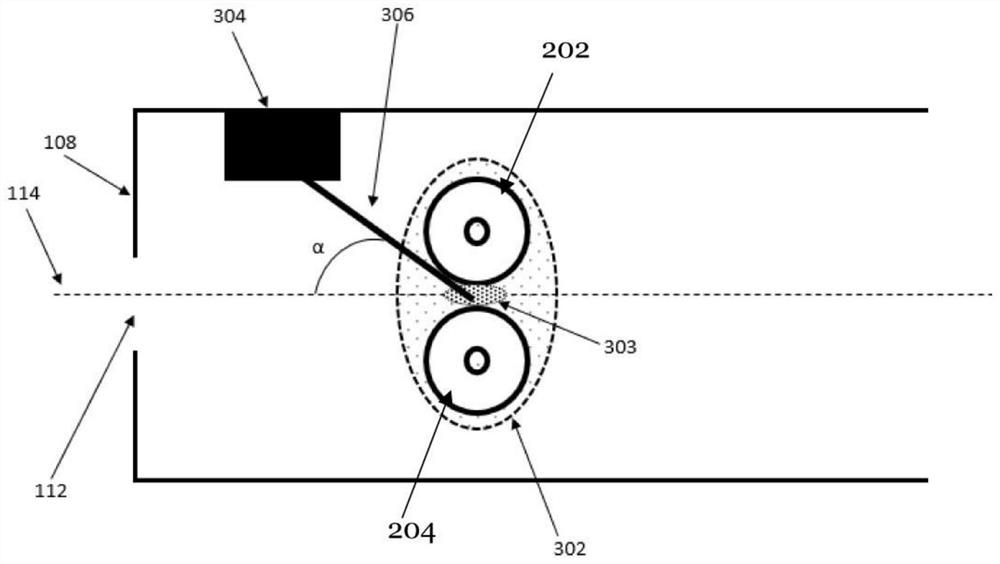

Contact type aluminum wire continuous annealing method and apparatus

InactiveCN101435017AQuality improvementImprove power transmission capacityFurnace typesCable/conductor manufactureFiberCarbon fibers

The invention discloses a contact aluminium wire continuous annealing method, comprising the following steps of wire drawing, continuous annealing and dual wire collecting. A contact aluminium wire continuous annealing device comprises an aluminium wire large drawing machine, a contact aluminium wire continuous annealer and a dual automatic disc exchanging wire collecting device; the wire feeding end of the contact aluminium wire continuous annealer is connected with the wire output end of the aluminium wire large drawing machine; and the wire output end of the contact aluminium wire continuous annealer is connected with the wire feeding end of the wire collecting device. The contact aluminium wire continuous annealer comprises a power module, a machine shell, at least one wire guiding wheel, at least one drawing wheel, at least one preheating copper contact wheel and at least one annealing copper contact wheel. The aluminium wire produced by adopting the device and the method has the advantages that aluminium wire adhering does not happen after annealing, the softness and hardness of the aluminium wires of the outer layer and the inner layer of the wire coil are consistent, the resistance is consistent, the quality is high, the length is large and the like; the invention can realize assembly line work, save energy, reduce the consumption, and can be widely applied to manufacture electrical wires, electrical cables and large-span overhead aluminium wires which use carbon fiber as a strengthening core.

Owner:德阳杰创线缆机械有限责任公司

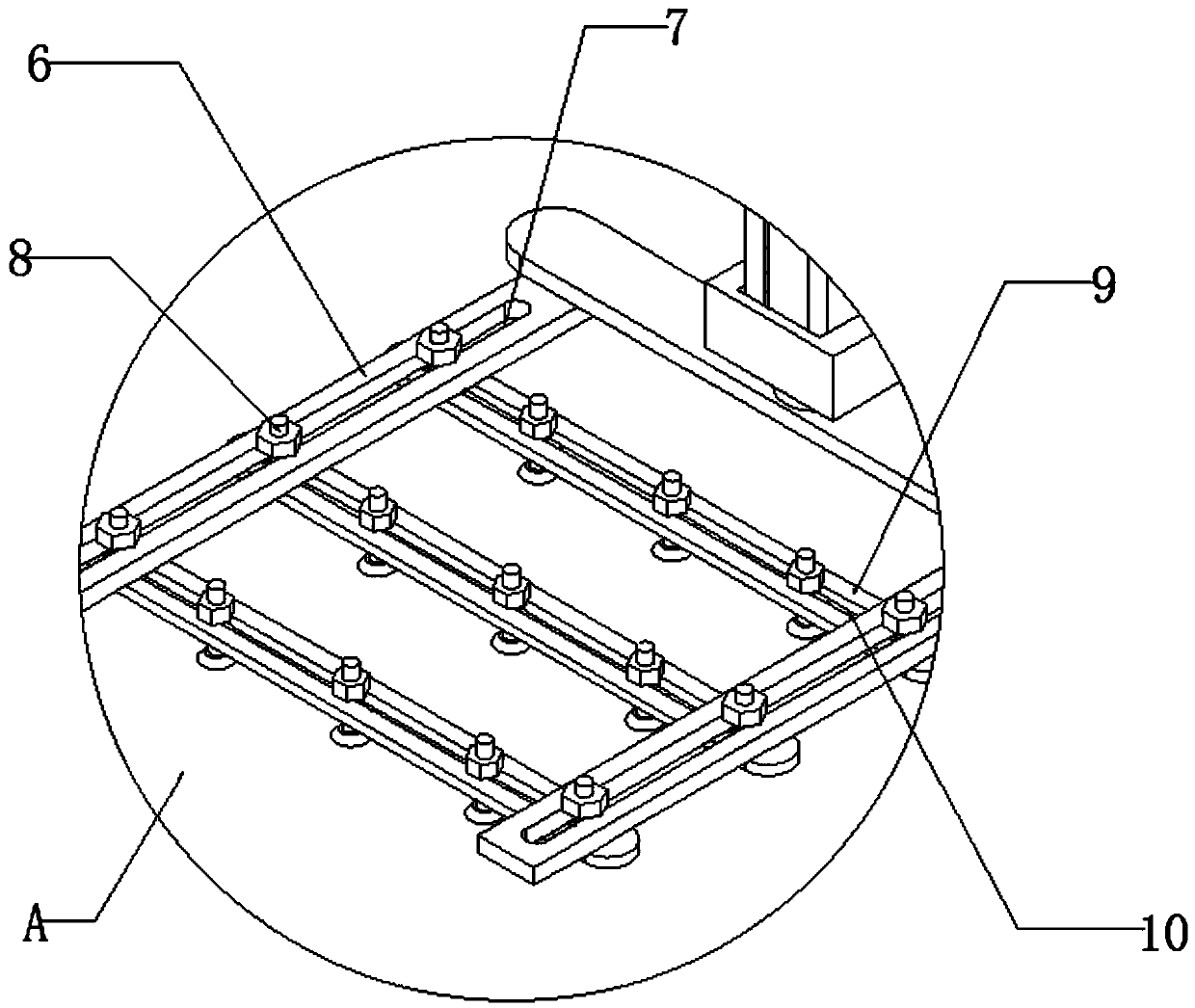

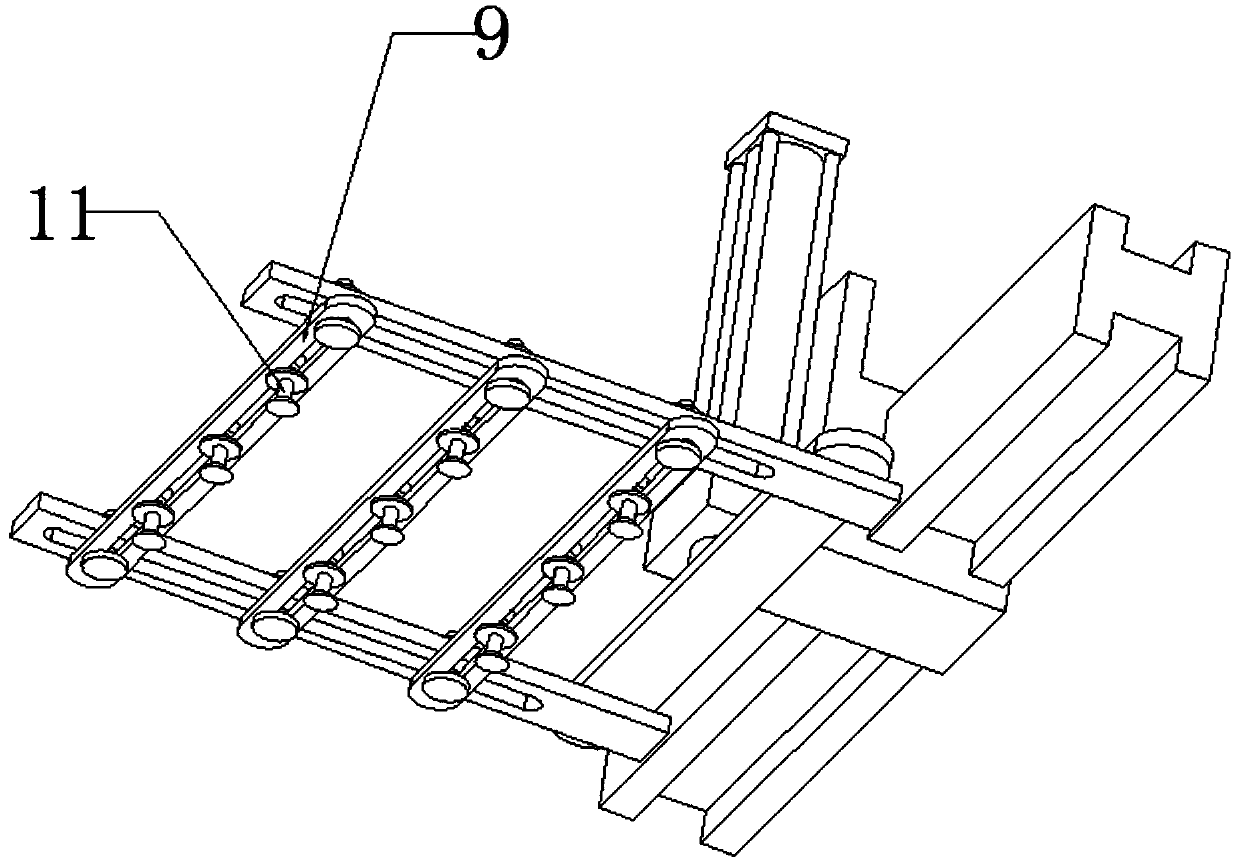

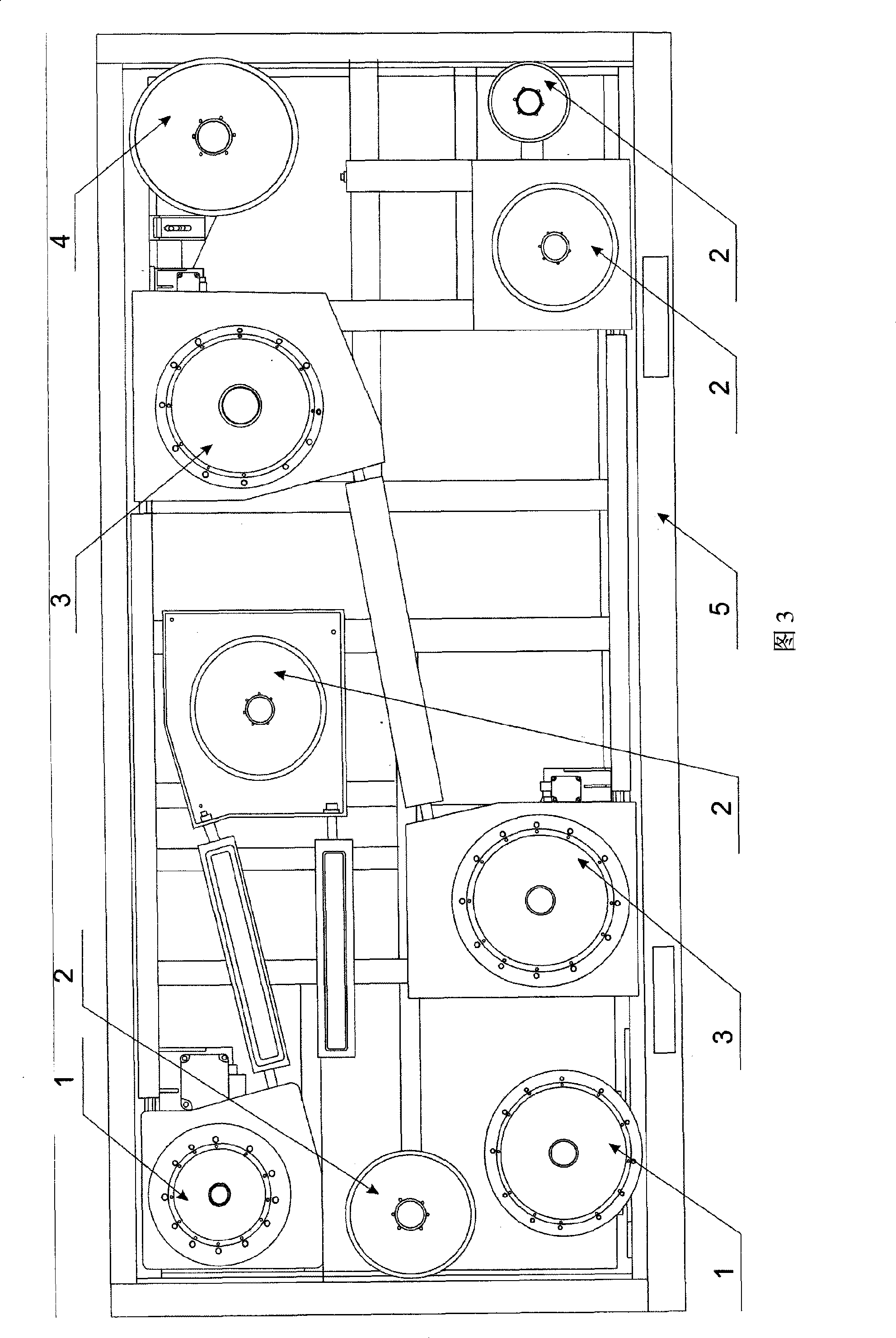

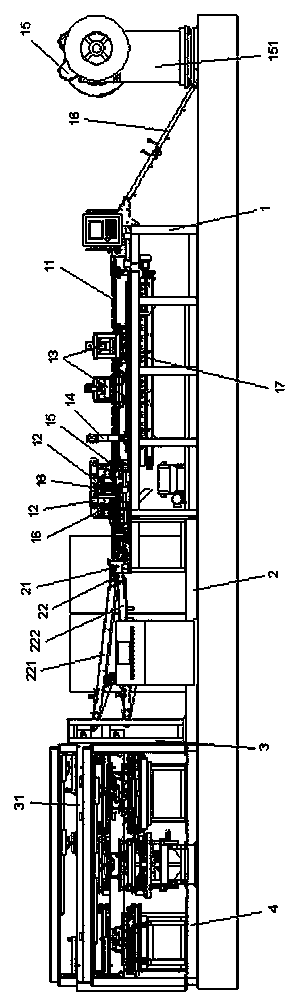

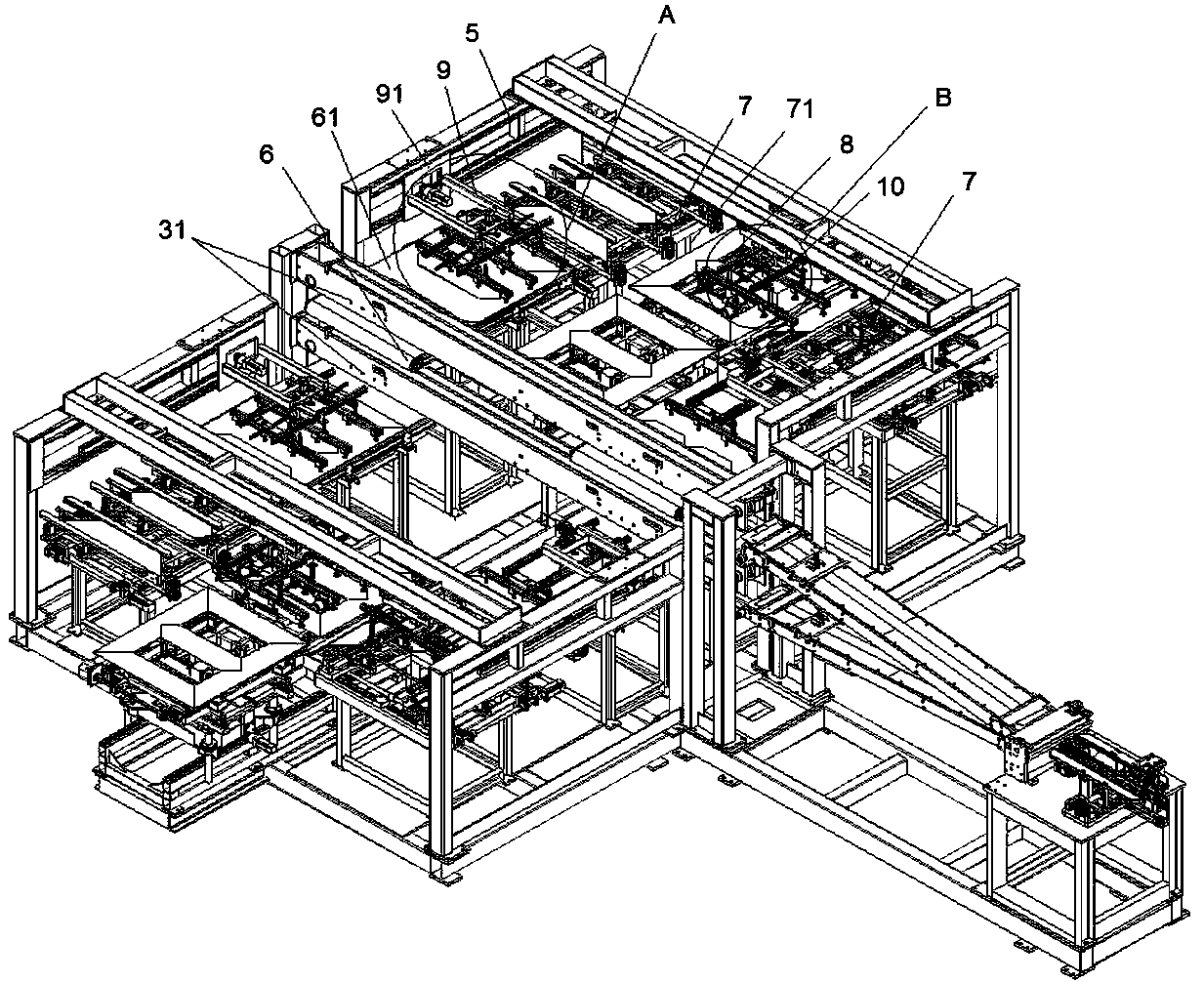

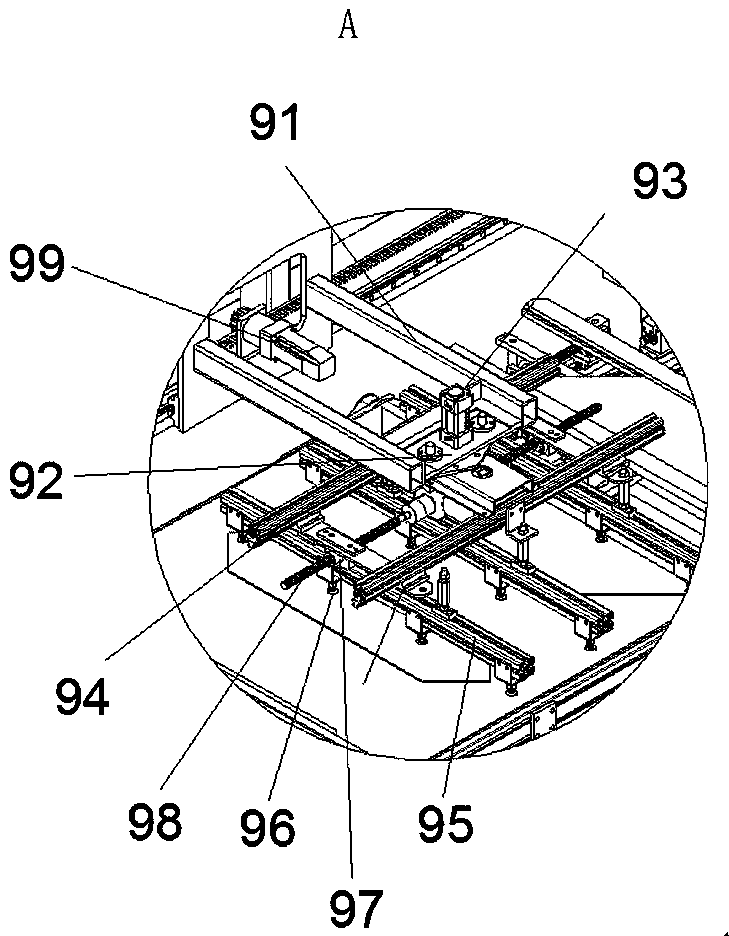

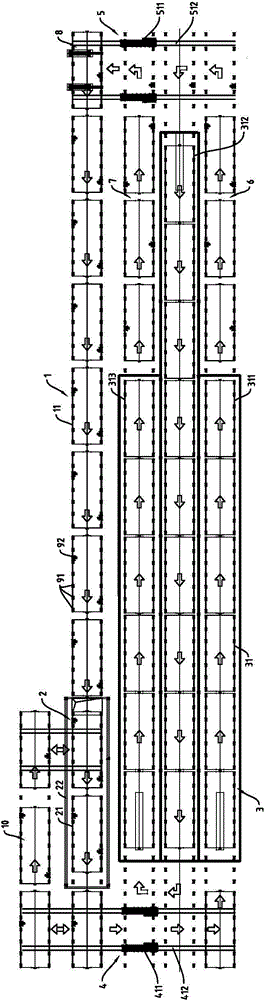

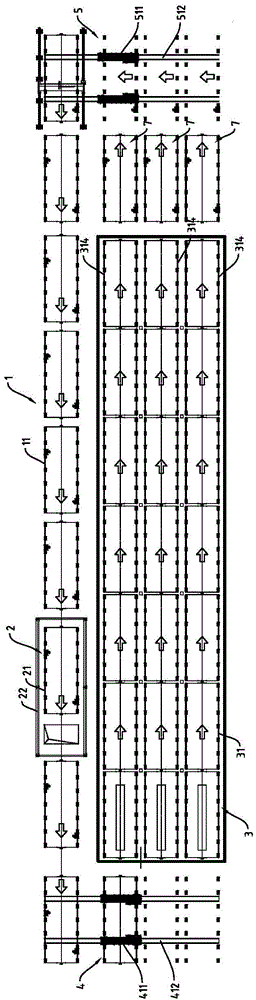

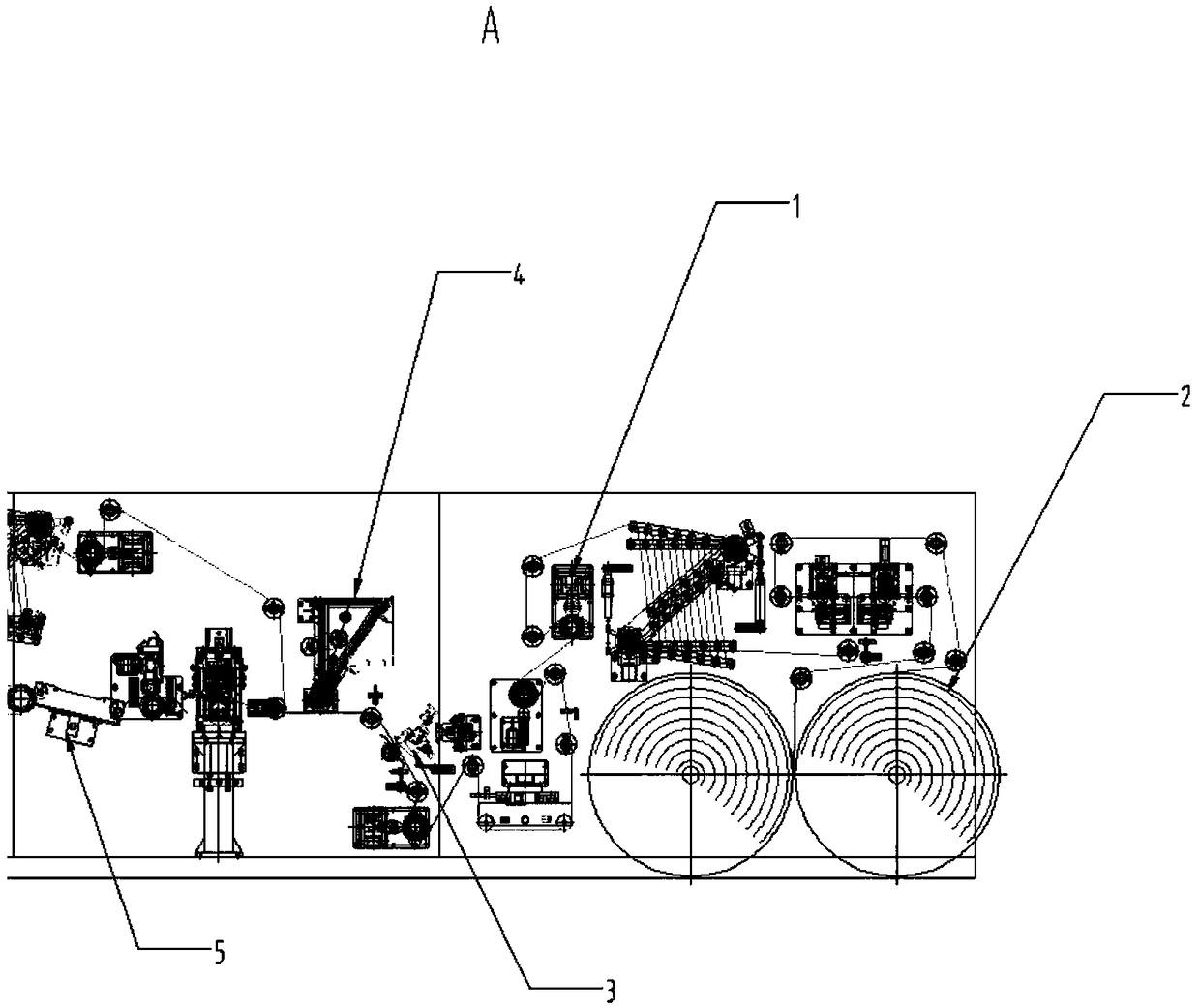

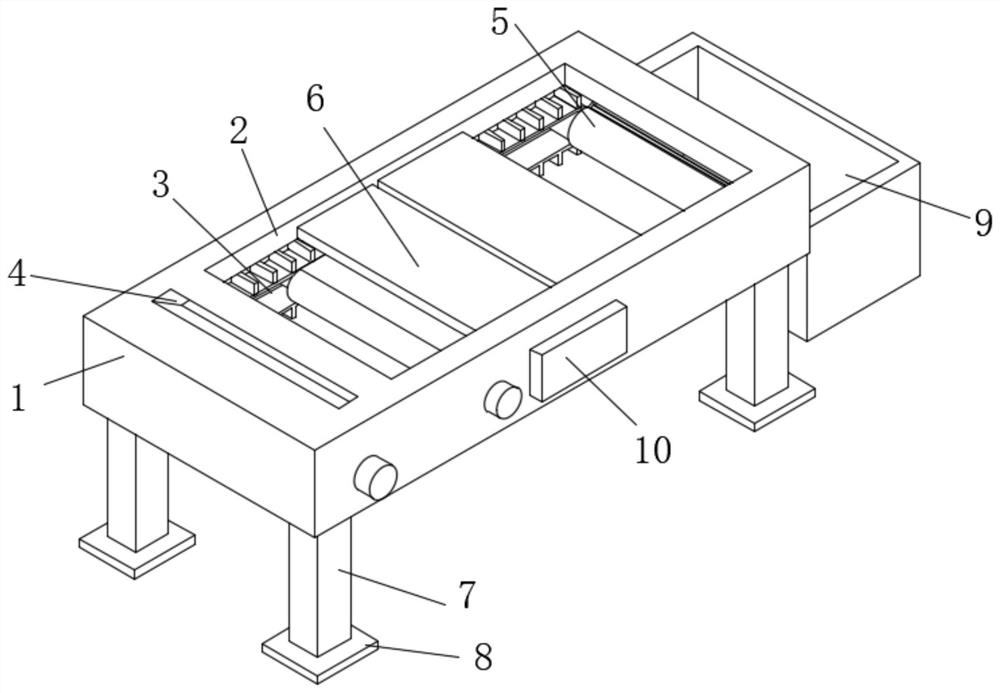

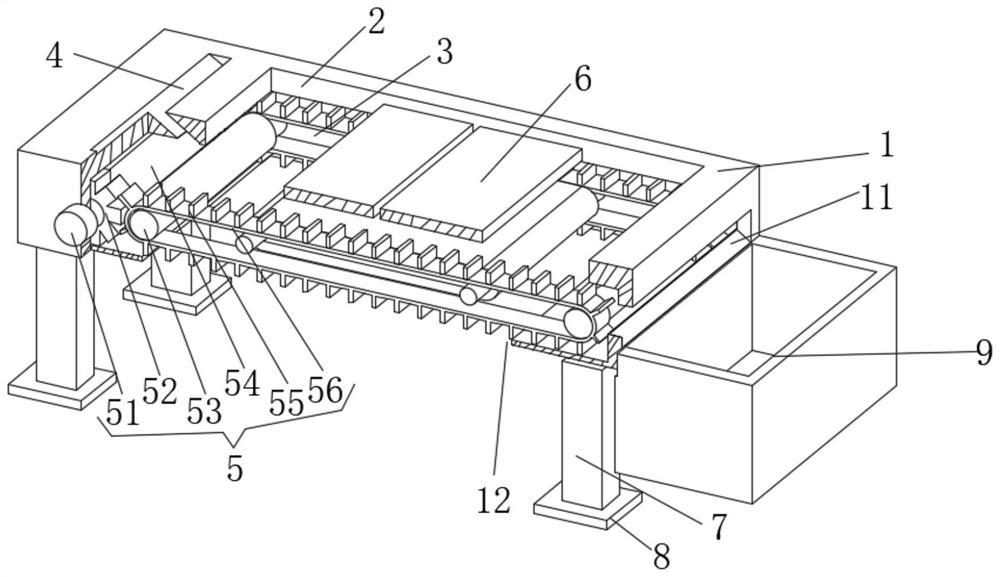

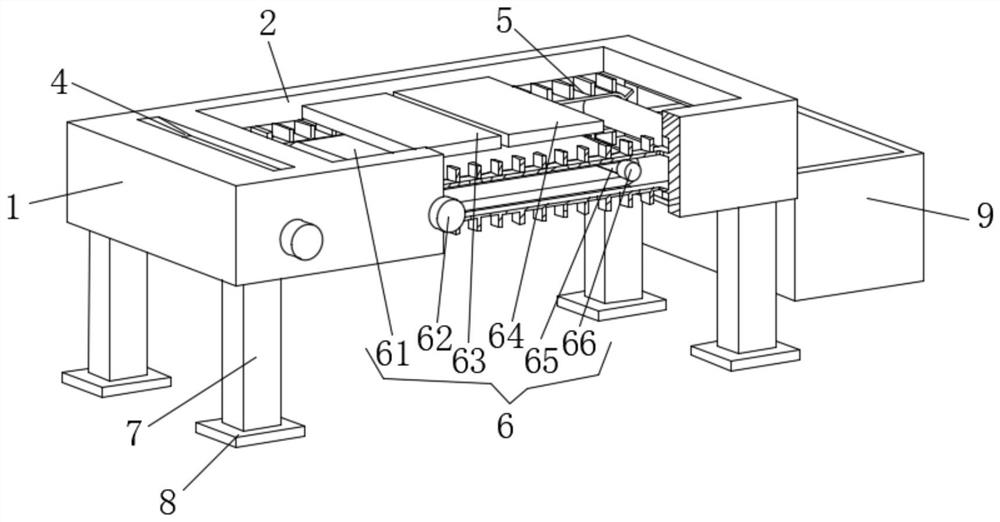

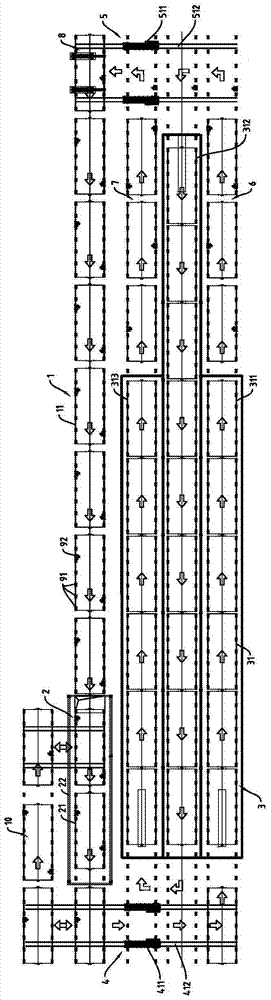

Transformer silicon steel sheet shearing and stacking machine

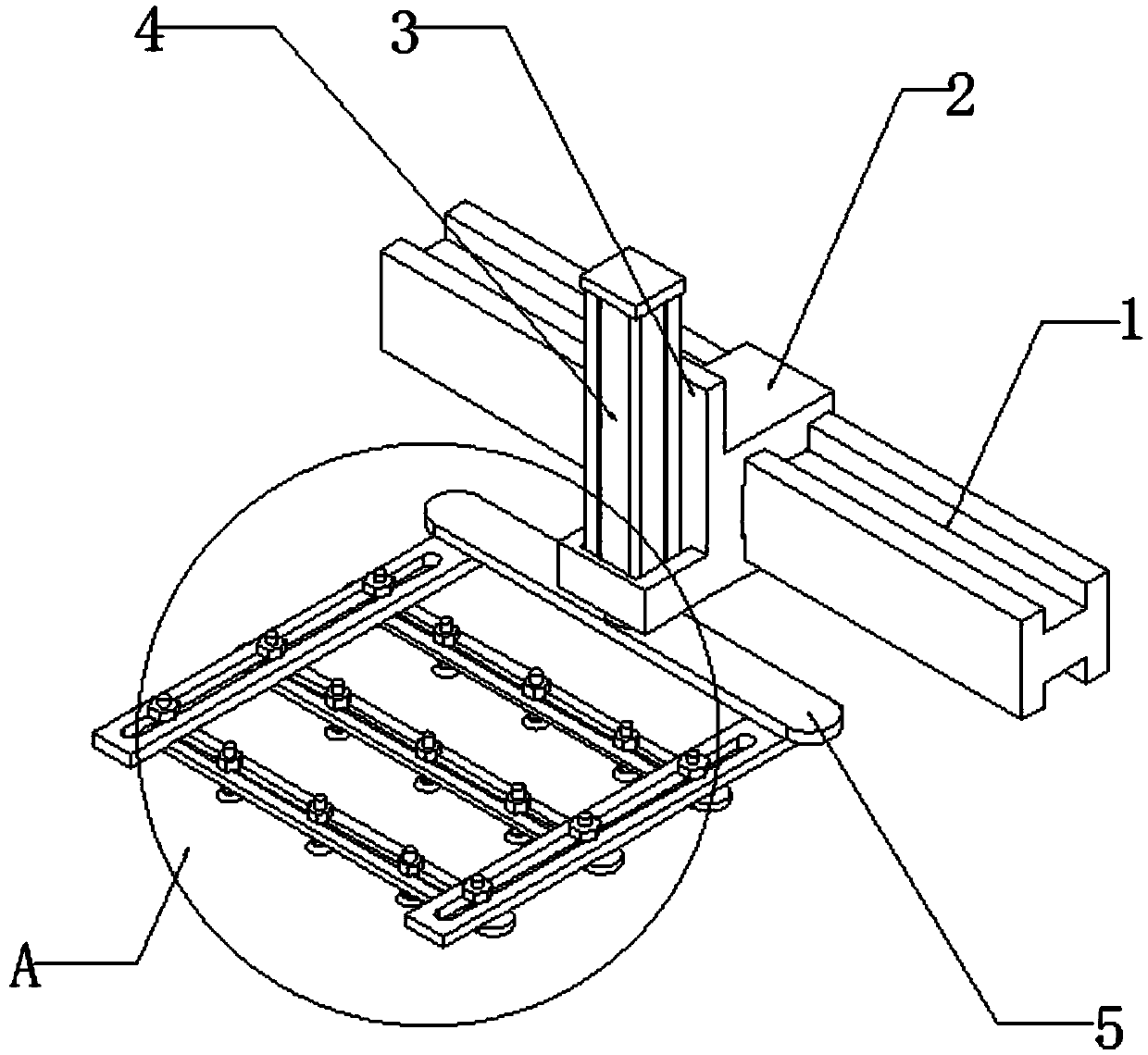

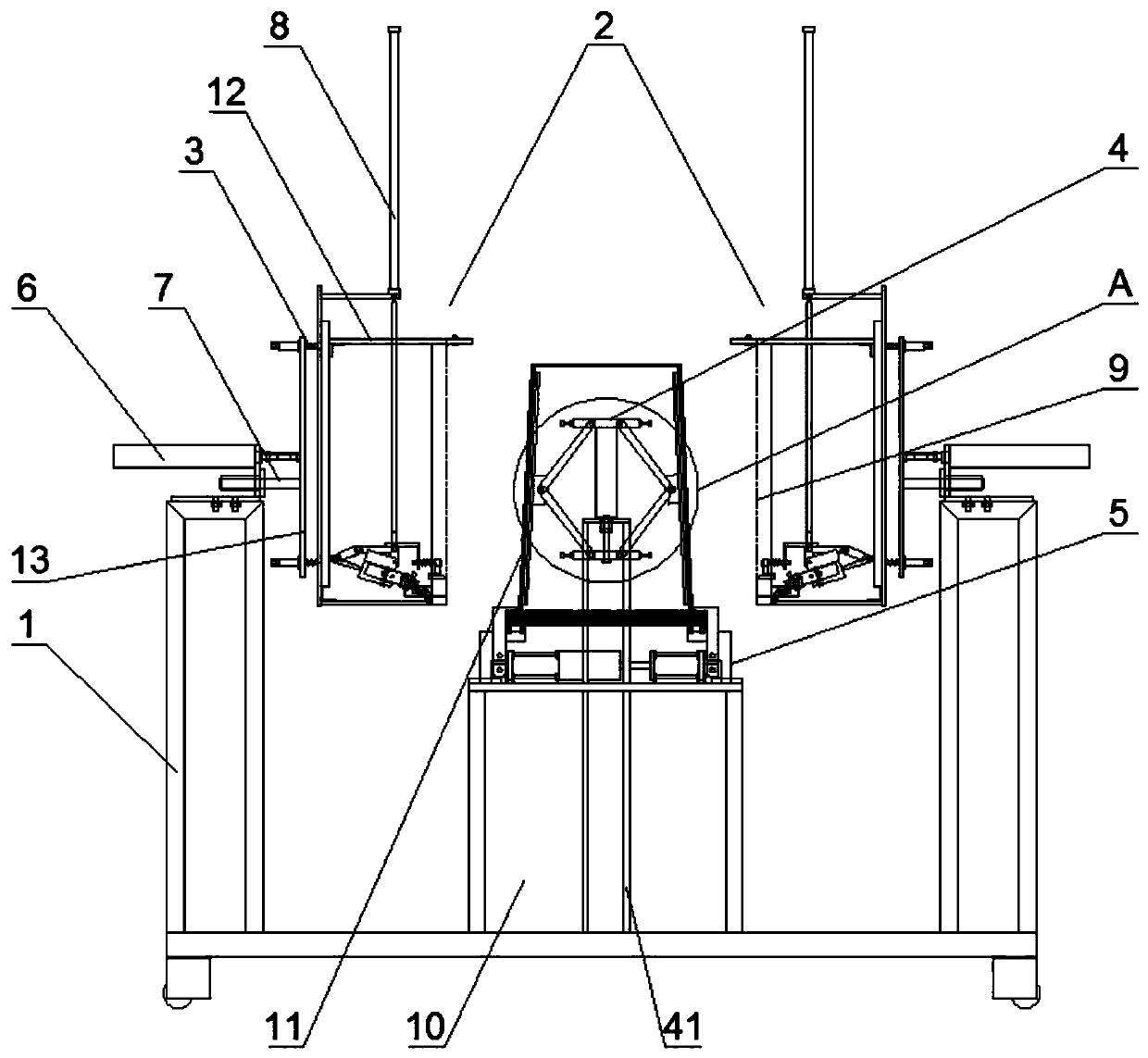

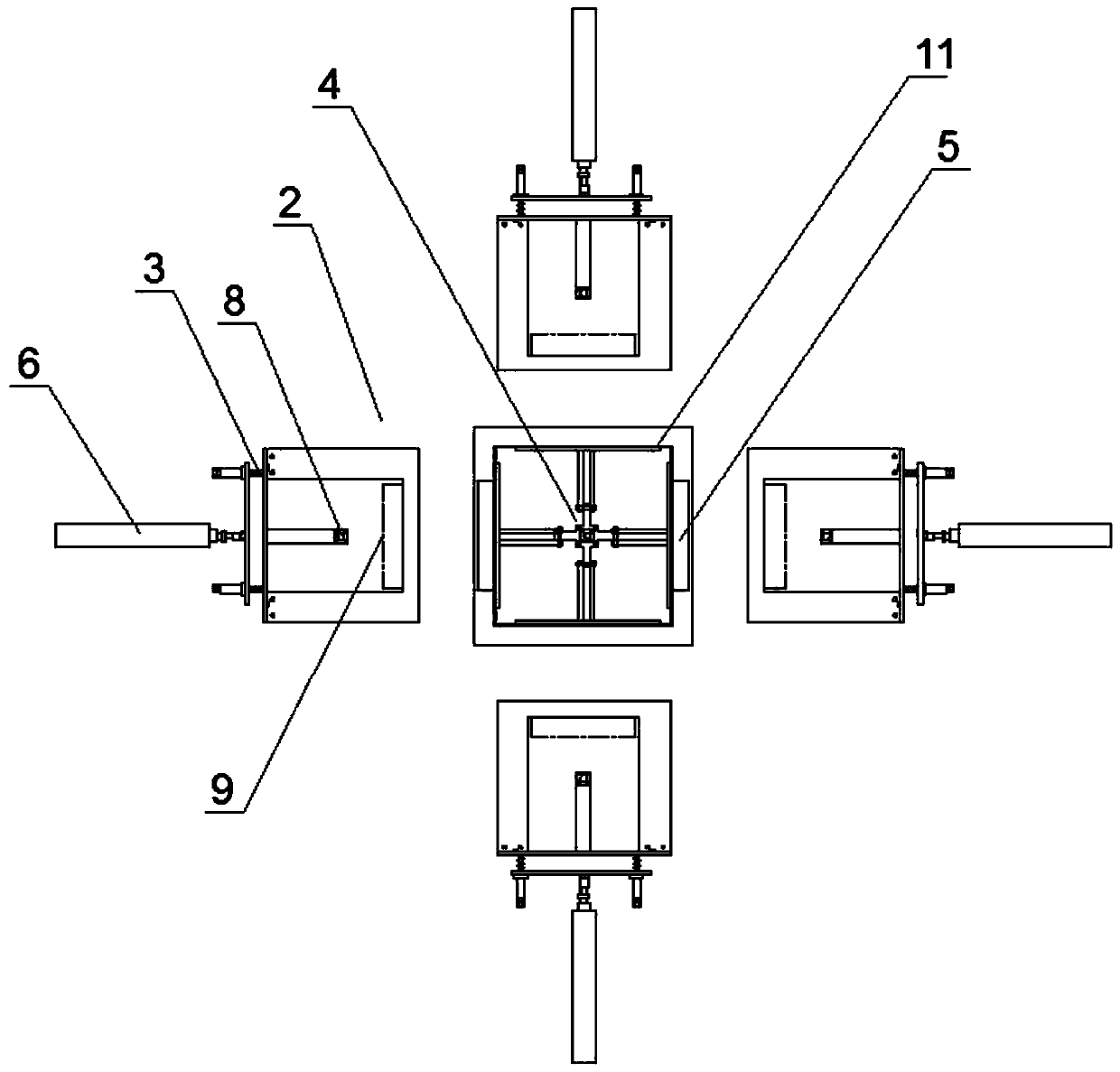

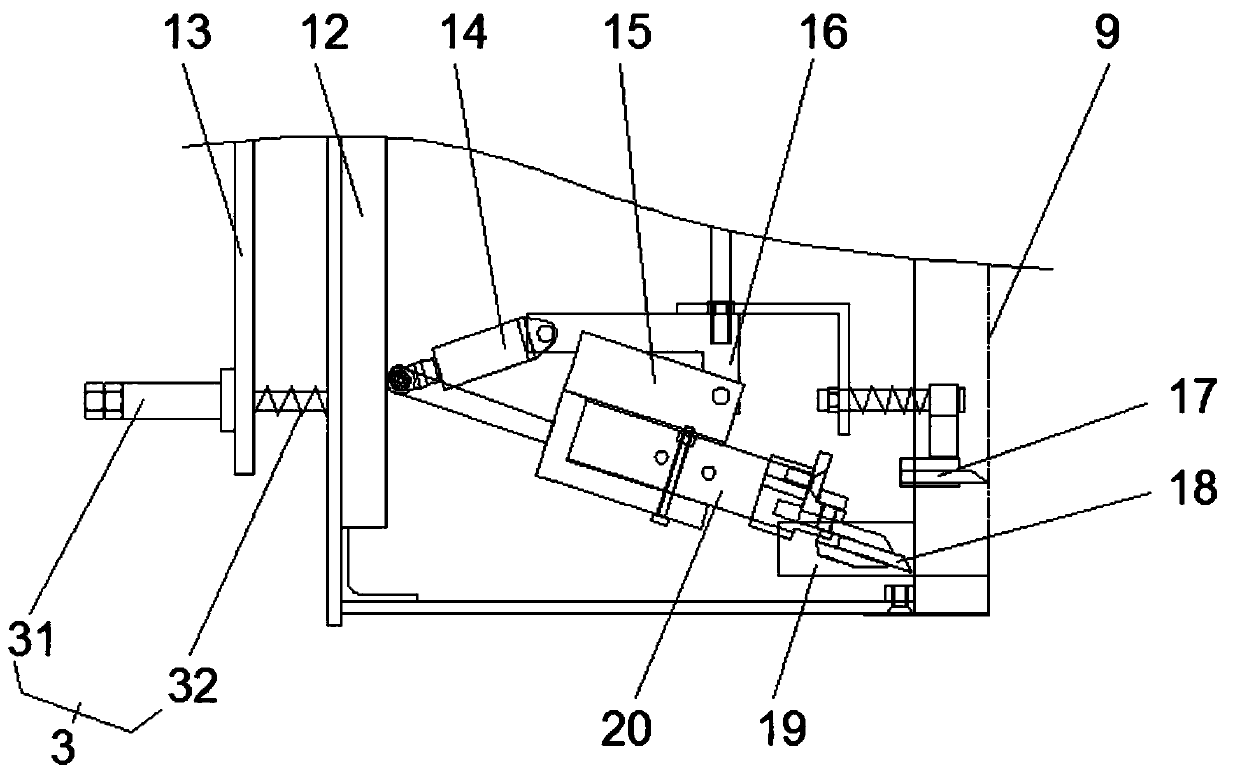

PendingCN110722359AEasy to assemble directlyAdjustable distanceOther manufacturing equipments/toolsMetal working apparatusPunchingTransformer

The invention discloses a transformer silicon steel sheet shearing and stacking machine, and relates to the technical field of transformer silicon steel sheet manufacturing equipment. An unwinding device, a supporting device and a conveying guide channel of the machine are sequentially connected, and the conveying guide channel is provided with a transverse shearing device, a V-shaped shearing device and a punching device. The conveying guide channel is connected with reverse suction and material arranging devices, and initial positioning devices and fine positioning devices are arranged on the lateral sides of the reverse suction and material arranging devices. Carrying devices are arranged above the initial positioning devices and the fine positioning devices, and a stacking table deviceis arranged between the fine positioning devices. The machine has the advantages that after silicon steel sheets are cut, the assembling process is directly started, the intermediate manual carryingand material arranging procedures are omitted, the labor intensity is reduced, few circulation links are needed, the damage to the silicon steel sheets is reduced, the placement time is short, rust isavoided, shearing, stacking and assembling are integrated, the production floor area is reduced, the energy consumption is reduced, the production efficiency is improved, corresponding distance adjustment can be carried out on silicon steel sheet iron cores with different specifications, and the application range is wider.

Owner:NANTONG SIRUI ENG

Method for producing ferrovanadium

The invention relates to a method for producing ferrovanadium, belonging to the technical field of metallurgy and aiming at solving the technical problem of providing a method which has lower production cost and is used for producing the ferrovanadium. The method for producing the ferrovanadium comprises the following steps of: a, mixing materials: uniformly mixing vanadium-containing raw materials, iron red powder, aluminum powder and CaO to obtain a mixed material, wherein the vanadium-containing raw material is at least one of ammonium poly-vanadate and ammonium metavanadate, the proportion by weight of the vanadium-containing raw materials in terms of vanadium to the iron red powder in terms of iron is 1: (0.16-0.26), the coefficient of mixed aluminum is 1.05-1.15, and the coefficientof the mixed CaO is 0.35-0.47; b, pelletizing: pelletizing the obtained mixed material, and drying pellets; and c, placing into a furnace for smelting: placing the dried pellets into the furnace, andsmelting till the mixed material is completely reacted; and d, taking out of the furnace to obtain the ferrovanadium.

Owner:PANZHIHUA UNIV

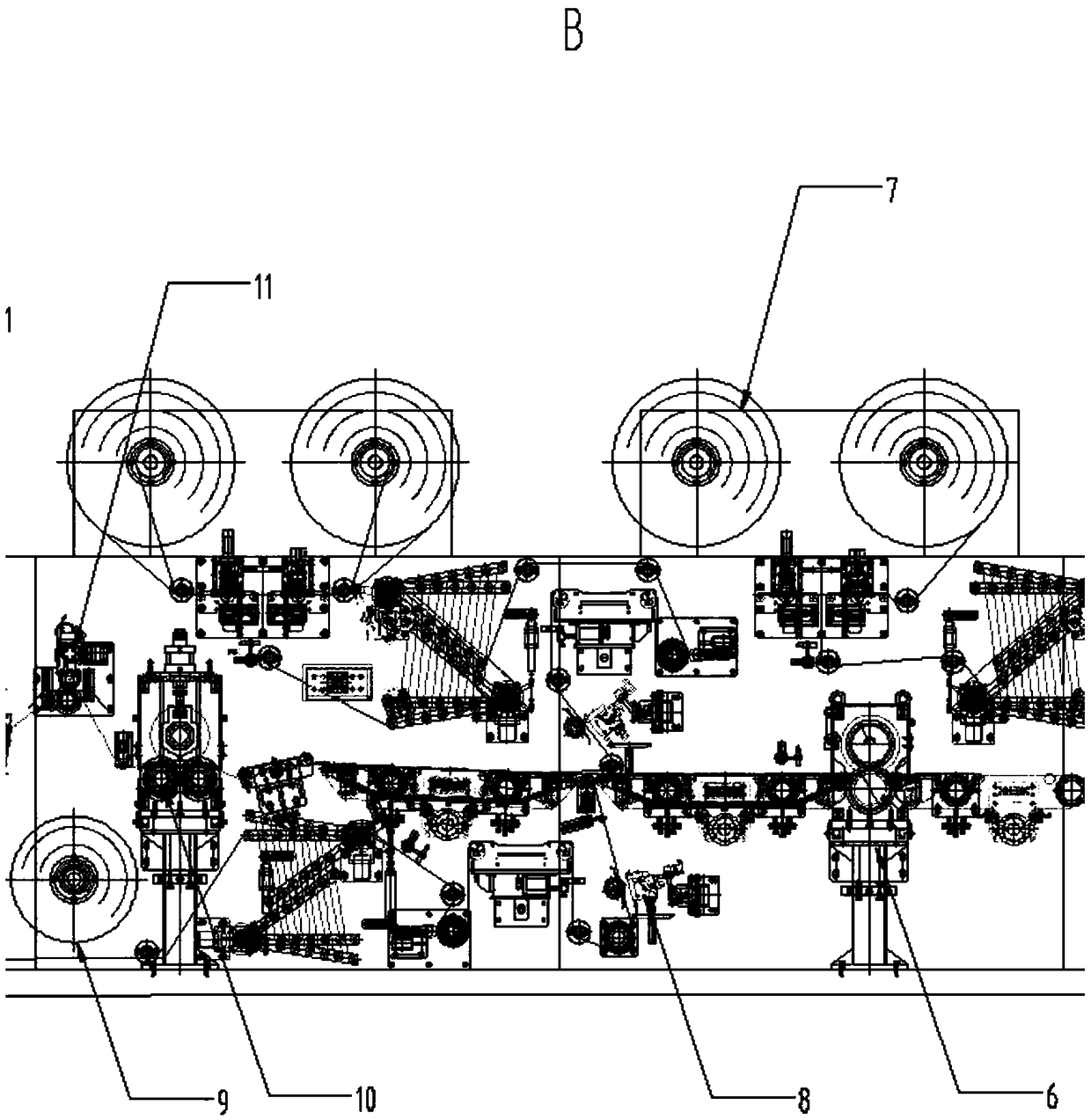

Double face printing apparatus and double face printing process

InactiveCN1880070AShort pathReduced production footprintRotary pressesOther printing apparatusEngineeringPlanet

The invention relates to a dual-surface printer, which comprises two planet printers, wherein the central compress rollers of printers are parallel mounted; there are two transverse bake channels above the printers; two bake layers are layered inside the bake stove. The invention can print without drying inter-color; and the paths of two times of drying can be reversed and layered, to shorten the base material path. And the invention also provides a relative printing method.

Owner:李新忠

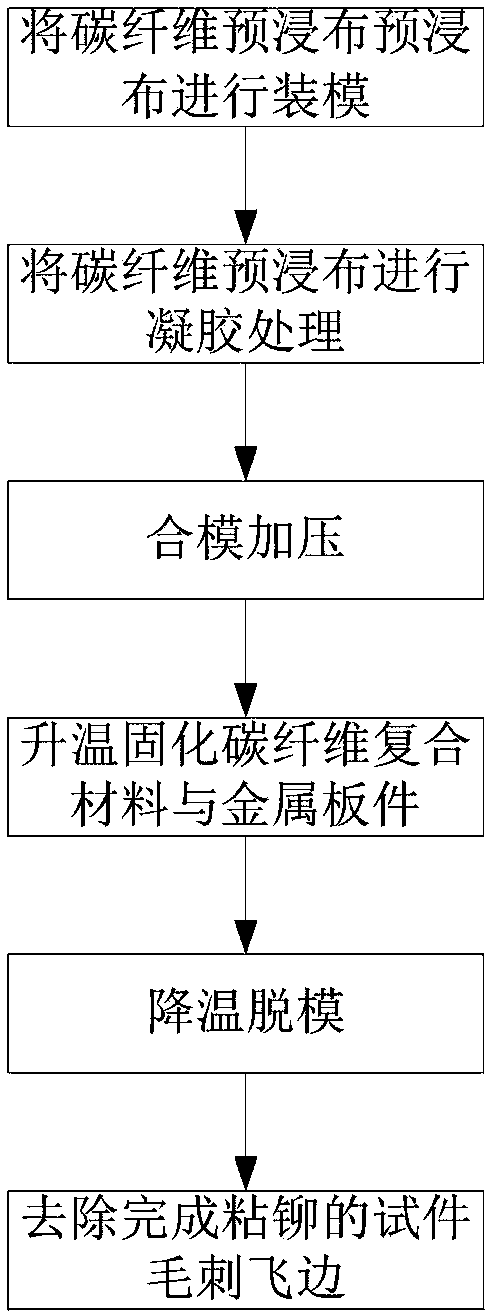

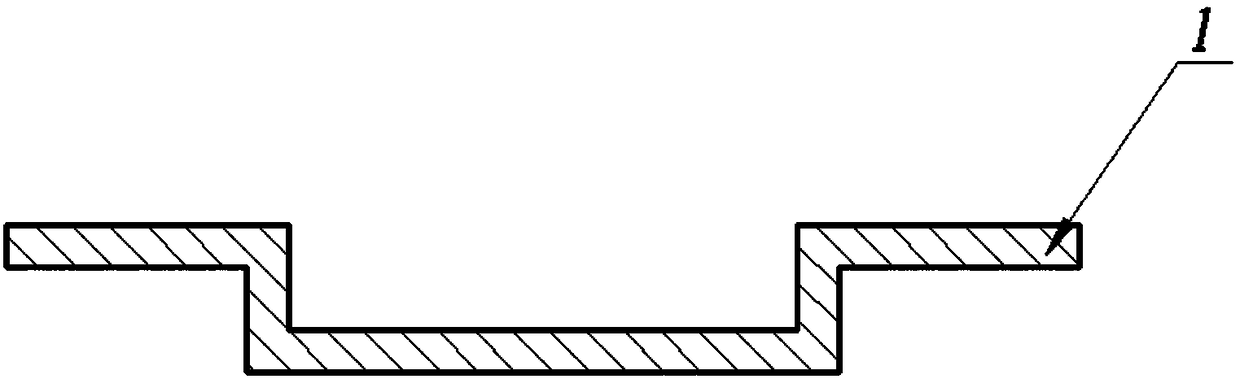

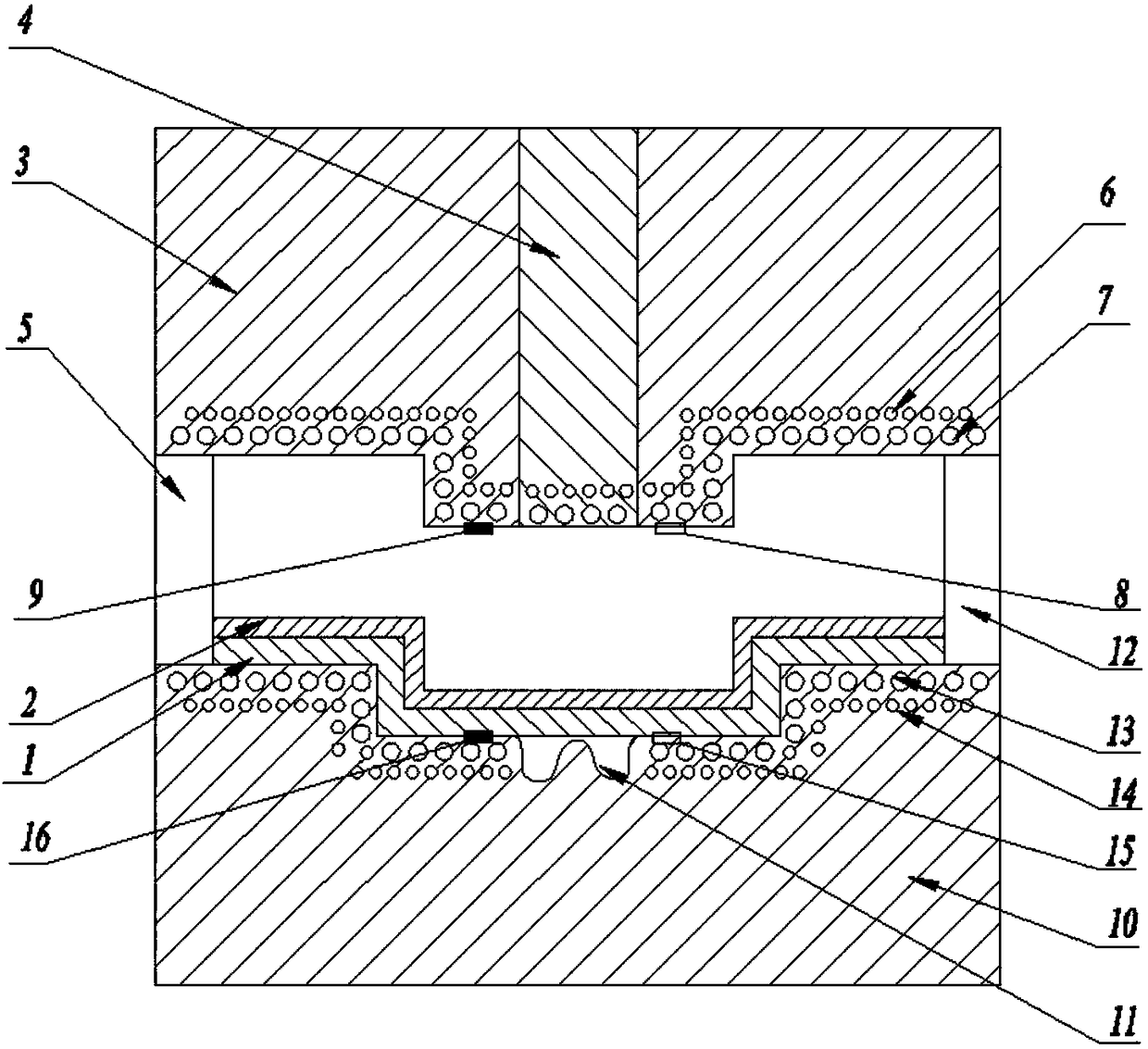

Integrated device and method for forming of carbon fiber composite material and sticky-riveting of carbon fiber composite material and metal sheet piece

PendingCN108297458ALow investment costReduced production footprintDomestic articlesWeight reductionCarbon fiber compositeBond properties

The invention relates to an integrated device and method for forming of a carbon fiber composite material and sticky-riveting of the carbon fiber composite material and a metal sheet piece, and belongs to the technical field of composite riveting. The technical problems that gaps exist in connecting of the composite material and a metal material, the composite material and an adhesive layer are damaged due to riveting, and the technology procedure is complicated exiting in the prior art are solved. The carbon fiber composite material and metal material sticky-riveting method applying the device comprises the following steps that a carbon fiber prepreg is subjected to die-filling; the carbon fiber prepreg is subjected to gelling; the gelled carbon fiber prepreg and a metal sheet are subjected to die-closing and pressurizing; the carbon fiber prepreg and the metal sheet piece are subjected to heating curing; cooling and die-releasing are conducted; and burrs and flashings at the edge parts when a carbon fiber composite material plate and a metal sheet sticky-riveting test piece are formed are removed. According to the integrated device and method for forming of the carbon fiber composite material and sticky-riveting of the carbon fiber composite material and the metal sheet piece, the effect that bonding can be completed while the carbon fiber composite material is subjected to die-pressing forming is achieved; and the bonding property is effectively improved, and the bonding strength is improved.

Owner:JILIN UNIV

Full-automatic vertical-surface screen printing machine and multi-surface printing process thereof

PendingCN110450525AReduce labor intensityGuaranteed printing effectScreen printersOther printing apparatusScreen printingUltimate tensile strength

The invention discloses a full-automatic vertical-surface screen printing machine and a multi-surface printing process thereof, and relates to the field of screen printing. The full-automatic vertical-surface screen printing machine specifically comprises a machine frame, wherein the peripheral sides of the upper surface of the machine frame are provided with screen plate assemblies for printing aworkpiece so that printing work can be carried out on the surface of the workpiece through the screen plate assemblies; and the middle of the upper surface of the machine frame is fixedly connected with a supporting platform, wherein a clamping and positioning mechanism for clamping and fixing the workpiece and an expansion shaping mechanism for flattening the workpiece through expansion are sequentially arranged above the supporting platform. According to the full-automatic vertical-surface screen printing machine and the multi-surface printing process thereof, a printing manner is designedas vertical surface printing so that multiple surfaces of one product can be simultaneously printed, thus greatly improving production efficiency and reducing labor intensity of operators as well as occupied areas for production; and meanwhile, through cooperation of a self-fitting mechanism, the expansion shaping mechanism and the clamping and positioning mechanism, printing steps are simplified,and the printing effect of the product is improved.

Owner:湖北天佳日用品有限公司

Method for preparing high-and-middle-class ceramic kaolin from kaolin scavenging tailings

InactiveCN110304898AHigh firing whitenessHigh plasticity indexClaywaresMagnetic separatorKaolin clay

The invention provides a method for preparing high-and-middle-class ceramic kaolin from kaolin scavenging tailings. The method comprises the steps: performing selective ball milling by using a ball mill firstly, then performing water grading and sorting by using hydrocyclones of different diameters, then using a high-gradient magnetic separator to remove magnetic materials, performing ultrafine grinding and stripping by using a grinding stripping machine finally, and then performing dehydration treatment so as to obtain the high-and-middle-class ceramic kaolin. The kaolin scavenging tailings is purified by using the method, the content of Al2O3 is increased, and the content of Fe2O3 is reduced, so that the obtained kaolin has high calcination whiteness at 1280 DEG C and a high plasticity index, and requirements of high-and-middle-class ceramics for kaolin are met. The method has small production occupied space, low cost, a large processing capacity, high production efficiency and a high degree of automation.

Owner:LONGYAN KAOLIN CLAY

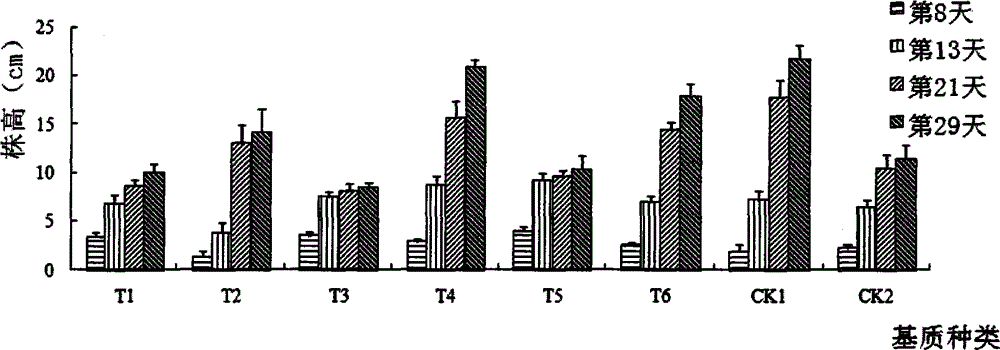

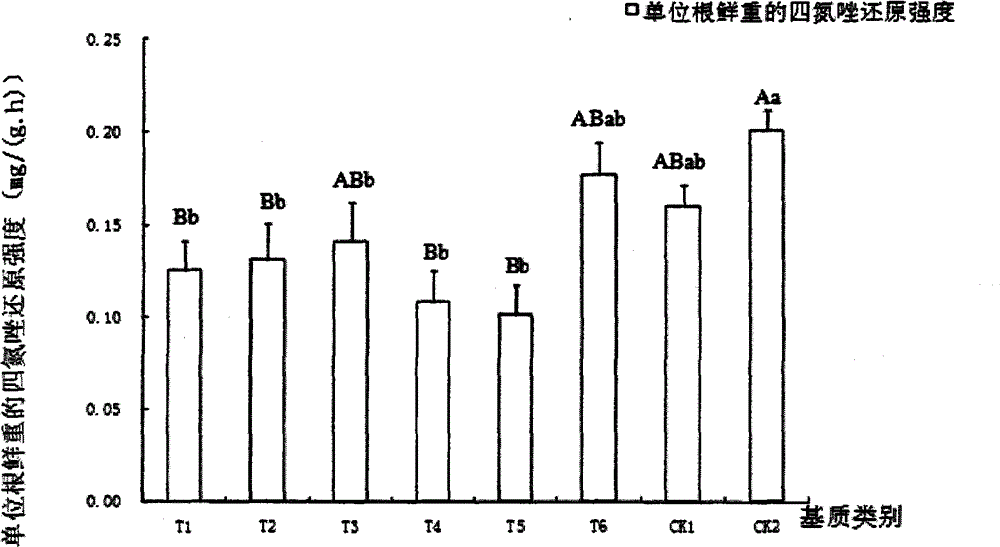

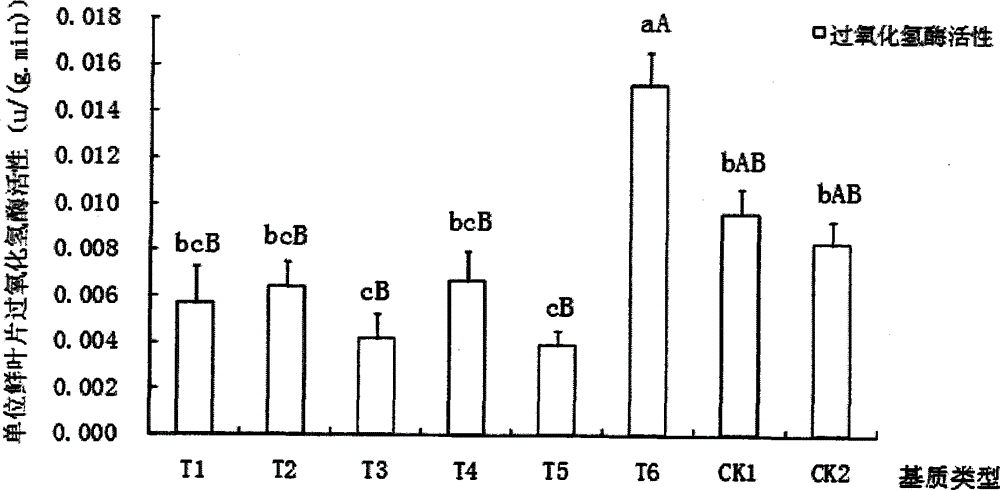

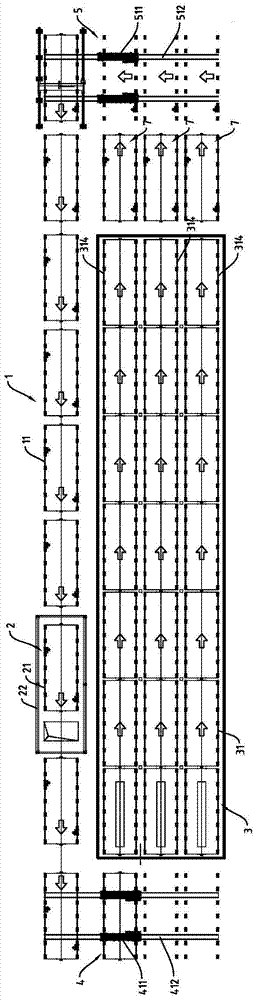

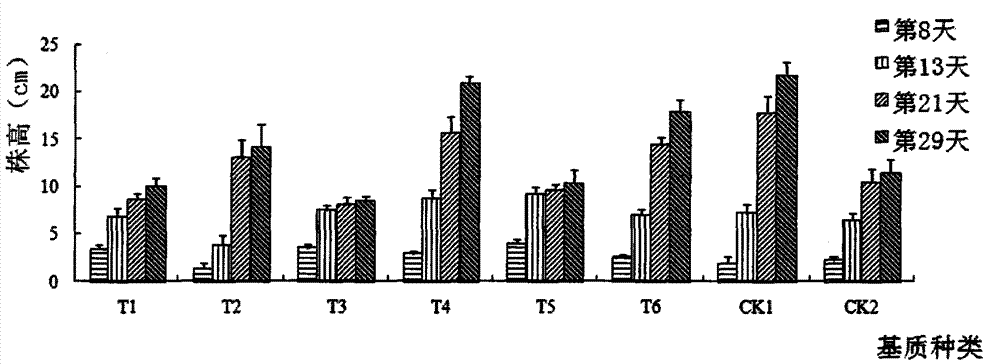

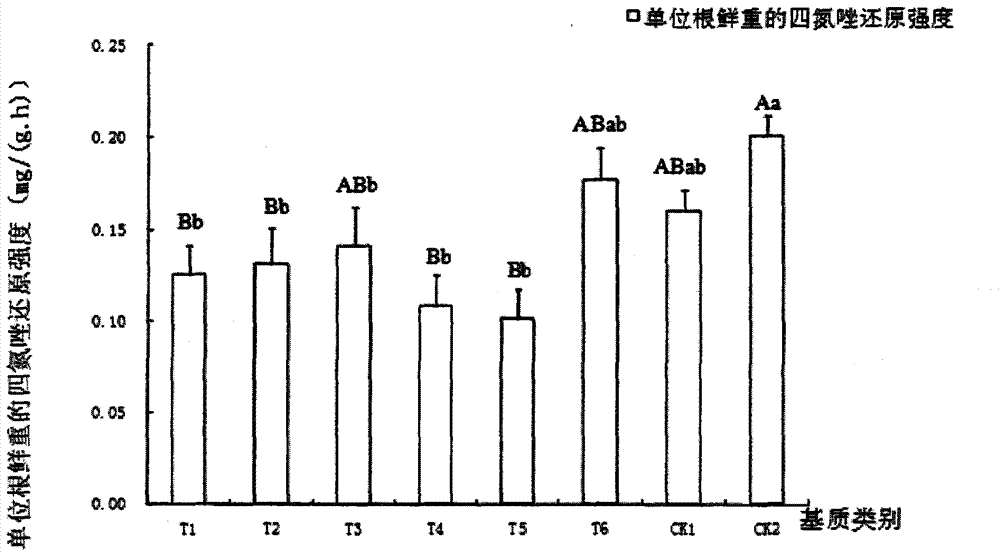

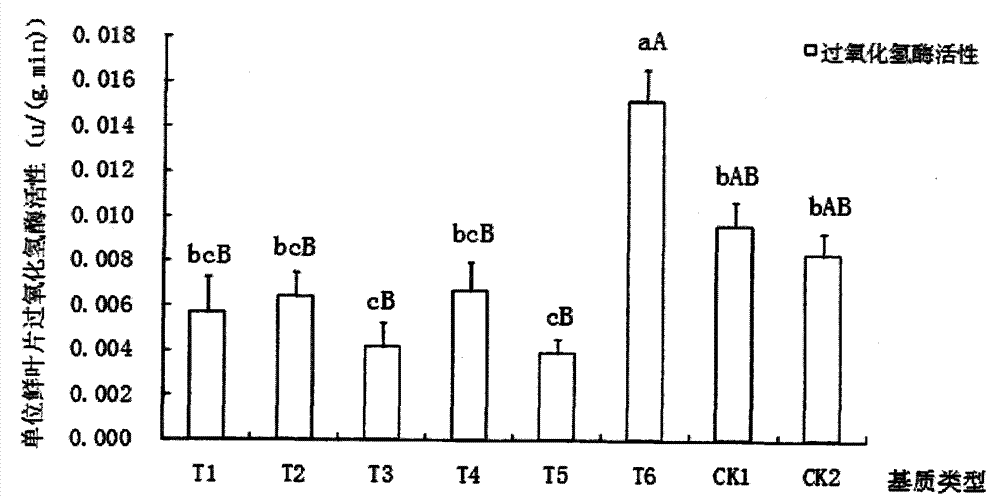

Lawn produced from municipal sludge compost mixed matrixes and preparation method thereof

InactiveCN104145669AAvoid scratchesReduce transpirationHorticultureFertilizer mixturesSludge compostIsolation layer

The invention discloses a lawn produced from municipal sludge compost mixed matrixes and a preparation method of the lawn. The preparation method comprises the following steps that air-dried decomposed coarse municipal sludge compost is selected for screening, and the grain diameter of the screened compost ranges from 2 mm to 5 mm; the compost is mixed with any two of rice chaff, vermiculite and perlite, and the mixture is stirred evenly to obtain the mixed matrixes; the land is leveled; insecticide is sprayed; an isolation layer is laid; the isolation layer is evenly covered with the mixed matrixes; grass seeds are evenly sown and are covered with the mixed matrixes for 0.5 cm after seeding is completed; the mixed matrixes are covered with a sunshade net. By means of the preparation method, the quality of the lawn can be improved, production cost and planting cost can be lowered, and land and water resources can be saved; moreover, the water control effect can be consolidated, energy conservation and emission reduction can be promoted, a large amount of excess sludge generated in the sewage disposal process can be effectively eliminated, pressure from gradual deficiency of garden matrixes and unstable sources can be relieved, and therefore the preparation method is a sustainable sludge recycling method with extremely high application value.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

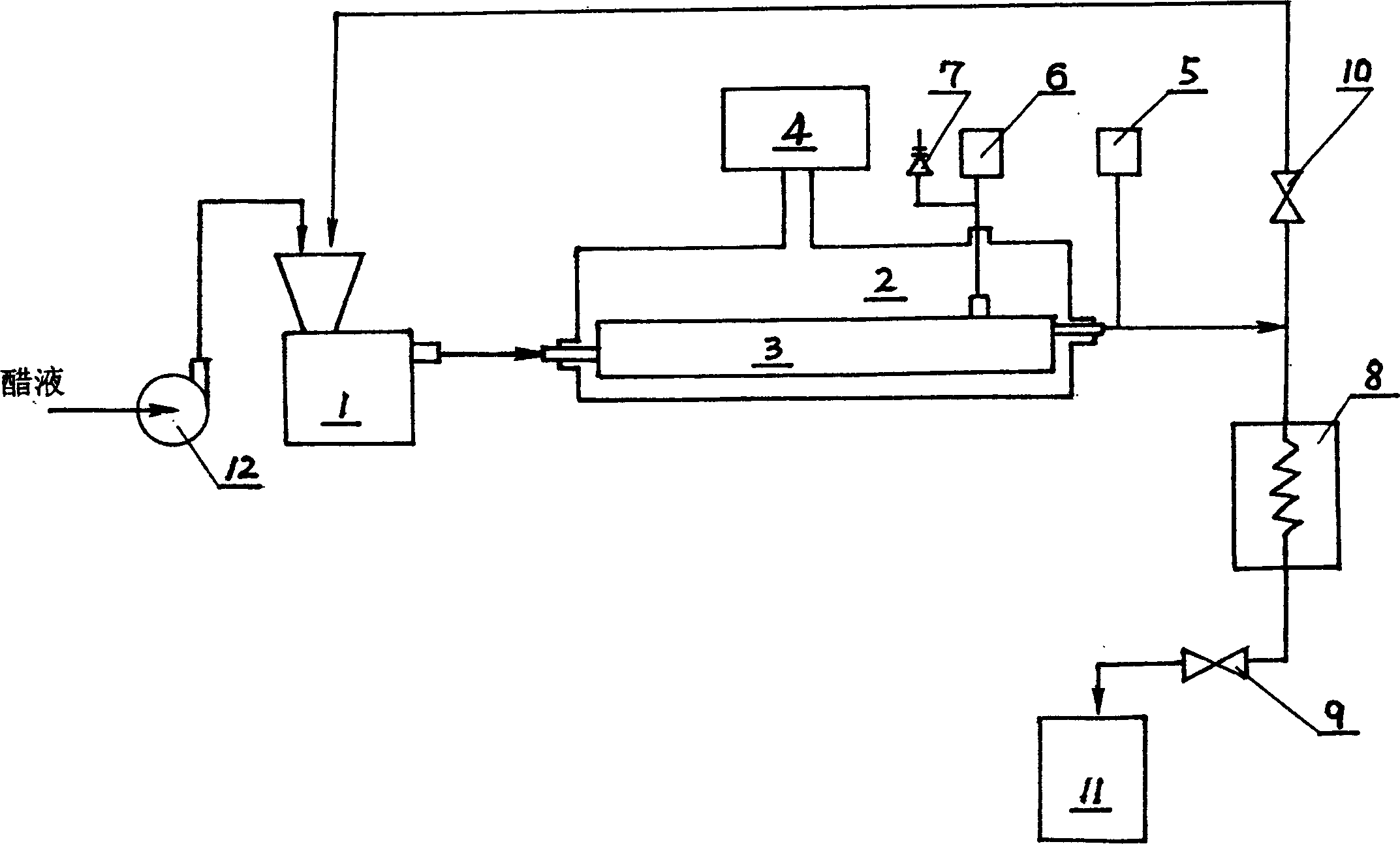

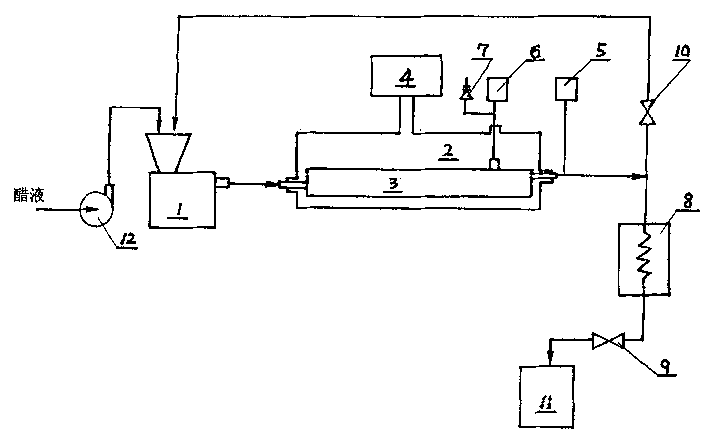

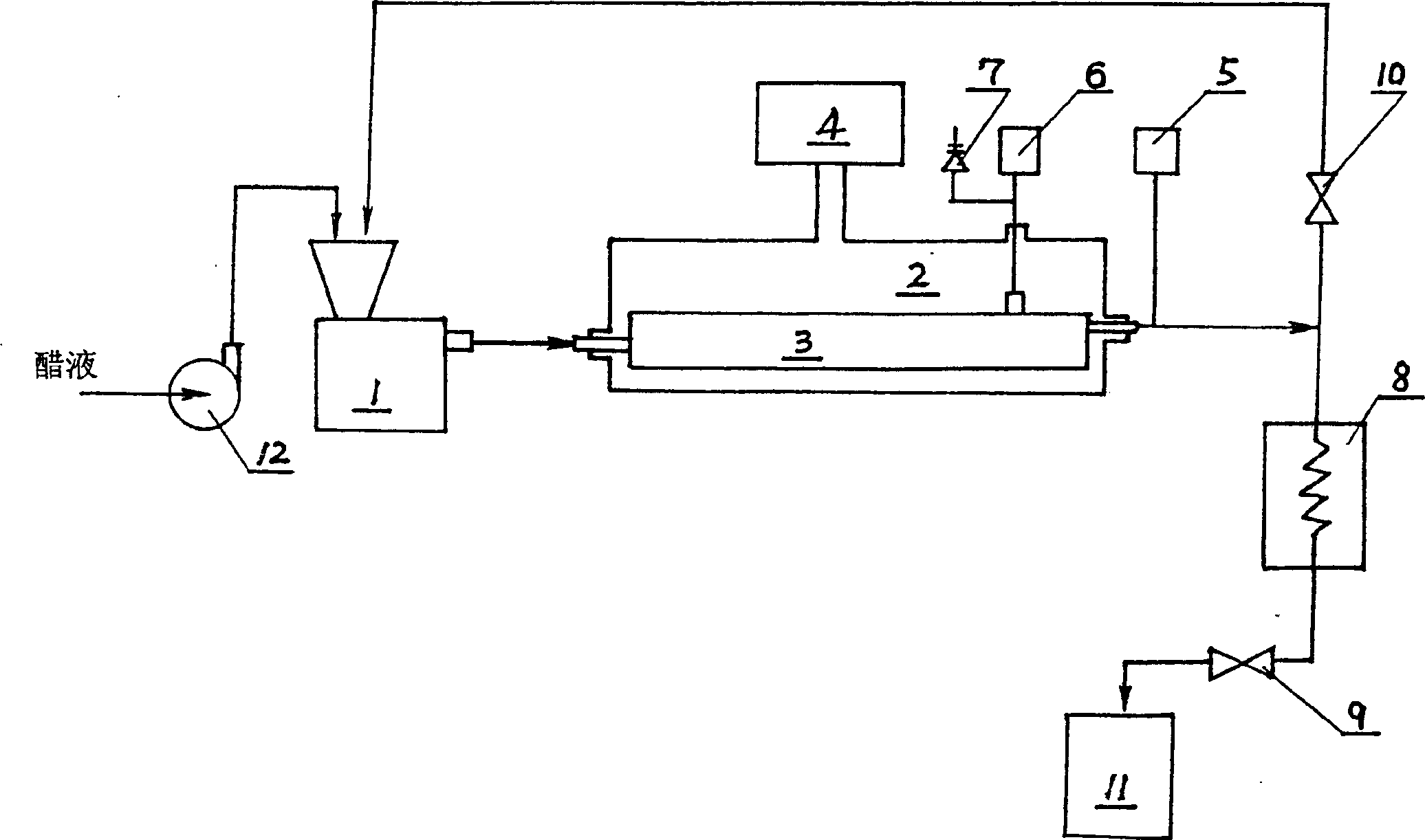

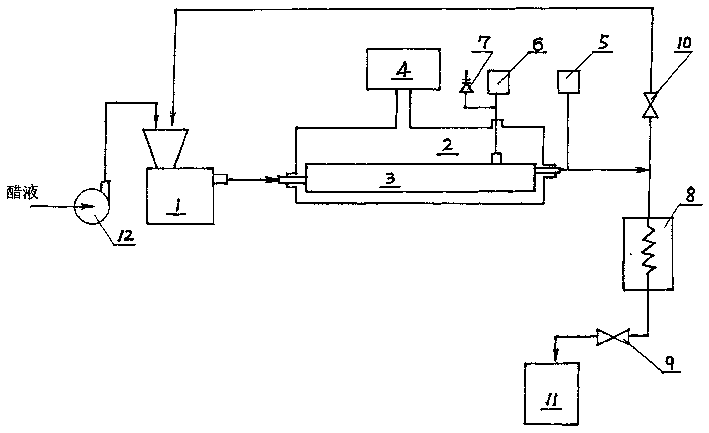

Maturing method of edible vinegar and its equipment

InactiveCN1460707AImprove qualityShorten the production cycleVinegar preparationIt equipmentMicrowave oven

The ageing method of edible vinegar includes the following steps: high-pressure homogenizing the edible vinegar at above 12 MPa, microwave irradiating it in microwave reactor and heating it to 55-98 deg.C, making it flow into cooling device, cooling, decompressing and collecting product. Its equipment for implementing said method includes high-pressure homogenerating machine, microwave oven, microwave reactor and cooling device.

Owner:SHANXI UNIV

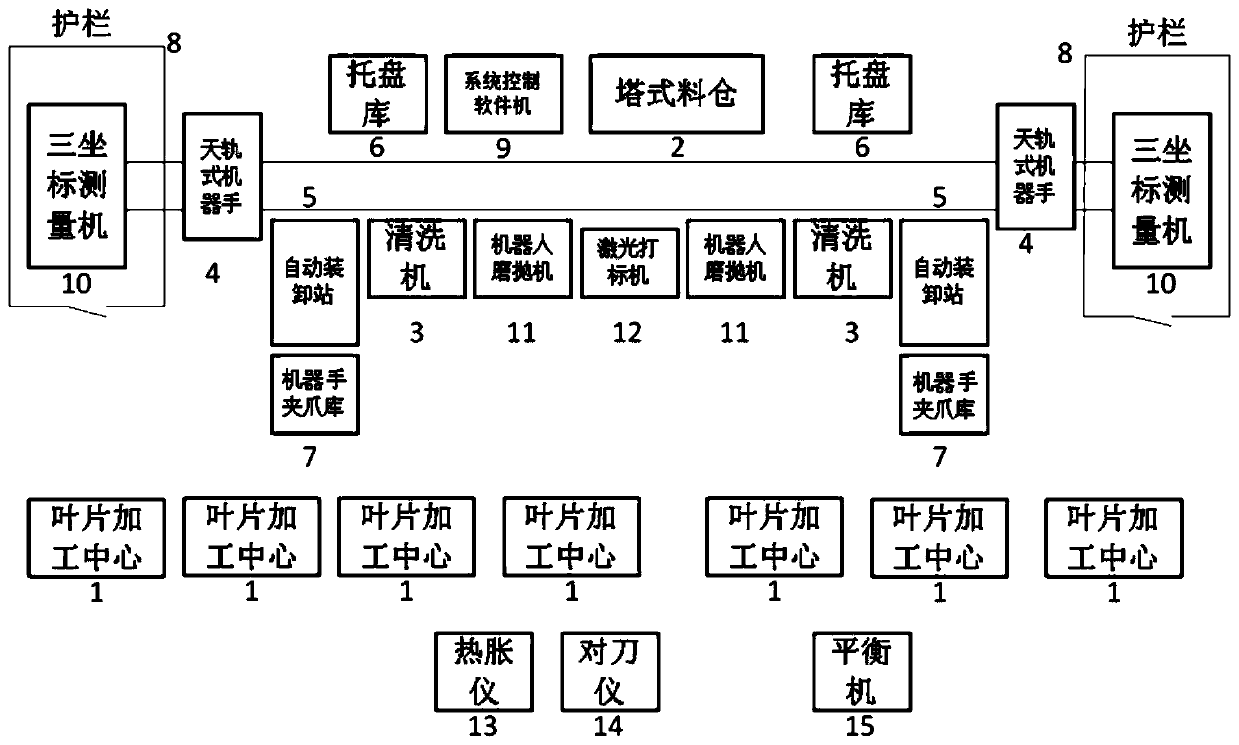

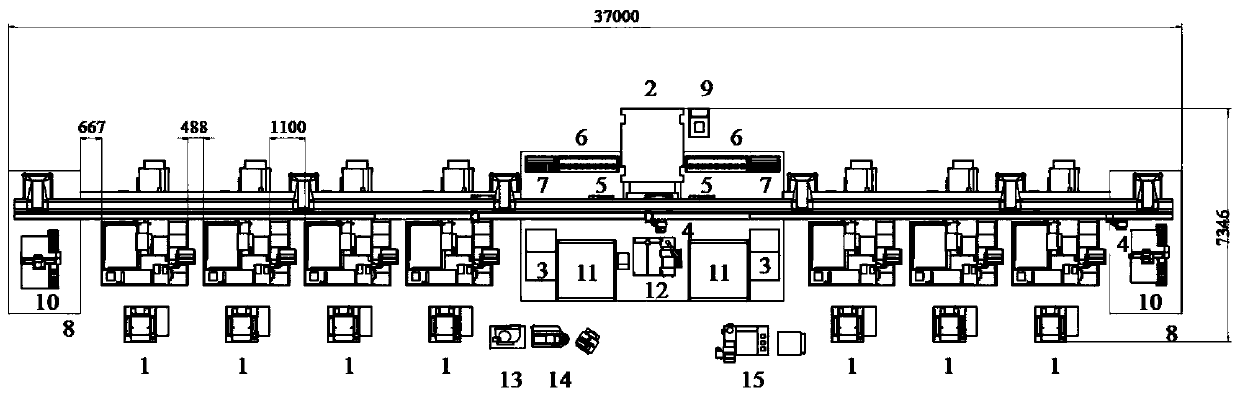

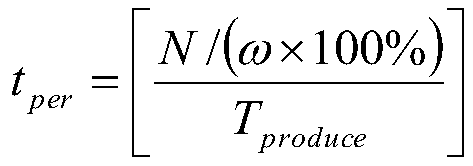

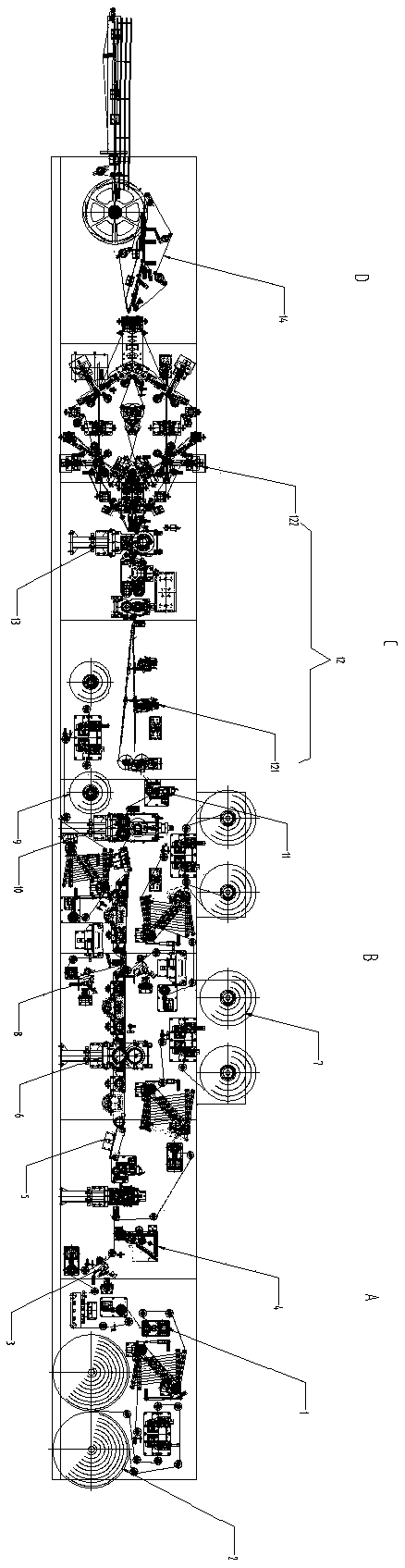

Digital full-automatic production line design method for gas compressor blades

ActiveCN110936174AImprove labor productivityImprove product qualityOther manufacturing equipments/toolsIndustrial engineeringAutomatic processing

The invention provides a digital full-automatic production line design method for gas compressor blades. The digital full-automatic production line design method comprises the following steps that firstly, it is determined that a technology that the blades are mainly processed by using a milling and turning combined technology is used as a main technological process, and corresponding equipment isselected according to the technological process; storage and logistics conveying equipment required by the automation replacement scheme of the process is determined; the production tact is determined according to the product productivity requirement; a production line body planning layout is made; a production line production debugging test is carried out; the production line capacity is comprehensively evaluated; the production line is optimized; and production line production is carried out, and production tasks are formally executed in batches. By applying the method, the gas compressor blade digital production line can be designed, automatic loading and unloading, automatic processing, detection and grinding and polishing of the whole process of the gas compressor blades are achieved, and unmanned intervention in the line is achieved; and the problem of mixed line control of the production plan is solved, and multiple different blades can be processed at the same time according to the production tasks and orders.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

PC (poly carbonate) wall board production system

The invention discloses a PC (poly carbonate) wall board production system, which comprises an operation region, a casting region and a caring region, wherein the caring region is in parallel arrangement with the operation region and the casting region, the operation region comprises an operation rail, the casting region comprises a conveying rail and a casting device, the casting device is arranged above the conveying rail and is used for casting a PC wall board, the caring region comprises at least one caring rail and a steam caring kiln, the caring rail supports a cast PC wall board mold to move on the caring rail, and the steam caring kiln is arranged at the front section of the caring rail. When the technical scheme is implemented, through the parallel arrangement of the operation region, the casting region and the caring region and through the flowing of the PC wall board mold in the operation region, the casting region and the caring region, the flow line production is formed, so that during the still caring of the PC wall board, the casting region can still carry out casting operation, and the production efficiency is greatly improved.

Owner:彭传森 +1

Double-face printing equipment and double-face printing process

InactiveCN106671565ANo need to dryShort pathRotary lithographic machinesSatelliteElectrical and Electronics engineering

The invention relates to double-face printing equipment which comprises two satellite type printing units. Installation directions of center compression rollers of the two satellite type printing units are parallel; and two drying tunnels with the walking direction being the transverse direction are arranged above the two satellite type printing units, are stacked vertically, and are arranged inside one drying box. By means of the double-face printing equipment, double-face satellite type printing can be carried out without between-color drying, the directions of routes of two times of drying can be opposite, the positions of the routes of two times of drying can be vertically stacked, the advancing route of a base material in the printing process is short, and the floor area of production can be saved. The invention further provides a double-face printing process using the above equipment.

Owner:重庆市鹏程印务有限公司

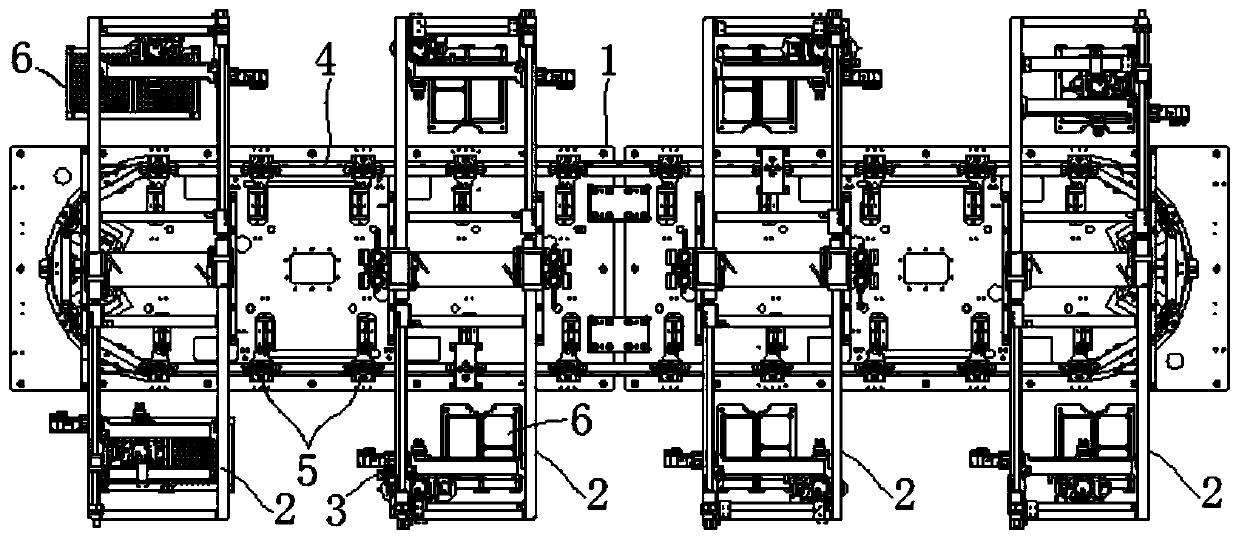

Lens assembling machine

PendingCN110421348AReduced production footprintIncrease productivityAssembly machinesSmall footprintEngineering

The invention relates to the technical field of assembly machines, in particular to a lens assembling machine. The lens assembling machine comprises a track table surface, wherein the track table surface is provided with a track; the track is annular and composed of a plurality of sections, wherein the track is configured with a plurality of stations, and the track is slidably provided with a movable seat; and the track table surface is provided with a portal frame, wherein the portal frame is provided with an X-axis, an Y-axis and a vacuum suction pen assembly, and the vacuum suction pen assembly is hung upside down on the portal frame. During the production of a product, the lens assembling machine can move along the track and carry out production operation in different stations, so thatoccupied area is small, the production efficiency is greatly improved, and meanwhile adverse effect caused by movement can be reduced.

Owner:东莞市泰诚光电有限公司

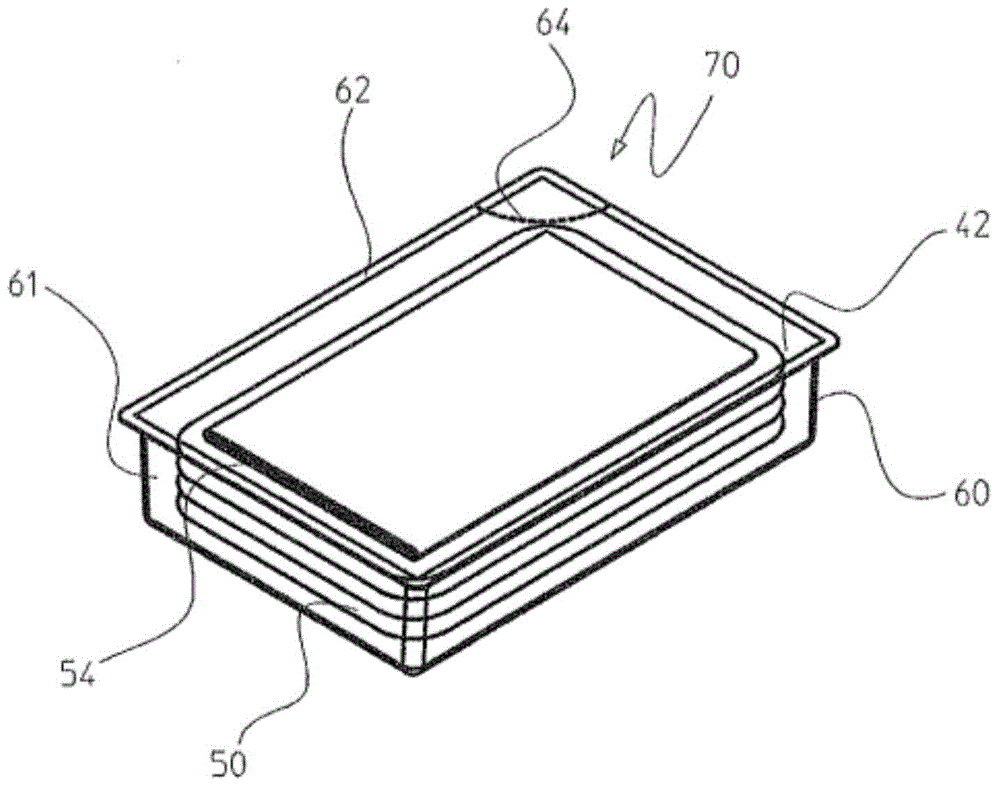

Device for producing a packaging for tablet

InactiveCN104554844AEasy to produceLow costPharmaceutical containersMedical packagingBlister packBlisters

Owner:UHLMANN PAC SYST

Maturing method of edible vinegar and its equipment

InactiveCN1200093CImprove qualityShorten the production cycleVinegar preparationIt equipmentMicrowave oven

Owner:SHANXI UNIV

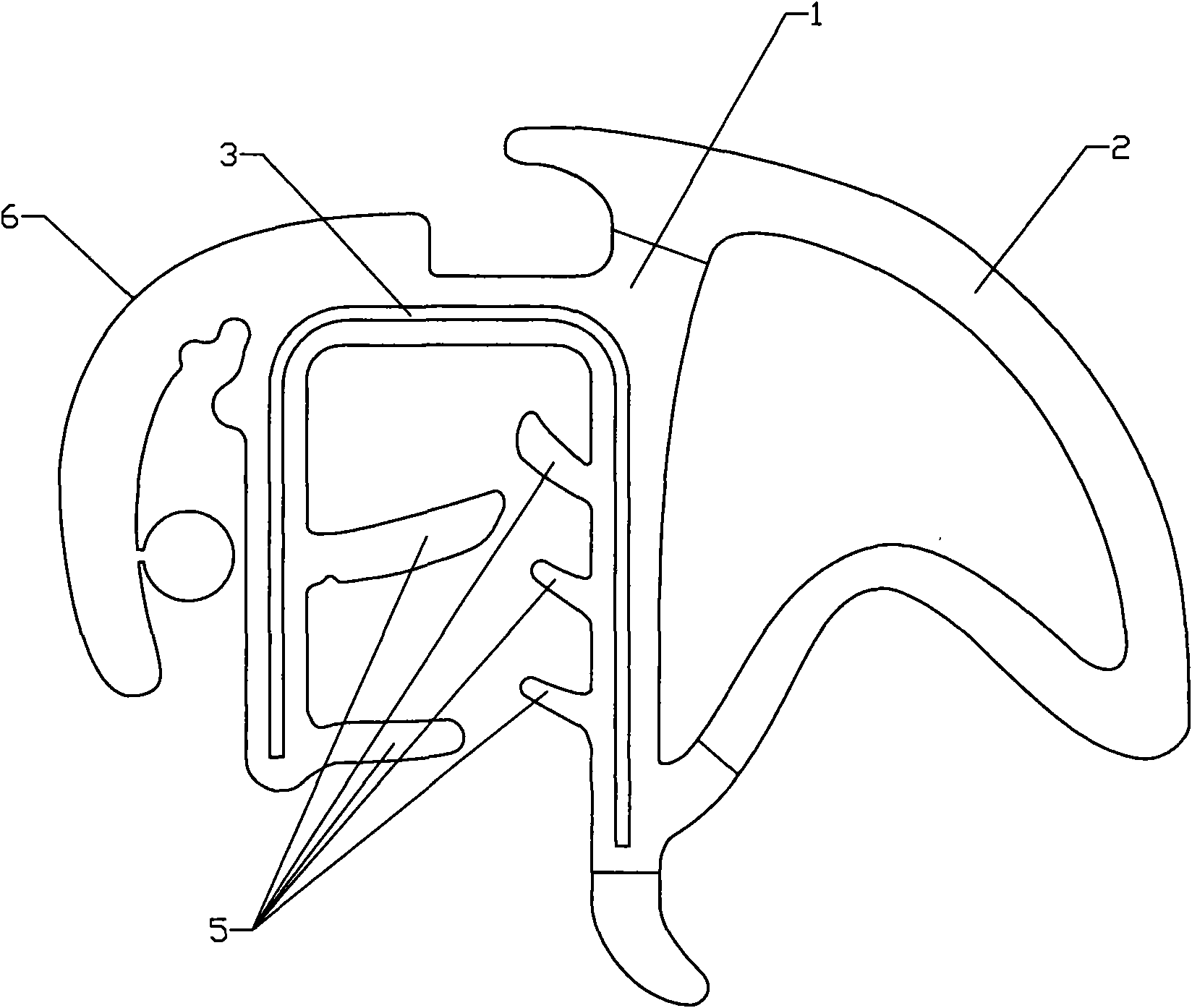

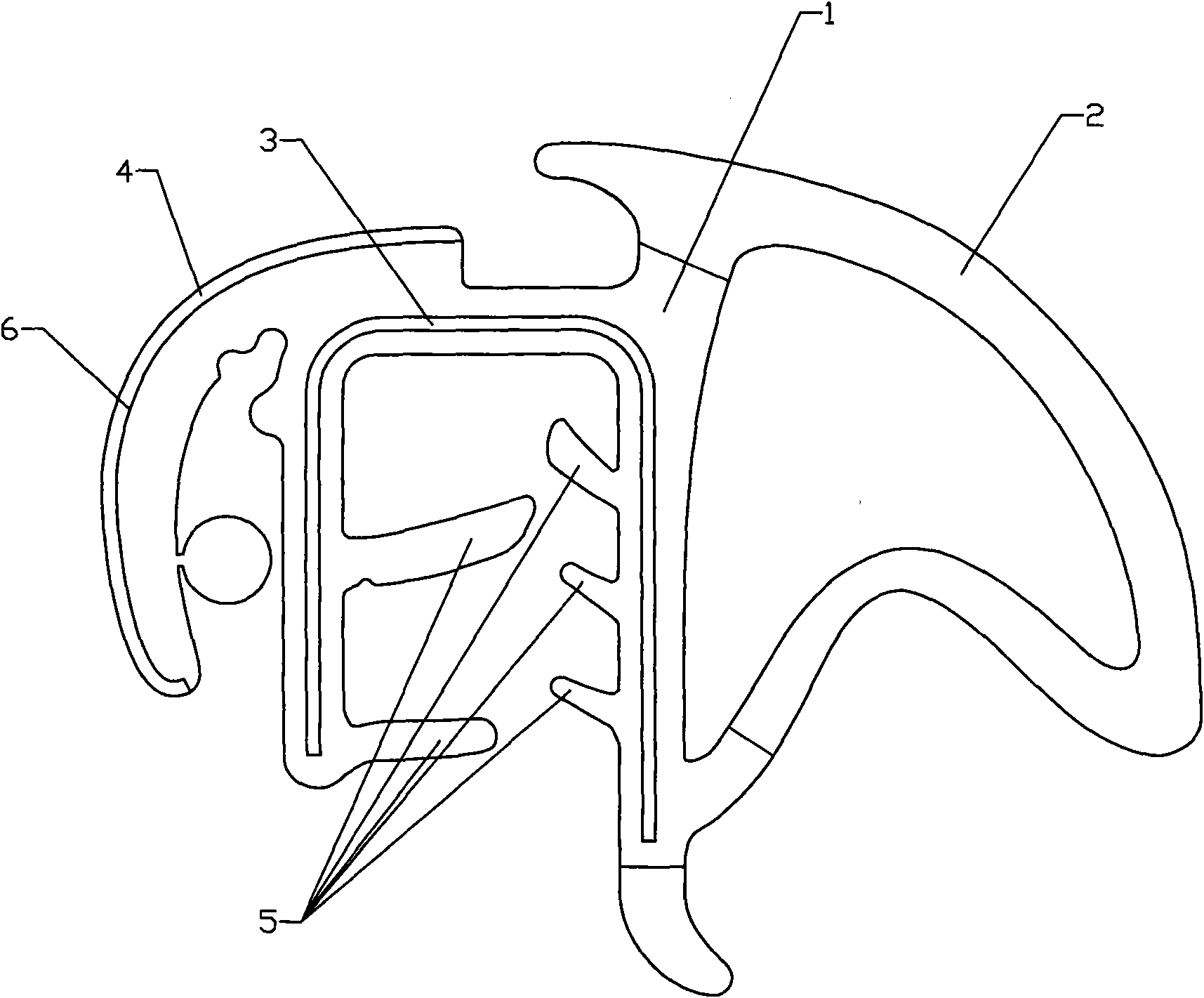

Sealing strip for door frame of automobile and manufacturing process thereof

ActiveCN101643019AShorten the lengthFew stepsEngine sealsVehicle sealing arrangementsProduction lineManufacturing engineering

The invention provides a sealing strip for the door frame of an automobile and a manufacturing process thereof. The sealing strip comprises a clamping part and a sealing part connected with the clamping part, wherein an exterior trimming layer is arranged on the outer surface of the clamping part, which is close to the interior part of the automobile, and bonded and coated with the exterior trimming layer. The manufacturing process comprises the following steps: (1) vulcanizing the outer surface of clamping part of the molded sealing strip body, which is exposed to the interior part of the automobile; and (2) bonding and coating the vulcanized outer surface with the exterior trimming layer. The sealing strip and the manufacturing process thereof provided by the invention has the advantagesof fewer steps, short production line, high production efficiency, low energy consumption, small production area, clean and pollution-free production and low rejection rate.

Owner:HENNIGES (CHINA) AUTOMOTIVE SEALING SYST CO LTD

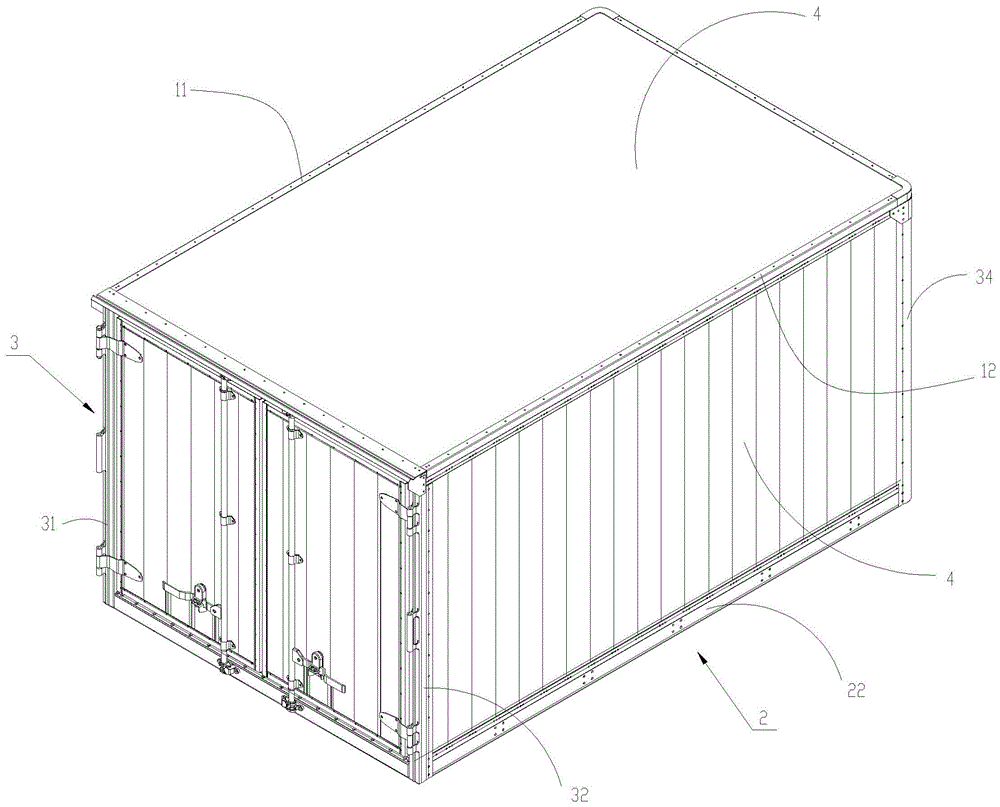

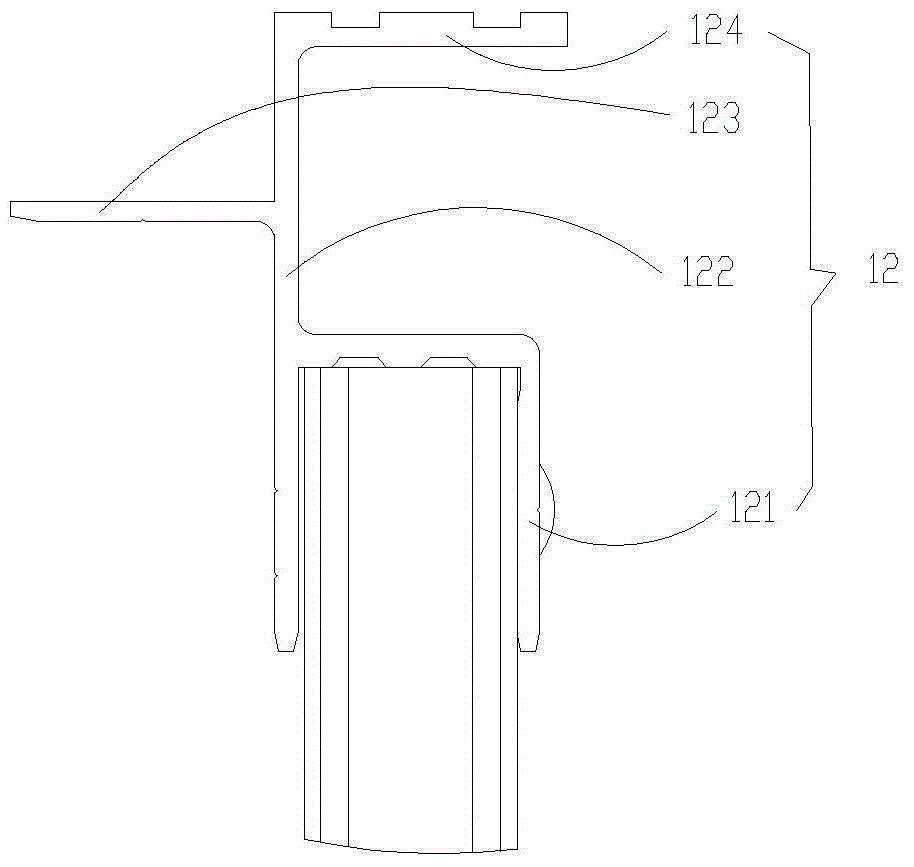

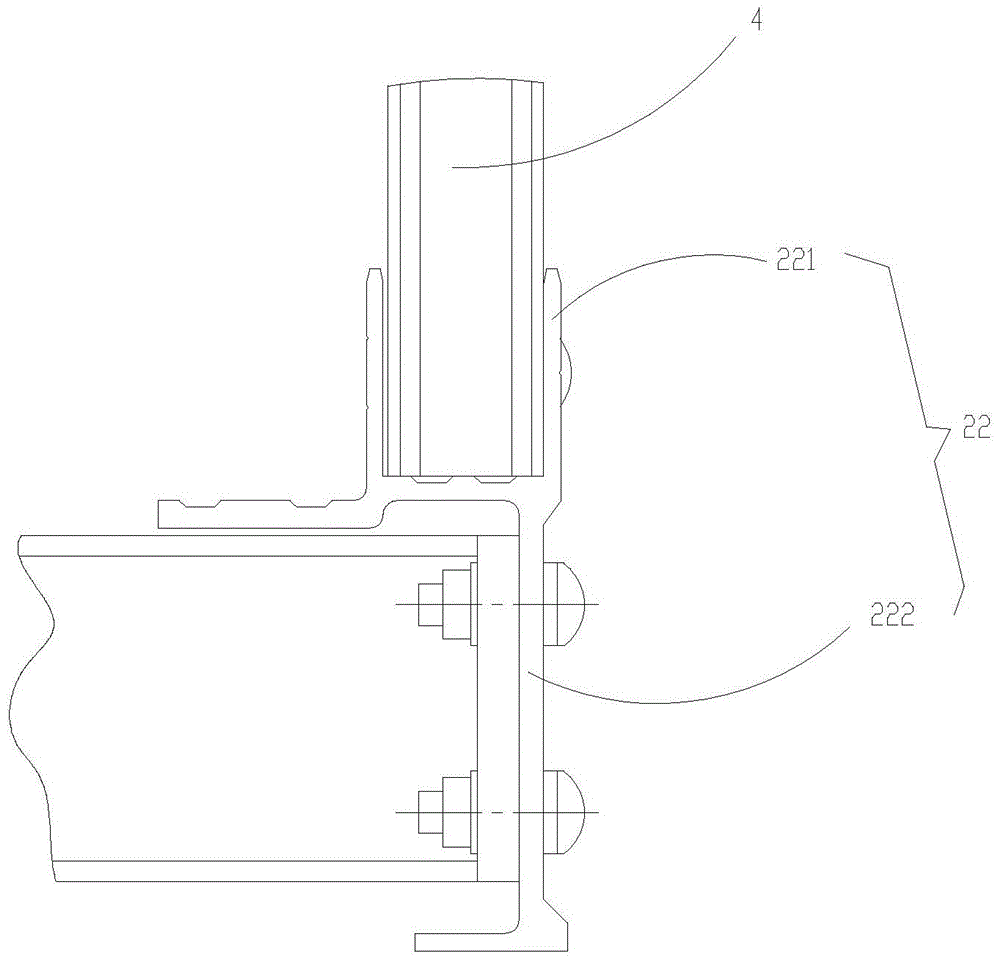

All aluminum van

ActiveCN104369783BGood sealing performanceFlat surfaceLarge containersLoading-carrying vehicle superstructuresAluminiumSmall footprint

The present invention provides an all-aluminum van, which includes a skeleton body with a rectangular parallelepiped frame structure, and several blocks respectively clamped at the front, left, right, top, and bottom ends of the skeleton body and forming a rectangular parallelepiped storage space with the skeleton body compartment board. Compared with the related technology, the compartment panels are clamped in the frame body, the overall sealing performance of the compartment is good, and the surface is smooth; the compartment panels are spliced with small compartment profiles, and the production area is small.

Owner:SNTO TECH GRP

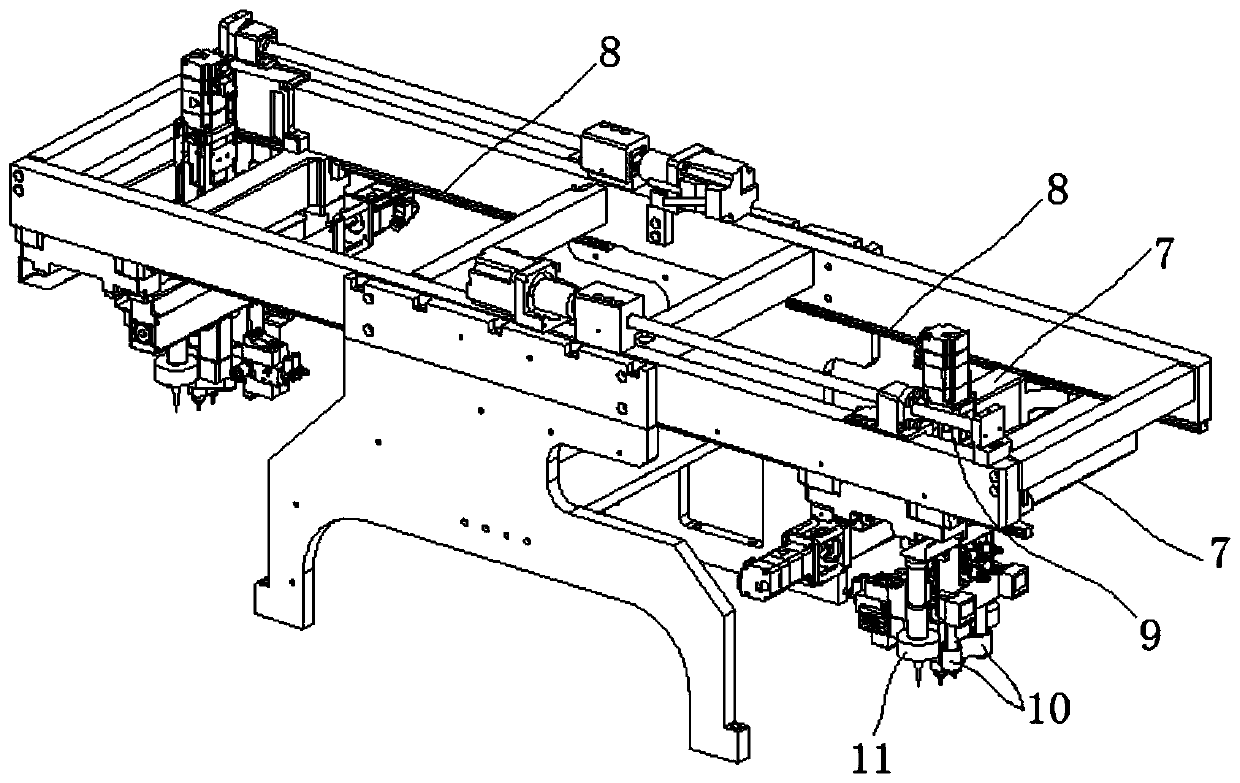

Double-path disposable-mattress manufacturing method and equipment

InactiveCN108703839AReduced production footprintIncrease the number ofAbsorbent padsBaby linensElectric energyDisposable bed pad

The invention discloses a double-path disposable-mattress manufacturing method and equipment. The equipment comprises a traction device, a core layer winding device, a core layer adhesive applying device, an SAP applying device, a slitting device, two core cutting devices, two surface layer winding devices, two surface layer adhesive applying devices, two PE applying devices, two compression roller devices, two surface layer cutting devices, two folding devices, two finished-product cutting devices and two conveying devices. The equipment is novel in structure, practical in function, capable of effectively reducing production floor space, capable of greatly increasing the number of products produced in unit time, capable of effectively increasing production efficiency, capable of loweringthe number requirement of operators, capable of effectively lowering manpower cost, capable of avoiding equipment abrasion and electric energy consumption caused by the starting of multiple equipmentand capable of effectively lowering production cost.

Owner:安徽珂力智能电气有限公司

Double face printing apparatus and double face printing process

The invention relates to a dual-surface printer, which comprises two planet printers, wherein the central compress rollers of printers are parallel mounted; there are two transverse bake channels above the printers; two bake layers are layered inside the bake stove. The invention can print without drying inter-color; and the paths of two times of drying can be reversed and layered, to shorten the base material path. And the invention also provides a relative printing method.

Owner:李新忠

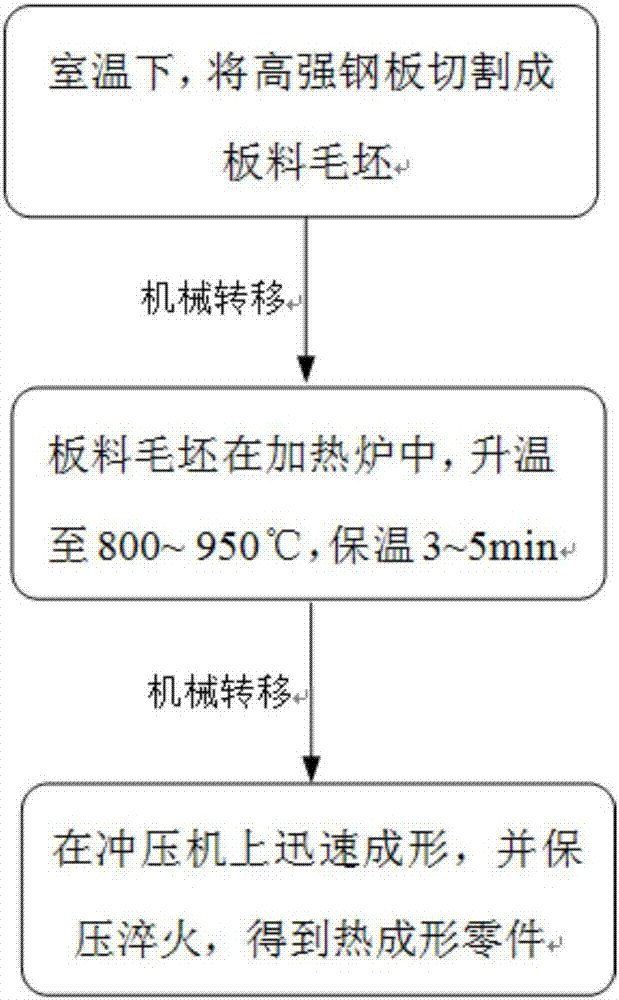

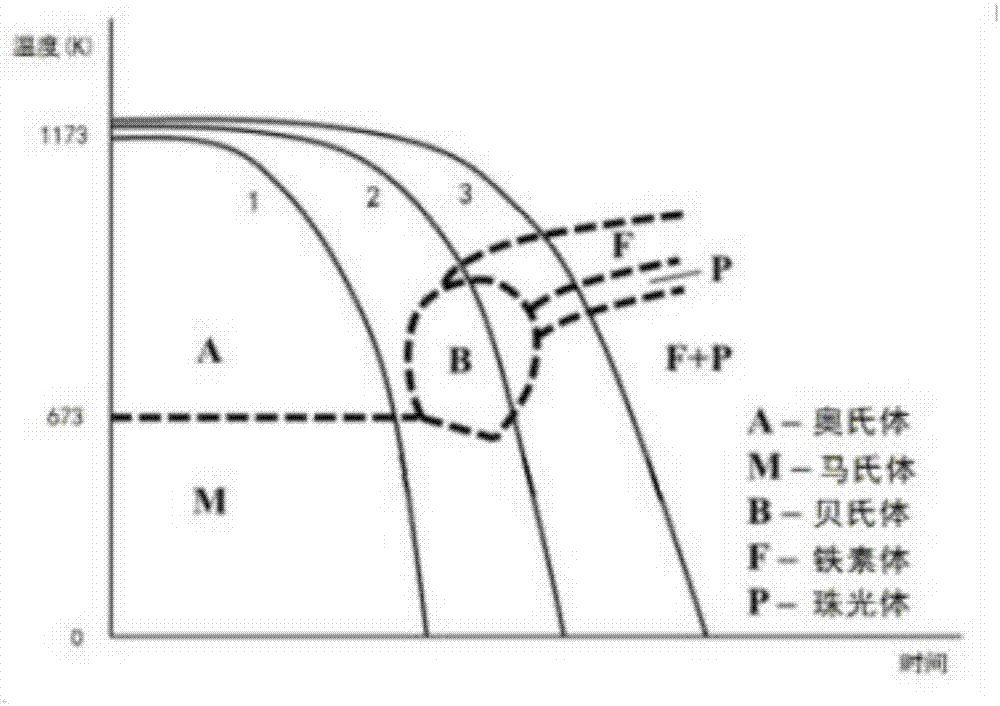

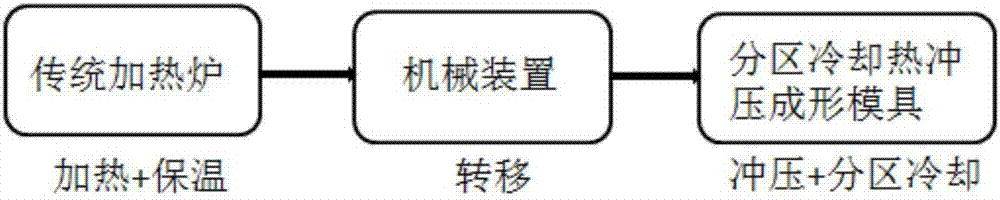

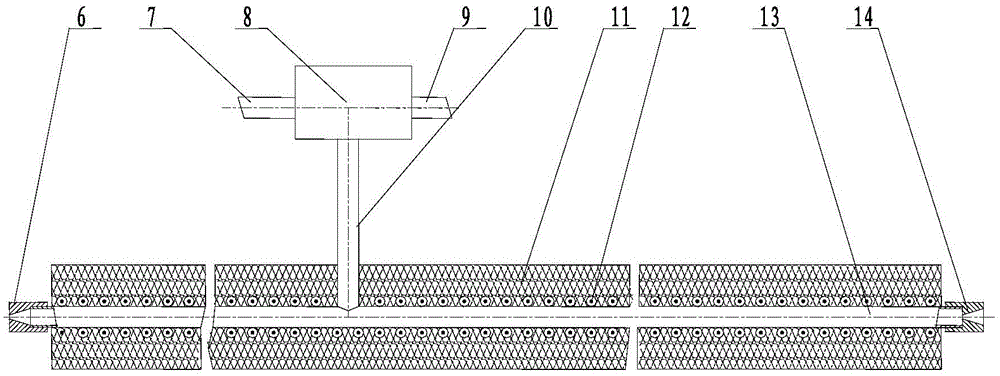

High-strength steel part hot-stamping forming device with gradient distributed performance

InactiveCN107999593ALow costLow investment costShaping toolsMetal working apparatusHot stampingAtmospheric pressure

The invention discloses a high-strength steel part hot-stamping forming device with gradient distributed performance. The high-strength steel part hot-stamping forming device with the gradient distributed performance comprises an upper die seat, an upper fixing plate, a plurality of upper die blocks, a lower die seat, a lower fixing plate and a plurality of lower die blocks; the upper fixing plateis mounted on the upper part of the upper die seat through a first air pressure device, the upper fixing plate is provided with an upper fixing plate protruding part and an upper fixing plate groovepart, and a second air pressure device is mounted on the upper fixing plate groove part; the multiple upper die blocks are fixedly connected with the upper fixing plate protruding part and the secondair pressure device correspondingly, and each upper die block is provided with a heating hole channel and a cooling water channel; the lower fixing plate is fixed to the upper part of the lower die seat, the lower fixing plate is provided with a lower fixing plate protruding part and a lower fixing plate groove part, and a third air pressure device is mounted on the lower fixing plate groove part;and the multiple lower die blocks are fixedly connected with the lower fixing plate protruding part and the third air pressure device correspondingly, and each lower die block is provided with a heating hole channel and a cooling water channel, wherein the upper fixing plate protruding part is matched with the lower fixing plate groove part.

Owner:JILIN UNIV

A kind of method of whole grain instant nutritional porridge

The invention discloses a production method of whole-grain fast-food nutritional porridge. Whole grains are taken as raw materials; the purpose of balanced nutrition is achieved through preprocessing and grinding the raw materials and proportioning nutritional ingredients well; the whole-grain fast-food nutritional porridge is prepared by the processes of extruding for curing by a double-screw extruder, accurately controlling the gelatinization degree of starch in the raw materials, granulating for forming, pre-drying, roasting, and cooling. High viscosity of a porridge body during brewing is ensured by accurately controlling the gelatinization degree of the starch in the raw materials in the preparation process, so that any thickener or auxiliary material does not need to be added, the manually cooked porridge can be brewed with hot water without adding cured powdery materials, good granule shape can be kept after the porridge is brewed for 20 minutes, and the appearance and the mouth feel of the fast-food nutritional porridge can be equivalent to those of porridge cooked at home.

Owner:谷伊家食品科技有限责任公司

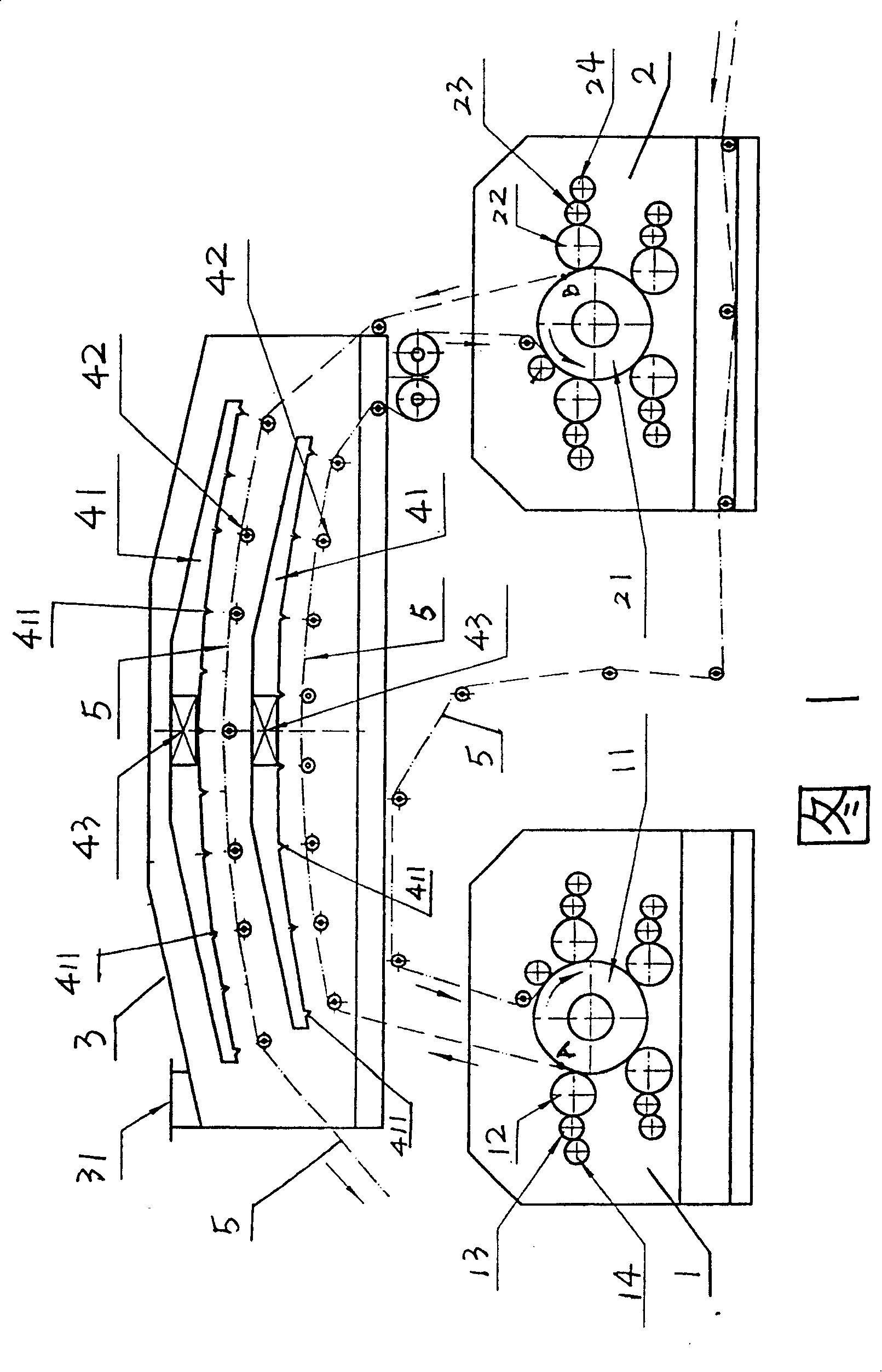

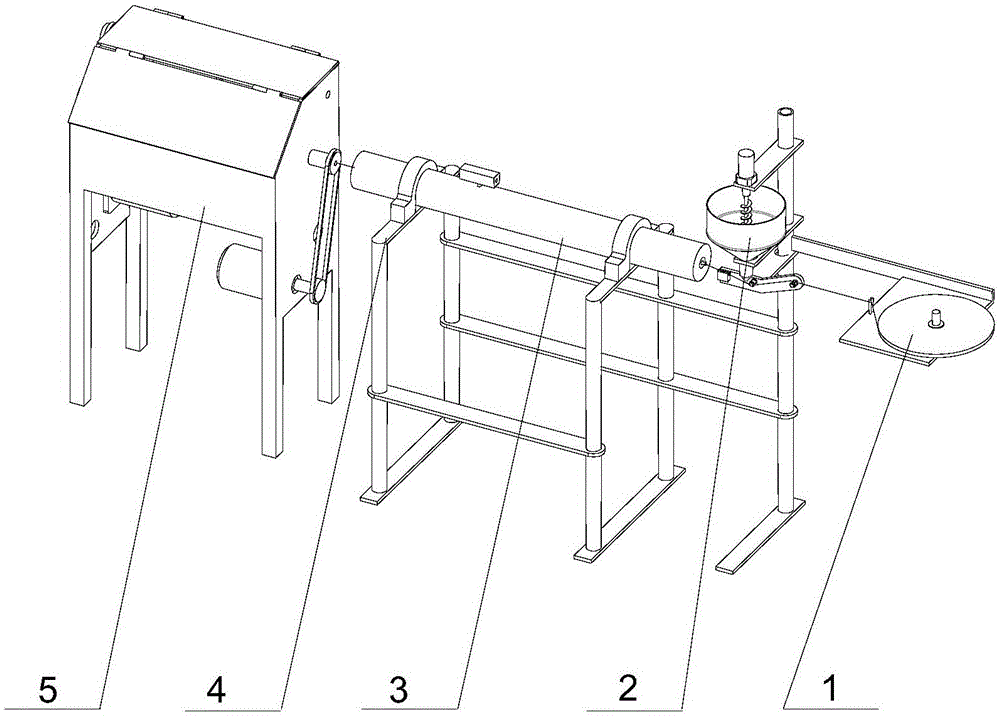

Wet lead wire preparing and drying integrated machine and wet lead wire preparing and drying integrated method

InactiveCN105016936ASmall footprintImprove intrinsic safetyEnergy inputDrying machines with progressive movementsFireworksEngineering

The present invention discloses a wet lead wire preparing and drying integrated machine and a wet lead wire preparing and drying integrated method, the wet lead wire preparing and drying integrated machine is mainly composed of a lead wire paper tray (1), a quantitative dosing device (2), a drying device (3), a rack (4) and a lead wire twisting and collecting device (5); firstly, the lead wire paper tray (1) is put on the rack, lead wire paper artificially passes through a dosing site of the quantitative dosing device (2), passes through the drying device (3), and then enters into the lead wire twisting and collecting device (5) for well fixing; secondly, an artificially mixed wet chemical agent is added into a chemical agent hopper of the quantitative dosing device (2); then the drying device (3) works, and when the temperature reaches the set temperature, the lead wire twisting and collecting device (5) is started automatically for lead wire preparing production. The wet lead wire preparing and drying integrated machine is applicable to the production of lead wire preparing production in fireworks industry, lead wires are directly dried on line, and directly coiled and packed into a finished product for storage without backwinding, sun-drying, and re-backwinding, and the production process is no longer limited by environmental conditions.

Owner:CHINA WUZHOU ENG GRP +1

Horizontal roller way type glass continuous tempering method

PendingCN112624587AImprove uniformityImprove flatnessGlass tempering apparatusTemperingHeating furnace

Owner:LUOYANG NORTHGLASS TECH

CNC automatic production line for automobile part machining

The present invention discloses a CNC automatic production line for automobile part machining. The CNC automatic production line includes a working platform, a conveying mechanism and a machining mechanism; a groove is formed in the right end of the upper surface of the working platform, rotating grooves are symmetrically formed in the front and rear inner walls of the groove, circulating holes are formed in the bottom wall of the groove, a feeding groove is formed in the left end of the upper surface of the working platform, and the lower end of the feeding groove communicates with the left ends of the interiors of the rotating grooves; the conveying mechanism is arranged in the rotating grooves; and the machining mechanism is arranged in the middle of the groove. The CNC automatic production line further includes a PLC, the PLC is arranged in the middle of the front surface of the working platform, and the input end of the PLC is electrically connected to an external power source. By using the CNC automatic production line for automobile part machining, the labor force is liberated, the production efficiency is greatly improved, the labor productivity is improved, the workpiece conveying process is more stable, falling is prevented, labor conditions are improved, the production balance is guaranteed, and remarkable economic benefits are achieved.

Owner:昆山纯柏精密五金有限公司

PC wall panel production system

The invention discloses a PC (poly carbonate) wall board production system, which comprises an operation region, a casting region and a caring region, wherein the caring region is in parallel arrangement with the operation region and the casting region, the operation region comprises an operation rail, the casting region comprises a conveying rail and a casting device, the casting device is arranged above the conveying rail and is used for casting a PC wall board, the caring region comprises at least one caring rail and a steam caring kiln, the caring rail supports a cast PC wall board mold to move on the caring rail, and the steam caring kiln is arranged at the front section of the caring rail. When the technical scheme is implemented, through the parallel arrangement of the operation region, the casting region and the caring region and through the flowing of the PC wall board mold in the operation region, the casting region and the caring region, the flow line production is formed, so that during the still caring of the PC wall board, the casting region can still carry out casting operation, and the production efficiency is greatly improved.

Owner:彭传森 +1

Lawn produced by using urban sludge composting mixed matrix and preparation method thereof

InactiveCN104145669BEffective consumptionRelieve stressHorticultureFertilizer mixturesSludge compostWater resources

The invention discloses a lawn produced by using urban sludge composting mixed matrix and a preparation method thereof, comprising the following steps: selecting air-dried and decomposed coarse compost of urban sludge for screening, and the particle size of the compost after screening is 2 mm to 5 mm Between; mix compost with any two of rice bran, vermiculite, and perlite, and stir evenly to obtain a mixed matrix; level the land; spray pesticides; lay an isolation layer; cover the mixed matrix evenly on the isolation layer ; Sow grass seeds evenly. After sowing, cover the mixed substrate with 0.5cm; cover with sunshade net. The invention can not only improve lawn quality, reduce production and planting costs, save land and water resources, but also consolidate water control achievements, promote energy saving and emission reduction, effectively eliminate a large amount of excess sludge produced during sewage treatment, and alleviate the gradual deterioration of garden substrates. The pressure of scarcity and unstable source is a very valuable and sustainable method of sludge resource utilization.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com