Contact type aluminum wire continuous annealing method and apparatus

An annealing equipment and contact technology, applied in heat treatment equipment, cable/conductor manufacturing, furnace type, etc., can solve the problem that the quality of the annealing of resistance furnace aluminum wire is difficult to guarantee and control, the heating and holding time is difficult to achieve consistency, and the aluminum wire Unable to meet the problems of annealing and softening, and achieve the effect of not being prone to uneven elongation, shortening the production cycle, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

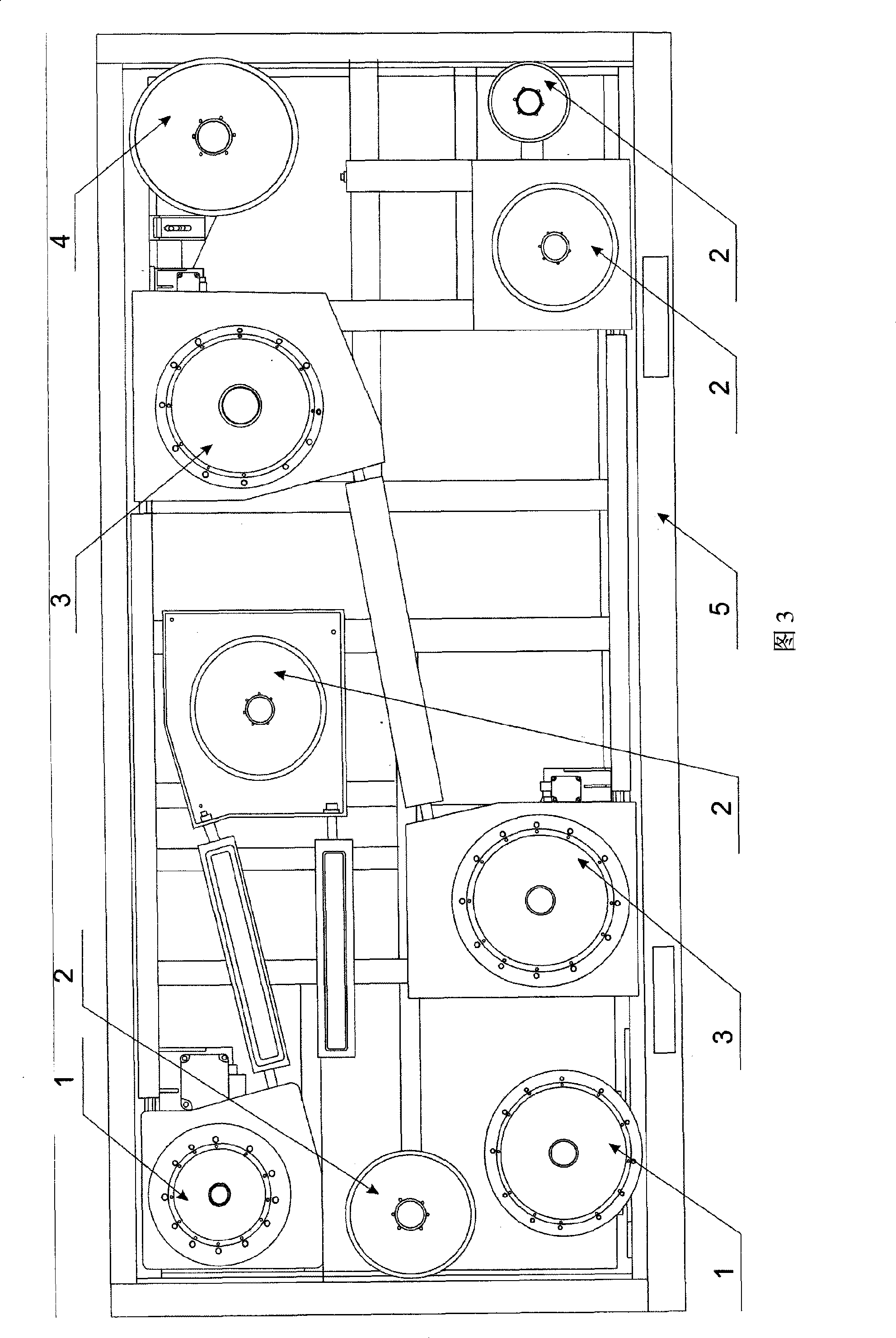

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

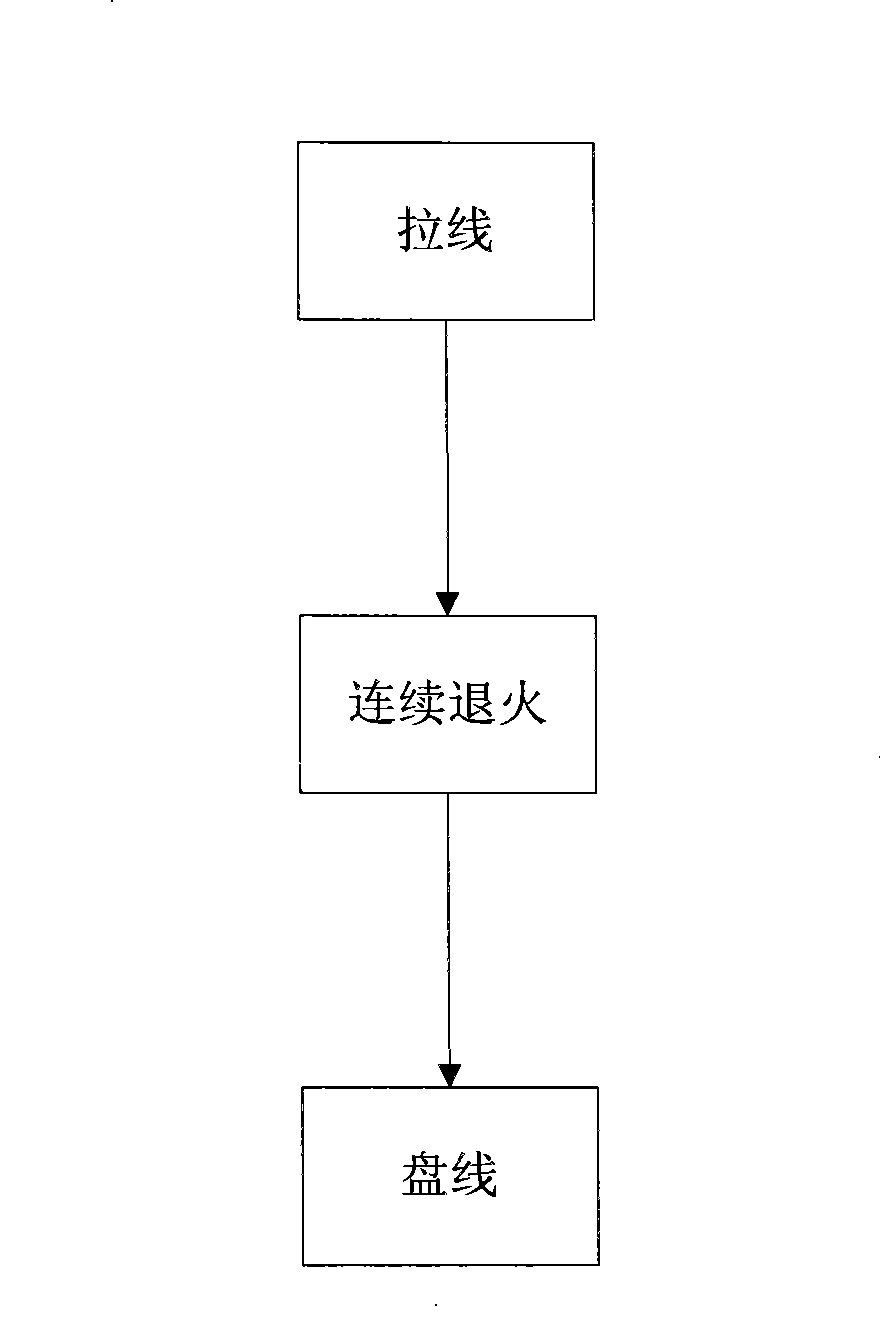

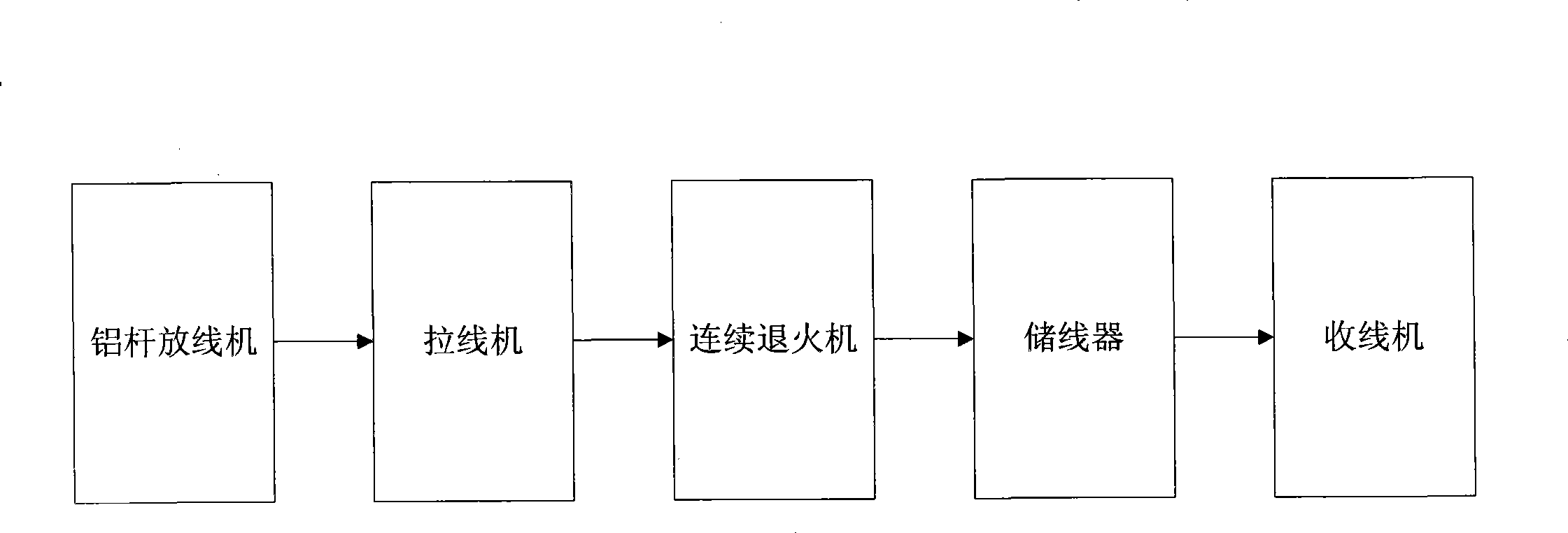

[0032] figure 1 It is a process flow chart of the contact type aluminum wire continuous annealing method provided by the present invention; figure 2 It is the connection schematic diagram of the contact type aluminum wire continuous annealing equipment provided by the present invention. As shown in the figure, a contact type aluminum wire continuous annealing method is characterized in that: the method includes the following steps:

[0033] A. Drawing wire: Use aluminum wire drawing machine to pull the Φ12-Φ8.0mm aluminum rod on the aluminum rod pay-off machine into Φ1.35-Φ6mm unannealed aluminum wire, and then directly enter the contact type aluminum wire continuous annealing machine for annealing;

[0034]B. Continuous annealing: put the unannealed aluminum wire in the contact-type aluminum wire continuous annealing machine, through the action of the wire wheel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com