Horizontal roller way type glass continuous tempering method

A horizontal roller and glass technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of excessive surface stress difference of glass products, high equipment cost, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

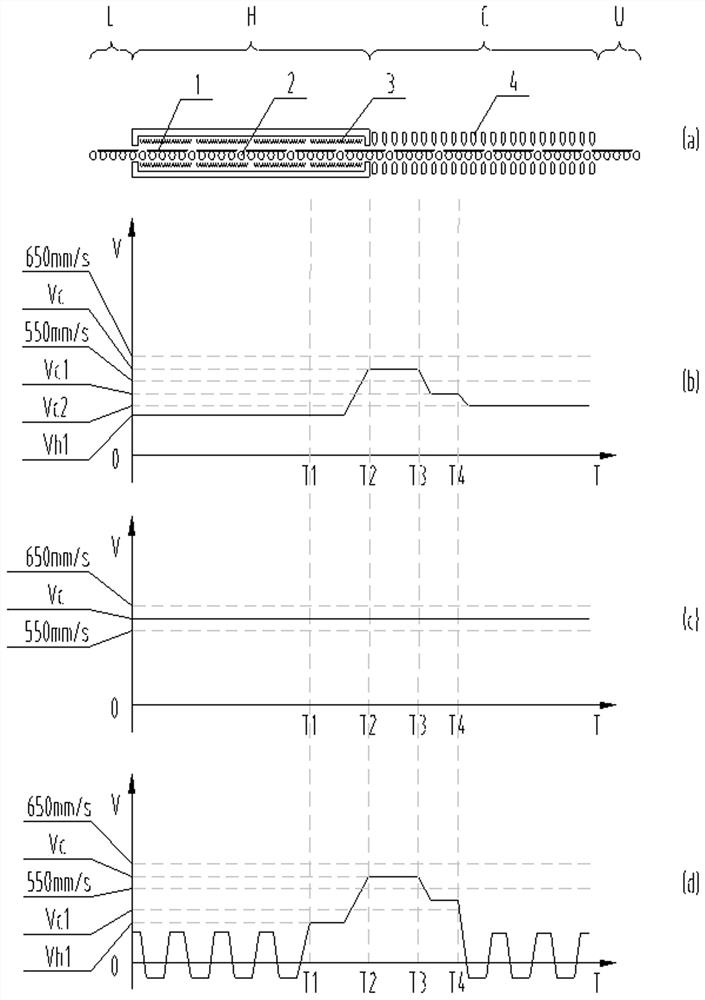

[0027] as attached figure 1 As shown in (a) and (b), the tempering process equipment of the present invention mainly includes a loading platform L, a heating furnace H, a tempering grid C, and an unloading platform U arranged in sequence along the process direction.

[0028] (b) shows the distribution diagram of the glass transmission speed in Embodiment 1 of the horizontal roller type glass continuous tempering method of the present invention. The horizontal axis of the coordinate system is the time parameter T, and the vertical axis is the speed parameter V. T1, T2, T3, and T4 represent the specific process moments in the glass tempering process: where T1 is the moment when the glass begins to soften, which is the initial moment of the softened state; T2 is the moment when the glass begins to be quenched; T3 is the moment when the glass begins to soften. The moment when quenching is completed; T4 is the moment when the glass is cooled to harden, which is the end moment of t...

Embodiment 2

[0036] As shown in (a) and (c) in the attached figure.

[0037] (c) shows the distribution diagram of the glass transmission speed in Embodiment 2 of the horizontal roller table continuous glass tempering method of the present invention.

[0038]This embodiment is a special case of the first embodiment, the difference is that the glass 1 moves downstream at a constant speed Vc during the whole tempering process.

Embodiment 3

[0040] As shown in (a) and (d) in the attached figure.

[0041] (d) shows the distribution diagram of the glass transmission speed in Embodiment 3 of the horizontal roller type glass continuous tempering method of the present invention.

[0042] The difference between this embodiment and Embodiment 1 is that when the glass 1 is in the unsoftened state of the heating furnace H or the tempered grid C, that is, the glass 1 is heated in the heating furnace H After the inside of C is cooled to harden (time T4), the glass 1 reciprocates under the drive of the conveying roller table 2, so that the glass 1 has a sufficient length in a short length space under the premise that the moving speed is not too low. heating or cooling time. When the glass 1 is in the hard state, compared with the delicate lower surface in the soft state, it has sufficient strength to resist scratches and collapses caused by glass reciprocating motion pauses, reversing acceleration, and will not affect the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com