Sealing strip for door frame of automobile and manufacturing process thereof

A manufacturing process and a technology for sealing strips, applied in the field of automobile door frame sealing strips and their manufacturing processes, can solve the problems of cumbersome and complicated flocking process, large production area, low production efficiency, etc. Small, productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

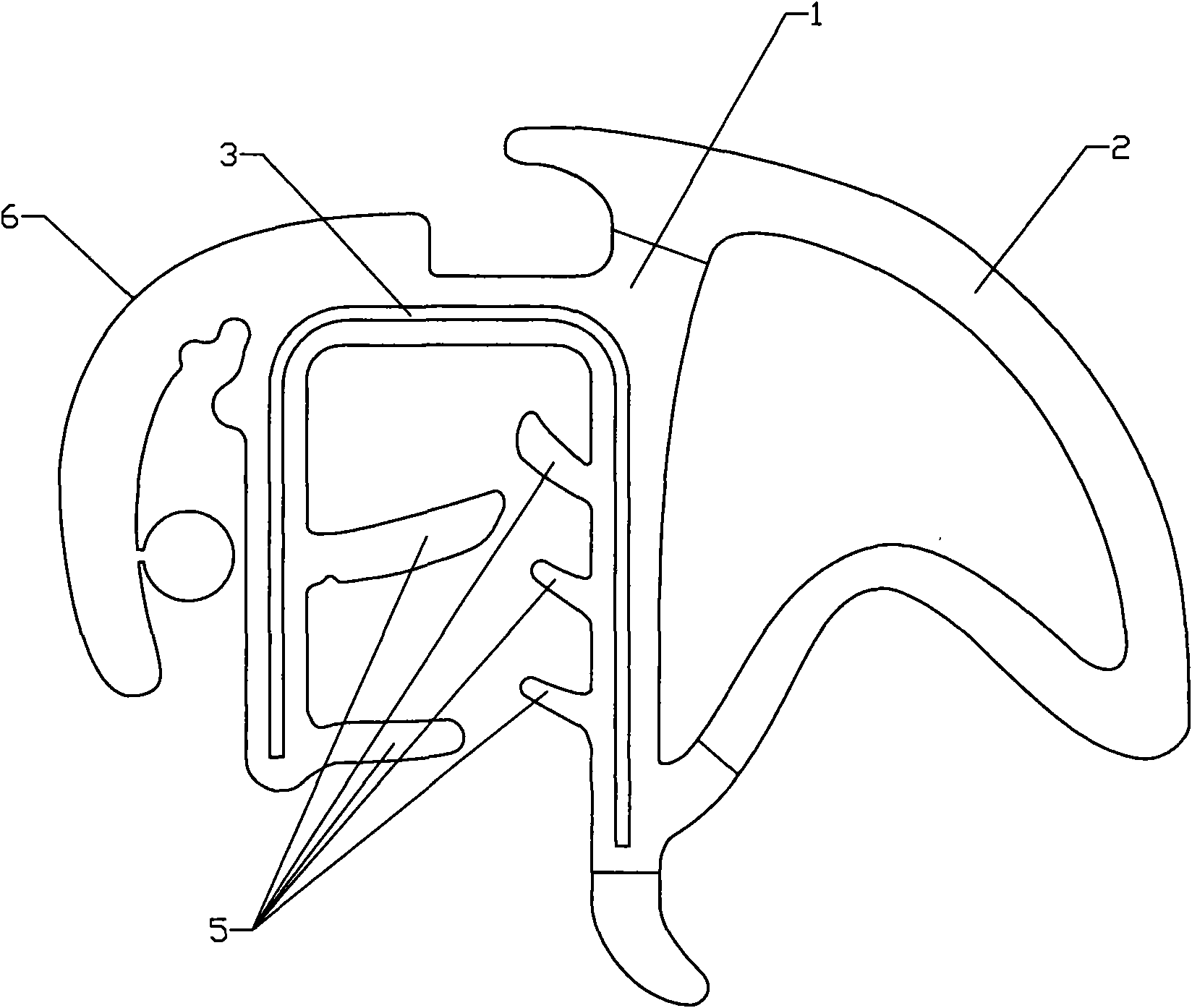

[0025] The manufacturing process of the automobile door frame sealing strip provided in this embodiment is to reprocess the already processed and formed sealing strip body to finally manufacture the automobile door frame sealing strip, including the following steps:

[0026] ① Vulcanize the outer surface 6 of the molded sealing strip body with the clamping part 1 exposed inside the car: the material of the clamping part is EPDM (EPDM, Ethylene-Propylene-DieneMonomer) , put the clamping part 1 into a hot air vulcanization box, and vulcanize the outer surface 6 at a temperature of 240°C;

[0027] ② Adhesive coating of the exterior decoration layer 4 on the outer surface 6 of the vulcanized clamping part 1: the exterior decoration layer 4 is in the form of a sheet, and the material of the exterior decoration layer 4 is a thermoplastic elastomer (i.e. TPE, thermoplastic lastomer), in this embodiment, the thermoplastic elastomer is specifically thermoplastic vulcanizate (i.e. TPV, ...

Embodiment 2

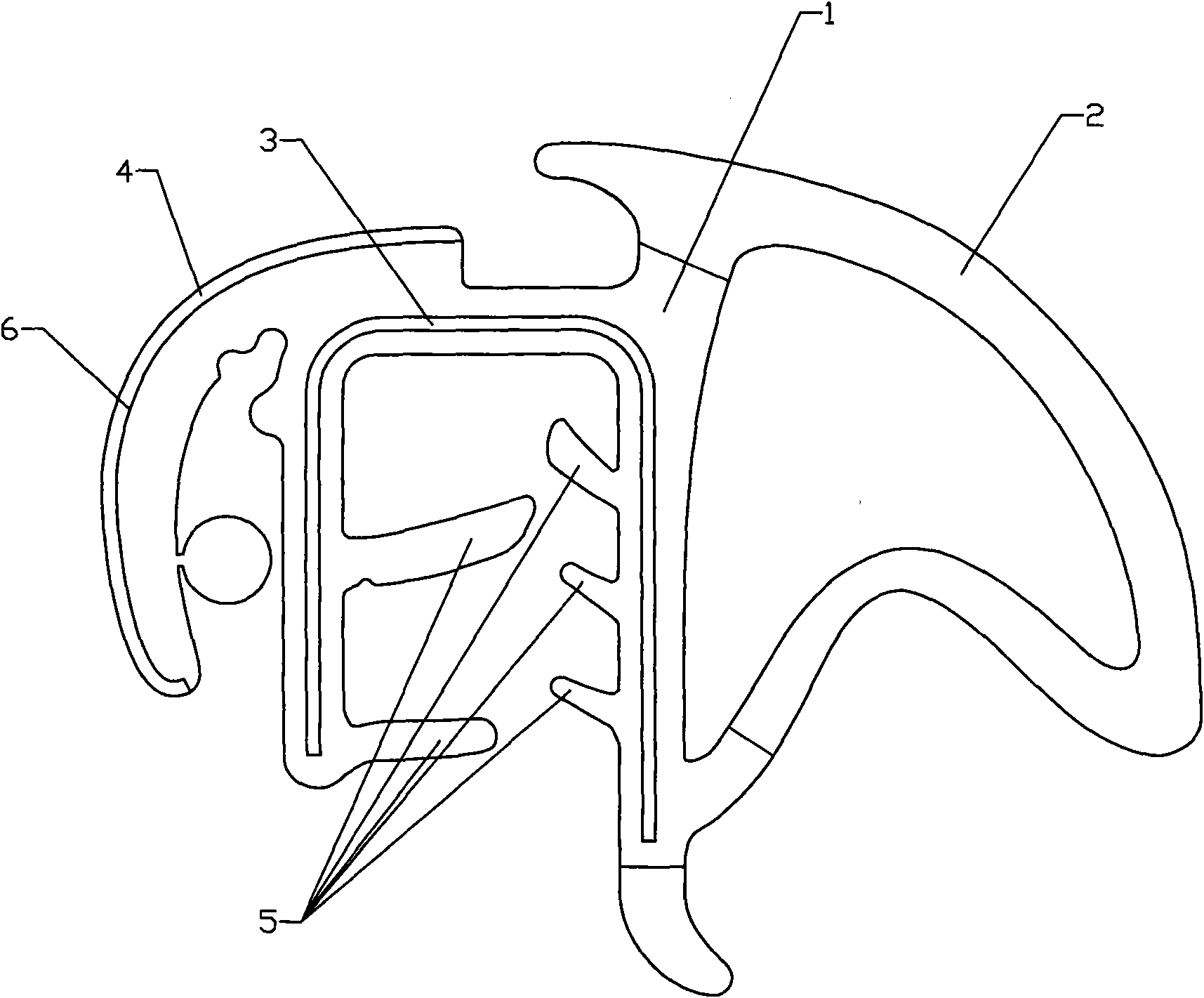

[0030] The manufacturing process of the automobile door frame sealing strip provided in this embodiment comprises the following steps:

[0031] a. Processing the exterior decoration layer 4 of the automobile door frame weather strip: extruding the exterior decoration layer 4 with a thermoplastic vulcanizate extruder (i.e. a common TPV extruder);

[0032] b. Vulcanize the outer surface 6 of the formed sealing strip body with the clamping part 1 exposed in the car: the material of the clamping part is EPDM (EPDM, Ethylene-Propylene-DieneMonomer) ), putting the clamping part 1 into a hot air vulcanization box, and vulcanizing the outer surface 6 at a temperature of 260°C;

[0033] c. Adhesively coat the outer decoration layer 4 on the outer surface 6 of the clamping part 1 after vulcanization: the outer decoration layer 4 is in the shape of a sheet, and the material of the outer decoration layer 4 is thermoplastic elastic body (that is, TPE, thermoplasticlastomer), in this embod...

Embodiment 3

[0036] The manufacturing process of the automobile door frame sealing strip provided in this embodiment comprises the following steps:

[0037] 1. process the described exterior layer 4 of the automobile door frame weather strip: utilize a thermoplastic vulcanizate extruder (i.e. a common TPV extruder) to extrude the exterior layer 4;

[0038] II. Vulcanize the outer surface 6 of the clamping part 1 of the formed weather strip body exposed in the car: the material of the clamping part is EPDM (EPDM, Ethylene-Propylene-DieneMonomer ), putting the clamping part 1 into a hot air vulcanization box, and vulcanizing the outer surface 6 at a temperature of 280°C;

[0039] III. Adhesively coating the outer decoration layer 4 on the outer surface 6 of the clamping part 1 after vulcanization: the outer decoration layer 4 is sheet-like, and the material of the outer decoration layer 4 is thermoplastic elastic body (that is, TPE, thermoplastic elastomer), in this embodiment, the thermopl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com