Lens assembling machine

A lens group and track technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as defects and low production efficiency, achieve the effects of small production area, increase production efficiency, and reduce defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

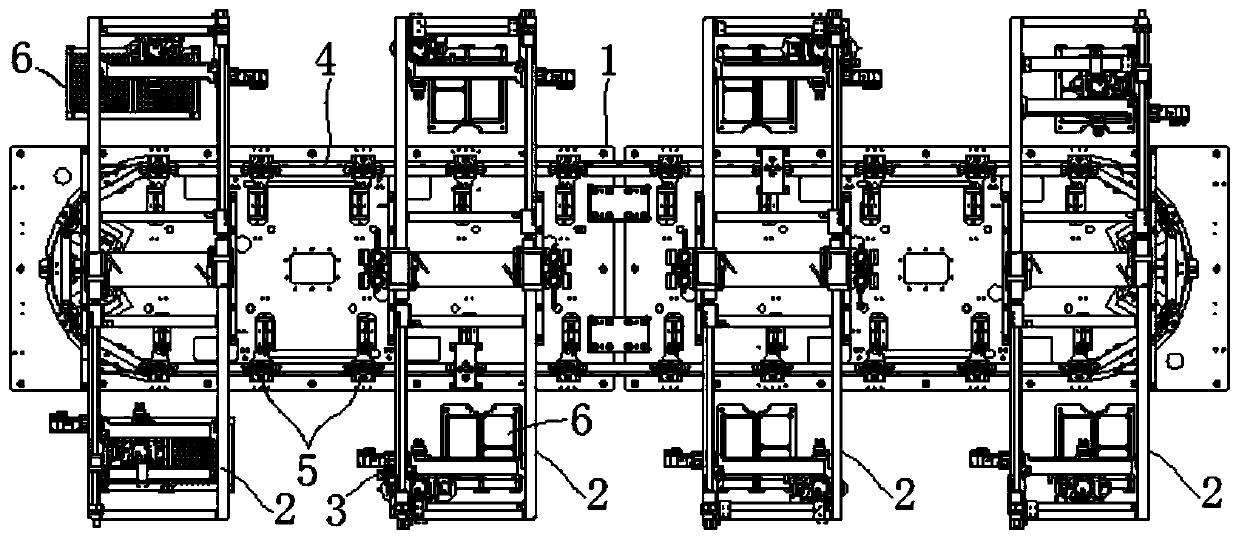

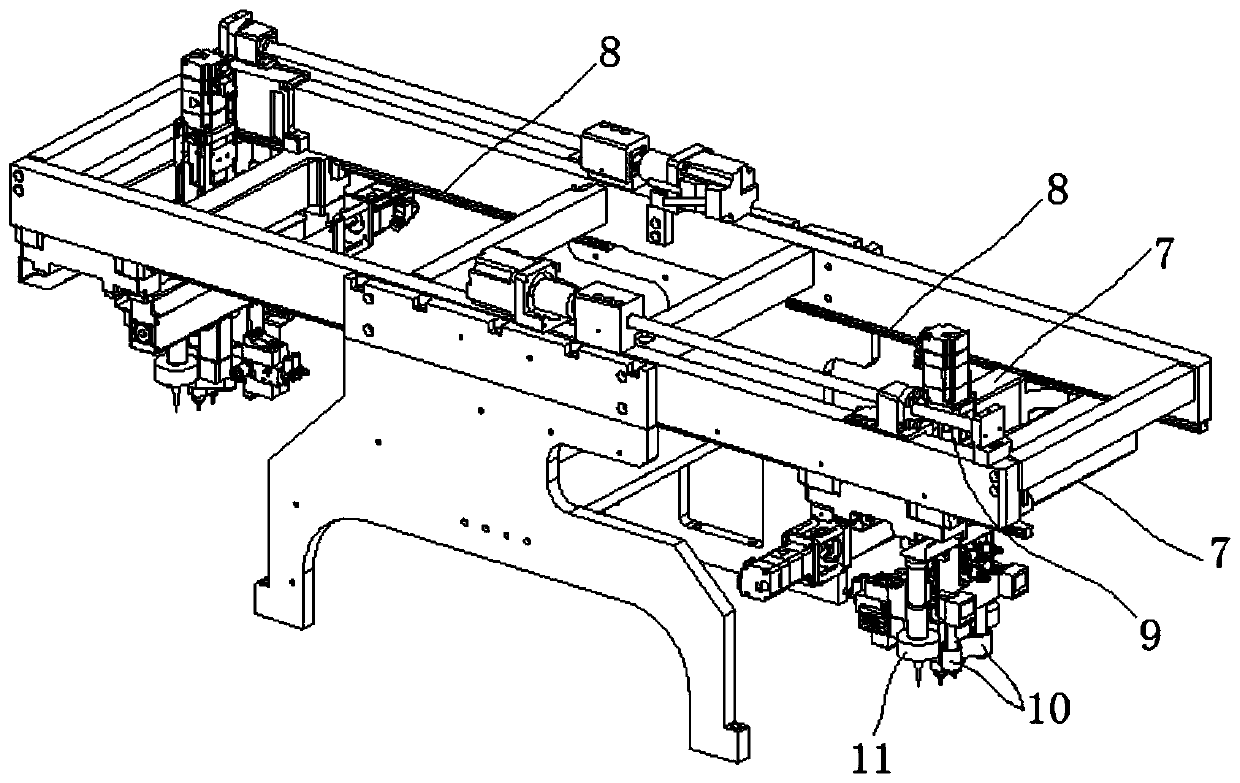

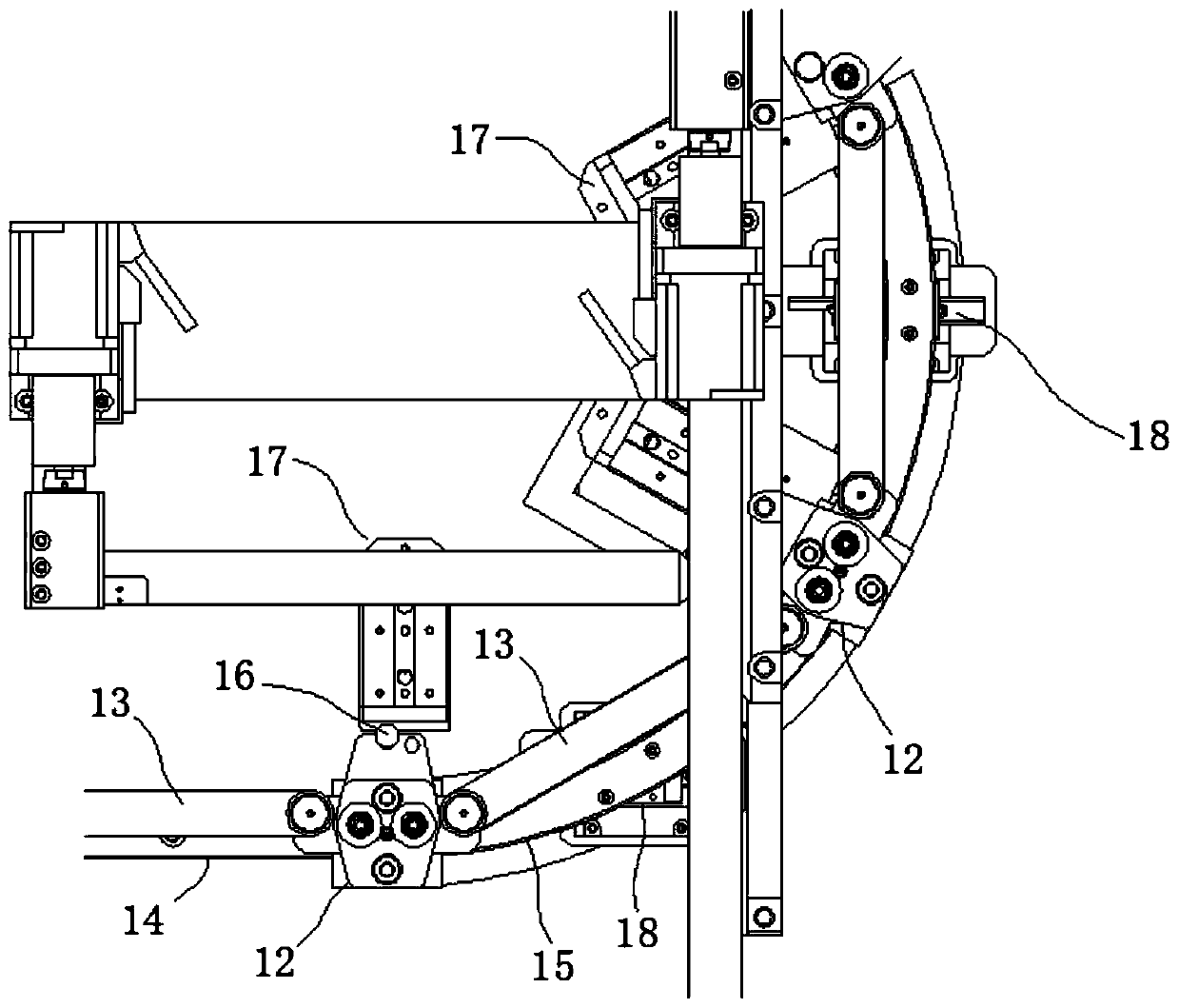

[0019] See figure 1 —— Figure 4 , The lens assembly machine of the present invention includes: track table 1, gantry frame 2, suction pen group 3, track 4, station 5, material tray 6, X axis 7, Y axis 8, Z axis 9, suction pen 10, camera 11 , moving seat 12, connecting rod 13, linear track 14, circular track 15, positioning pin 16, cylinder 17, adjustment track 18, insertion hole 19, moving block 20, insertion rod 21.

[0020] The present invention includes a track table 1, a track 4 is installed on the track table 1, the track 4 is ring-shaped, the track 4 is composed of multiple sections, a plurality of stations 5 are arranged on the track 4, and a moving seat 12 is slid on the track 4. The product Placed in the mobile seat 12, the mobile seat 12 is used for product processing, the mobile seat 12 moves along the track 4, and performs corresponding operations betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com