Dyeing process to minimise waste water production

A technology of dyes and yarns, applied in the field of textile dyeing with minimized waste water generation, can solve the problems of fabric state deterioration, adjustment properties, and complex specific properties, etc., and achieve the effect of saving costs and reducing transfer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

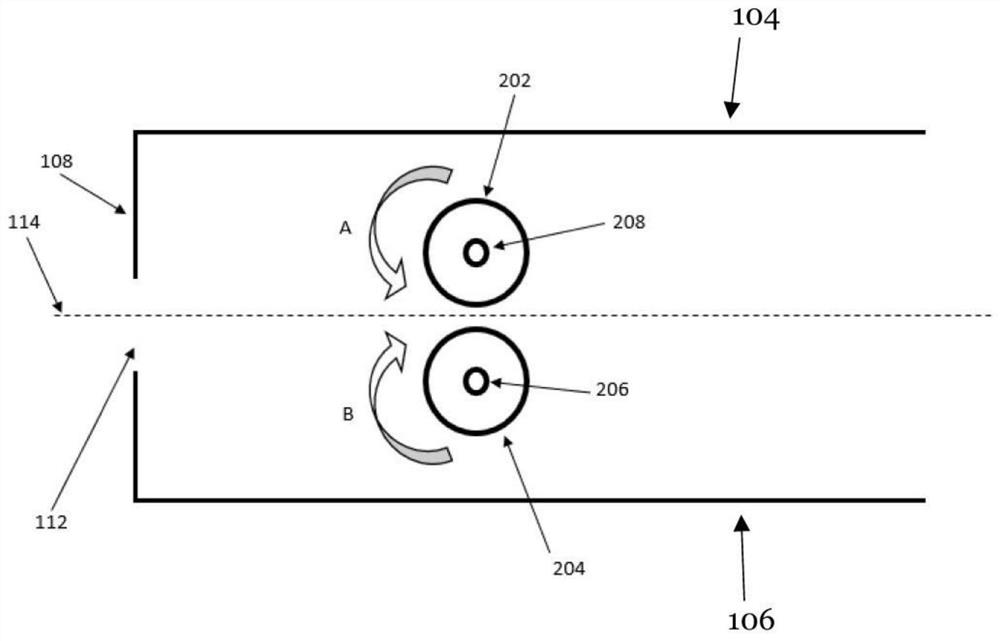

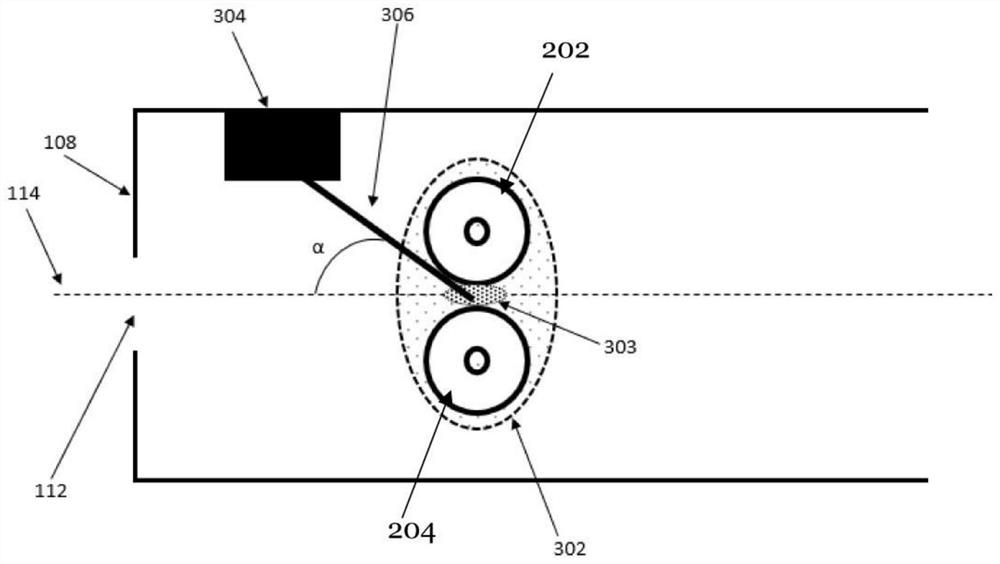

[0077] Hereinafter, exemplary embodiments of the present invention will be described in more detail with reference to the accompanying drawings. Although specific feature combinations are described below with respect to exemplary embodiments of the invention, it should be understood that the disclosure is not limited to these embodiments. In particular, not all features must be present to implement the invention, and an embodiment may be modified by combining certain features of one embodiment with one or more features of another embodiment. Furthermore, while the exemplary embodiments relate to dyeing textiles, the invention also includes dyeing yarns or strands that are not disposed in textiles. What will be described below with reference to textiles applies equally well to yarns or strands.

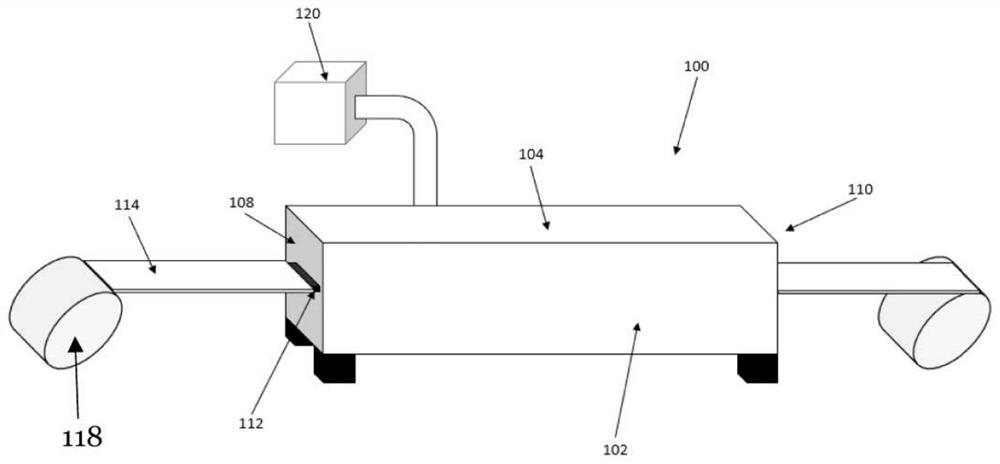

[0078] In an exemplary embodiment of the invention, the pretreatment and staining system includes a chamber 100 . The chamber 100 is an area enclosed by two side walls 102 , a top wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com