Patents

Literature

123results about How to "Save capital" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Live lactobacillus composite ecological microbial agent

The invention relates to biologic pharmacy and a multi-functional ecological product. A live lactobacillus composite ecological microbial agent is prepared by fermenting and culturing probiotics taking live lactobacilli and microzymes as representatives by a fermentation tank, and the strains of other live probiotics are selected from one or more than one of nitrobacteria, sulphur bacteria, photosynthetic bacteria and bacilli. The invention has extensive application range in the pasturage breeding of poultry, such as pig breeding, chook breeding, cattle breeding, animal breeding and the like, the poultry breeding industry or aquiculture such as fish breeding and the like, and has a plurality of functions of enhancing the immunity after being eaten by animals, reducing the use of antibiotics, saving the use cost of medicines, obviously enhancing the reproduction rate, shortening the breeding period, obviously and effectively saving feedstuff and enhancing the income of an economic breeding farmer.

Owner:孙建忠

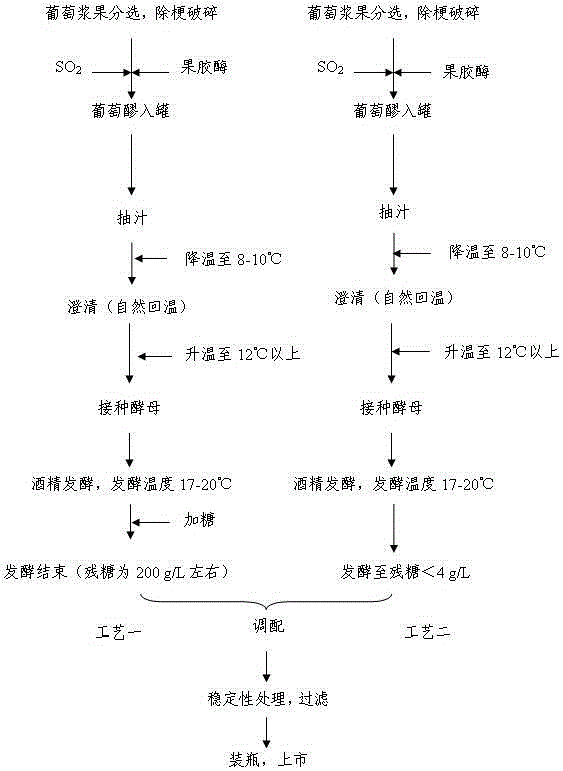

Fresh wine and brewing technique thereof

ActiveCN104403861AEasy to operateClear appearanceMicroorganism based processesWine preparationBrewingRaw material

The invention relates to fresh wine and a brewing technique thereof, and belongs to the technical field of fresh wine fermentation and brewing. The invention aims to solve the technical problem of providing a brewing technique which can be used for producing high-quality fresh wine with grapes that are not quite mature under influence of weather and are not suitable for aged wine production in principle, and the brewed fresh wine has elegant, fine and pure fruit aroma and light body, and tastes refreshing and crisp. The brewing technique of the fresh wine comprises the following operation steps of selecting raw materials, removing stems, crushing, soaking, conducting low-temperature clarification, conducting alcoholic fermentation, stopping fermentation, blending raw wine, conducting stabilized processing and filling.

Owner:山西戎子酒庄有限公司

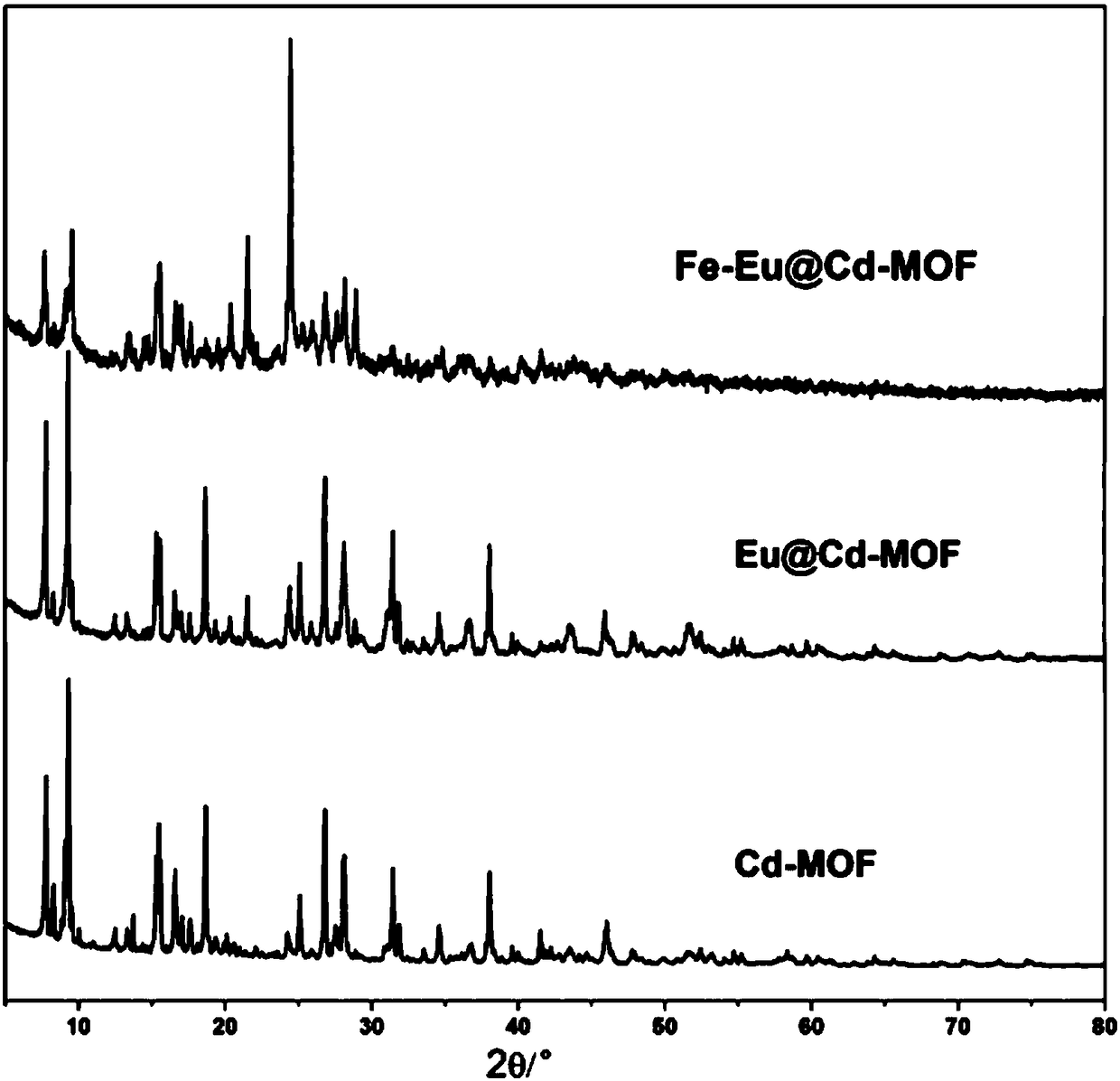

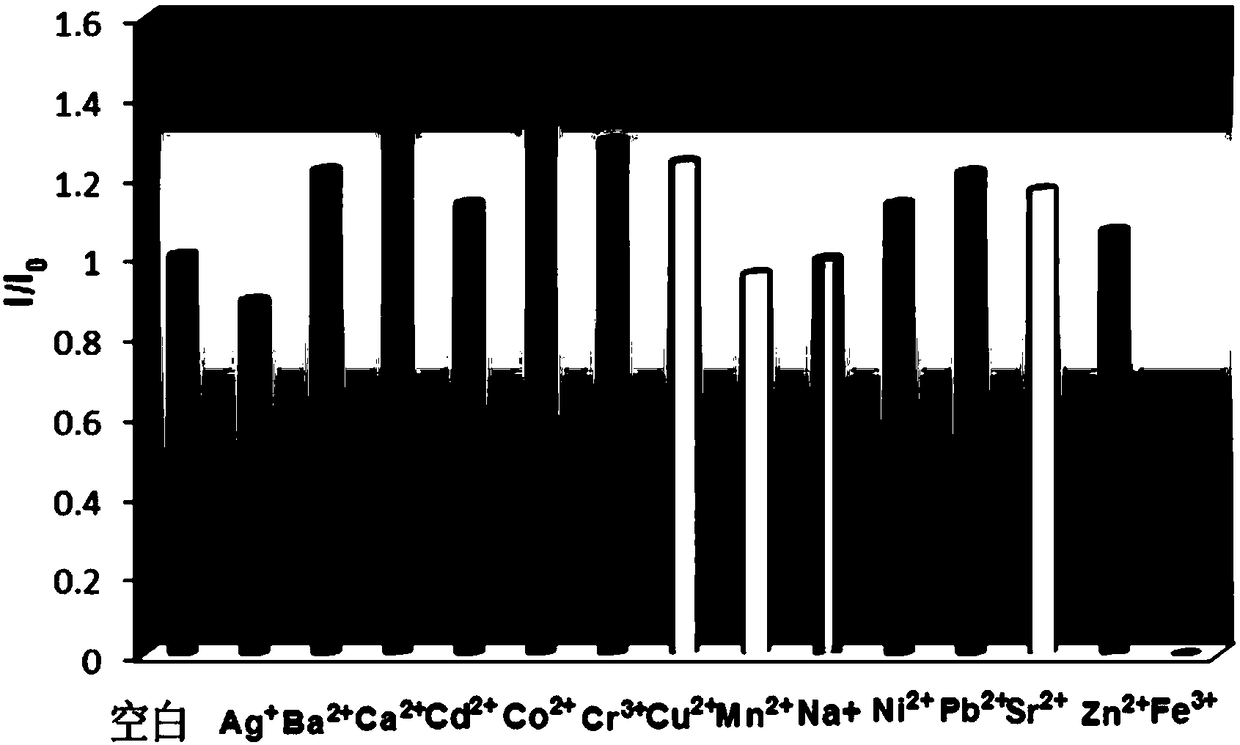

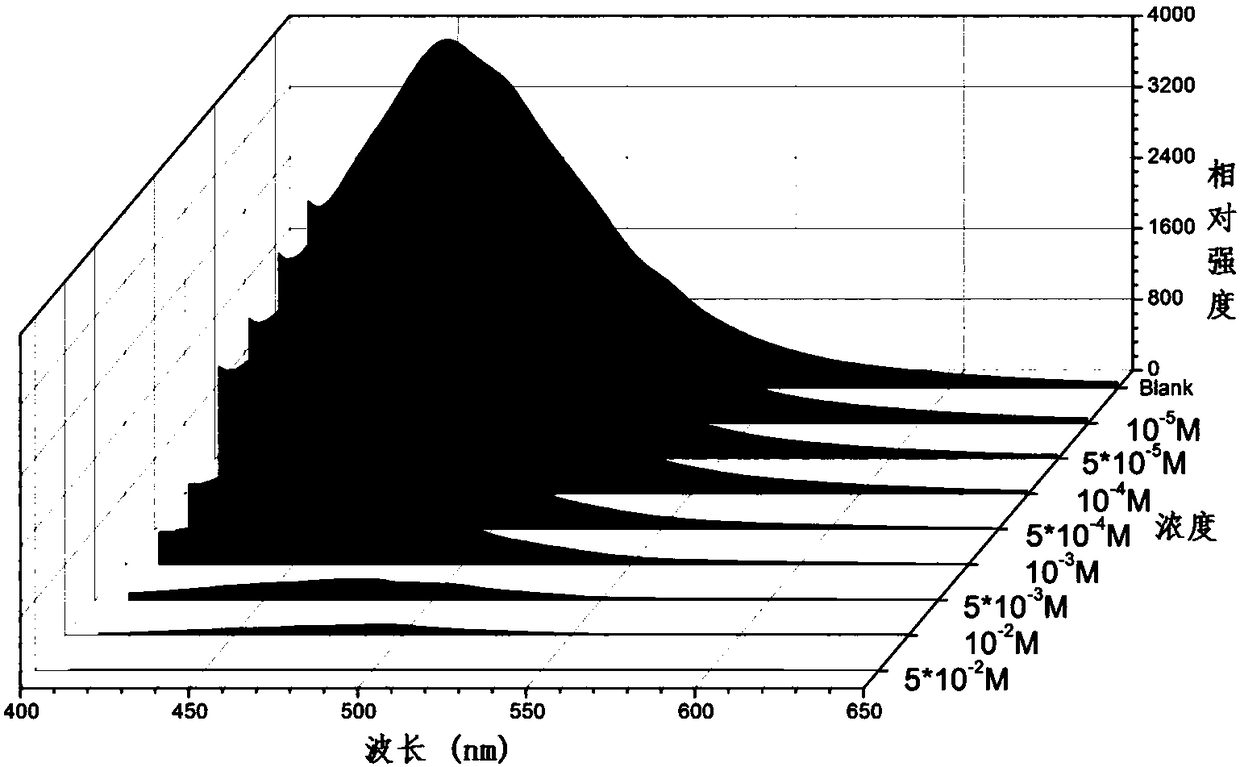

Fluorescence probe for recognizing iron ions in water body and preparation method and application thereof

ActiveCN108546551AEasy to synthesizeThe synthesis process is simpleFluorescence/phosphorescenceLuminescent compositionsProduction rateBlue emission

The invention discloses a fluorescence probe for recognizing iron ions in a water body and a preparation method and an application thereof. The preparation method of the invention includes the following steps of: 1) dispersing TPT, OH-H<2>BDC and cadmium nitrate tetrahydrate in a mixed solvent composed of DMA and water to prepare a precursor solution; 2) preparing a Cd-MOF material by subjecting the precursor solution to a solvothermal reaction; and 3) adding the Cd-MOF material to a Eu<3+> solution, and obtaining the fluorescence probe with Eu<2+> load through stirring, suction filtration anddrying, wherein Eu<3+> is "in-situ reduced" into Eu<2+> ions with specific blue emission during a functional "post-modification" process. The preparation method of the invention is simple, and the production rate is high; and a test sample of the fluorescence probe does not need pretreatment or the pretreatment is simple, the recognition on Fe<3+> ions is sensitive, the fluorescence quenching rate can reach 99%, and the fluorescence probe can be used for recognizing and detecting the Fe<3+> ions in the water body.

Owner:SHANGHAI INST OF TECH

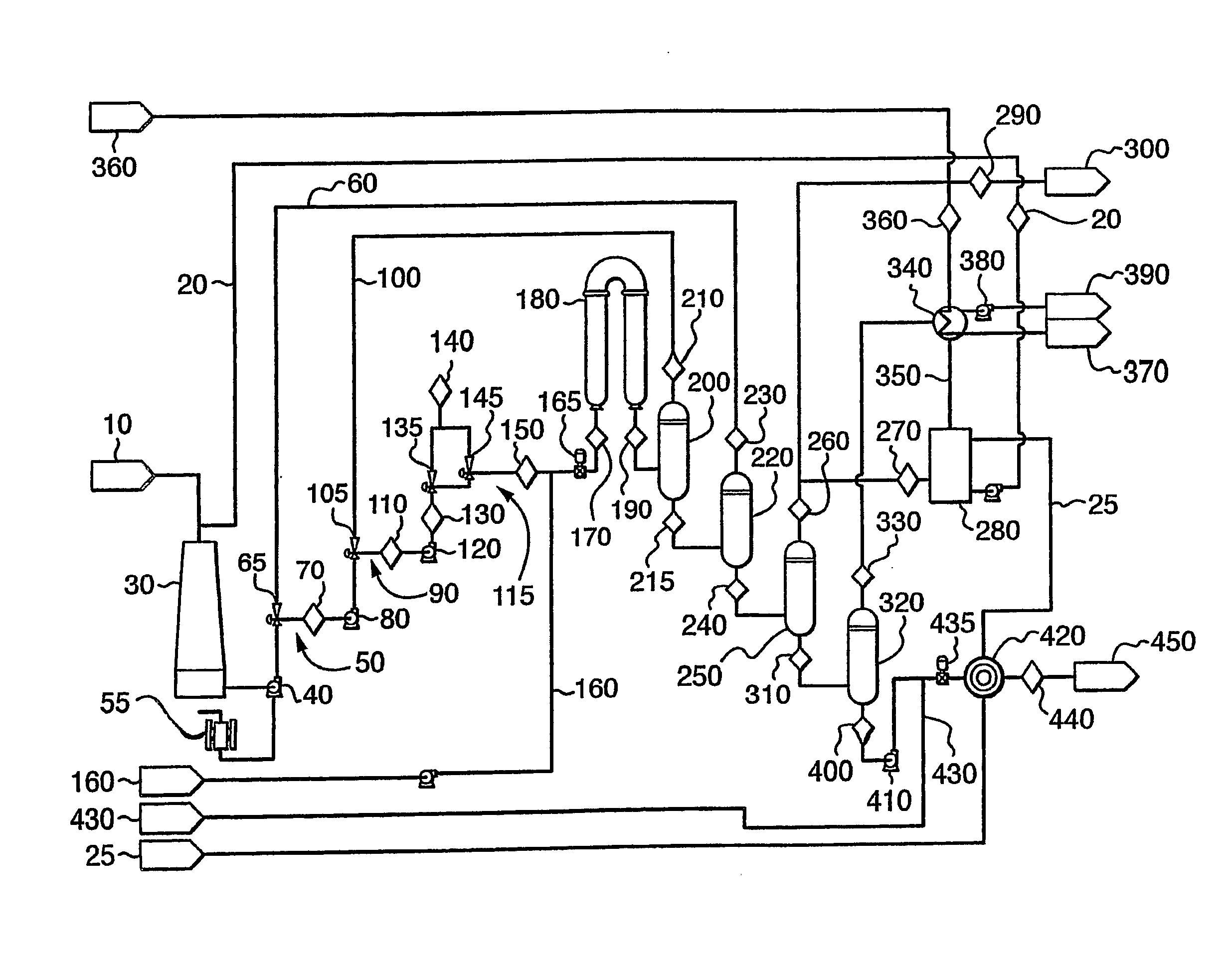

Continuous Flowing Pre-Treatment System with Steam Recovery

InactiveUS20080064906A1Avoid spendingMinimize contactSolid waste disposalDigestersSufficient timeCellulase

The present invention is directed to a continuous process for pretreating a lignocellulosic feedstock. A feedstock slurry is provided, which has a solids concentration of 10% to 33% by weight. The feedstock slurry is pumped through a heating train of at least two stages, each stage including a pump to increase stage pressure and a direct steam injection to heat the feedstock slurry. Acid is also added to the feedstock slurry prior to the heating train, during a heating stage, or after leaving the heating train; the acid is added at a concentration of 0% to 12% weight of acid on weight of initial feedstock. A heated, acidified feedstock slurry is thus produced. The heated, acidified feedstock slurry is flowed through a pre-treatment reactor at a temperature of 160° C. to 280° C. for a time sufficient to increase efficiency of conversion of cellulose in the feedstock to glucose using cellulase enzymes. After the slurry exits the pre-treatment reactor, it is cooled using two, or more than two flashing stages at successively lower pressures, without intermittent increases in pressure. The steam energy, at or near its flash temperature, from two or more than two of the flashing stages is used to heat the feedstock slurry in the heating train.

Owner:IOGEN ENERGY CORP

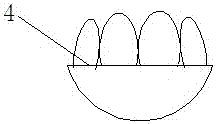

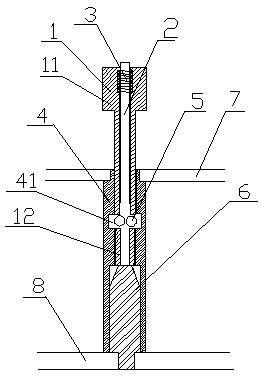

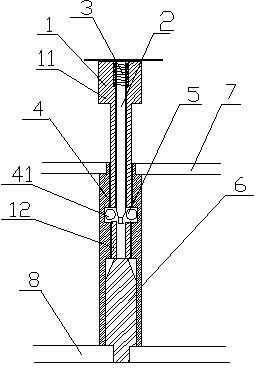

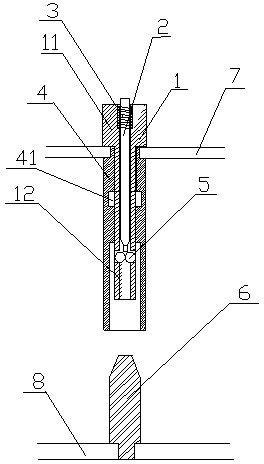

Mangosteen shell-opening device and use method of same

The invention provides a mangosteen shell-opening device and a use method of the same. The mangosteen shell-opening device is characterized by comprising a hydraulically-driven connection shaft, a shell-removing cutter arranged on the lower part of the connection shaft, fruit body spacing structures mounted on two sides of the shell-removing cutter and a fruit body bearing device perpendicular to the shell-removing cutter. The mangosteen shell-opening device is simply structured and convenient to use; work intensity of workers can be reduced; and enterprises personnel investment can be lowered. The mangosteen can be separated at the same time and fruit pulp can be remained the whole; and worker finger pollution can be avoided and production efficiency can be improved.

Owner:ZHEJIANG FENGYU ECOLOGICAL TECH CO LTD

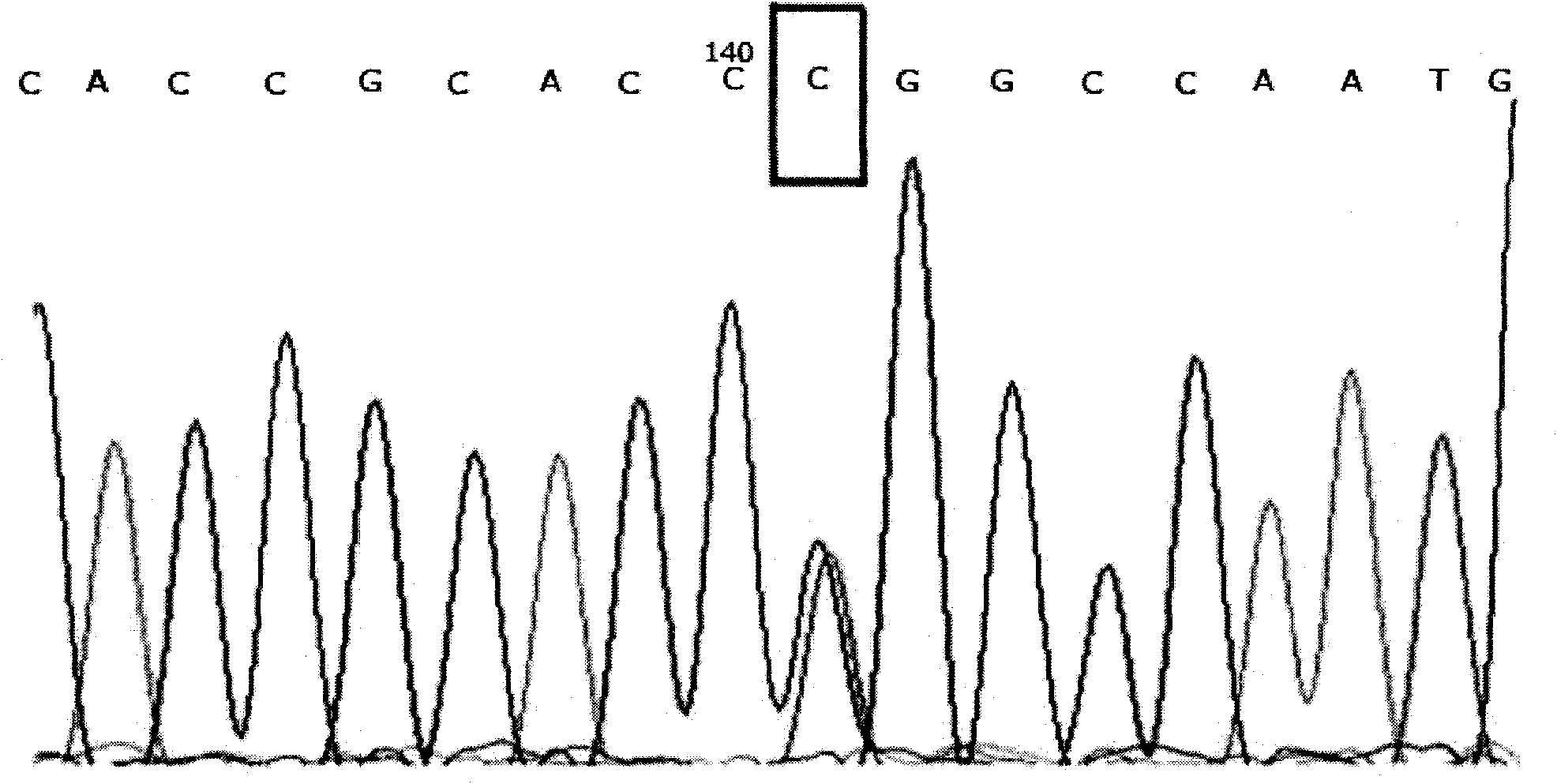

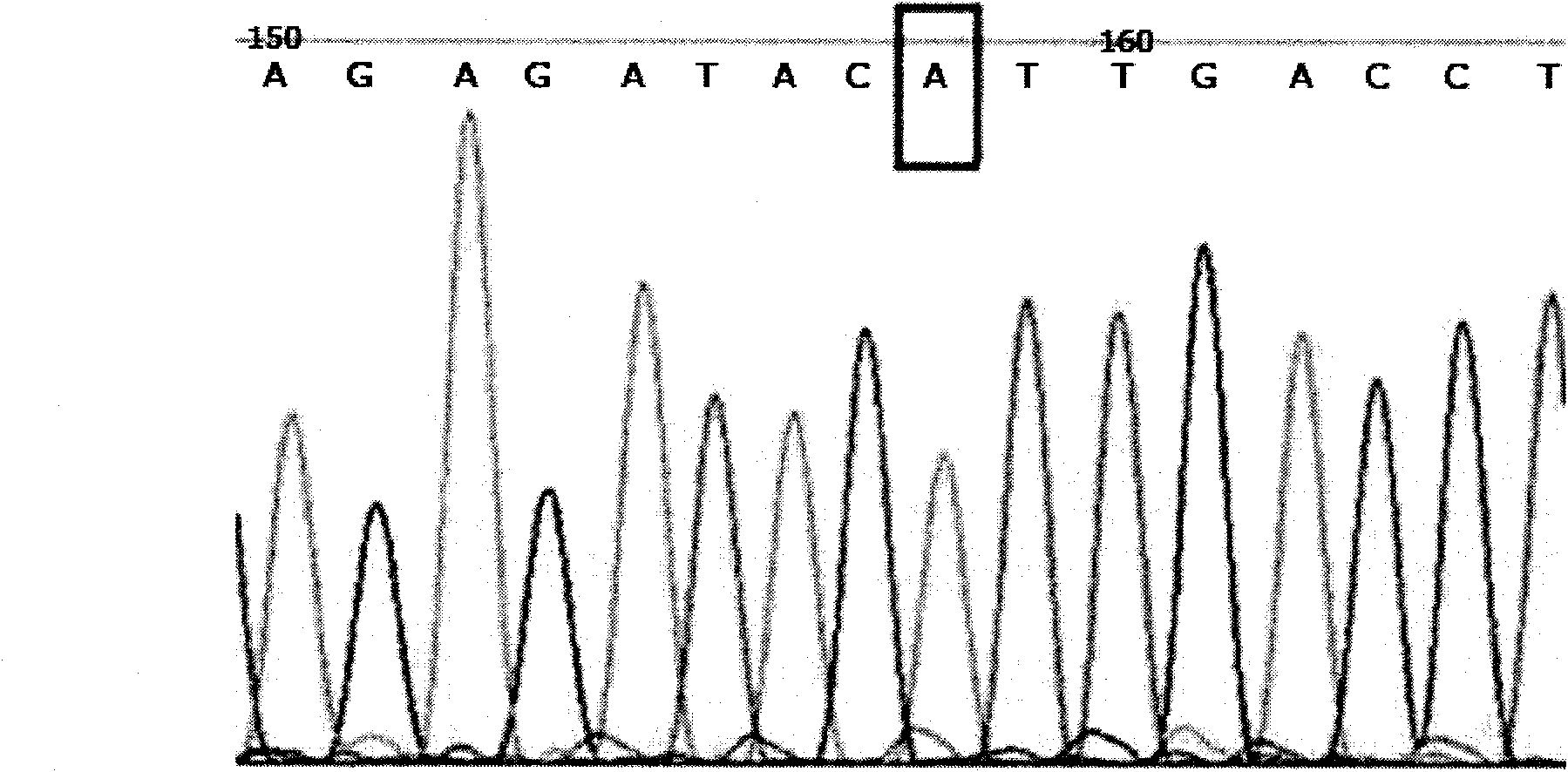

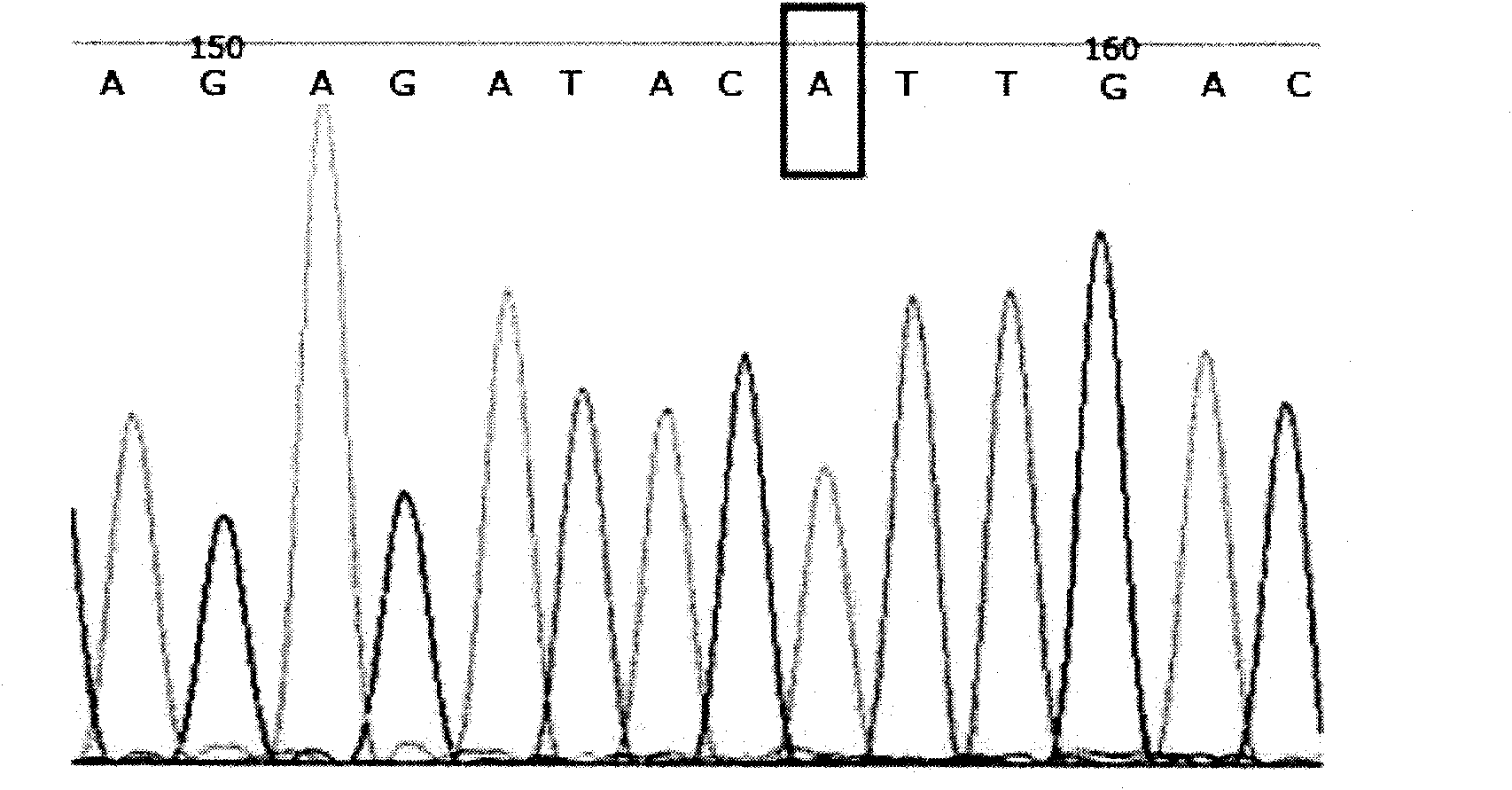

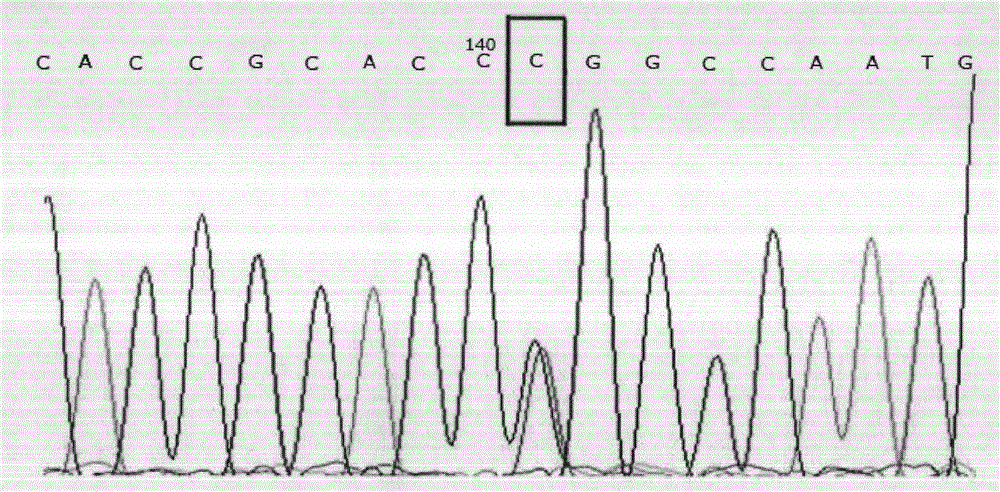

Kit for detecting SNP locus of gene associated with individualized medication of warfarin and PCR amplification method thereof

ActiveCN101899519AStrong specificityReduce the binding forceMicrobiological testing/measurementForward primerDisease

The invention provides a kit for detecting SNP locus of a gene associated with individualized medication of warfarin and a PCR amplification method thereof. The kit comprises two forward primers and a reverse primer used for detecting SNP locus of a gene VKORC1(-1639G / A) and / or two forward primers and a reverse primer used for detecting SNP locus of a gene CYP2C9(1075A / C). The kit of the invention can realize the high-efficiency and high-pass detection of the SNP loci of VKORC1(-1639G / A) and CYP2C9(1075A / C), so that the quantized control on the amount of warfarin is achieved; furthermore, the method plays a certain role in prevention of thrombotic diseases, choice of anticoagulants, research and development of new anticoagulants and prognosis of thrombotic diseases.

Owner:SUZHOU KUANGYUAN MOLECULAR BIOTECH

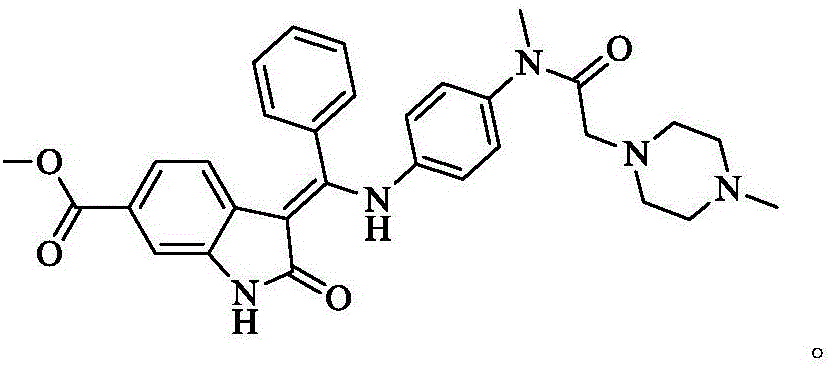

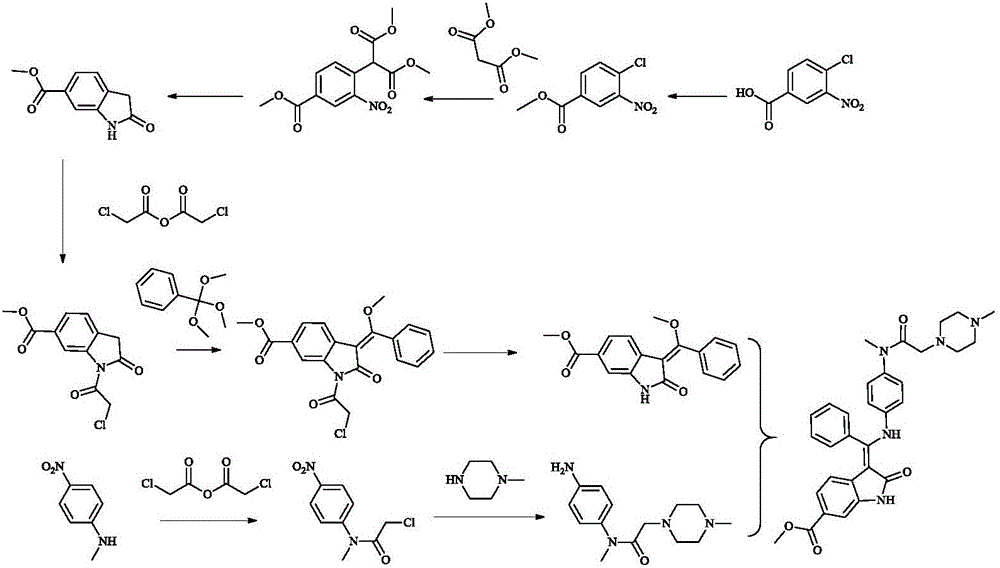

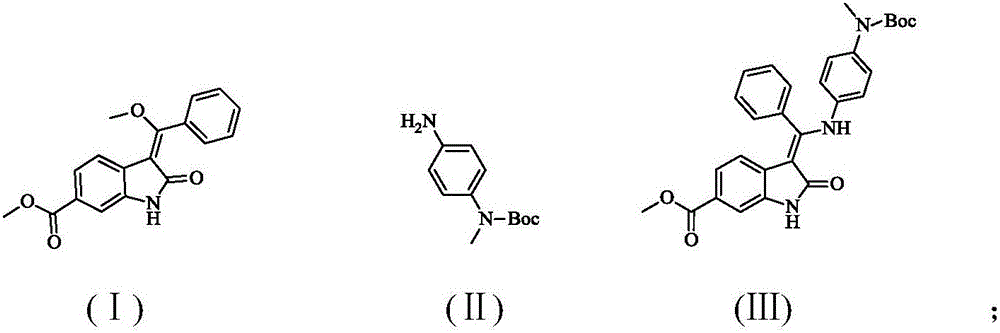

A synthetic method of Nintedanib and an intermediate of Nintedanib

ActiveCN105837493AReasonable designLow reaction temperatureOrganic chemistryAcetic acidChloroacetic acids

A synthetic method of Nintedanib and an intermediate of Nintedanib are disclosed. The method includes reacting a compound shown as a formula (II) and a compound shown as a formula (I) under acidic conditions to produce a compound shown as a formula (III), removing t-butyloxycarboryl of the compound shown as the formula (III) with an acid, adding an alkali, reacting to produce a compound shown as a formula (V), reacting the compound shown as the formula (V) with an activated derivative of chloroacetic acid to produce a compound shown as a formula (VI), and reacting with N-methyl piperazine to produce the Nintedanib. The novel synthetic method with mild reaction conditions for the Nintedanib is provided. The intermediate for synthesizing the Nintedanib is also provided.

Owner:SOUTHEAST UNIV

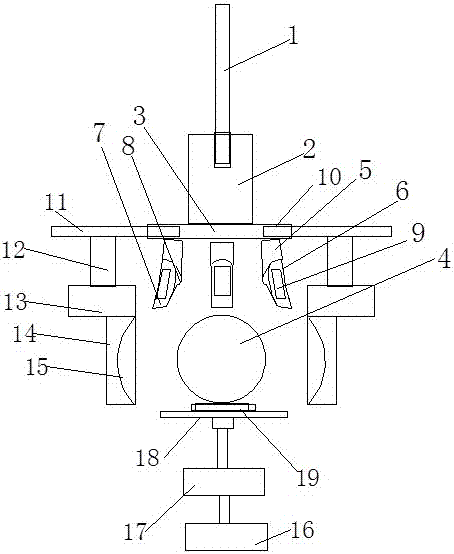

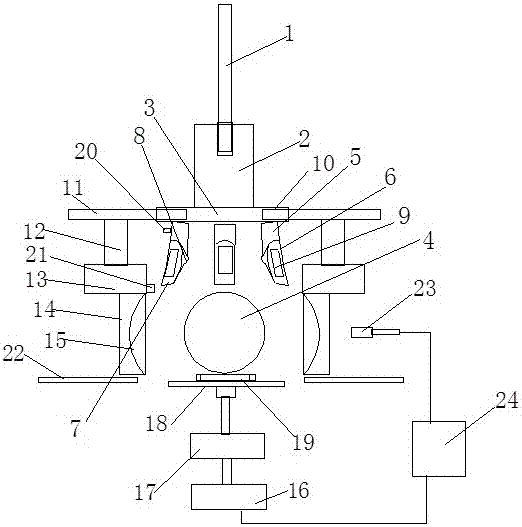

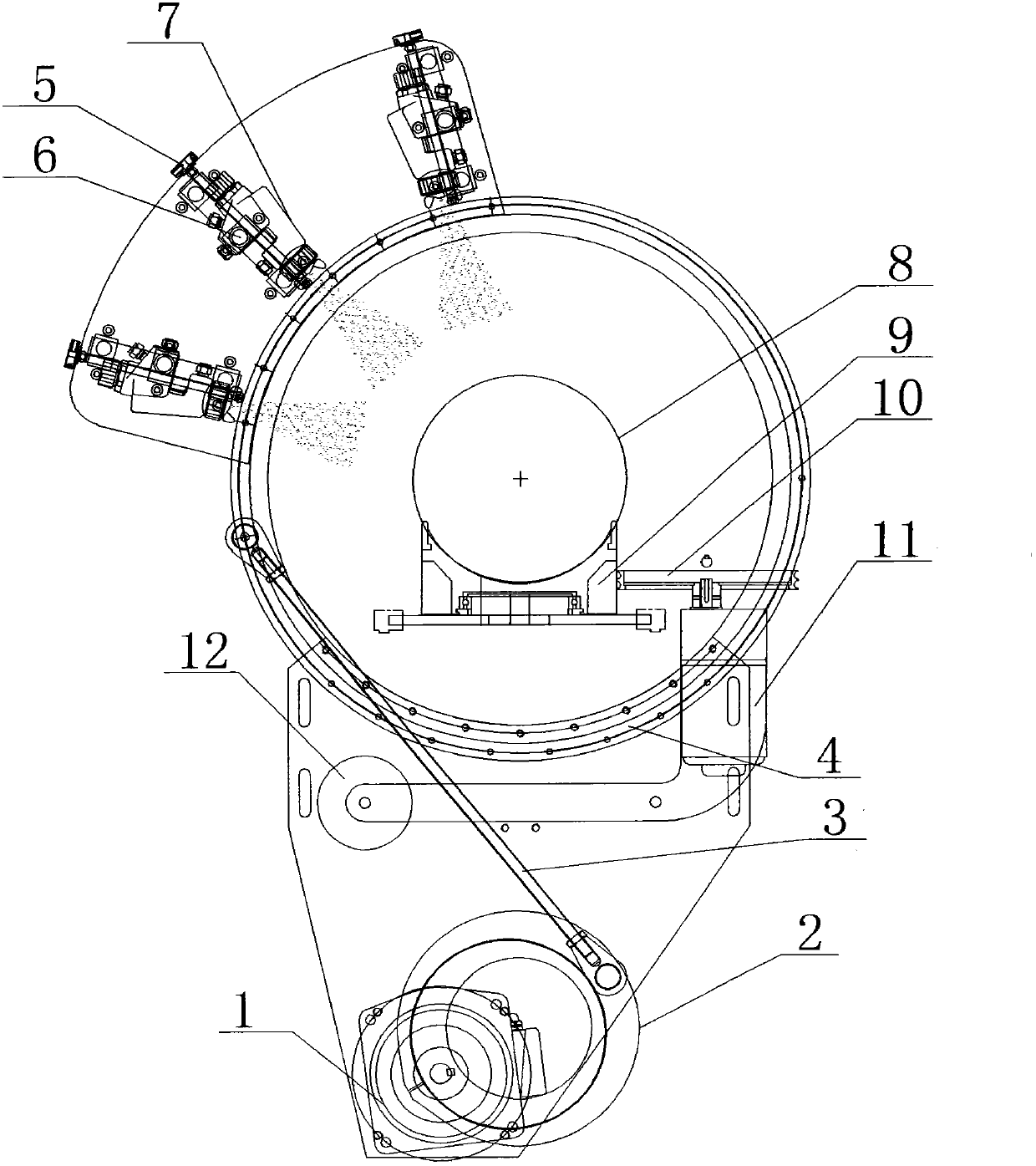

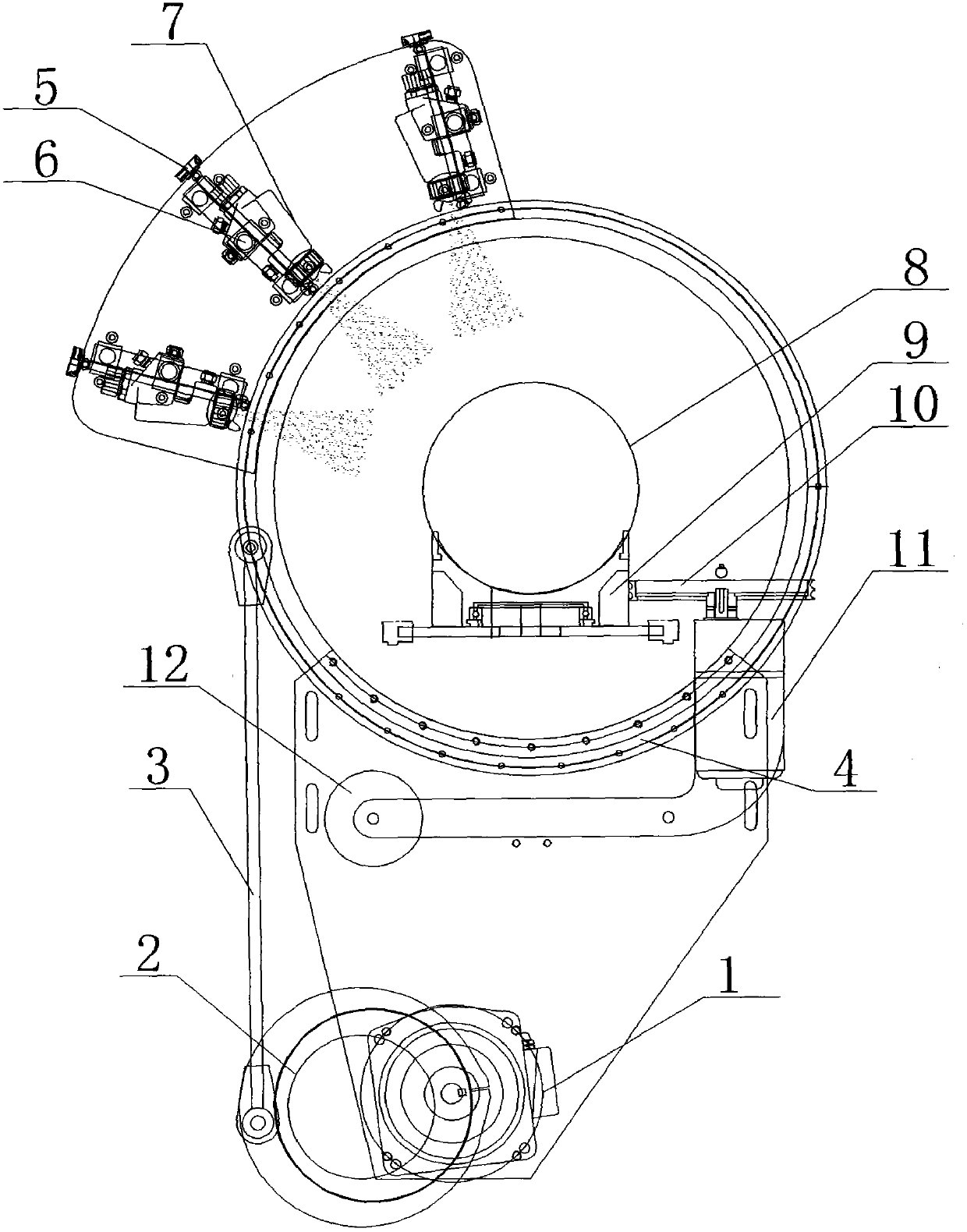

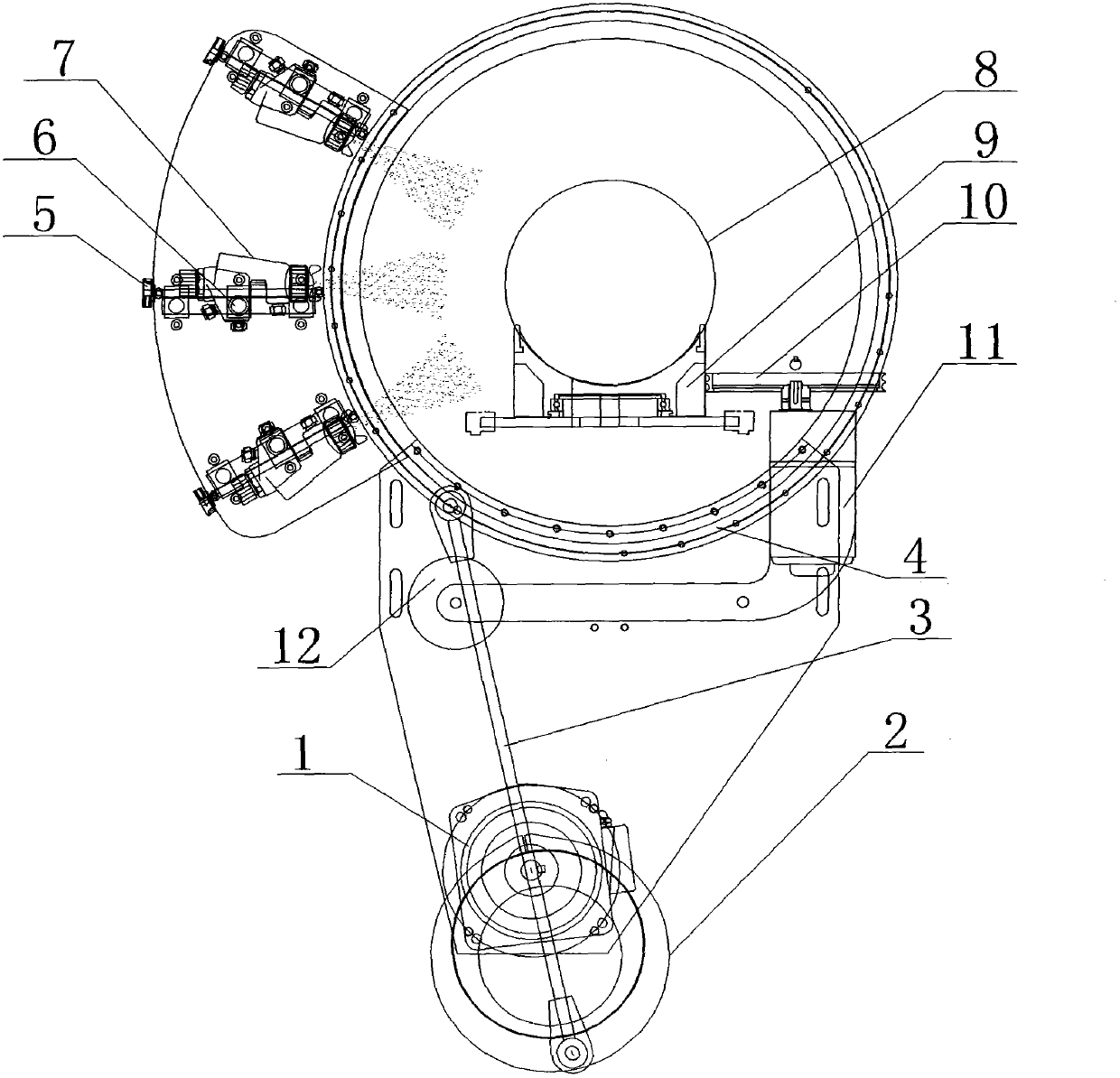

Automatic spherical surface coating machine

InactiveCN103272732ARealize automatic sprayingSimple structureSpraying apparatusCircular discSpherical form

The invention relates to an automatic spherical surface coating machine which is characterized in that three adjusting devices are arranged on a round disc bearing. Installation rods are arranged on the adjusting devices. Coating guns are arranged on the installation rods. Distances between the coating guns to the surface of a spherical workpiece and angles of the coating guns can be adjusted through the adjusting devices. A decentralizer is arranged below the round disc bearing which is connected with the decentralizer through a connecting rod. The decentralizer is arranged on a revolving shaft of a swing motor. The adjusting devices on the round disc bearing can swing up and down under the drive of the swing motor. An amplitude of swing of the adjusting devices can be adjusted through the decentralizer. An initial coating position can be adjusted through the connecting rod. The spherical workpiece is absorbed onto a self-absorbing clamp which can rotate around the principal axis of the clamp. A friction wheel is arranged on the outer side of the self-absorbing clamp. The self-absorbing clamp is jointed with the friction wheel which is installed on a rotation motor fixed on a tightening device. The automatic spherical surface coating machine is simple in structure, easy to operate and maintain, high in efficiency and constant in quality and general staff can operate the machine after being trained.

Owner:佘建锋

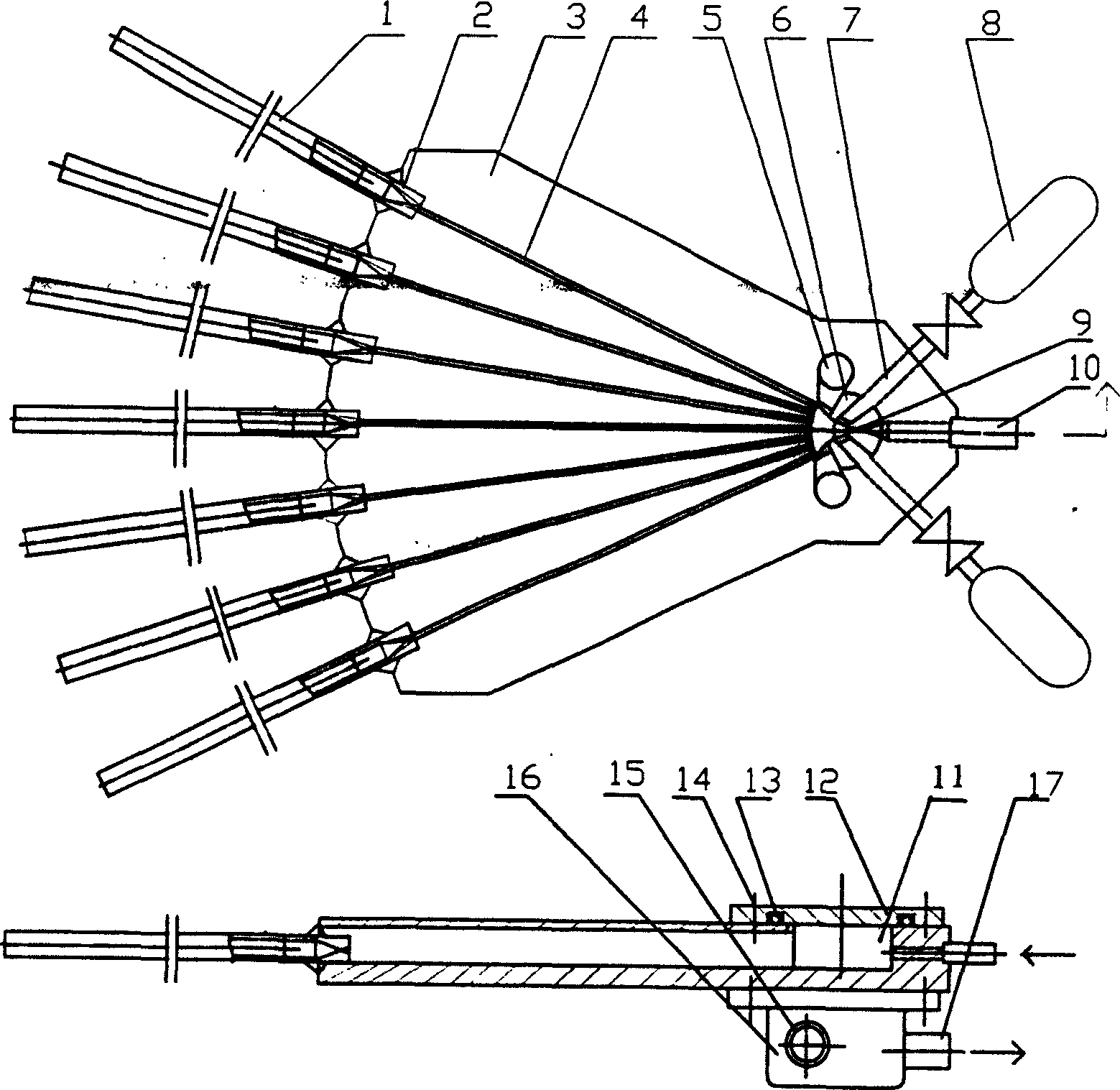

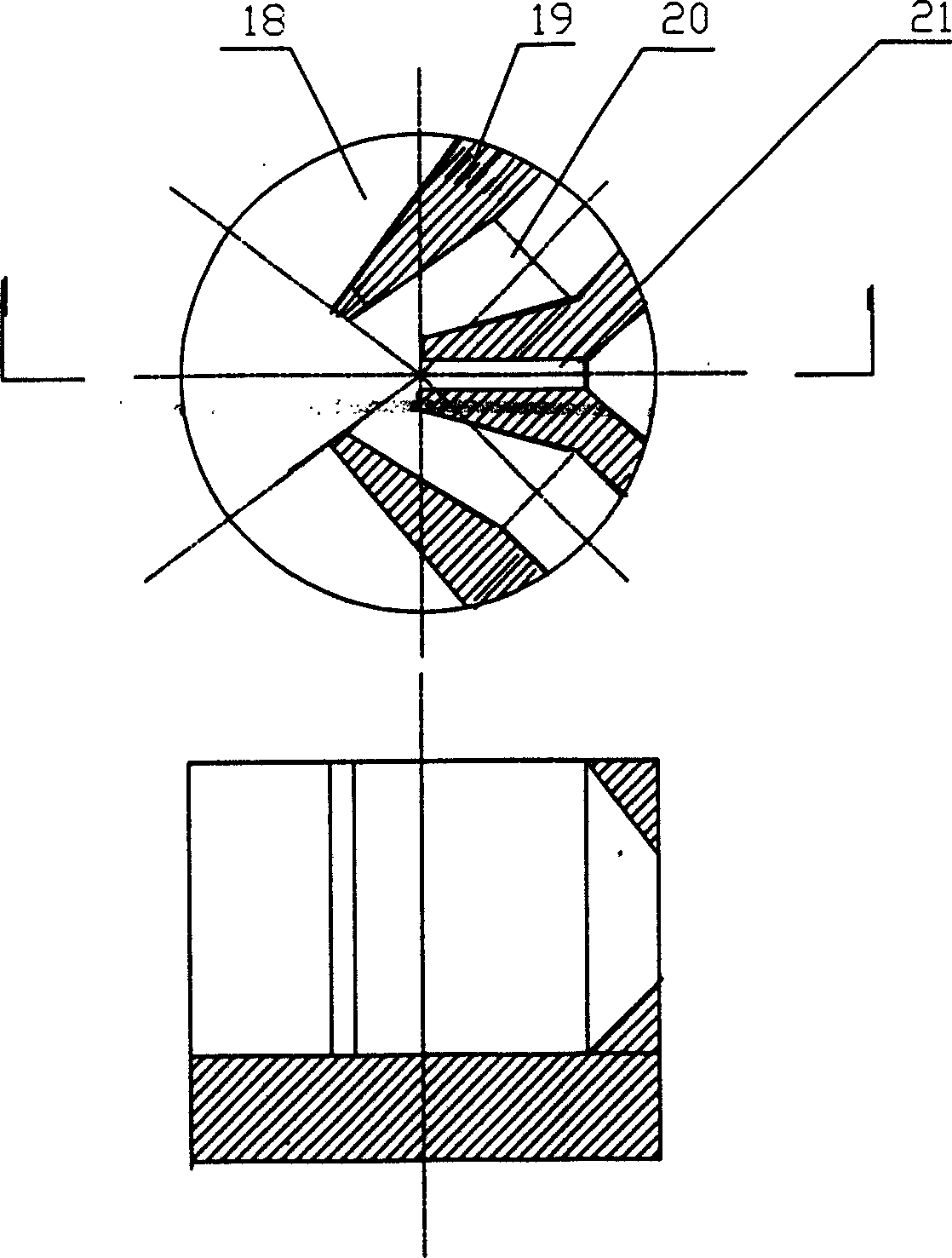

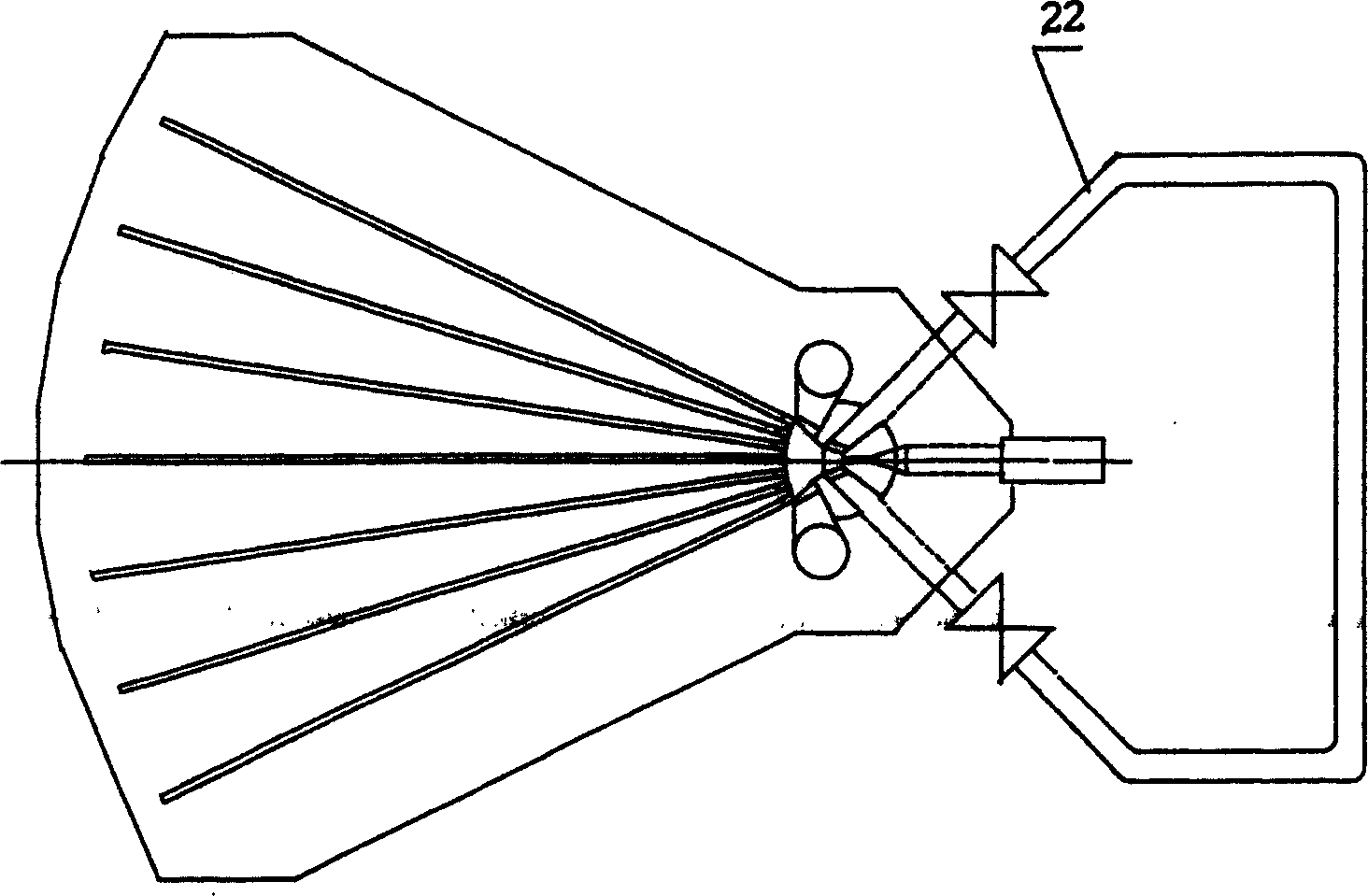

Multi-tube jetting oscillating refrigerator and its refrigeration method

InactiveCN1563856ASimple structureExtended operating cycleCompression machinesContinuous flowEngineering

Cold-heat effect of shock oscillation tube combined with jet oscillation technique is adopted in the invention to reach purpose of refrigeration. The machine is composed of main machine body, static ejector nozzle, oscillation receiving tube and acoustic oscillator etc. Under combined action of gas distributor and acoustic oscillator, gas is jetted in periodic deflexion and periodic intermittent into receiving tubes around to generate flow in high frequency oscillation. Further, under interaction effect and inference of series of wave including shock wave, compression wave and expansion wave, the machine completes unsteady expanding work and energy conversion so as to realize refrigeration through gas. Features are simple structure adjustable continuous flow, suitable to work medium in phases of gas and liquid.

Owner:DALIAN UNIV OF TECH

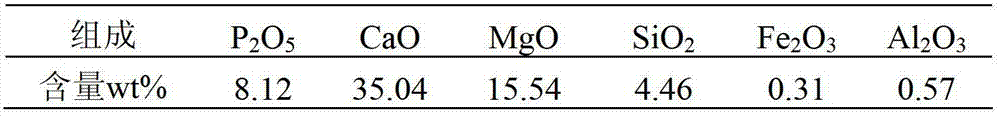

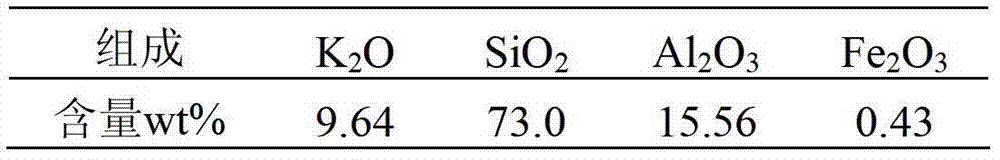

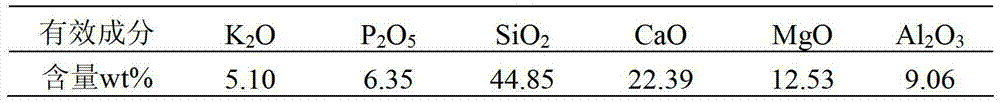

Method for producing alkaline fertilizer from insoluble potassium-containing rock by kiln process

ActiveCN103086778AIncreased alkalinityReduce the temperatureFertilizer mixturesPotassiumPhosphogypsum

The invention discloses a method for producing an alkaline fertilizer from insoluble potassium-containing rock by a kiln process, belonging to the technical field of chemical production. The method comprises the following steps: mixing phosphate rock tailings or low-grade phosphate rock with the insoluble potassium-containing rock according to the weight ratio of 1:(0.4-0.9), further adding anthracite accounting for 3-8% of the total mixed weight, drying, grinding and further preparing a material block; and then placing into a kiln, roasting at the temperature of 1000-1200 DEG C for 30-150 minutes to prepare sintered clinker, finally performing water quenching, reducing the temperature of the sintered clinker to 400-700 DEG C, and draining, drying, crushing and grinding the sintered clinker after water quenching to prepare the alkaline fertilizer. According to the method disclosed by the invention, the roasting temperature is only 1000-1200 DEG C, the energy consumption is low, and the process is simple; and phosphogypsum is not used, SO2 gas causing serious pollution of air is not contained in tail gas, and the special treatment of the tail gas is not required.

Owner:KINGENTA NORSTERRA CHEM CO LTD

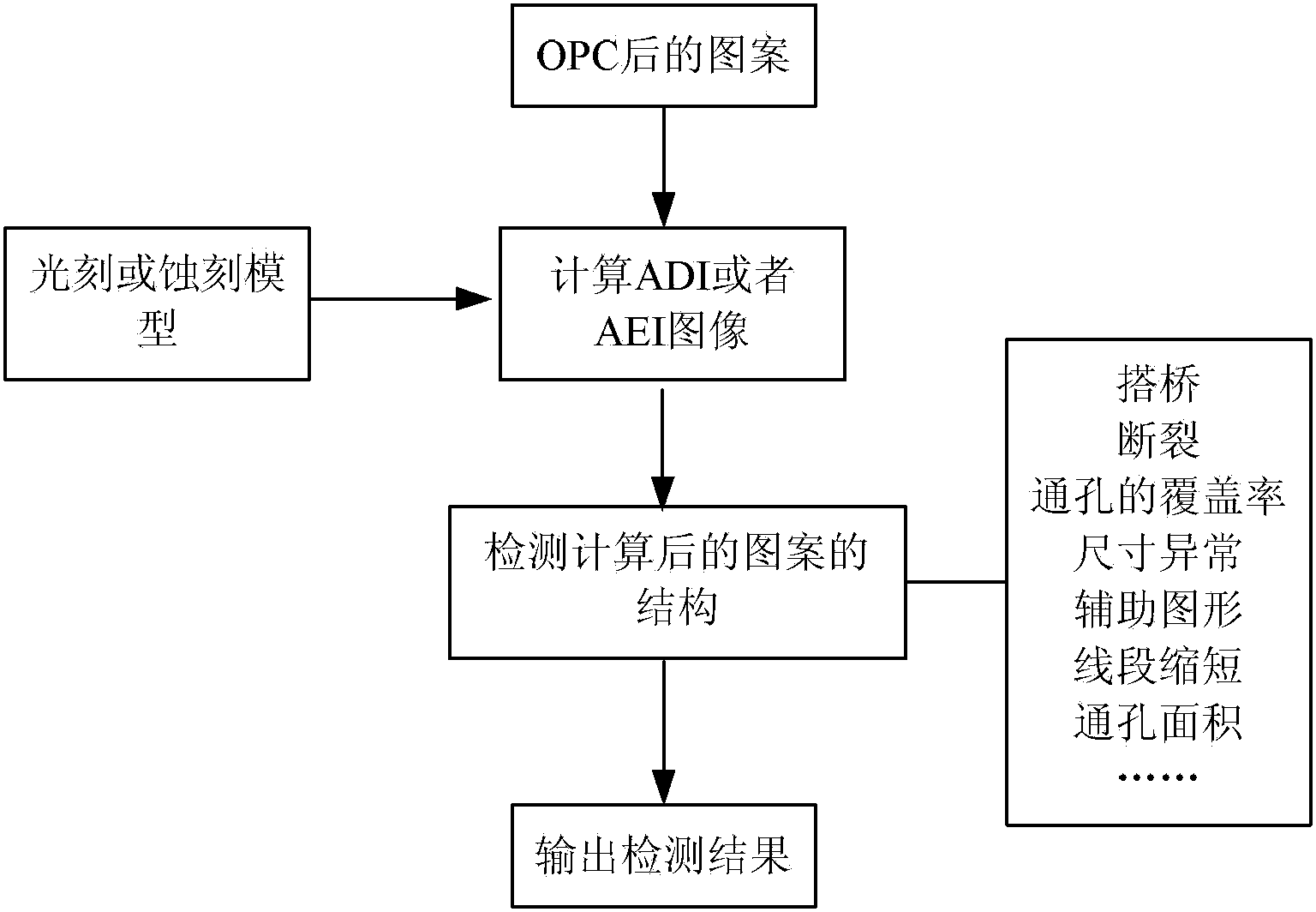

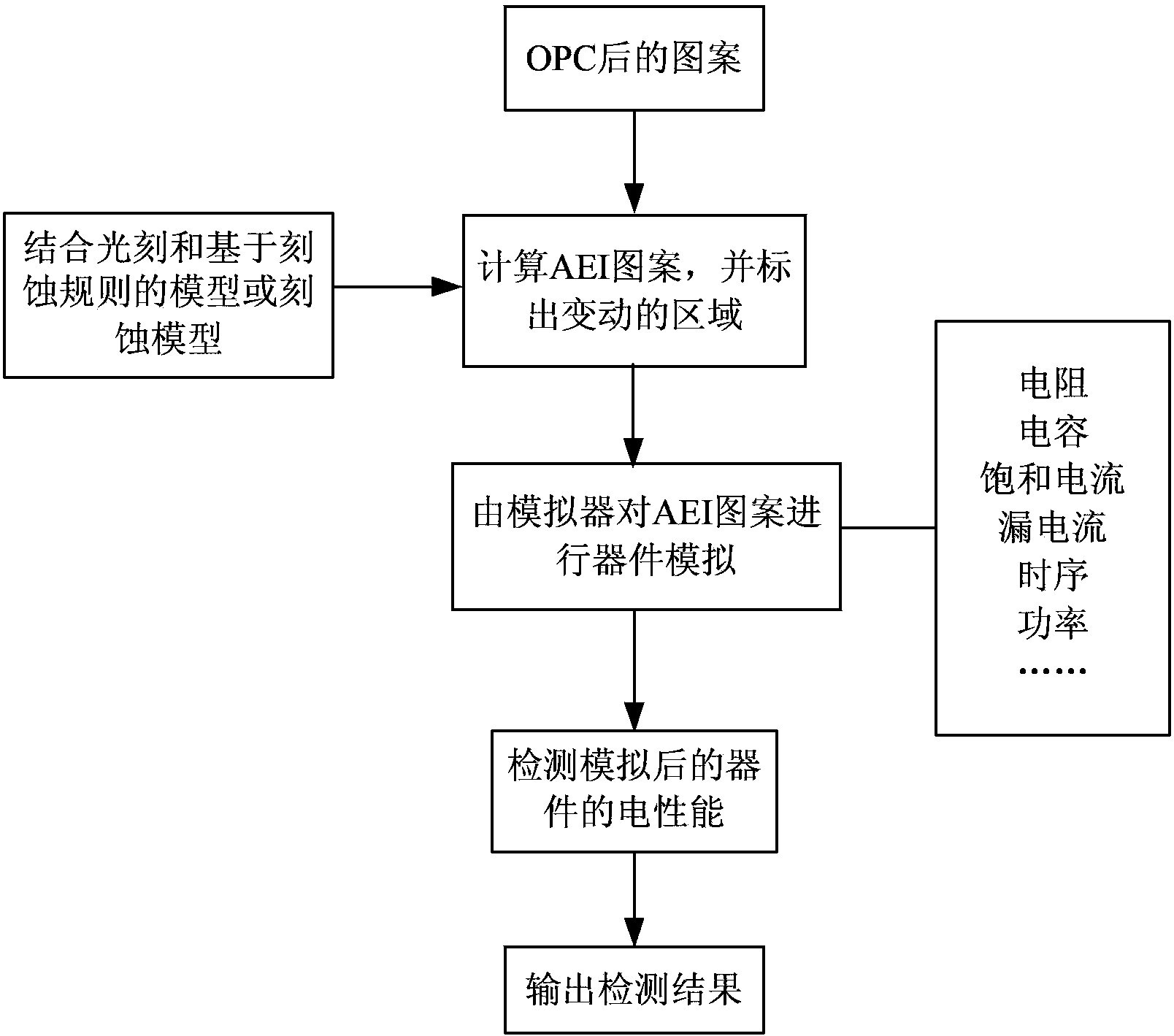

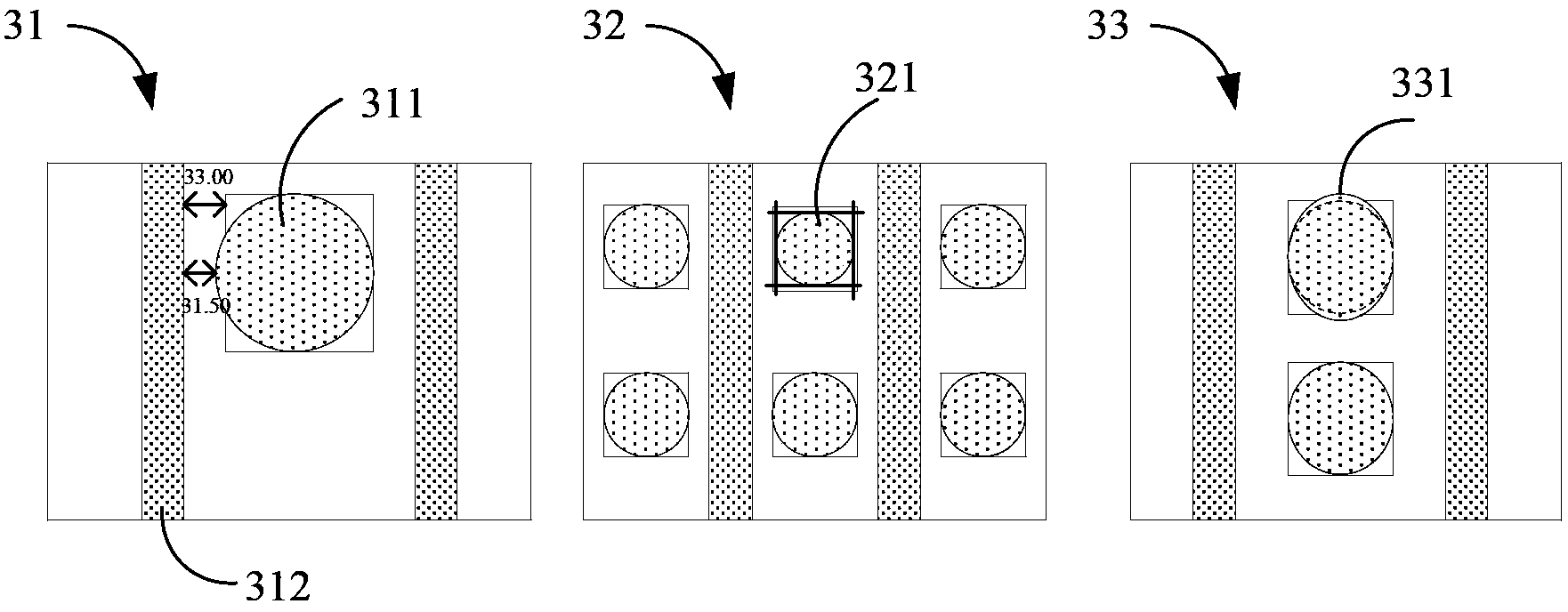

OPC (Optical Proximity Correction) verification method and method for preparing mask

InactiveCN103777459ASimple designShorten the timeOriginals for photomechanical treatmentElectricityDevice simulation

The invention discloses an OPC (Optical Proximity Correction) verification method and a method for preparing a mask. The method comprises the following steps: providing a pattern subjected to OPC, calculating an AEI (After Etch Inspection) outline and marking an area beyond the target value error according to the pattern subjected to OPC, performing device simulation, detecting the electrical property of the simulated device, judging the advantages and disadvantages of the pattern subjected to OPC, and preparing the mask on the basis. The verification of the OPC is introduced into the aspect of directly detecting the electrical property of the device, photoetching variation with a bad effect on the production of the device can be captured, and a good foundation is laid for manufacturing a high-quality device. Meanwhile, the weak design spot can be caught according to the detection on the electrical property, and continuous improvement of a mask manufacturing process is promoted, so that the design process is effectively optimized, and the time and investment are greatly saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Soft pink fresh wine brewing technology

ActiveCN105176722AMaximize potential qualityReduce waste of resourcesWine preparationVitis viniferaVintage

The invention discloses a soft pink fresh wine brewing technology and belongs to the technical field of wine brewing. The soft pink fresh wine brewing technology includes using two brewing technologies for brewing two kinds of raw wine respectively and blending the two kinds of raw wine. The soft pink fresh wine brewing technology includes the steps of (1) brewing sweet pink wine; (2), brewing dry pink wine; (3) blending the two kinds of raw wine; (4) performing rapid aftertreatment; (5) filling to come into the market. The soft pink fresh wine brewing technology has the advantages that the soft pink fresh wine brewing technology solves the use problem of poor-quality grapes in special years, makes full use of potential quality of the grapes, is easy to operate and has no difficulty in implementation basically since related required equipment is possessed by fine wine producers, thereby being popularized extensively easily; the time from fermentation to bottling to come into the market is short, so that long-time bottle storage is unneeded, and capital is saved.

Owner:山西戎子酒庄有限公司

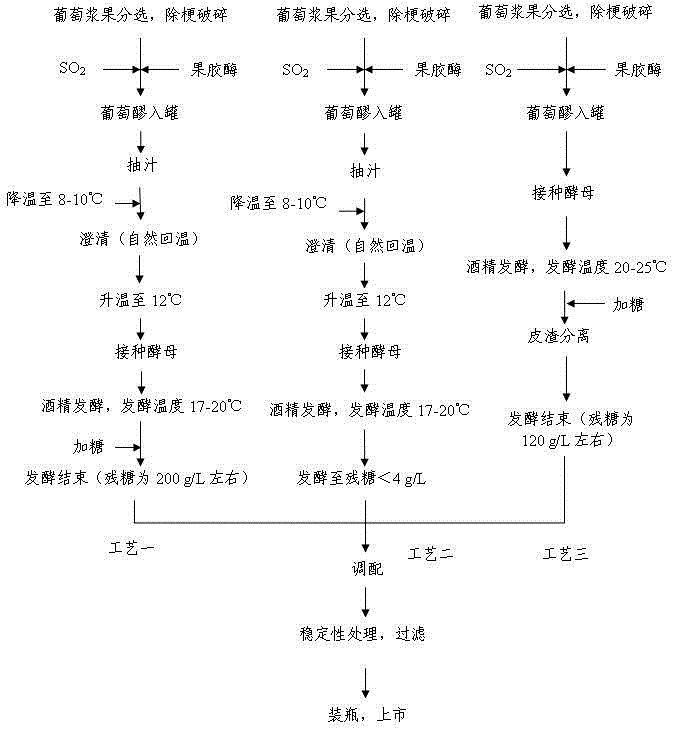

Brewage technique of thick sweet red fresh wine

ActiveCN105039044AMaximize potential qualityReduce waste of resourcesWine preparationVitis viniferaVintage

The invention relates to a brewage technique of a thick sweet red fresh wine, belonging to the technical field of wine brewage. The technique comprises three brewage processes for respectively brewing three unblended wines, and the three unblended wines are blended. The technique comprises the following steps: (1) brewing a sweet pink wine; (2) brewing a dry pink wine; (3) brewing a sweet red wine; (4) blending the unblended wines; (5) quickly carrying out after-treatment; and (6) filling and sending to the market. The technique successfully solves the problem of utilization of poor-quality grape raw materials in special years, fully utilizes the potential quality of the grape raw materials, is easy to operate, is easy to implement since every production enterprise has required related equipment, and can easily implement large-scale popularization. The technique requires short time from fermentation to bottling and appearance on the market, and does not need long-time bottle storage, thereby saving the cost.

Owner:山西戎子酒庄有限公司

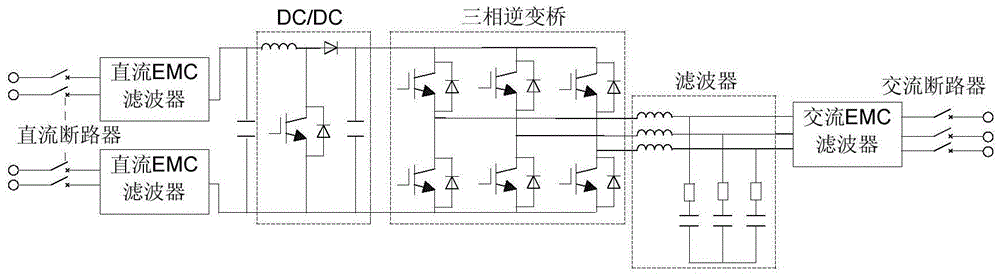

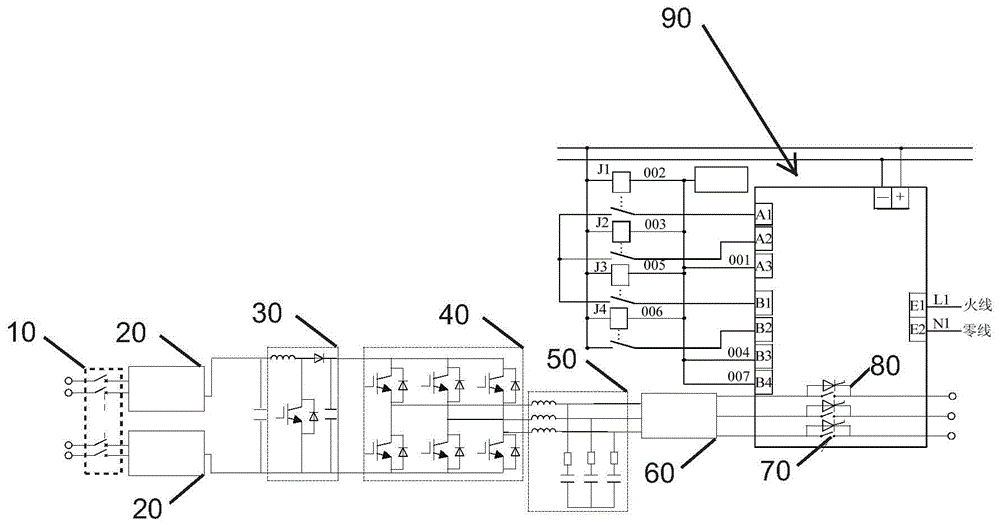

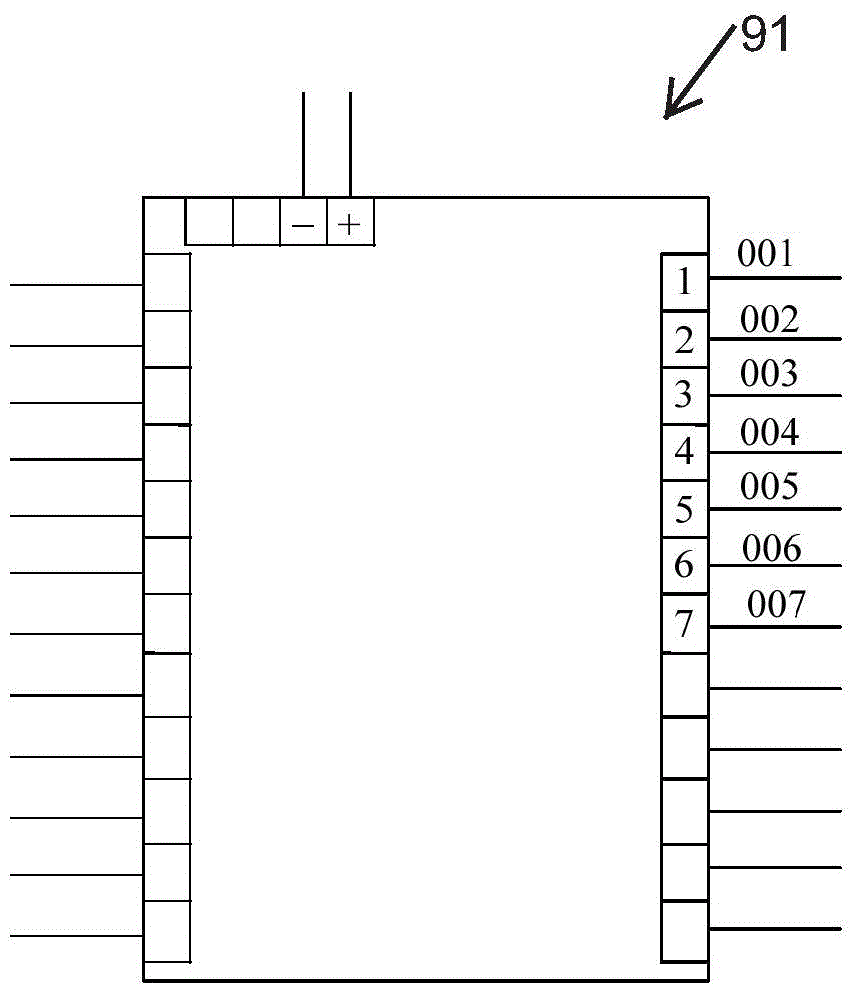

Soft start photovoltaic inverter and photovoltaic power generation system

ActiveCN104993684AReduce shockSmall starting currentAc-dc conversionPhotovoltaicsCapacitanceDc circuit breaker

The invention discloses a soft start photovoltaic inverter and a photovoltaic power generation system. The soft start photovoltaic inverter comprises a direct current breaker, a voltage stabilization capacitor, a three-phase inverter bridge, a filter and a thyristor. The direct current breaker, the voltage stabilization capacitor, the three-phase inverter bridge and the filter are electrically connected in sequence. An input end of the thyristor is electrically connected with an output end of the filter. The thyristor is configured in a way that by controlling a conduction angle of the thyristor, output voltage of the soft start photovoltaic inverter is enabled to be gradually increased from zero, and when the thyristor is fully conducted, the output voltage of the soft start photovoltaic inverter reaches the maximum value. The photovoltaic power generation system comprises a photovoltaic assembly, a combiner box, a box type transformer station, a boost station and the soft start photovoltaic inverter. The soft start photovoltaic inverter can reduce start current, reduce impact of starting of the photovoltaic inverter on a power grid, and improve the equipment integration degree.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Coal gasification greywater pretreatment method

ActiveCN106673292AReduce ammonia nitrogen contentReduce calcium and magnesium ion contentWater treatment parameter controlSpecific water treatment objectivesSodium carbonateEngineering

A coal gasification greywater pretreatment method comprises 3 steps: (1) a lye tank and a lye pump are arranged, mixed alkaline liquor comprising a caustic alkali solution and sodium carbonate is added to conversion condensate in a stripping tower feeding tank in a coal gasification device conversion system, the PH of the conversion condensate waiting for steam stripping in the stripping tower feeding tank is adjusted to 12, and caustic alkali is 30% industrial liquid alkali. (2) a bottom liquid of a stripping tower is sent into a buffer tank between a high-pressure flash evaporation tank and a low-pressure flash evaporation tank to be mixed with black water, and a mixed liquid is sent into the low-pressure flash evaporation tank for flash evaporation; (3) a real-time PH meter is arranged in front of an inlet of a low-pressure greywater pump, an acid fluid tank and an acid fluid pump are arranged, and a proper amount of hydrochloric acid is added to the low-pressure greywater tank for partial neutralization to adjust the PH to be in a range of 8.5-9.0. The content of ammonia nitrogen in greywater can be effectively reduced, the content of calcium and magnesium ions in the greywater is reduced, and system scaling is prevented. The method is simple and easy to implement, favorable for large-scale industrial production, lower in cost, capable of saving a lot of costs and suitable for popularization and use.

Owner:山东品高钢结构工程股份有限公司

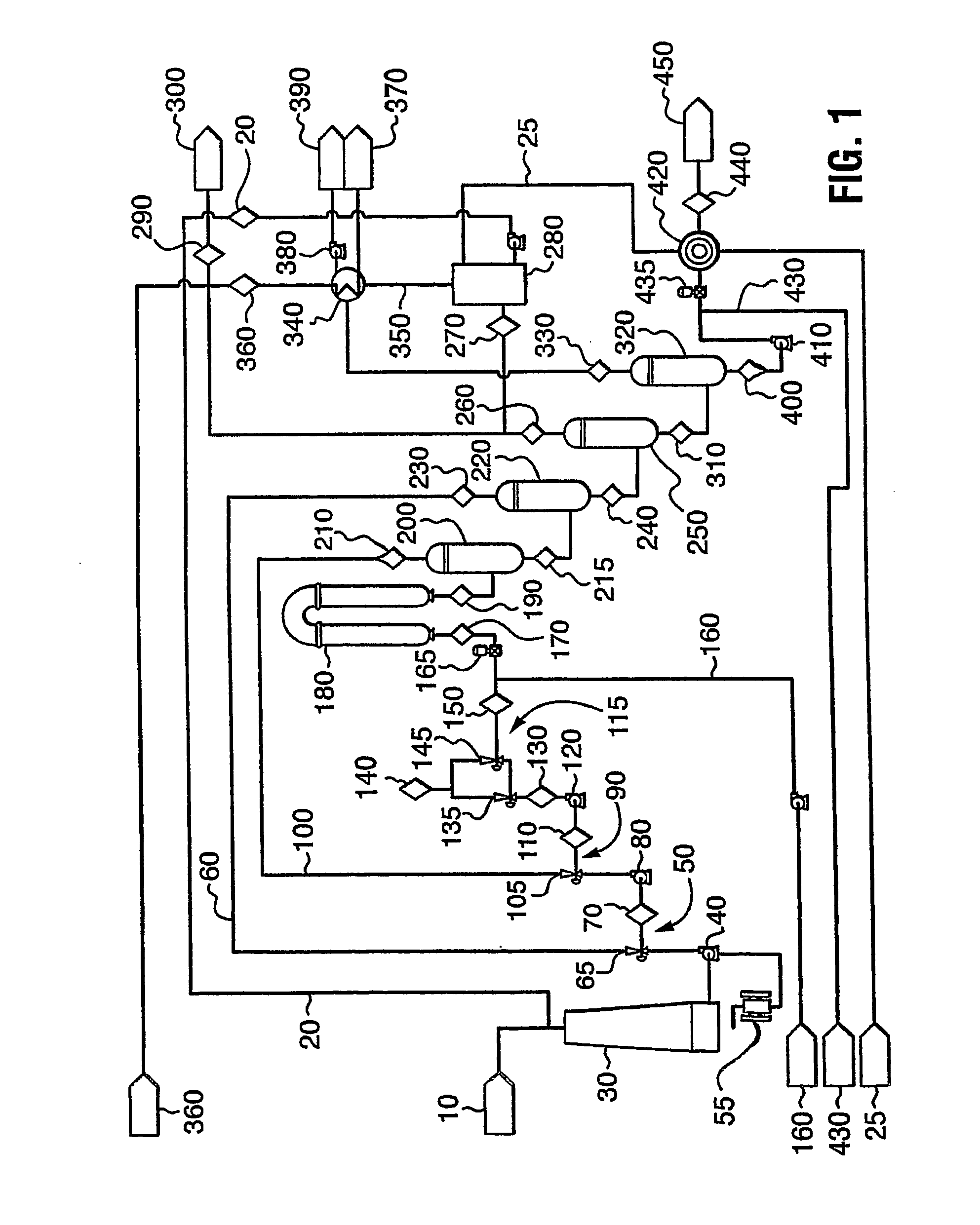

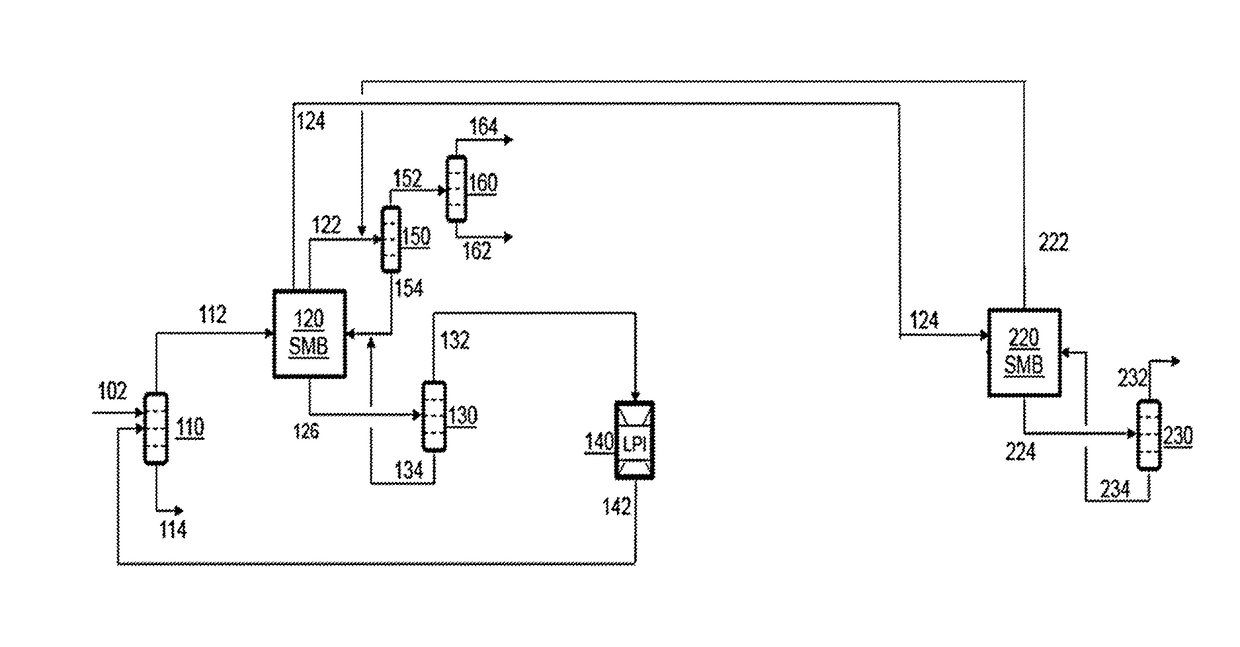

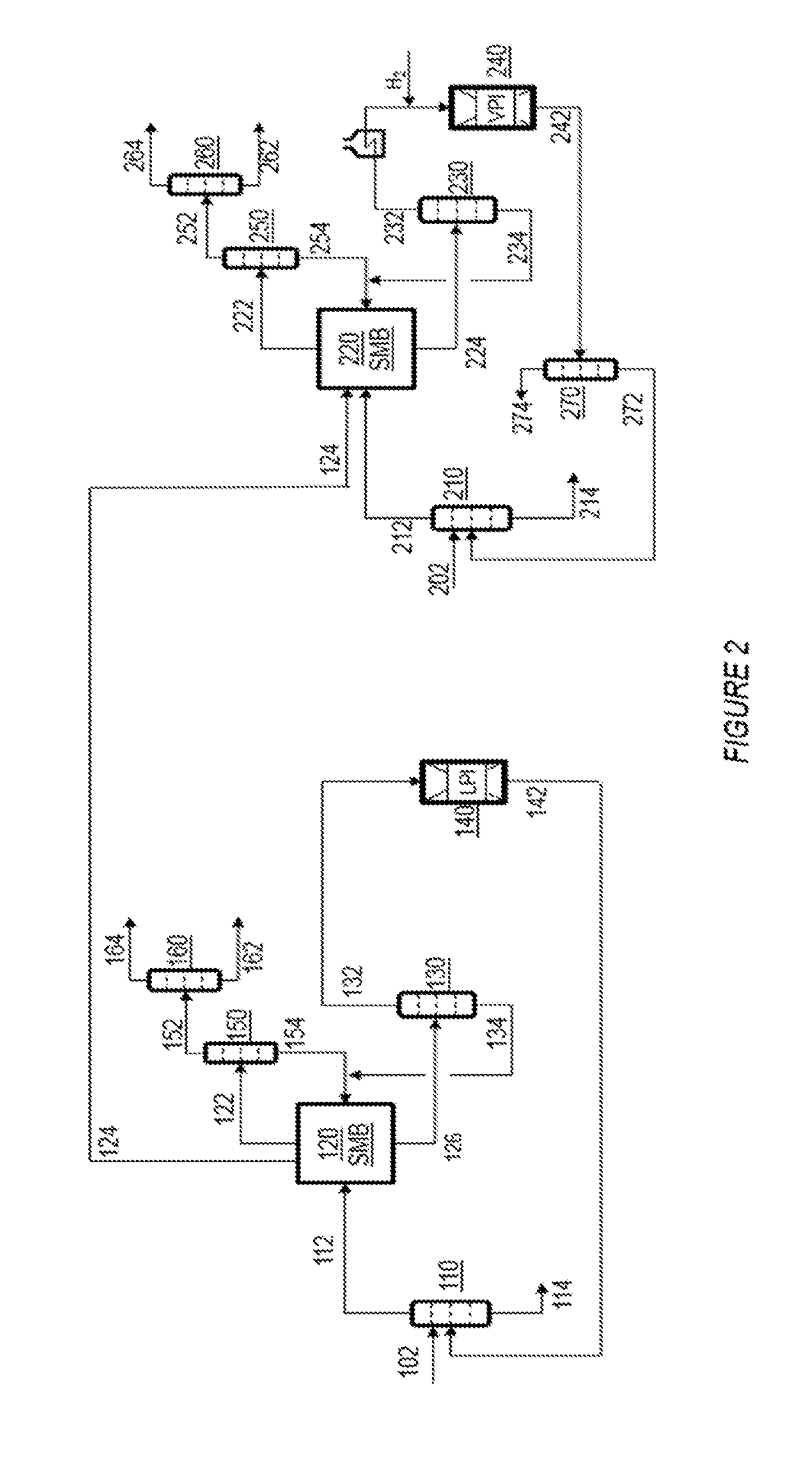

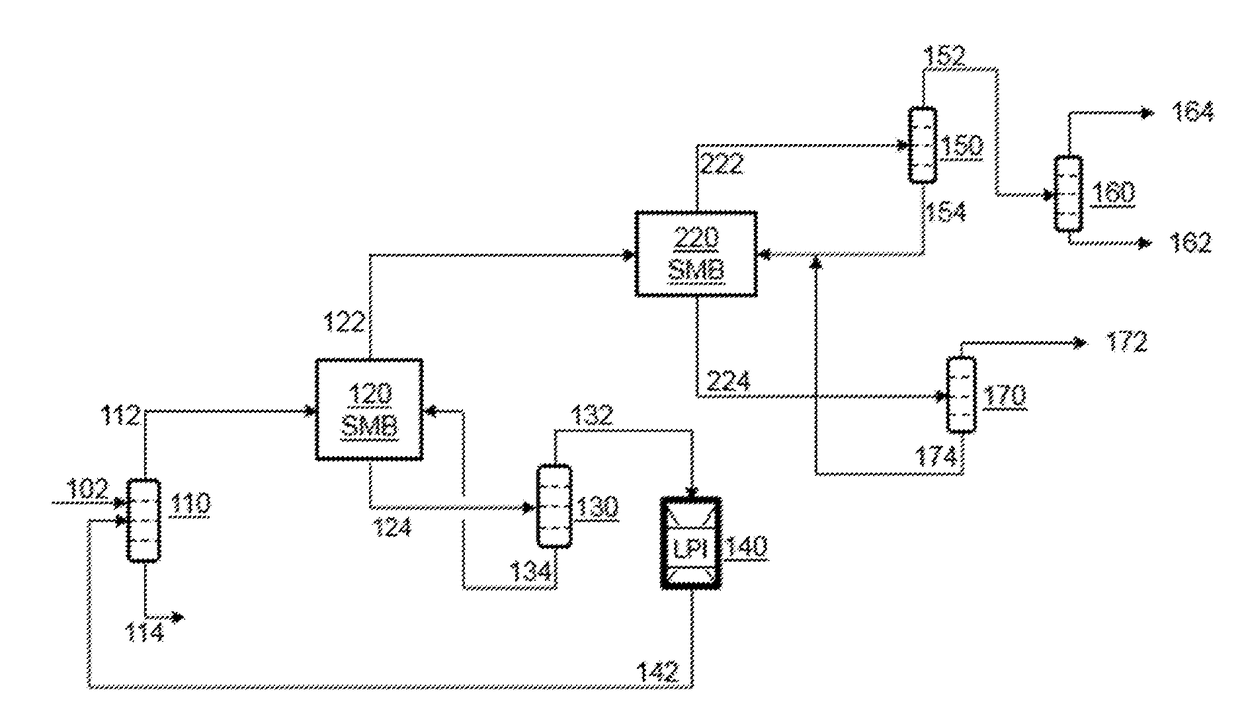

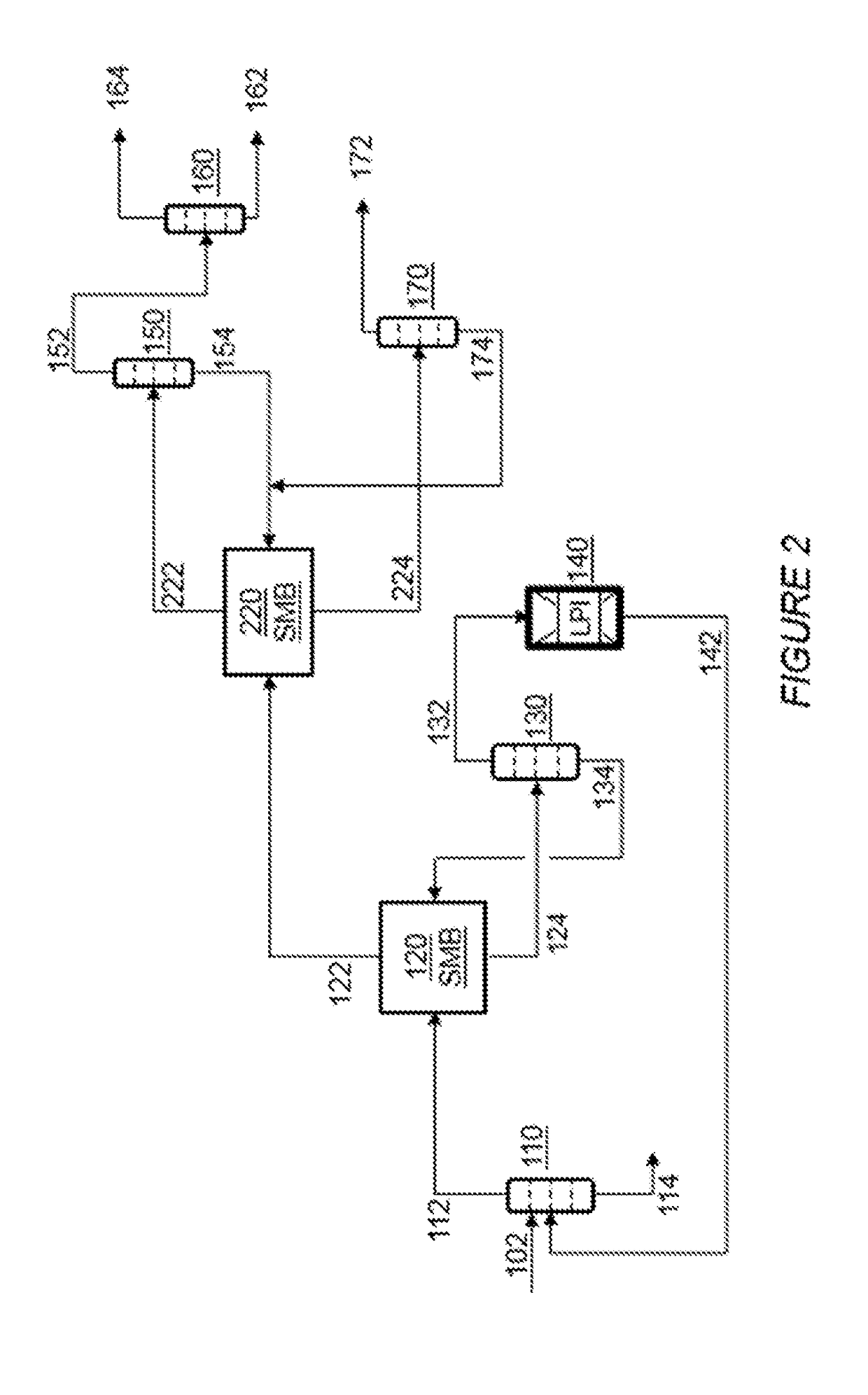

Processes for Recovering Paraxylene

InactiveUS20180002252A1Resist buildupSave energyOrganic compounds purification/separation/stabilisationHydrocarbon by hydrogenationIsomerizationHydrogen

Disclosed is a process for recovering paraxylene in which a first simulated moving bed adsorption unit is used to produce two extract streams—one rich in paraxylene and a paraxylene-rich extract stream that is lean in ethylbenzene and an ethylbenzene-rich extract stream that is lean in paraxylene- and a paraxylene-depleted raffinate stream. A significant amount of the ethylbenzene is removed in the ethylbenzene-rich extract stream (at least enough to limit buildup in the isomerization loop), so the paraxylene-depleted raffinate stream may be isomerized in the liquid phase. Avoiding vapor phase isomerization saves energy and capital, as liquid phase isomerization requires less energy and capital than the vapor phase isomerization process due to the requirement of vaporizing the paraxylene-depleted stream and the use of hydrogen, which requires an energy and capital intensive hydrogen recycle loop.

Owner:EXXONMOBIL CHEM PAT INC

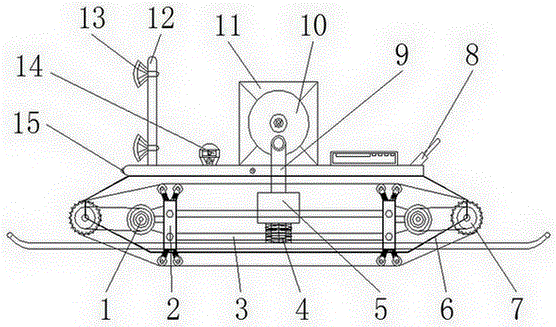

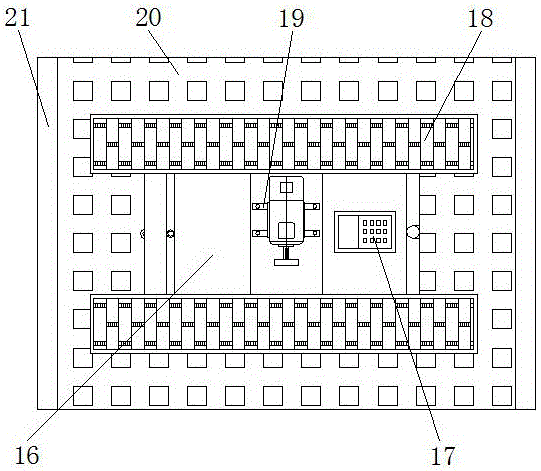

Intelligent robot for ground ramming

The invention discloses an intelligent robot for ground ramming. The intelligent robot comprises drive motors, an auxiliary wheel fixing frame, a searchlight, a GPS locator, infrared range finders, caterpillar bands, a motor support, a flat plate and guard bars. The drive motors are connected with gears. The auxiliary wheel fixing frame is connected with a connecting rod. A crank rod is connected with the flat plate. The gears are arranged on a gear fixing plate. A control panel is arranged at the left end of a signal receiver. The searchlight is arranged on a supporting rod. The caterpillar bands are arranged on the two sides of a supporting panel. According to the intelligent robot for ground ramming, innovative design is conducted in combination with existing building ground ramming equipment, the devices capable of being controlled intelligently are arranged on the intelligent robot for ground ramming, no manpower assisting is needed, manpower resources are saved greatly, and the investment is saved; and the GPS locator and the infrared range finders are arranged, and the effect and safety of working of the robot can be well guaranteed.

Owner:苏州曾智沃德智能科技有限公司

Liquid for improving viscidity of bat for table tennis rubber and maintaining the same, and method for producing the same

InactiveCN101220235AIncrease elasticityReduce viscosityRosin coatingsRacket sportsPolymer sciencePre-condition

The invention discloses a thickening and maintenance solution for the rubber sheet of a table tennis bat and the preparation method thereof and belongs to the field of thickening and maintaining the rubber sheet of the table tennis bat. The invention is characterized in that: the solution mainly contains high molecular resin, a regulator for PH value, a humectant, a surface active agent and menstruum; wherein, the high molecular resin is water-soluble polymer that can form a layer of protective film on the rubber sheet of the table tennis bat; the regulator for PH value is organic alkali regulator; the surface active agent adopts nonionic surfactant. The invention helps to raise the glutinosity of the rubber sheet and greatly prolong the service life of the rubber sheet under the pre-condition of not affecting the elasticity of bats.

Owner:SHENYANG POLYTECHNIC UNIV

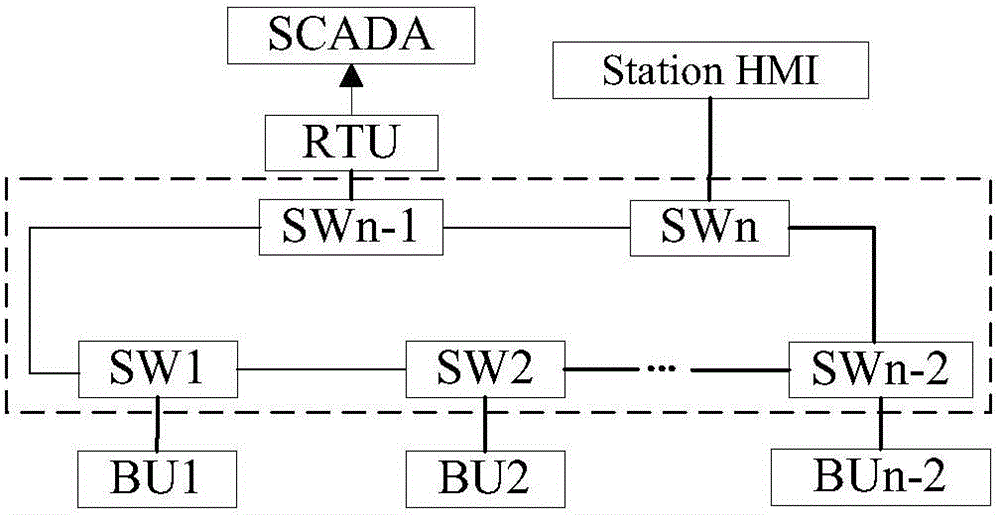

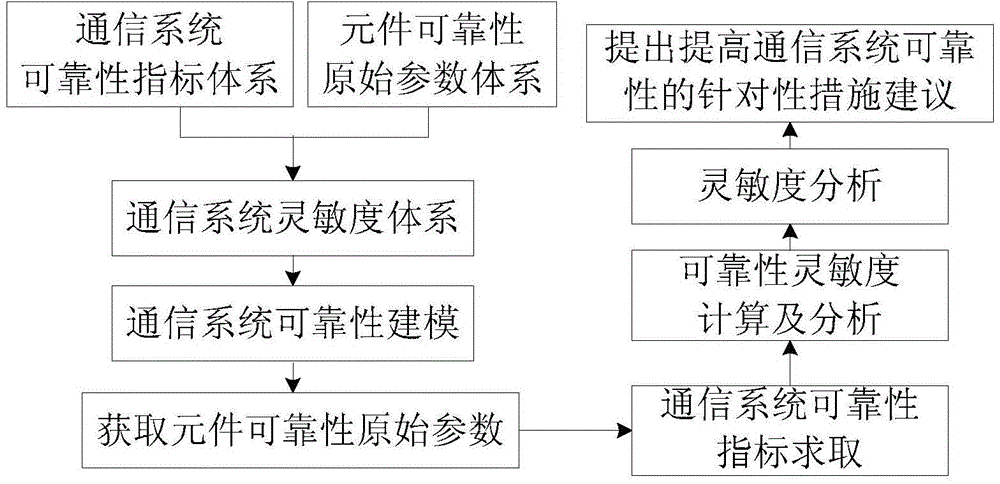

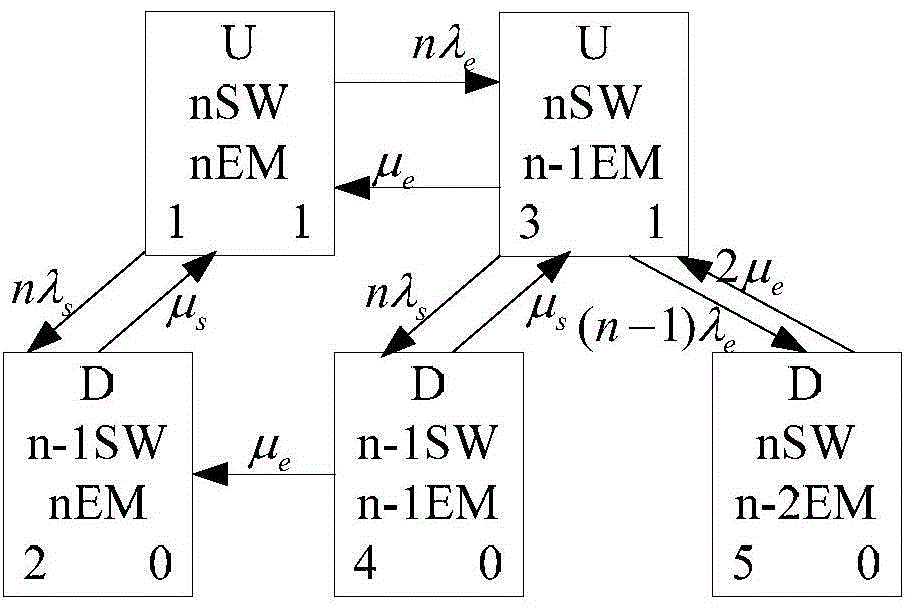

Smart substation communication system reliability and flexibility analysis method and system

ActiveCN104601384AReliability QuantificationImprove reliabilityData switching networksSmart substationAnalysis method

The invention discloses a smart substation communication system reliability and flexibility analysis method and system applied to a smart substation communication system. The method includes 1, establishing a reliability indicator system; 2, establishing an original parameter system; 3, establishing a flexibility system; 4, acquiring a system state space model; 5, acquiring original parameters; 6, acquiring reliability indicators; 7, calculating the flexibility; 8, analyzing the flexibility; 9, providing reliability improving measurement advances; 10, completing the flexibility analysis, and implementing the reliability and flexibility analysis method. The flexibility of the smart substation communication system is analyzed, the weak link of the smart substation communication system can be found out, and the reliability of the smart substation communication system can be improved.

Owner:STATE GRID CORP OF CHINA +2

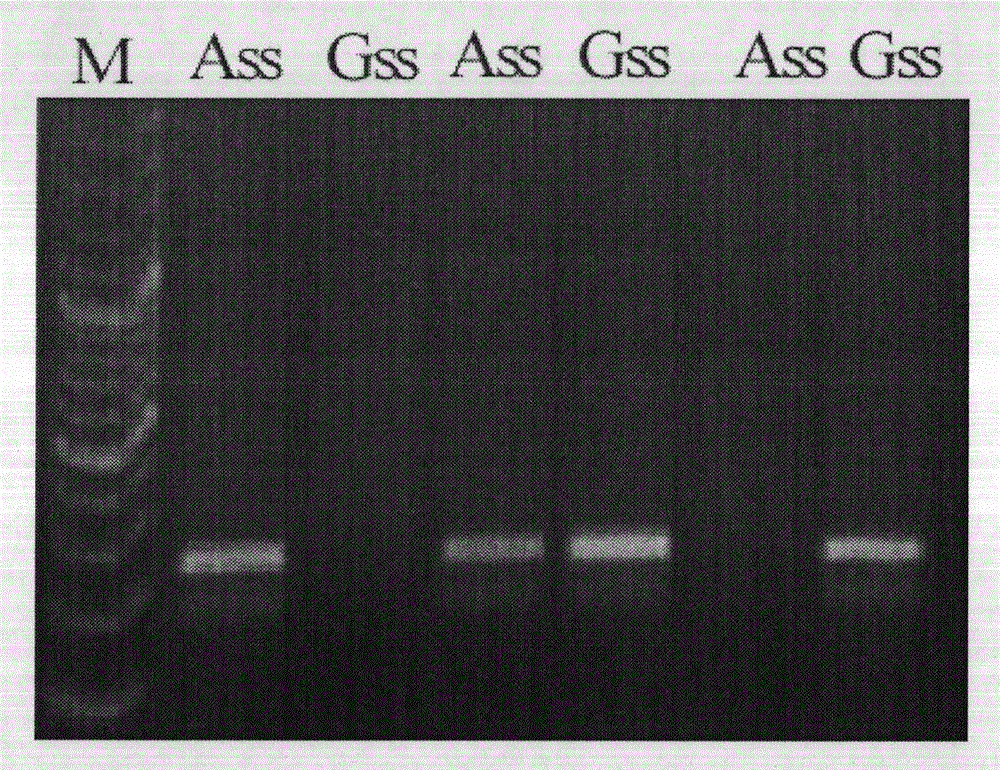

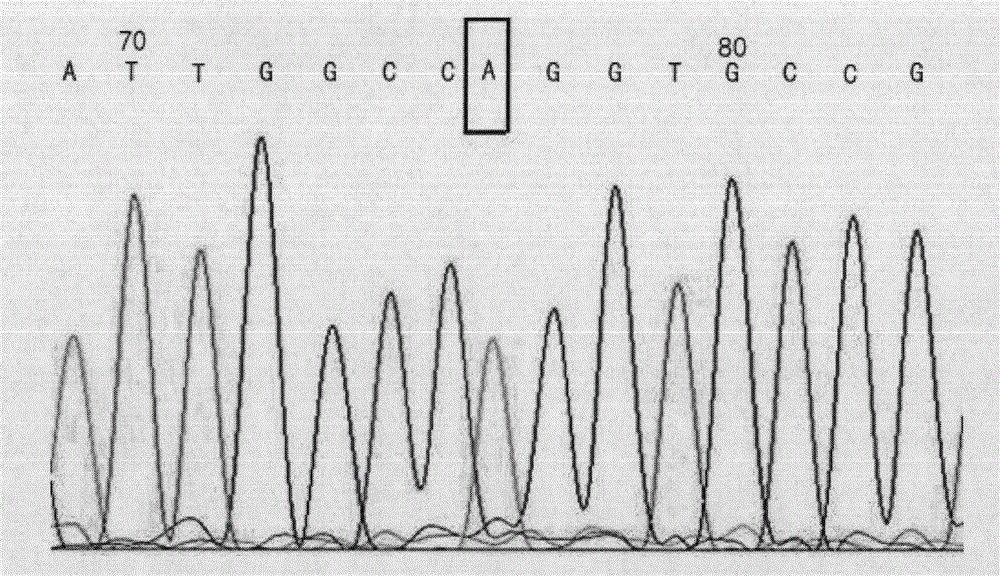

Kit for warfarin personalized medication related gene SNP locus detection and PCR amplification method using same

InactiveCN102719524AStrong specificityReduce the binding forceMicrobiological testing/measurementForward primerDisease

A kit for warfarin personalized medication related gene SNP locus detection and a PCR amplification method using same. The kit includes two forward primers and one reverse primer for detecting gene VKORC1 (-1639G / A) SNP locus and / or two forward primers and one reverse primer for detecting gene CYP2C9 (1075A / C) SNP locus. The kit provided by the invention can realize VKORC1 (-1639G / A) and CYP2C9 (1075A / C) SNP locus detection with high efficiency and high throughput, so as to achieve warfarin dose quantification control, and even play a certain role for prevention of thrombotic disease, selection of anticoagulant drug, research and development of the novel anticoagulant drug, and prognosis of thrombotic disease.

Owner:SUZHOU UNIV +1

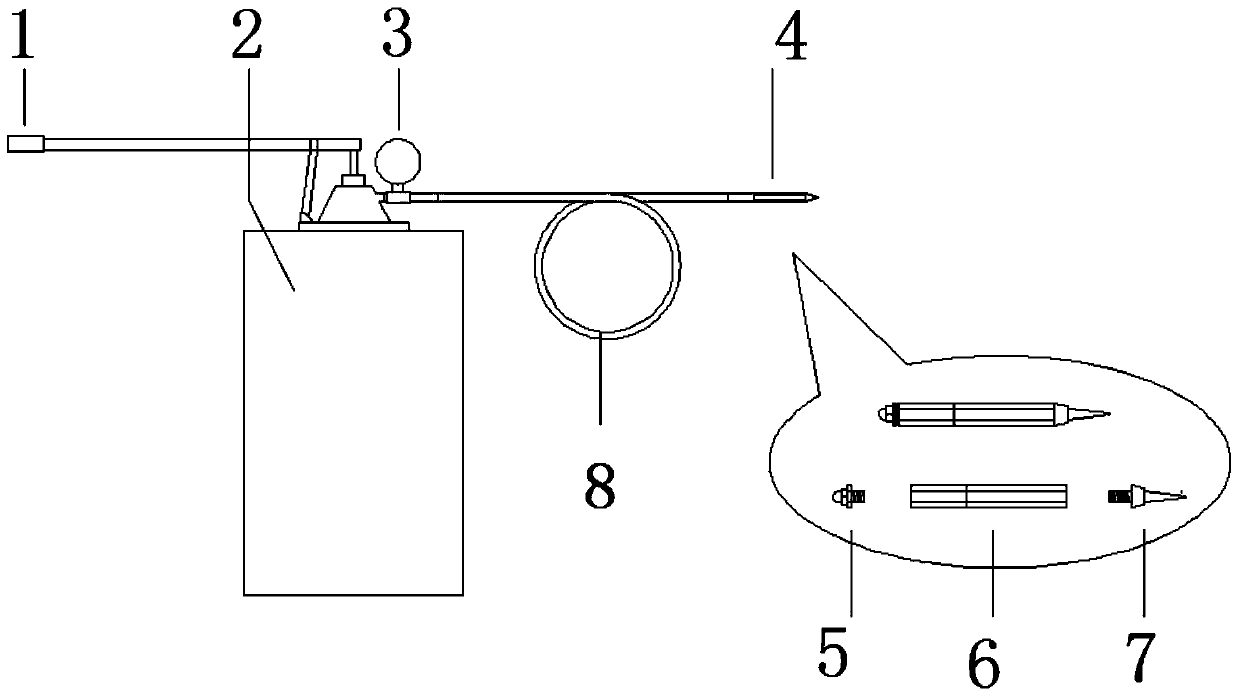

Device and method for repairing tiny cracks in in-service concrete pole through grouting

ActiveCN103590618AImprove work efficiencySimple structureBuilding repairsTowersReinforced concreteEngineering

The invention discloses a device and method for repairing tiny cracks in an in-service concrete pole through grouting. The device comprises a hand-operated high-pressure grouting pump and a water stopping needle head. The hand-operated high-pressure grouting pump comprises a hand-operated hydraulic device, a pressure gauge, a material filling barrel and a grouting pipe. The water stopping needle head comprises an injection nozzle, an extending pipe and a needle tip. The hand-operated hydraulic device is fixed to the upper end of the material filling barrel, the inlet of the grouting pipe is connected with the outlet of the hand-operated hydraulic device, the pressure gauge is fixed to the inlet of the grouting pipe, the outlet of the grouting pipe is connected with the injection nozzle of the water stopping needle head, the injection nozzle is connected with the extending pipe, and the extending pipe is connected with the needle tip. The method and the device solve the problem of repairing the tiny cracks in the in-service concrete pole and overcome the limitation of an existing repairing method, and the method is simple and high in operability.

Owner:STATE GRID CORP OF CHINA +1

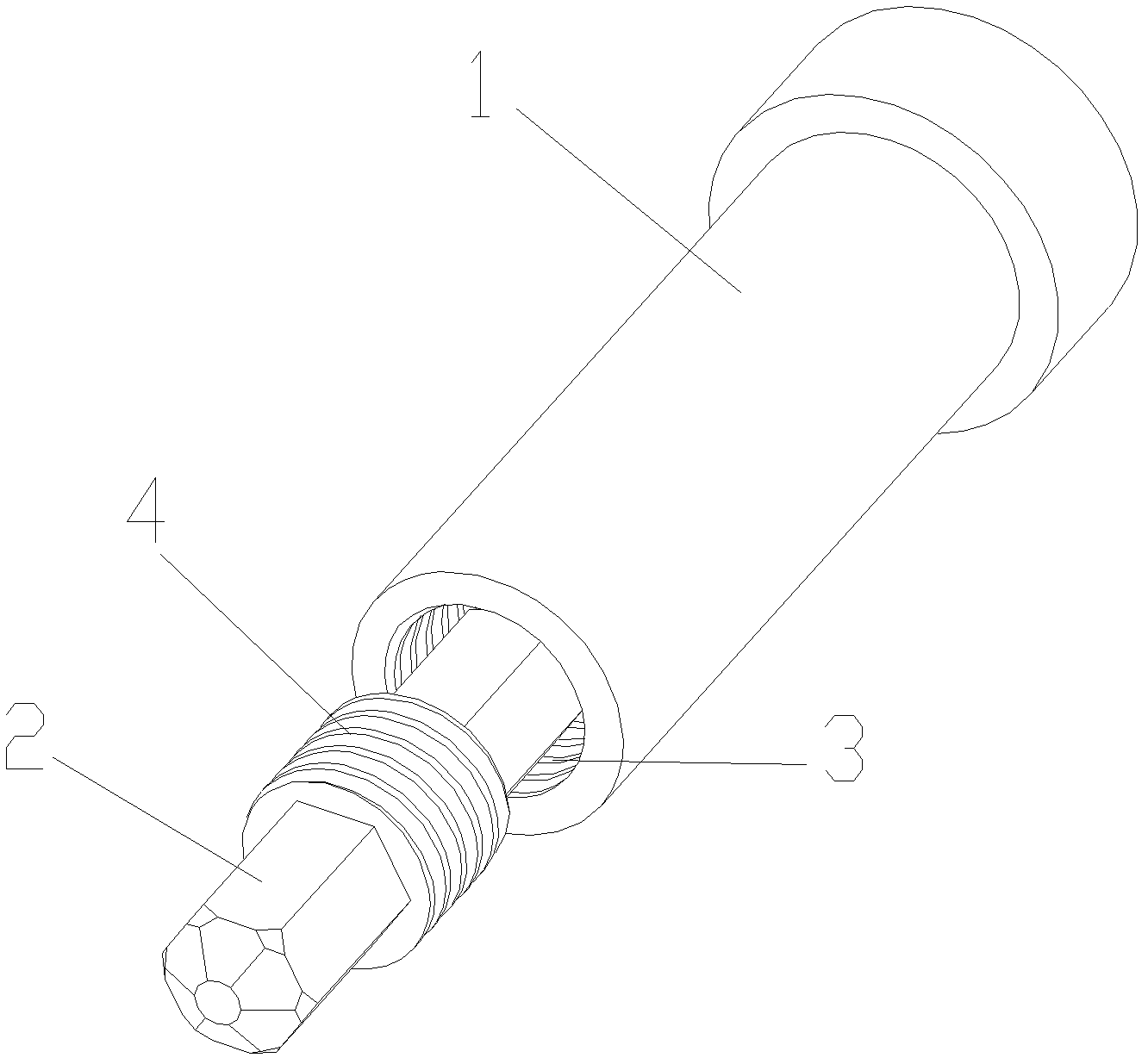

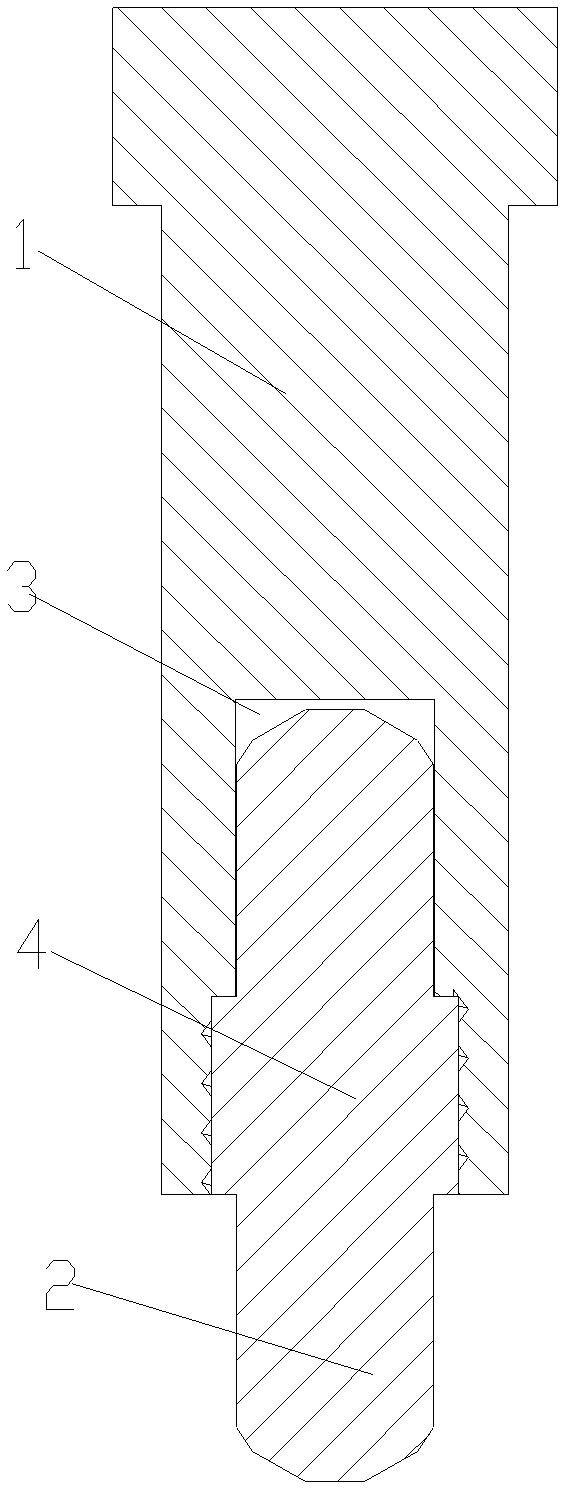

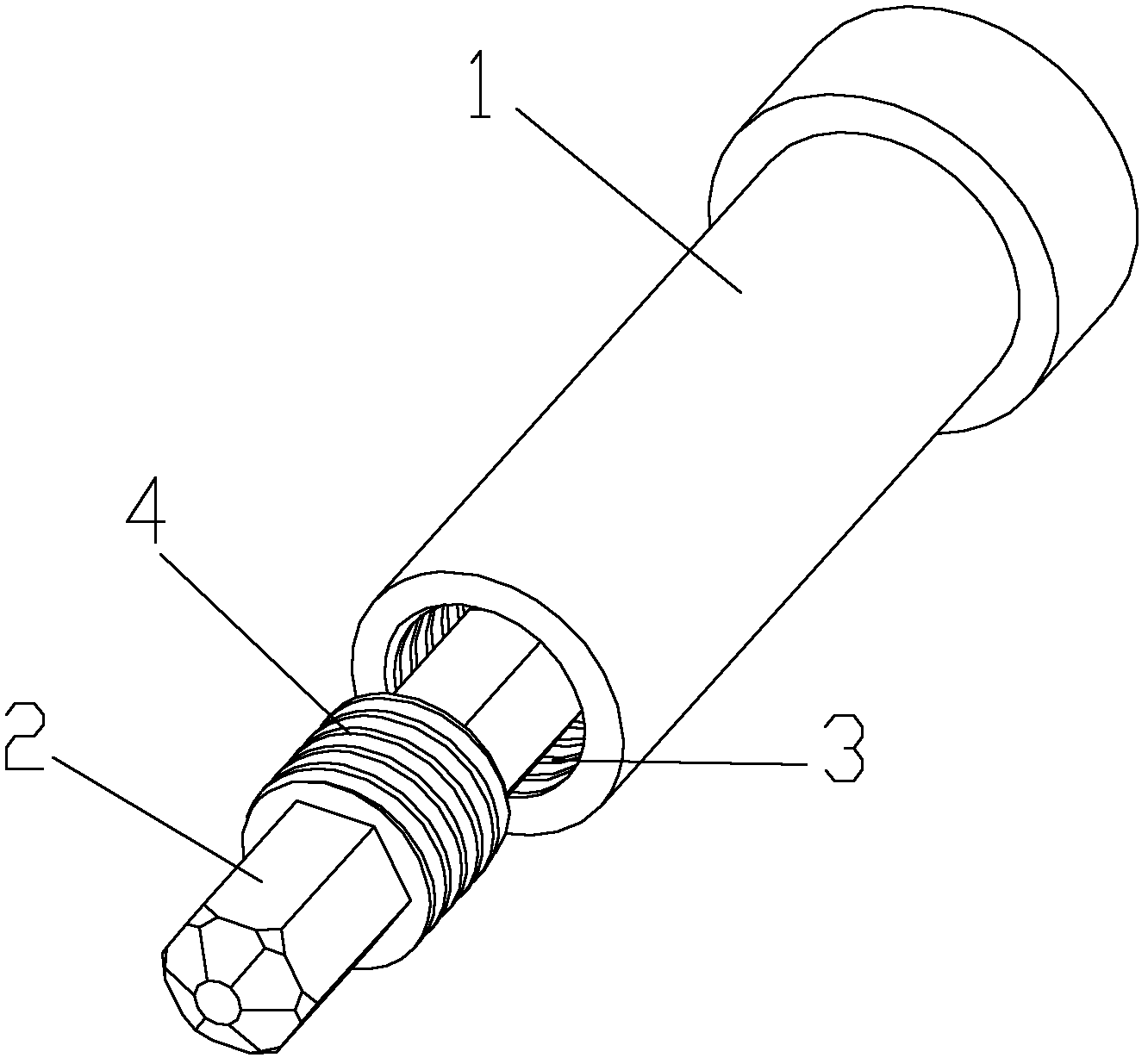

Punch device

InactiveCN102581138ASolve the problem that the damage must be replaced immediatelyShorten the timeShaping toolsEngineeringScrew thread

Owner:苏州新凌高强度紧固件有限公司

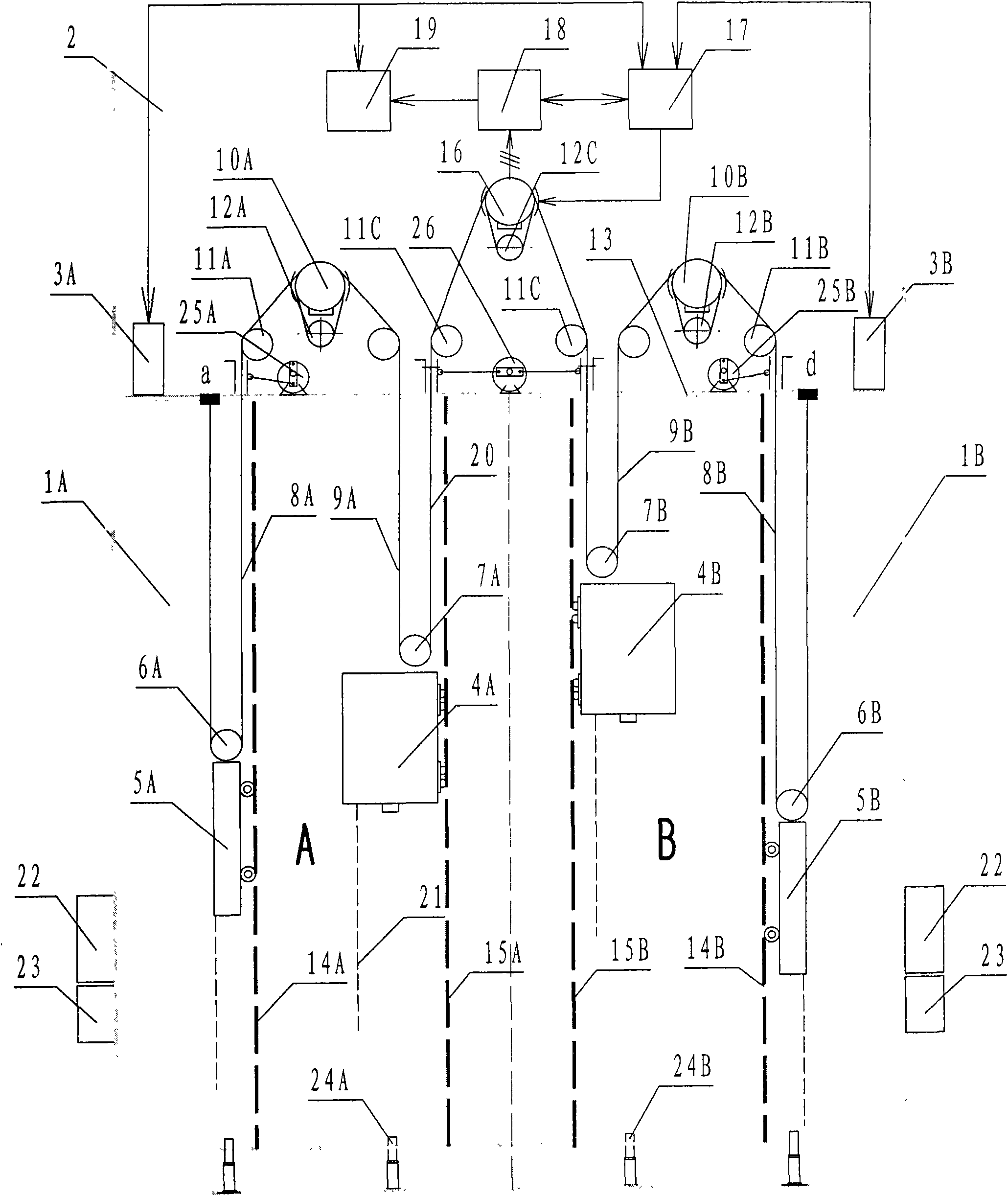

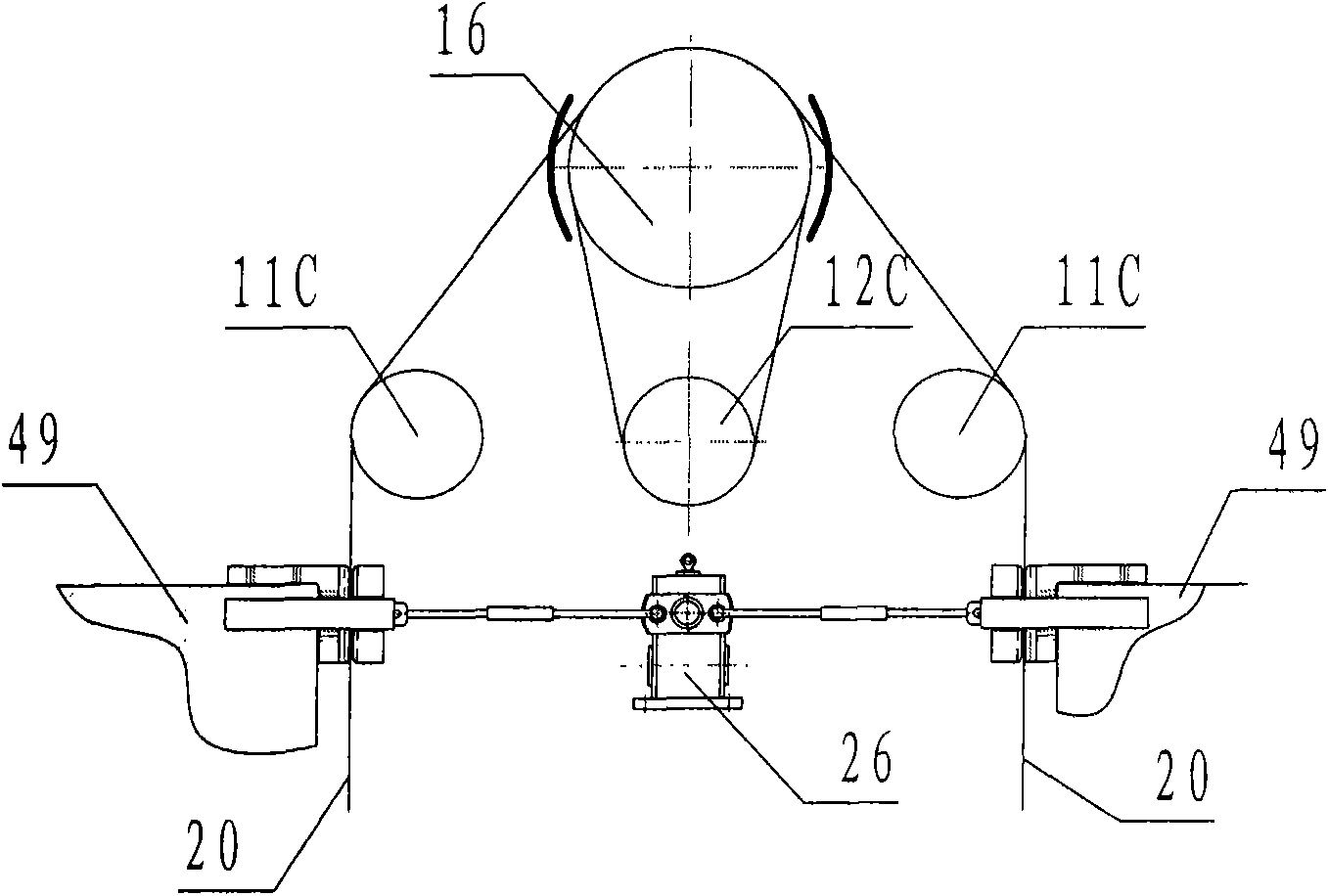

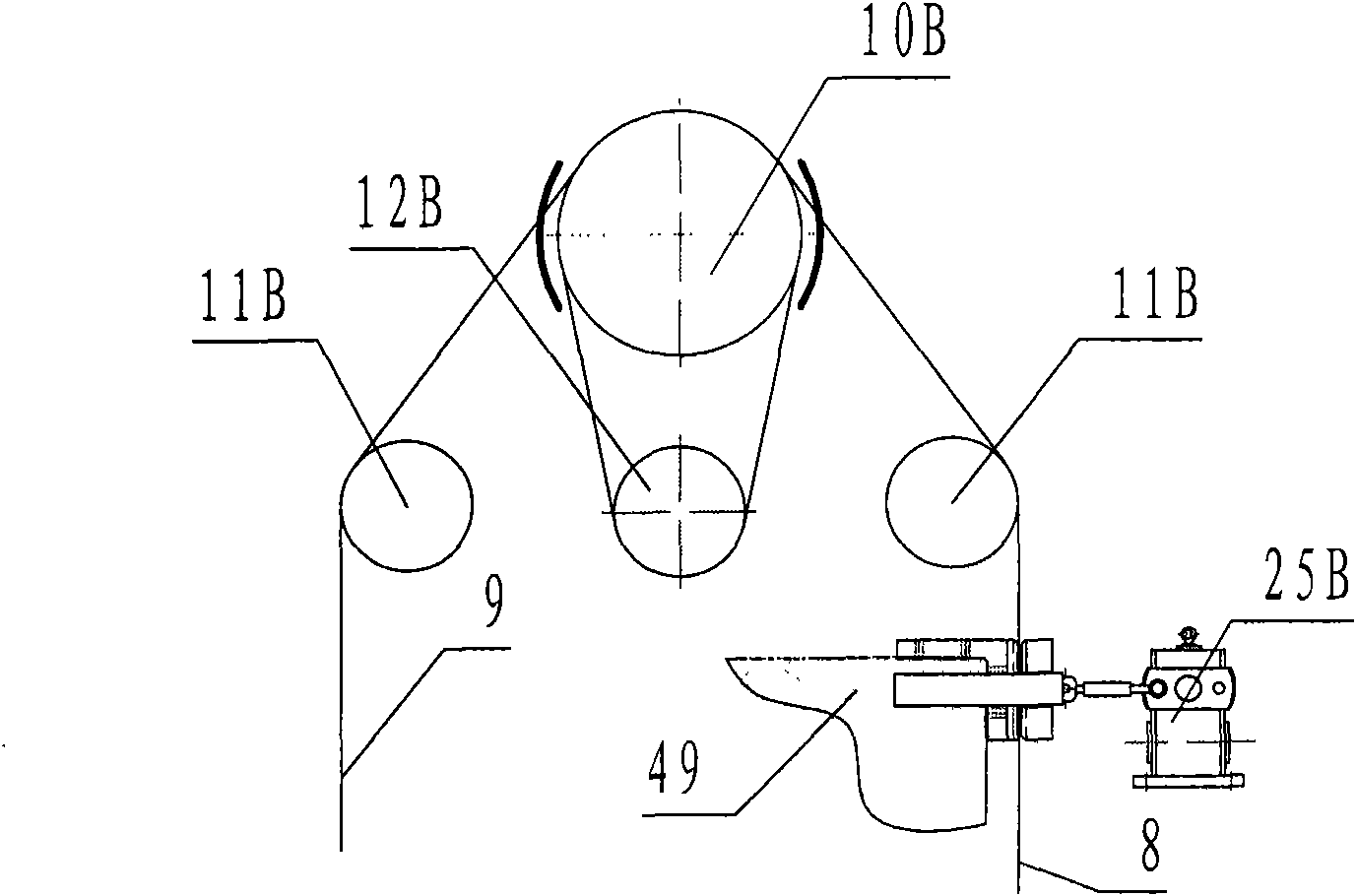

Passive-potential energy speed-controlling escape elevator for civil high-rise buildings

InactiveCN101575063AIncrease frictionIncrease braking powerElevatorsBuilding liftsMagnetic dampingLocking pliers

The invention relates a passive-potential energy speed-controlling escape elevator for civil high-rise buildings, which mainly solves the technical difficulties of the existing escape equipment, such as numerous operational steps, low rescue efficiency and impossibility of passively conveying succors. The passive-potential energy speed-controlling escape elevator for civil high-rise buildings comprises two elevators arranged in parallel in the elevator well; each elevator comprises a cage, a counterpoise, an elevator hoisting machine, counterpoise hoisting lines, cage hoisting lines, an elevator controller, cage guides and counterpoise guides. A potential-energy speed controlling device is arranged between two elevator hoisting machines in a one-well double-elevator engine room. The potential energy hoisting lines are arranged on a magnetic damping hoisting machine of the potential-energy speed controlling device. The potential energy hoisting lines are connected with the cage hoisting lines. A potential-energy line locking pliers is arranged under the beam pulley of the magnetic damping hoisting machine. A counterpoise line locking pliers is arranged under the beam pulley of the elevator hoisting machine. Two cages arranged on the two sides of the magnetic damping hoisting machine move to and fro under the gravitational potential energy of additional weight.

Owner:赵长飞

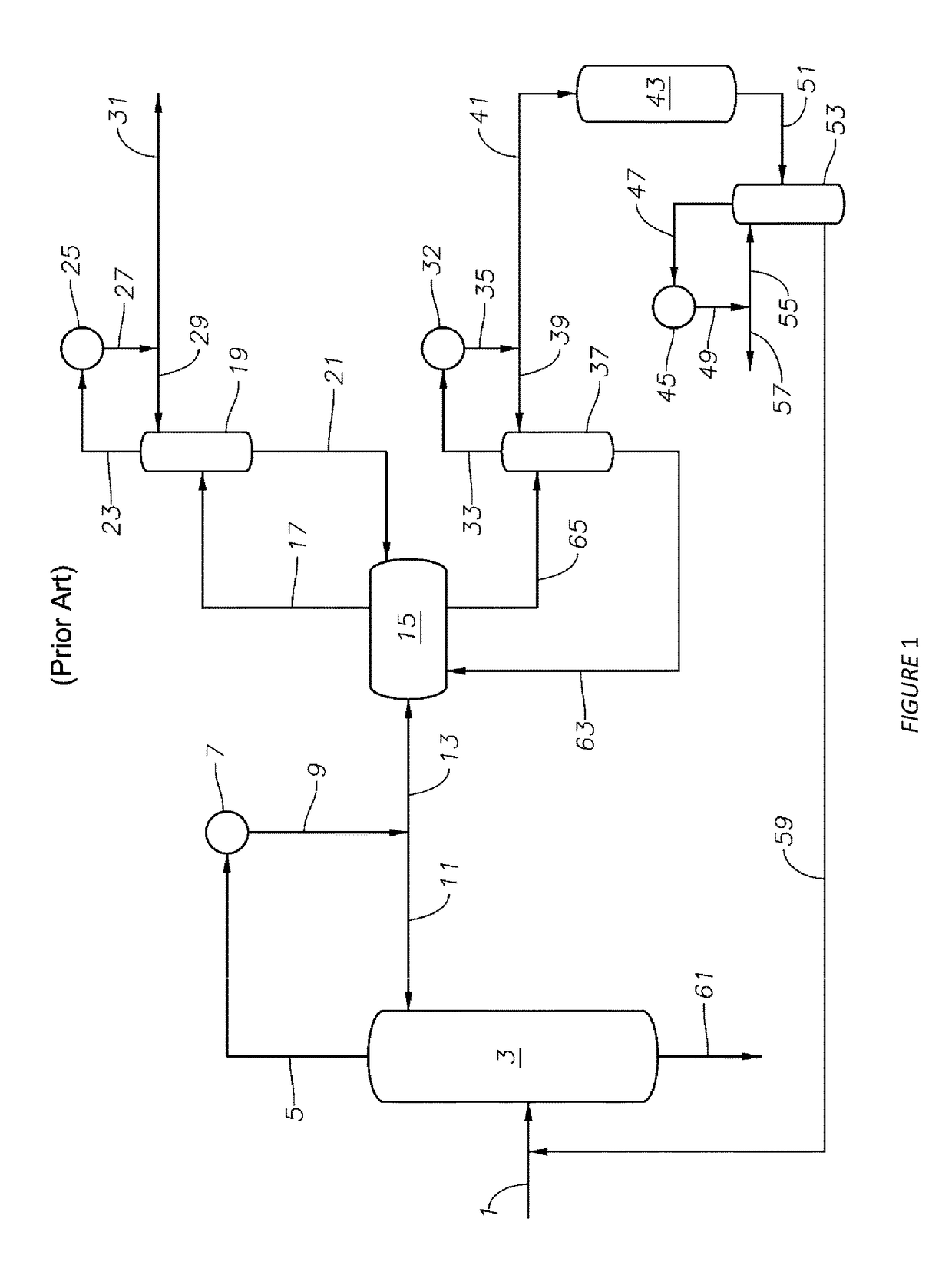

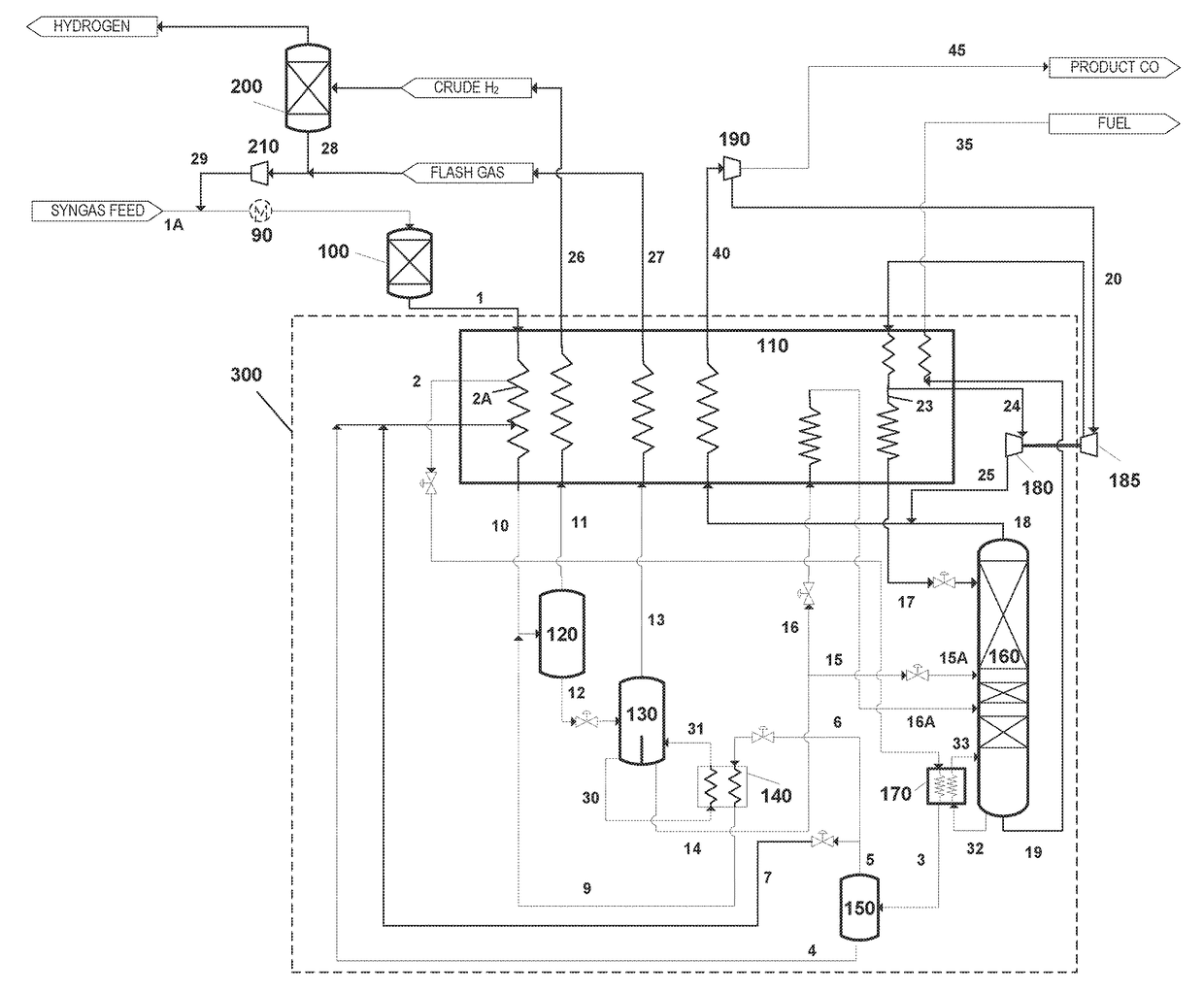

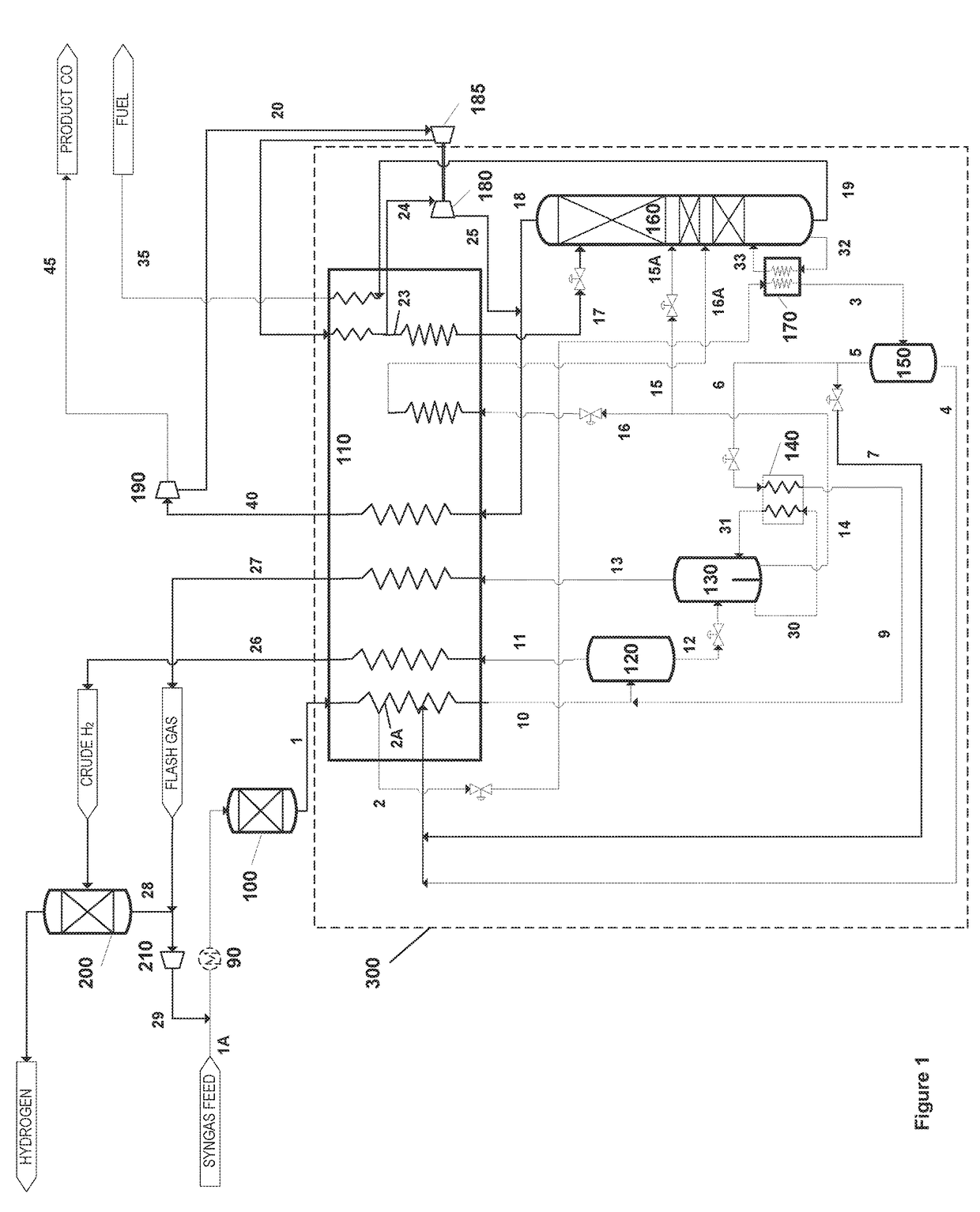

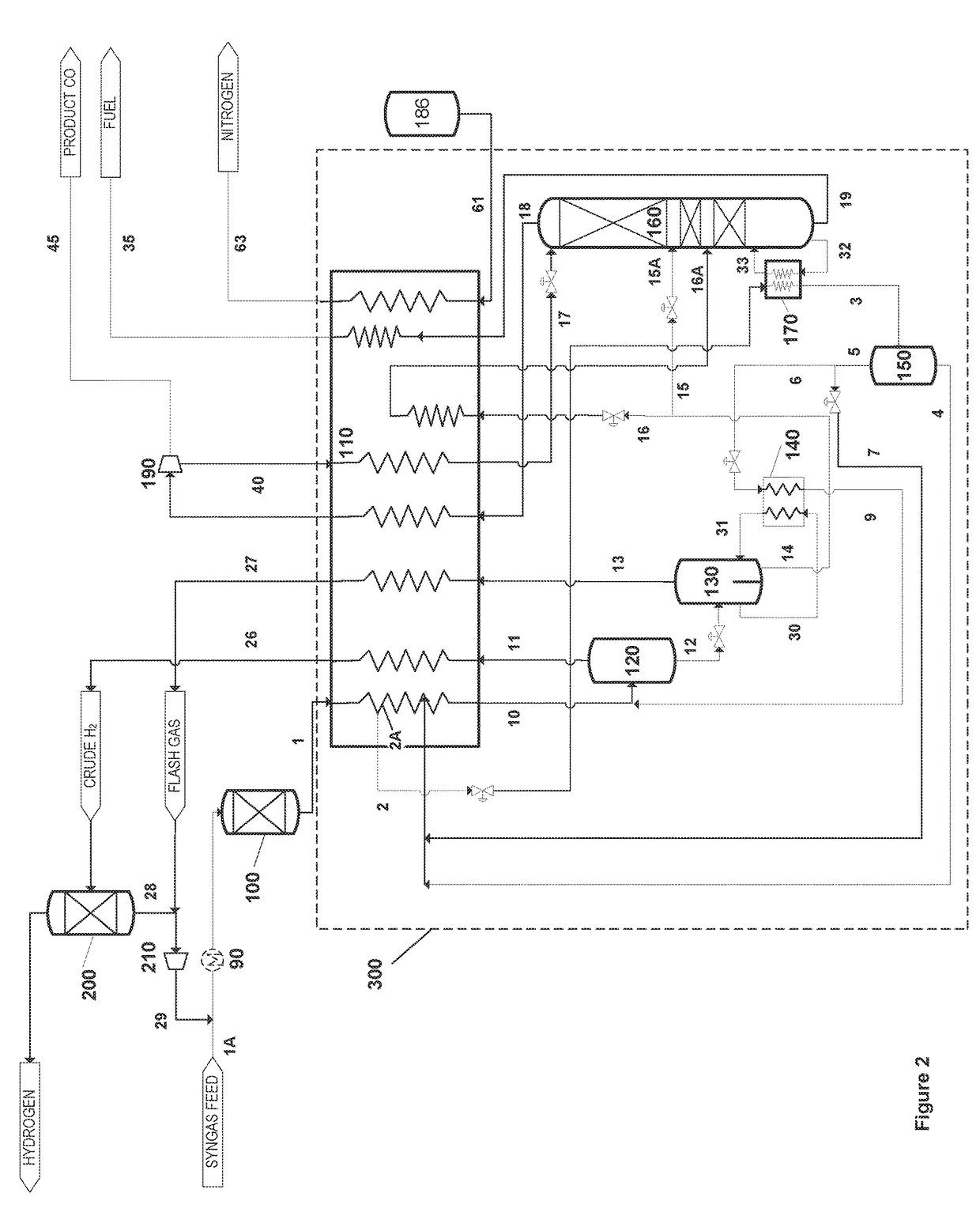

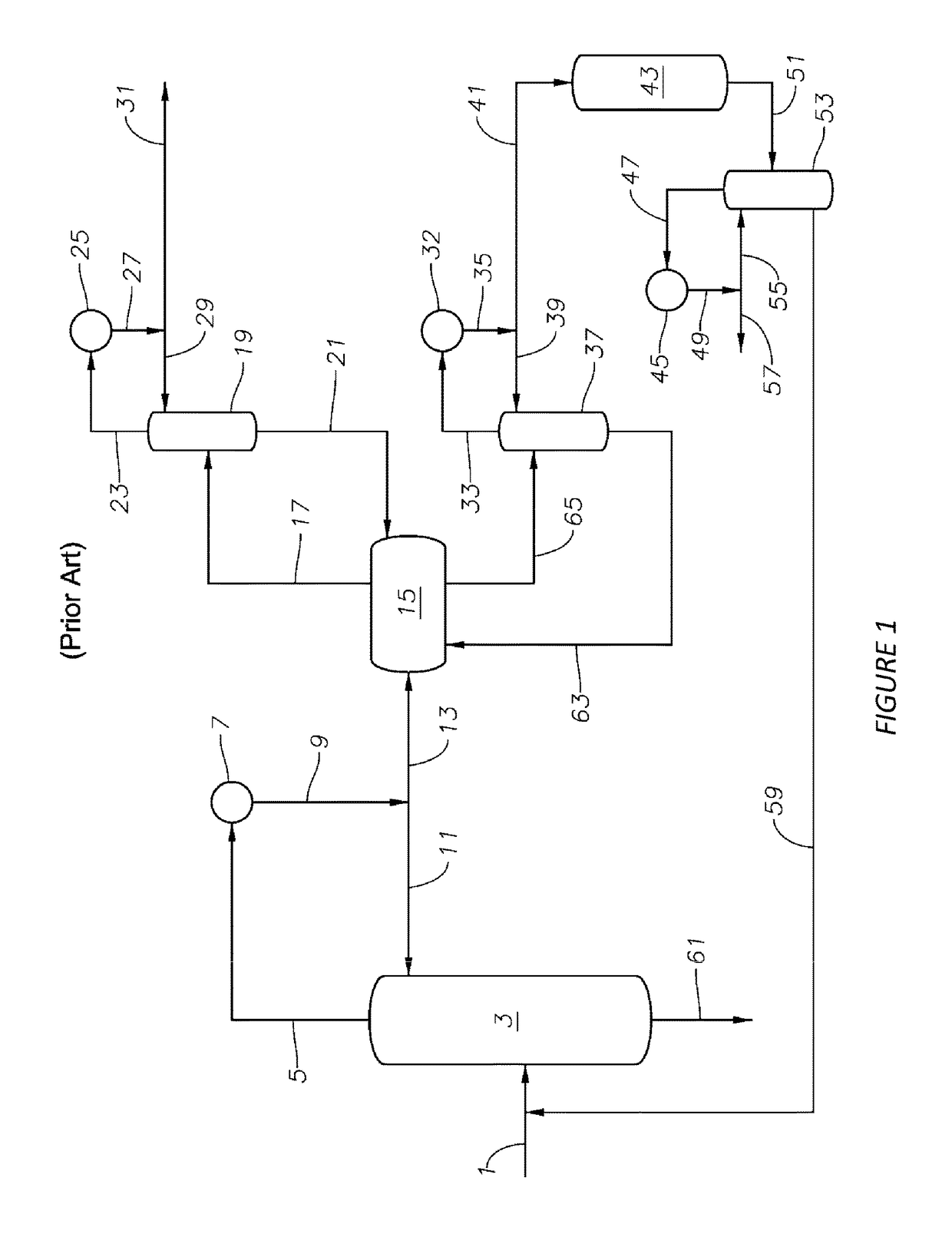

Process and apparatus for producing carbon monoxide

ActiveUS20180058757A1Minimum required reflux flowSave capitalSolidificationLiquefactionSyngasReboiler

The present invention relates to a cold box cycle which allows for independent control of the heat supplied for reboilers associated with the separation columns. More specifically, the invention relates to the tight control of the hydrogen removal separation, thus avoiding the possibility of excess reboiling in this separation. Optimal reboiling also results in a lower temperature of the hydrogen depleted liquid from this separation. As this stream is used to provide a portion of the cooling at the cold end of the primary heat exchanger, lower temperatures facilitate cooling of the incoming syngas feed, reducing carbon monoxide (CO) losses into the crude hydrogen stream from the high pressure separator. Lower CO in the crude hydrogen allows for smaller hydrogen purification equipment.

Owner:PRAXAIR TECH INC

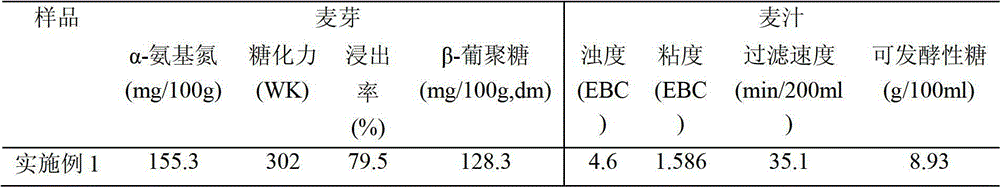

Wort manufacturing method capable of improving wort filtration performance and increasing fermentable sugar content

InactiveCN102978052AReduced beta-glucan contentImprove filtering effectWort preparationMalt preparationSteepingFiltration

The invention discloses a wort manufacturing method capable of improving wort filtration performance and increasing fermentable sugar content. In the barley steeping stage, by the combined use of a malt growth promoter at a certain concentration and promoters for relevant enzyme systems in the malt growth process, the expressions and activities of the relevant enzyme systems in the wort manufacturing process are regulated, the malt quality is improved, and the key point is that the beta-glucan content in the malt is reduced; and, in the malt saccharifying stage, the concentrations of the promoters for the relevant enzyme systems are controlled, so that the synergetic effect of the relevant enzyme systems in the saccharifying stage is strengthened to the greatest extent to effectively decompose starch and protein. By carrying out the above steps, the beta-glucan content in comparison with that of a control malt finished product is significantly reduced, the viscosity and the turbidity of a wort finished product are significantly reduced, the filtration performance of the wort is greatly improved, and the fermentable sugar content of the wort is significantly increased, too. By the wort manufacturing method, the cost is largely saved to achieve a certain economic benefit.

Owner:YANGZHOU UNIV

Automatic backing plate for workbench of film covering machine

InactiveCN102218890AReduce manufacturing costSimple structureLamination ancillary operationsLaminationMicrocomputerEngineering

The invention discloses an automatic backing plate for the workbench of a film covering machine, and relates to the field of woodworking machines. The automatic backing plate comprises a backing plate block (1), a locking rod (2), a support (4) and an ejector rod (6). The backing plate block (1) is of a hollow structure and comprises two split parts, namely, an upper part (11) and a lower part (12). A spring (3) is sleeved on the locking rod (2) which passes through the hollow part of the backing plate block (1) and is capable of moving. Steel balls (5) are arranged below the locking rod (2). The backing plate block (1) is connected with the ejector rod (6). The support (4) is sleeved out of the backing plate block (1) and the ejector rod (6). The automatic backing plate provided in the invention has a simple construction and totally employs a mechanical structure, which enables low cost; the plate can be mounted on different film covering machine workbenches and produces a same film covering effect as an imported microcomputer-controlled automatic backing plate does, thereby reducing production cost for an enterprise and enabling the enterprise to use the saved capital for expanded production so as to accelerate the development of the enterprise.

Owner:刘海洋

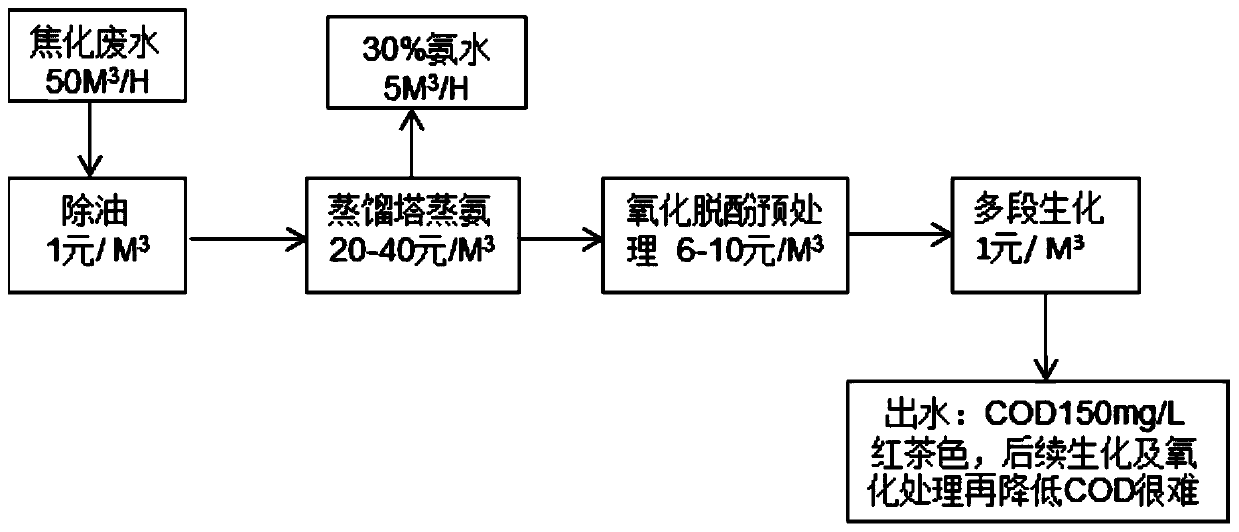

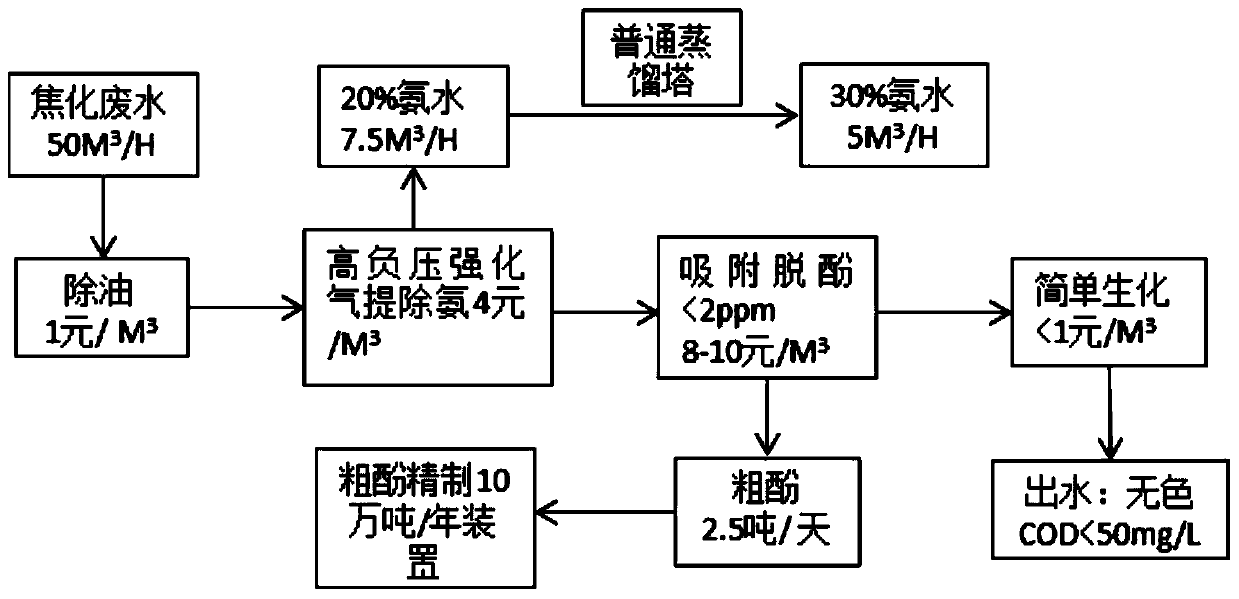

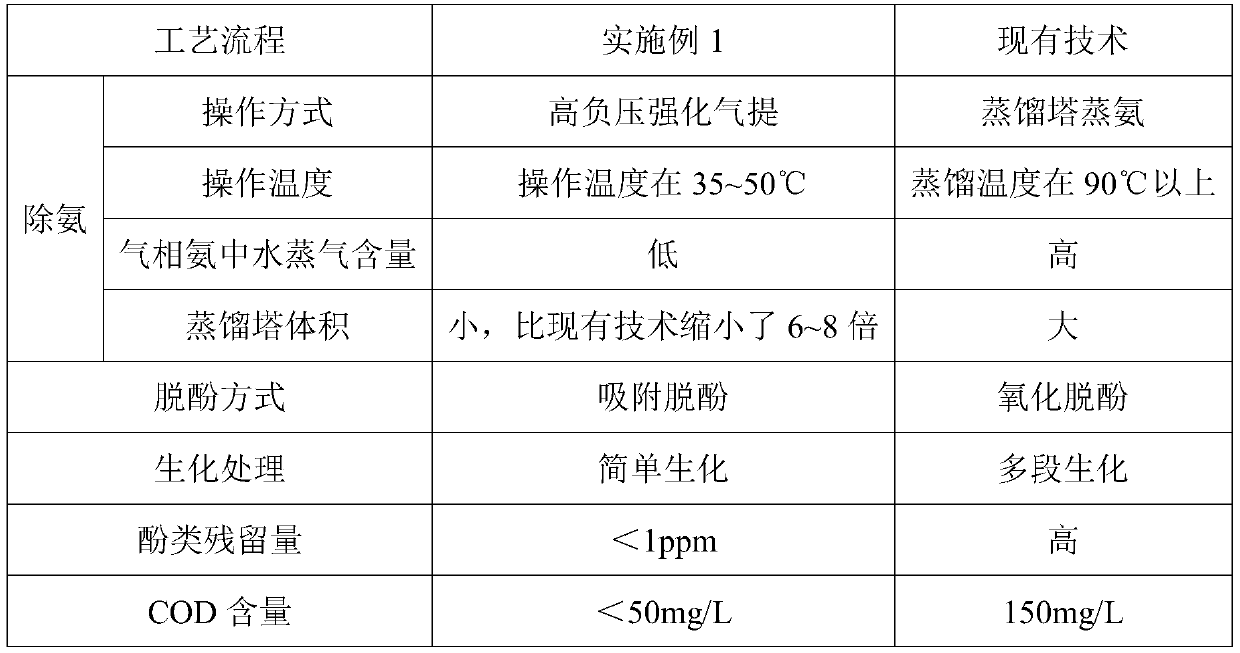

Low-cost and high-efficiency treatment technology for coking and semi-coke wastewater

PendingCN110498564AReduce processing costsReduce water vapor contentFatty/oily/floating substances removal devicesSpecific water treatment objectivesGas phaseSorbent

The invention belongs to the technical field of wastewater treatment, and provides a low-cost and high-efficiency treatment technology for coking and semi-coke wastewater. The technology comprises thefollowing steps: S1, deoiling: removing coal tar and large-particle suspended oil and suspended matters in the coking and semi-coke wastewater to obtain deoiled coking and semi-coke wastewater; S2,performing high negative pressure enhanced gas stripping ammonia removal: carrying out high negative pressure enhanced gas stripping on the deoiled coking and semi-coke wastewater obtained in step S1 under -0.08 to -0.03 MPa at 35-50 DEG C in order to obtain gas phase ammonia and liquid phase wastewater; S3, performing adsorbing dephenolization: performing adsorbing dephenolization on the liquid phase wastewater obtained in step S2 by adopting an adsorbent to adsorb phenols in the wastewater in order to obtain dephenolized wastewater; and S4, biochemically treating effluent: biochemically treating on the dephenolized wastewater obtained in step S3, and discharging the treated water after reaching standards. The technology solves the problems of high cost and poor treatment effect of the coking and semi-coke wastewater in the prior art.

Owner:石家庄惠洁科技有限公司

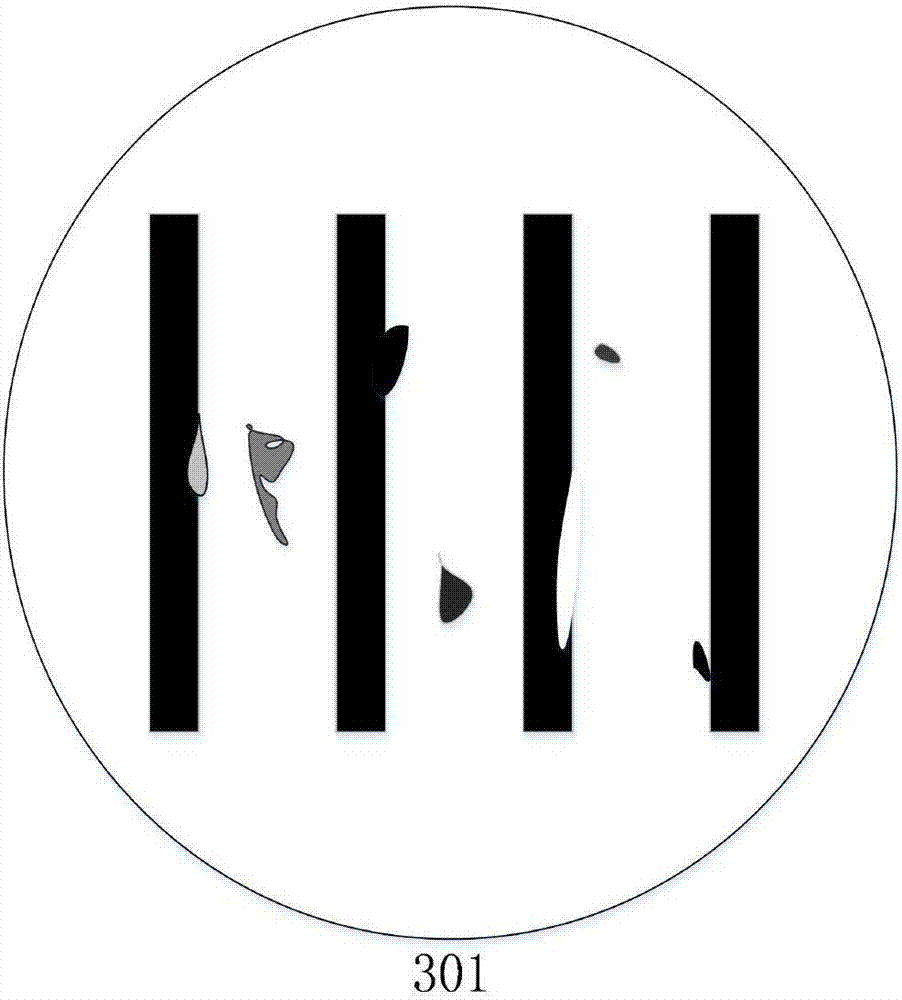

Image processing method based on vertical-and-horizontal-conversion amplifying grating and application thereof

InactiveCN107101583ASmall amount of calculationHigh speedUsing optical meansGratingImaging processing

The invention relates to an image processing method based on a vertical-and-horizontal-conversion amplifying grating and an application thereof. The method comprises the following steps of 1), preprocessing a grating image and reconstructing a grid line; 2), adding a virtual oblique line on the reconstructed grid line, and converting refining in a gate distance direction to a grid line length direction, and adjusting an amplification power; 3), performing line summation on a pixel matrix, and finding out an intersection point between the reconstructed grid line and the virtual oblique line; and 4), through a triangular similar relation, calculating a micro displacement and an integral displacement which are represented by the number of pixels through acquiring the relative position of the intersection point to two ends of the grid line, the grating distance and a grating number reading head pulse number N. The image processing method settles wastage of defective gratings caused by factors such as operation, process and tools in grating manufacture and measurement error caused by phenomena such as damage, spot and inclination in a long-term use process. Cost is greatly saved. The image processing method has advantages of high calculation amount, high speed and effective production efficiency improvement.

Owner:GUANGDONG UNIV OF TECH

Process for the Recovering of Paraxylene

InactiveUS20180002253A1Save energySave capitalHydrocarbon by isomerisationMolecular sieve catalystRecovery methodIsomerization

Disclosed herein are processes for recovering paraxylene in which a first simulated moving bed adsorption unit is used to produce a paraxylene-rich extract stream that also contains a significant amount of the ethylbenzene and a paraxylene-depleted raffinate stream. Because a significant amount of the ethylbenzene is removed in the paraxylene-rich extract stream (at least enough to limit buildup in the isomerization loop), the paraxylene-depleted raffinate stream may be isomerized in the liquid phase. Avoiding vapor phase isomerization saves energy and capital, as liquid phase isomerization requires less energy and capital than the vapor phase isomerization process due to the requirement of vaporizing the paraxylene-depleted stream and the use of hydrogen, which requires an energy- and capital-intensive hydrogen recycle loop.

Owner:EXXONMOBIL CHEM PAT INC

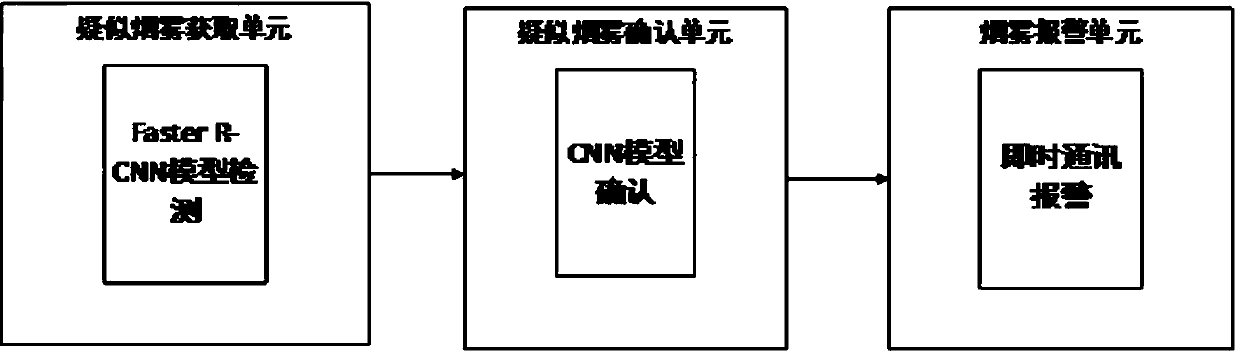

Smoke detection method of integrated convolutional neural network

PendingCN110956611AReduce the cost of smoke detectionImprove real-time performanceImage enhancementImage analysisConvolutionReal-time computing

The invention provides a smoke detection method of an integrated convolutional neural network. The system comprises a suspected smoke acquisition module, a suspected smoke confirmation module and a smoke alarm module. The suspected smoke acquisition module detects an image acquired in real time through a Faster R-CNN model, and acquires an image containing suspected smoke; the suspected smoke detection module detects a candidate area of the suspected smoke image by using a convolutional neural network; the smoke alarm module responds to the processing result of the suspected smoke confirmationmodule, so the smoke detection cost is greatly reduced, the recognition efficiency and accuracy are improved, the recognition flexibility is high, no extra storage and calculation expenditure exists,the complexity of the system is reduced, and the system is efficient and energy-saving.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com