Fluorescence probe for recognizing iron ions in water body and preparation method and application thereof

A technology of fluorescent probes and iron ions, applied in the field of fluorescent sensors, can solve the problems of unfavorable promotion, high detection cost, and the use of large instruments, and achieve the effects of saving capital, high sensitivity, and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh according to the 1:1 molar ratio of 2,4,6-tris(4-pyridyl)-1,3,5-triazine (TPT) to 5-hydroxyisophthalic acid, and mix to form a mixture Ligand;

[0023] (2) According to Cd(NO 3 ) 2 .4H 2 Weigh Cd(NO 3 ) 2 4H 2 O;

[0024] (3) Put the reagents weighed in (1) and (2) in DMA / H under ultrasonic or stirring 2 O (where DMA and H 2 The volume ratio of O is 4:4) mixed and dissolved in 8 milliliters of solvents to prepare a precursor solution;

[0025] (4) Transfer the precursor solution obtained in (3) into a hydrothermal kettle, perform solvothermal reaction at 120°C for 72 hours, suction filter, wash, and dry to obtain a three-dimensional structure Cd-MOF material.

[0026] (5) Add 3 mg of Cd-MOF in (4) to 3 ml of 0.1 mol / L Eu(NO 3 ) 3 solution, stirred for 48 hours, suction filtered, and dried to obtain Eu 2+ @Cd-MOF probe material.

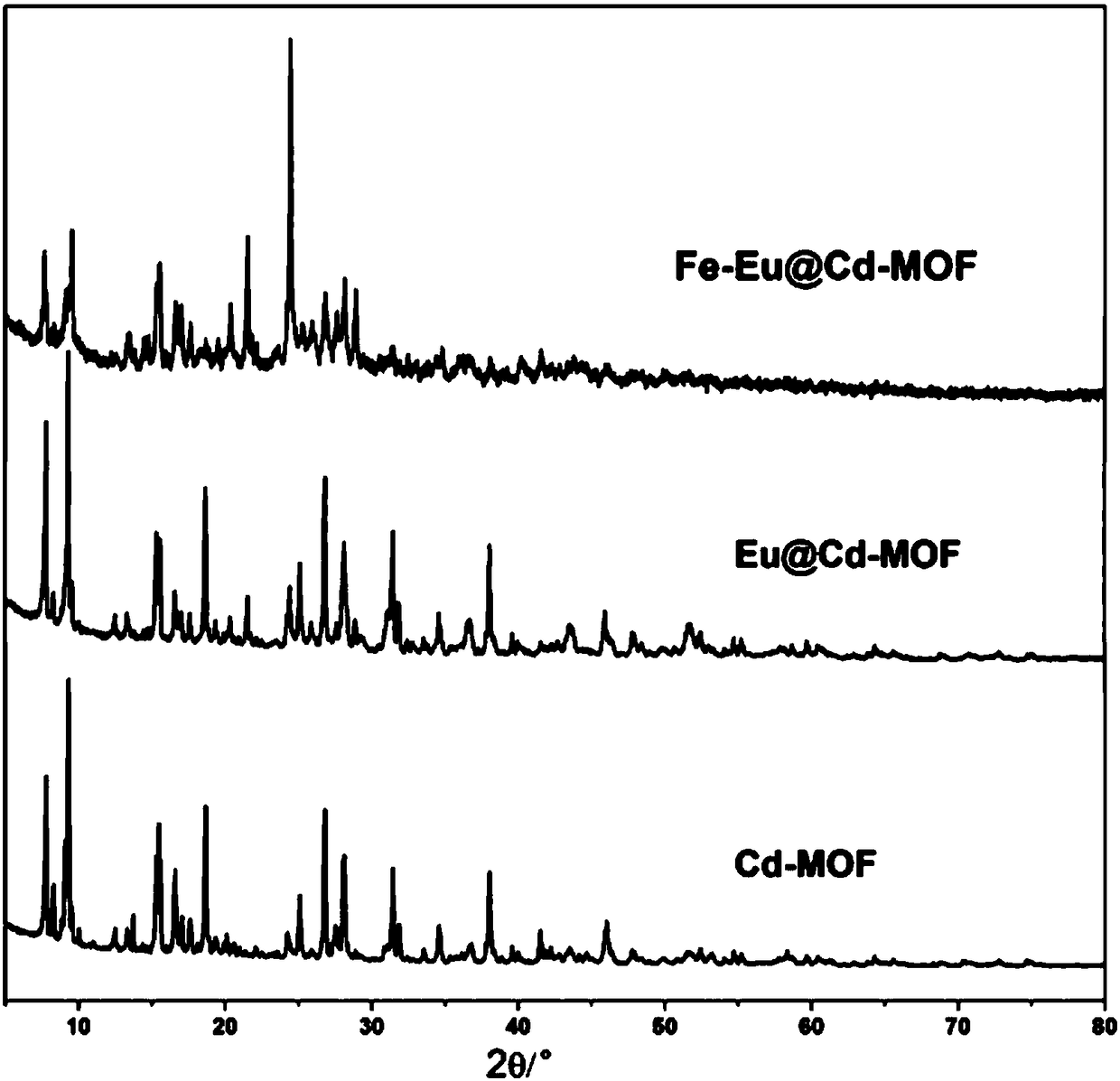

[0027] By X-ray powder diffraction, we characterized the stability of the material as figure 1 As shown, after the "po...

Embodiment 2

[0030] Eu 2+ Synthesis and application of @Cd-MOF materials

[0031] (1) Weigh according to the 1:1 molar ratio of 2,4,6-tris(4-pyridyl)-1,3,5-triazine (TPT) to 5-hydroxyisophthalic acid, and mix to form a mixture Ligand;

[0032] (2) According to Cd(NO 3 ) 2 .4H 2 Weigh Cd(NO 3 ) 2 .4H 2 O;

[0033] (3) Put the reagents weighed in (1) and (2) in DMA / H under ultrasonic or stirring 2 O (its volume ratio is 4:4) mixed and dissolved in 8 milliliters of solvents to prepare a precursor solution;

[0034] (4) Transfer the precursor solution obtained in (3) into a hydrothermal kettle, perform solvothermal reaction at 120°C for 72 hours, suction filter, wash, and dry to obtain a rod-like crystalline material Cd-MOF.

[0035] (5) Add 3 mg of Cd-MOF material in (4) to 3 ml of 0.1 mol / L Eu(NO 3 ) 3 solution, stirred for 48 hours, suction filtered, and dried to obtain Eu 2+ @Cd-MOF probe material.

[0036] By X-ray powder diffraction, we characterized the stability of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com