Automatic backing plate for workbench of film covering machine

A workbench, laminating machine technology, applied in the direction of lamination auxiliary operation, layered products, lamination, etc., can solve the problems of high-cost equipment, development obstacles, high cost, etc., to accelerate development, save capital, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

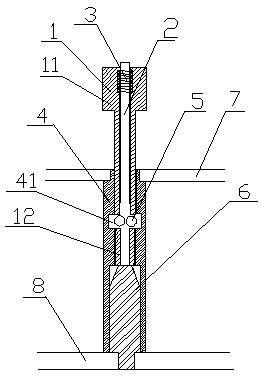

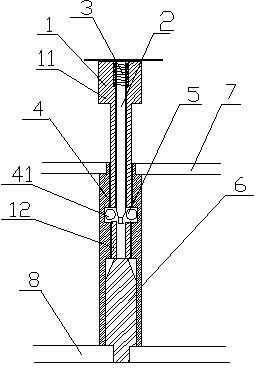

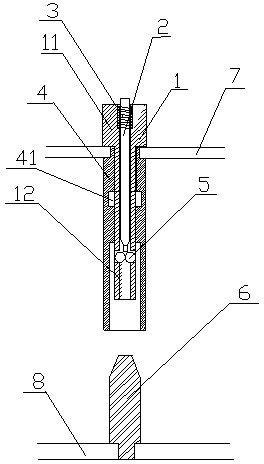

[0016] Such as figure 1 As shown, it includes a backing block 1, a locking rod 2, a support body 4 and an ejector rod 6. The backing block 1 is hollow, and the backing block 1 is divided into two separate parts, the upper part 11 and the lower part 12. The locking rod 2 The bottom end is set as a cone, the locking rod 2 is covered with a spring 3 and penetrates the hollow part of the backing block 1, the bottom of the spring 3 is fixed in the upper part 11 of the backing block 1, and the locking rod 2 is on the backing block 1 can move up and down along the direction of the hollow part. The backing plate 1 is connected with the ejector rod 6, the support body 4 is sleeved on the outside of the backing plate 1 and the ejector rod 6, two or more steel balls 5 are arranged under the locking rod 2, and the support body 4 corresponds to The position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com