Punch device

A technology of punches and punch holders, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting processing production, damage to parts where punches and workpieces are in contact, and wasting time, so as to save time and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

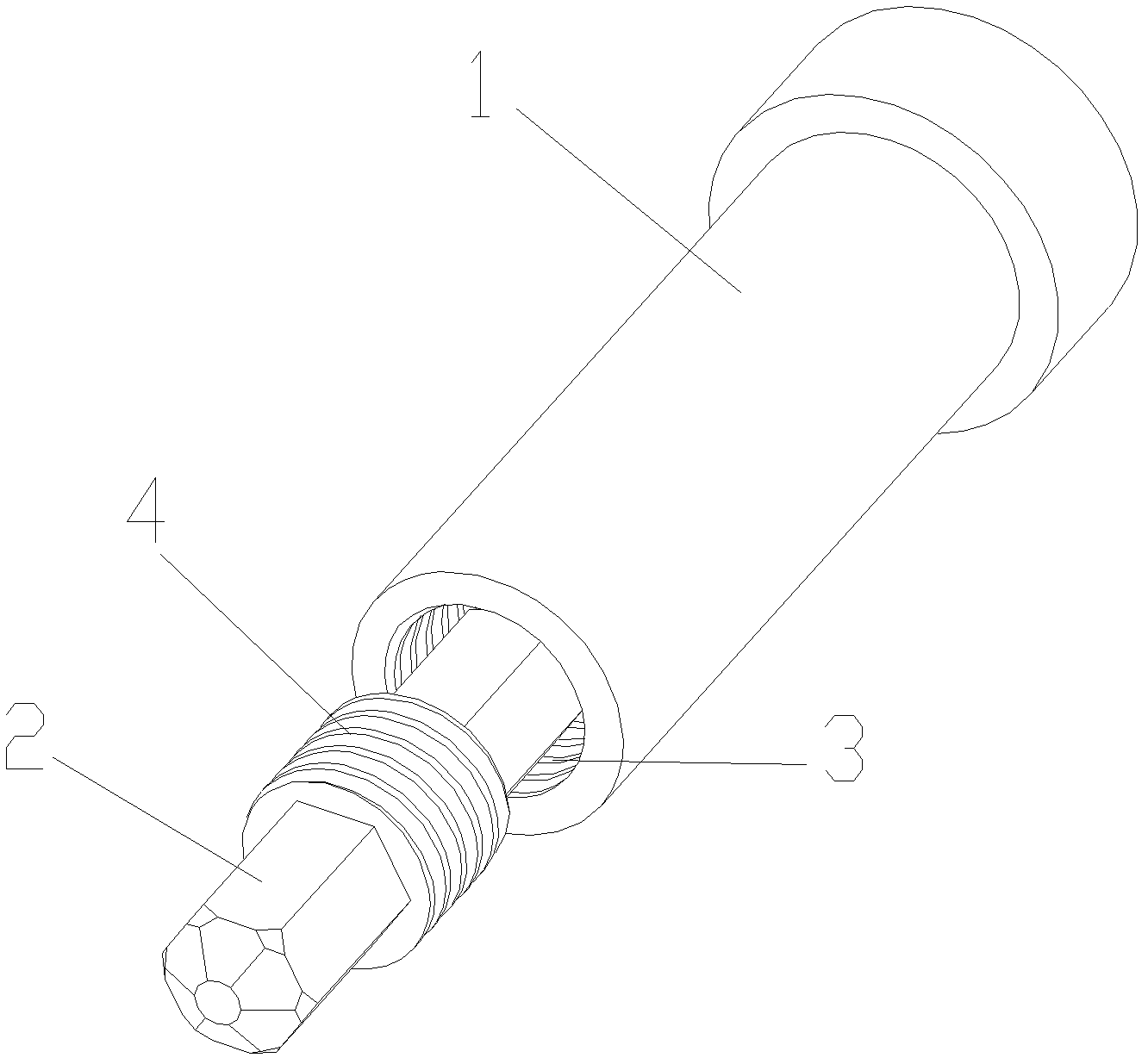

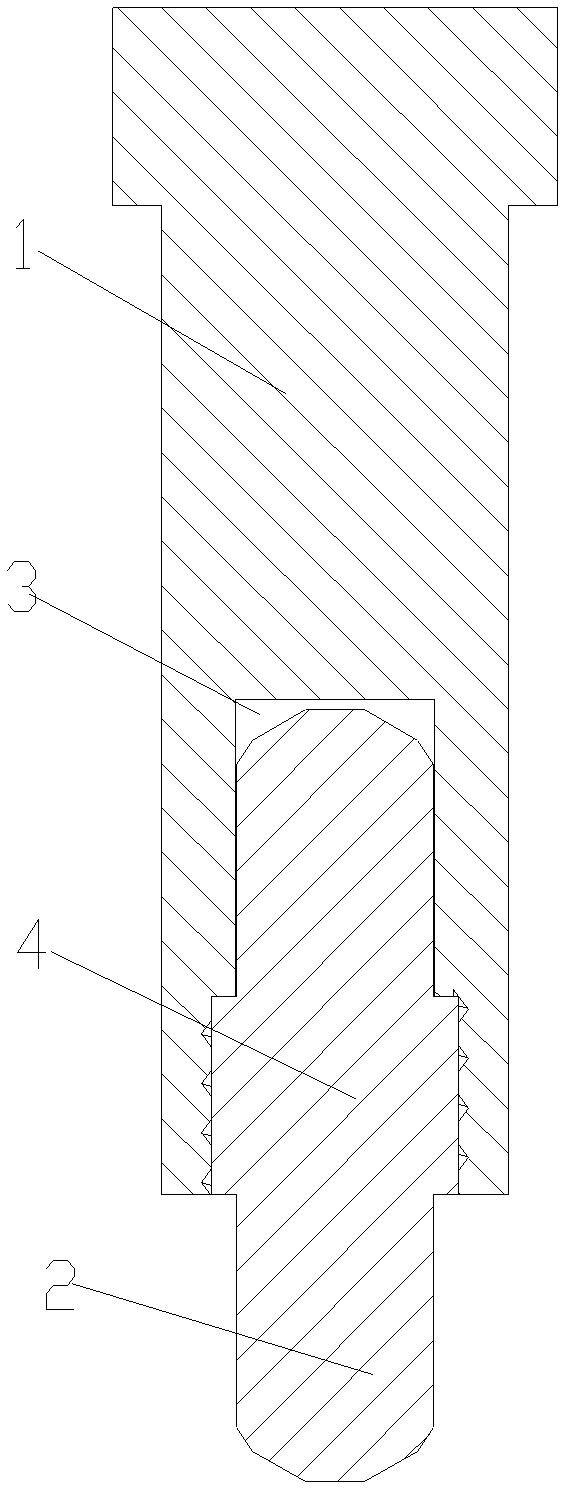

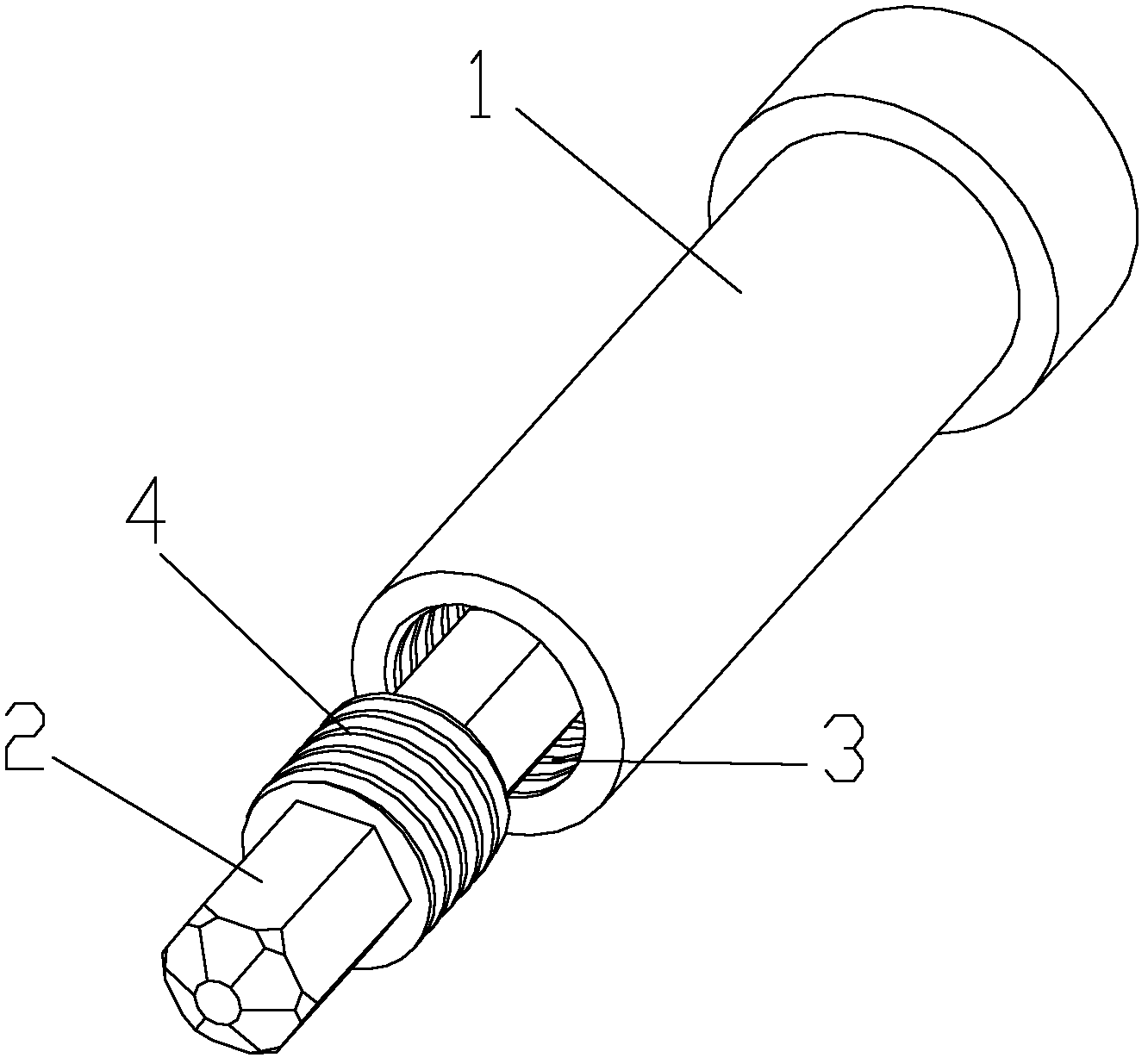

[0012] attached Figure 1-2 It is a punch device according to the present invention, comprising a punch seat 1 and a punch 2, the punch seat 1 is provided with a punch groove 3; the inner wall of the punch groove 3 is provided with threads; The punch 2 is composed of two symmetrical heads and a fixed cylinder 4; the fixed cylinder 4 is connected to the punch groove 3 through threads; the design of the double-head replaceable punch is matched with the screw connection to make the punch Realize a separate structure, so that when one head of the punch is damaged during use, it is not necessary to replace the punch device as a whole, just unscrew the punch, and replace it with another head for production and use again, without the need to replace the whole immediately Lose.

[0013] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com