Low-cost and high-efficiency treatment technology for coking and semi-coke wastewater

A technology of semi-coke wastewater and treatment process, which is applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high cost of semi-coke wastewater and poor treatment effect, and achieve saving Cost savings, low water vapor content, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

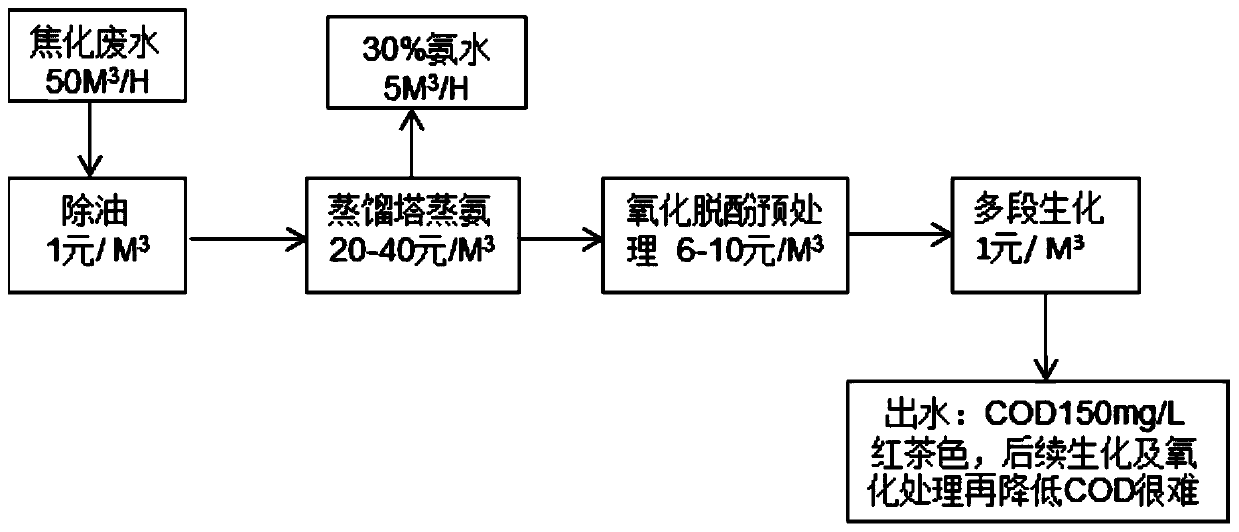

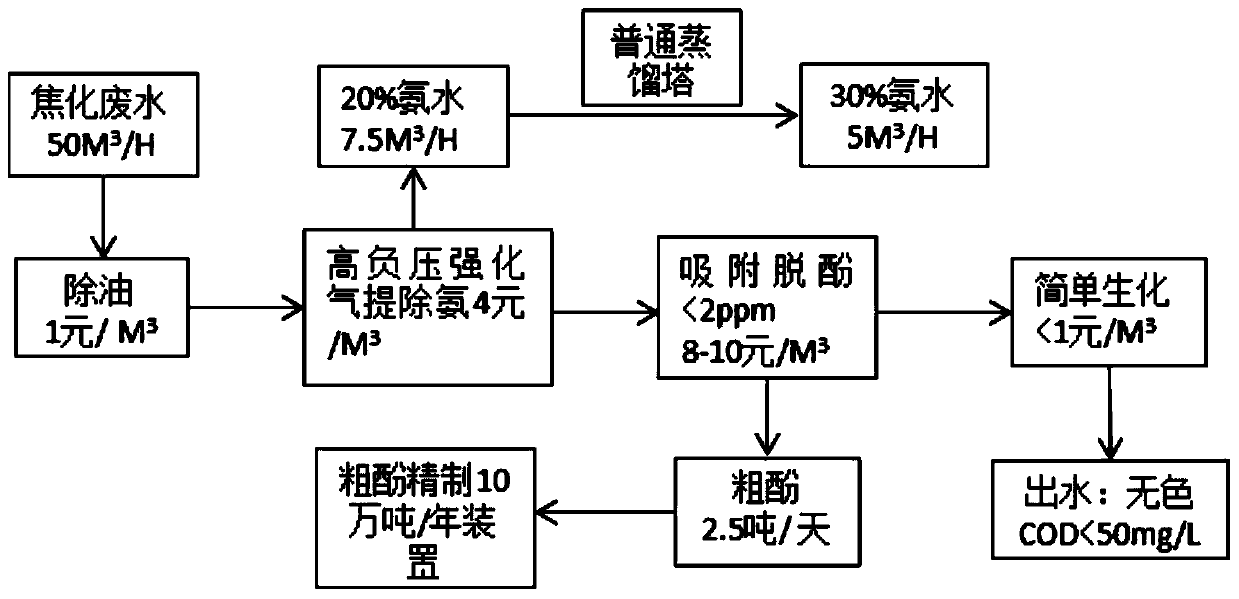

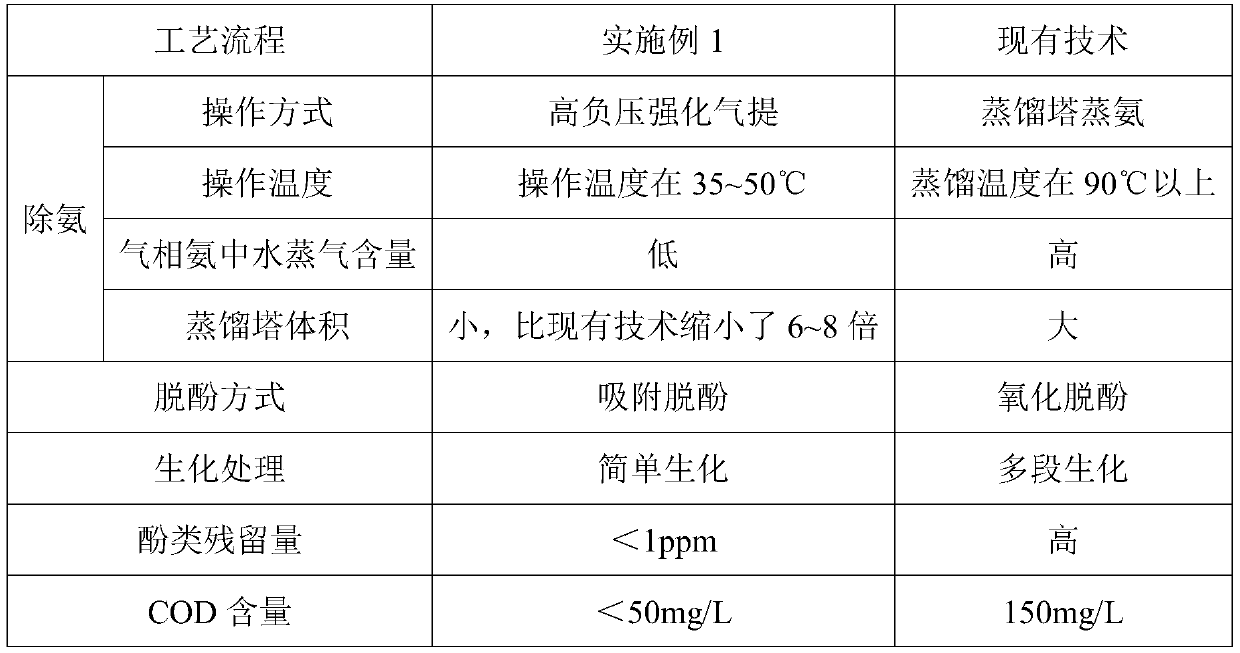

[0029] Such as figure 1 As shown, a low-cost and high-efficiency treatment process for coking wastewater includes the following steps:

[0030] S1. Degreasing

[0031] Coal tar, suspended oil and suspended solids with large particles were removed from the coking wastewater to obtain deoiled coking wastewater; wherein, the coking wastewater was from Maanshan Iron and Steel Co., Ltd., and the COD in the coking wastewater was 5000mg / L;

[0032] S2. High negative pressure enhanced gas stripping to remove ammonia

[0033] The deoiled coking and semi-coke wastewater obtained in step S1 is subjected to high negative pressure enhanced gas stripping at -0.05MPa and 35-50°C to obtain gas phase ammonia and liquid phase wastewater; the gas phase ammonia is cooled to obtain a mass concentration of 20 % ammoniacal liquor, the ammoniacal liquor with mass concentration of 30% can be obtained by using ordinary distillation tower to distill the ammoniacal liquor;

[0034] S3. Adsorption deph...

Embodiment 2

[0039] A low-cost and high-efficiency treatment process for semi-coke wastewater, comprising the following steps:

[0040] S1. Degreasing

[0041] Remove the coal tar, suspended oil and suspended matter with larger particles in the semi-coke wastewater, and obtain the deoiled semi-coke wastewater; wherein, the semi-coke wastewater comes from Shaanxi Coal Industry Chemical Group Co., Ltd., and the COD in the semi-coke wastewater is 5000mg / L;

[0042] S2. High negative pressure enhanced gas stripping to remove ammonia

[0043] The deoiled semi-coke and semi-coke wastewater obtained in step S1 are subjected to high negative pressure enhanced gas stripping at -0.03MPa and 50°C to obtain gas phase ammonia and liquid phase wastewater; the mass concentration of gas phase ammonia is 20% after cooling ammoniacal liquor, the ammoniacal liquor with a mass concentration of 30% can be obtained by using an ordinary distillation tower to distill the ammoniacal liquor;

[0044] S3. Adsorp...

Embodiment 3

[0049] A low-cost and high-efficiency treatment process for semi-coke wastewater, comprising the following steps:

[0050] S1. Degreasing

[0051] Remove the coal tar and suspended oil and suspended solids with larger particles in the semi-coke wastewater to obtain the deoiled semi-coke wastewater; wherein, the semi-coke wastewater comes from Shaanxi Yulin Shaanxi Coal Construction Co., Ltd., and the COD in the semi-coke wastewater is 9000mg / L;

[0052] S2. High negative pressure enhanced gas stripping to remove ammonia

[0053] The deoiled semi-coke and semi-coke wastewater obtained in step S1 are subjected to high negative pressure enhanced gas stripping at -0.08MPa and 35°C to obtain gas phase ammonia and liquid phase wastewater; the mass concentration of gas phase ammonia is 20% after cooling ammoniacal liquor, the ammoniacal liquor with a mass concentration of 30% can be obtained by using an ordinary distillation tower to distill the ammoniacal liquor;

[0054] S3. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com