Device and method for repairing tiny cracks in in-service concrete pole through grouting

A repair method and concrete technology, which can be used in building maintenance, building types, buildings, etc., can solve the problems of large size of water stop needle and unsuitable grouting, and achieve the effect of increasing pressure, simple structure and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

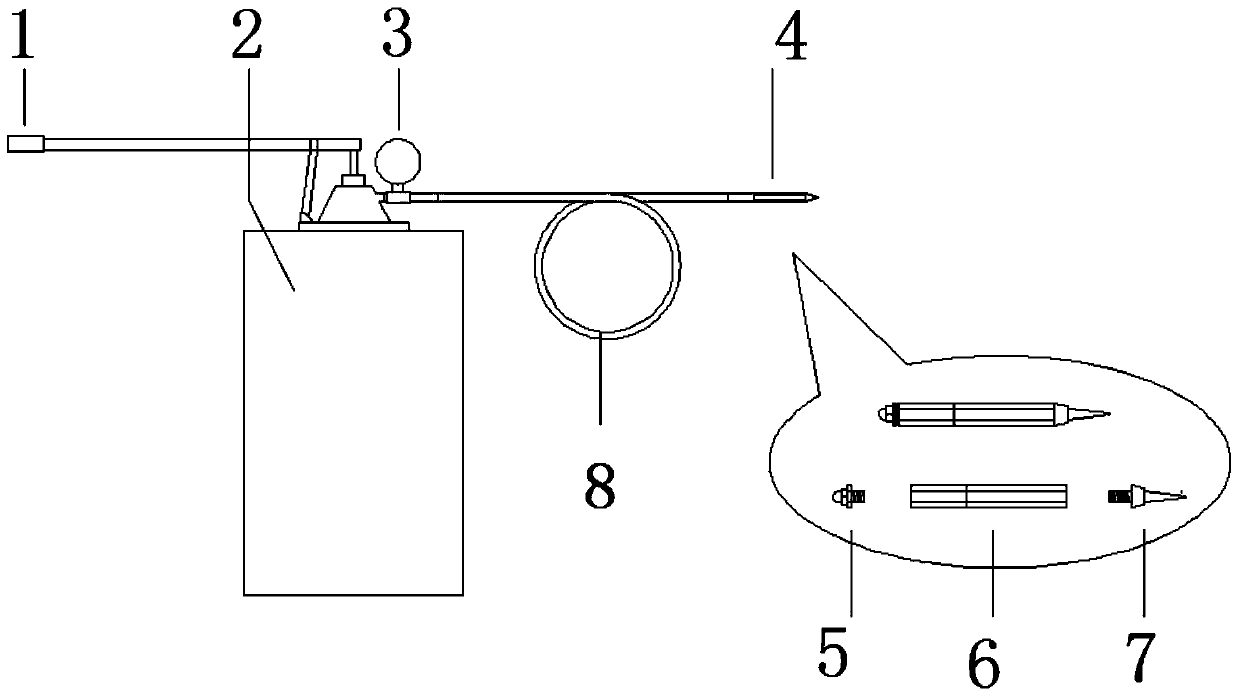

[0028] Such as figure 1 As shown, a kind of equipment for grouting repair of small cracks in concrete electric poles in service includes a manual high-pressure grouting pump and a water stop needle 4, and the manual high-pressure grouting pump includes a manual hydraulic device, a pressure gauge 3, a charging cylinder 2 and a grouting pipe 8. The water stop needle 4 includes the injection nozzle 5, the extension pipe 6 and the needle point 7, wherein the manual hydraulic device is fixed on the upper end of the charging cylinder 2, the inlet of the grouting pipe 8 is connected to the outlet of the manual hydraulic device, and the pressure gauge 3 is fixed on the grouting At the entrance of the pipe 8, the outlet of the grouting pipe 8 is connected to the injection nozzle 5 of the water stop needle, the injection nozzle 5 is connected to the extension pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com