Device for producing a packaging for tablet

A packaging box and tablet technology, applied in the direction of drug packaging, packaging, packaged food, etc., can solve the problem of not having any medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

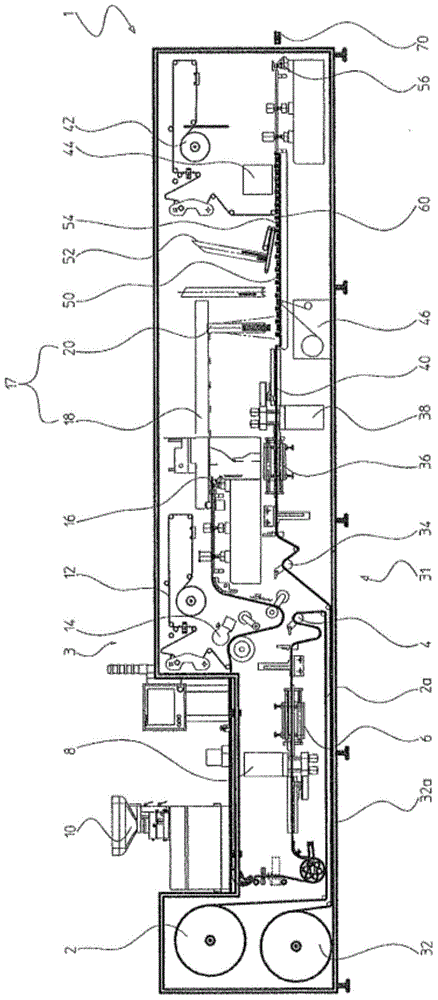

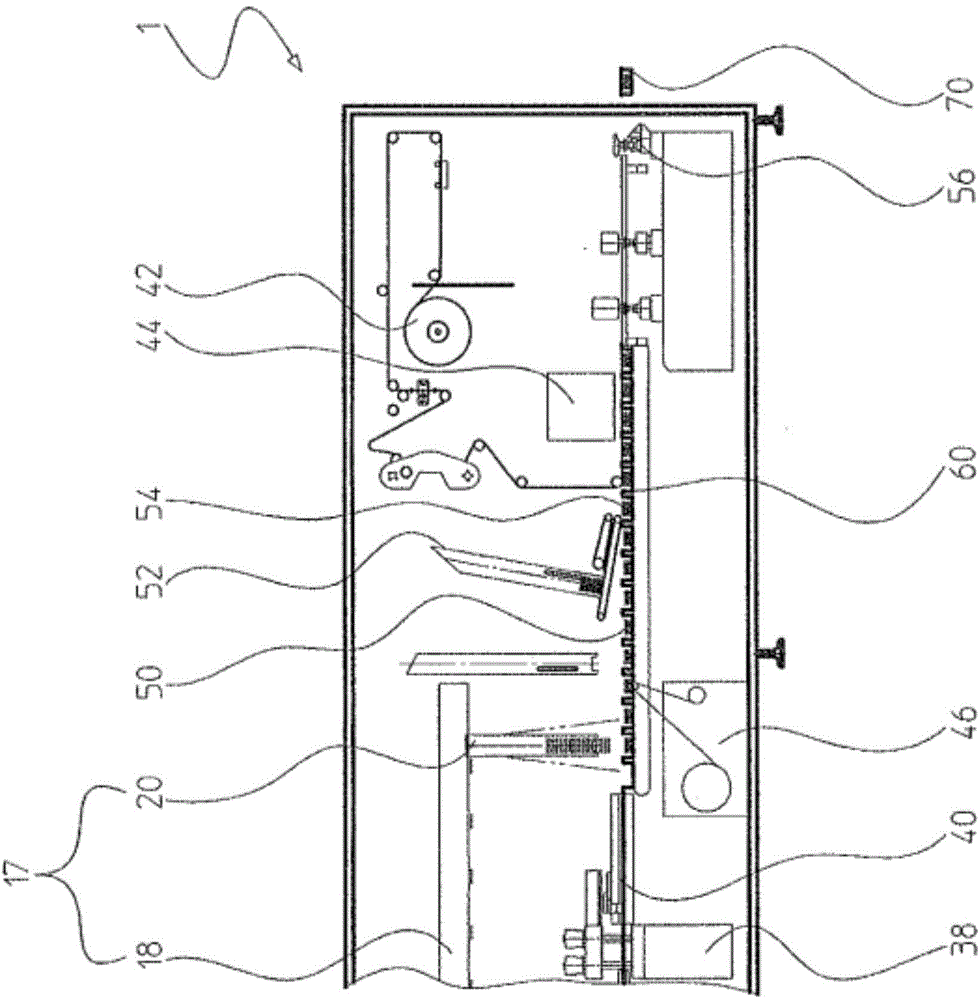

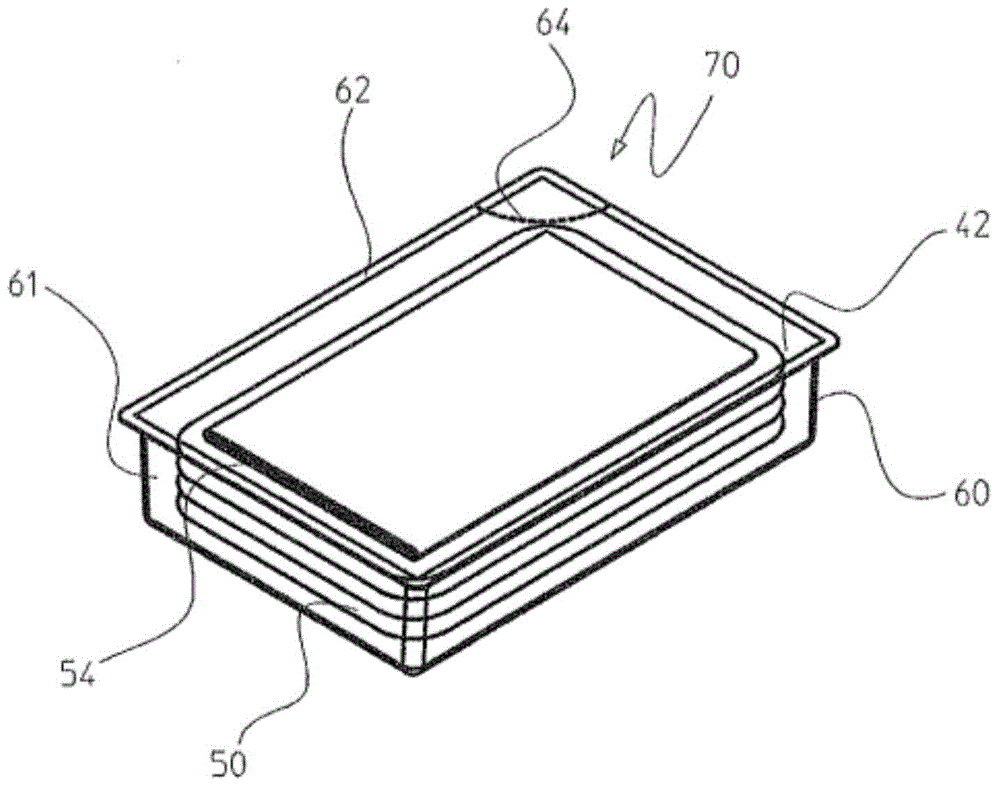

[0032] figure 1 An embodiment of a plant 1 for producing a tablet pack 70 is given by way of example. In the first line of the plant 1 , blister packs 50 are produced in a unit 3 for producing blister packs 50 . To this end, the first formable sheet 2a from the first formable sheet roll 2 is supplied via the first formable sheet uncoiler 4 to a first heating mechanism 6 where it is heated. In the following first forming means 8 wells or pockets 66 intended to receive medical or pharmaceutical products, such as tablets or the like, are formed in the first formable sheet 2a. In the filling mechanism 10 the pocket 66 of the first formable sheet 2a is filled with tablets 68 . The first lidding web 12 from another feed decoiler is supplied to the first sealing mechanism 14, wherein the first lidding web 12 is sealed to the first formable web 2a now containing the filled pocket. The individual blister packs 50 are then punched out by the first punch mechanism 16 sealing the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com