Anti-loose self-locking nut and production method thereof

A technology of self-locking nut and production method, applied in nuts, screws, bolts, etc., can solve the problems of easy loosening, falling off, and loosening of nuts, and achieve the effect of convenient threaded connection, not easy to warp, and prevent loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

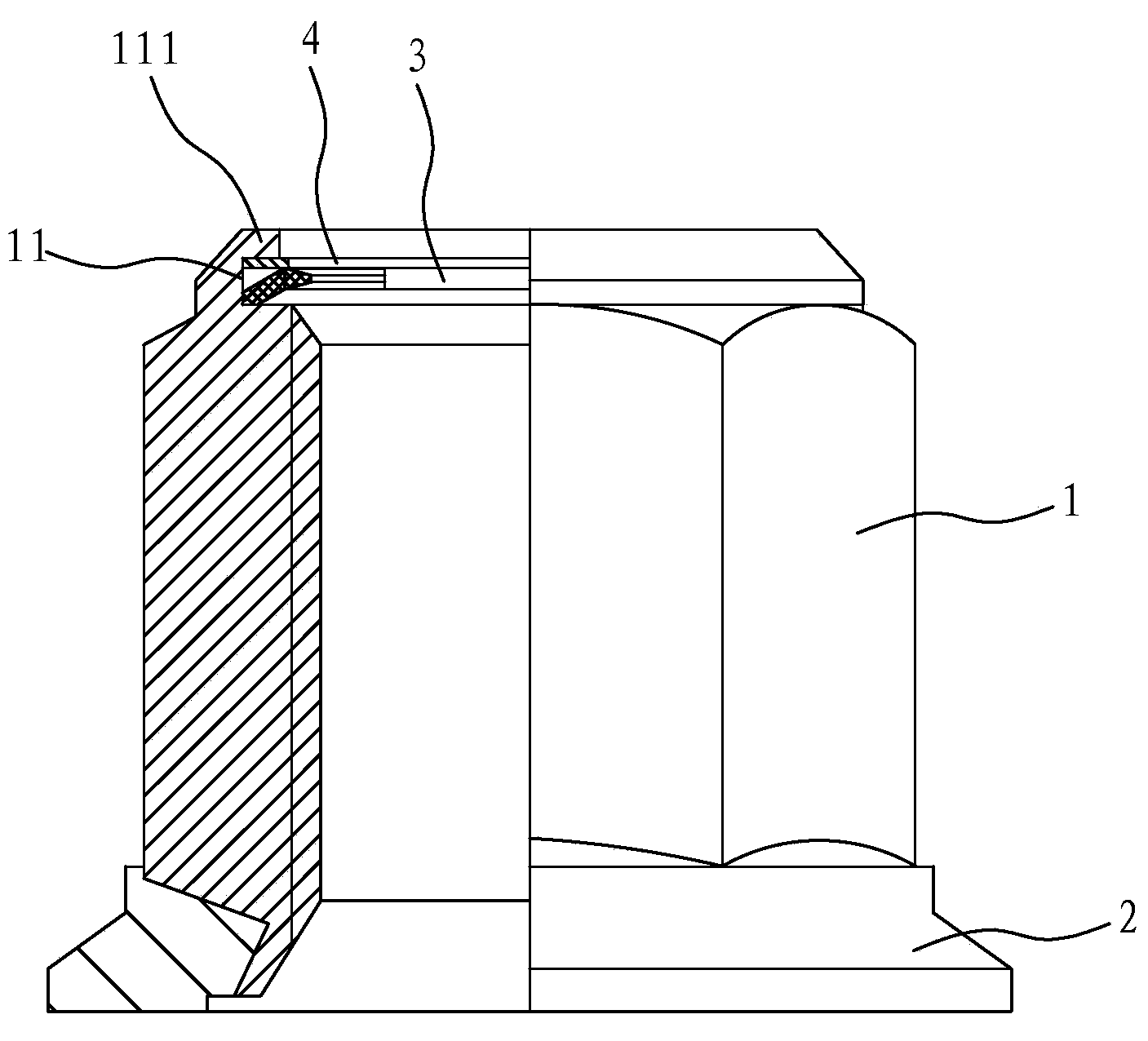

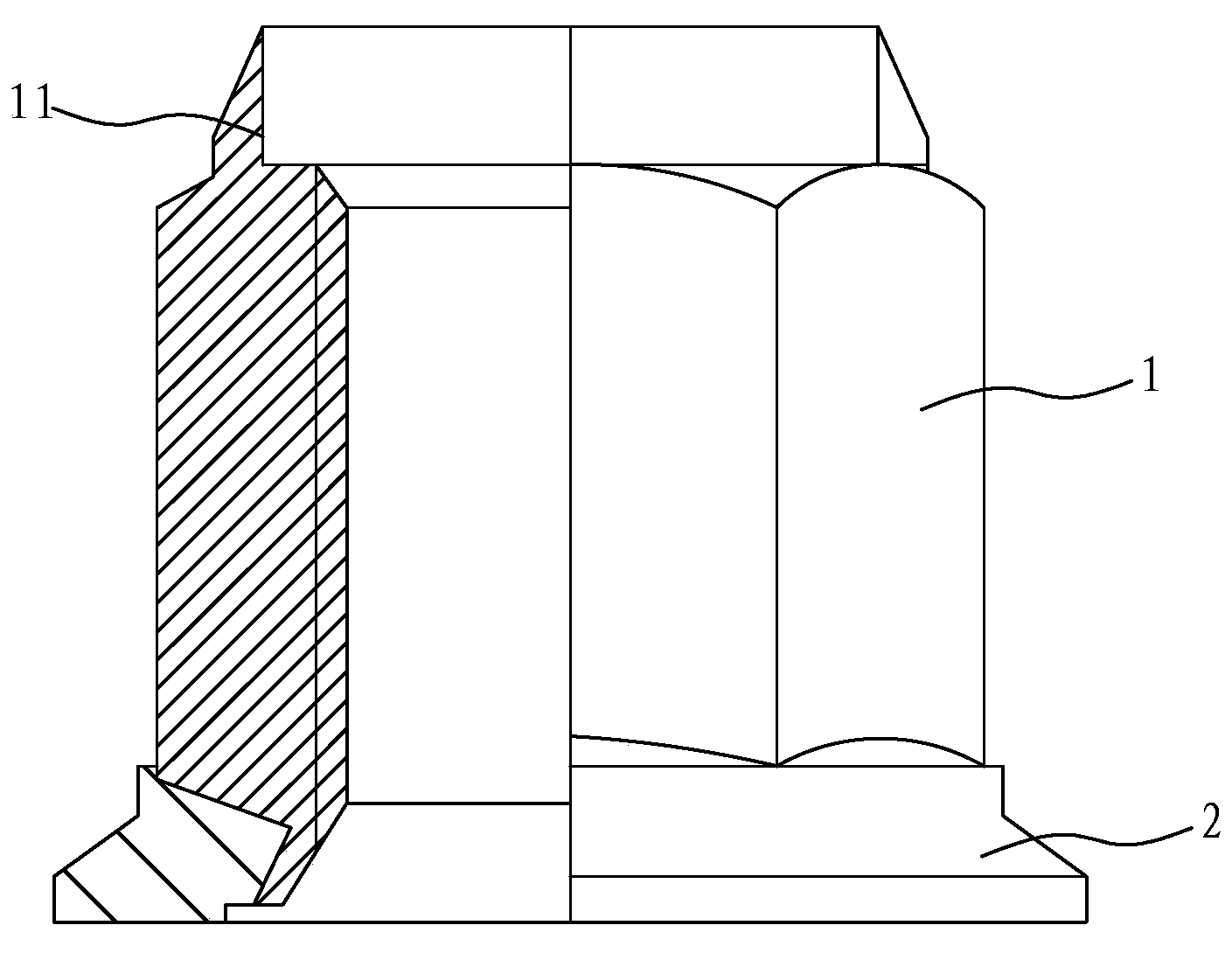

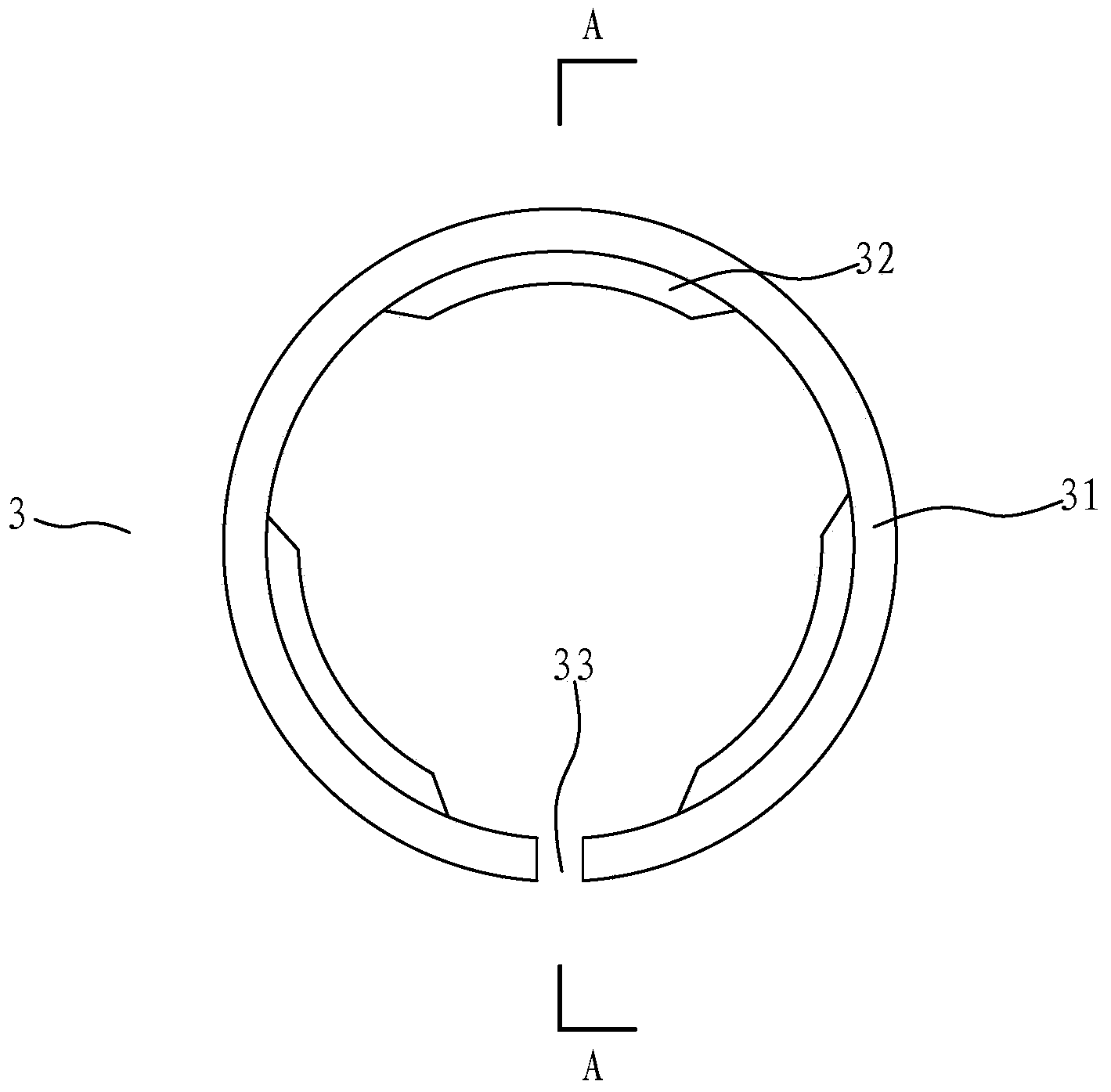

[0023] refer to Figure 1 to Figure 5 , the present embodiment provides an anti-loosening self-locking nut, comprising a nut body 1, a nut washer 2 rotatably arranged at the lower end of the nut body 1, the upper end of the nut body 1 is provided with a stepped groove 11, and the stepped groove 11 A spring steel sheet 3 is placed inside, and the stepped groove 11 forms a bent portion 111 by means of riveting, and the spring steel sheet 3 is clamped in the stepped groove 11 through the bent portion, and the spring steel sheet 3 includes An annular piece 31 with elastic restoring force, three clamping pieces 32 that are evenly distributed on the upper end of the ring piece 31 and protrude inward, and the clamping pieces 32 protrude radially inward into the thread of the nut body 1 In the hole 12, the screw thread of the bolt that can cooperate with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com