Large-diameter valve sealing ring surfacing method

A valve sealing and large-diameter technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor product quality, cracking of the surfacing layer, and large dilution rate of the surfacing layer, so as to improve product quality and production High efficiency, improved hardness and wear resistance, and reasonable welding process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

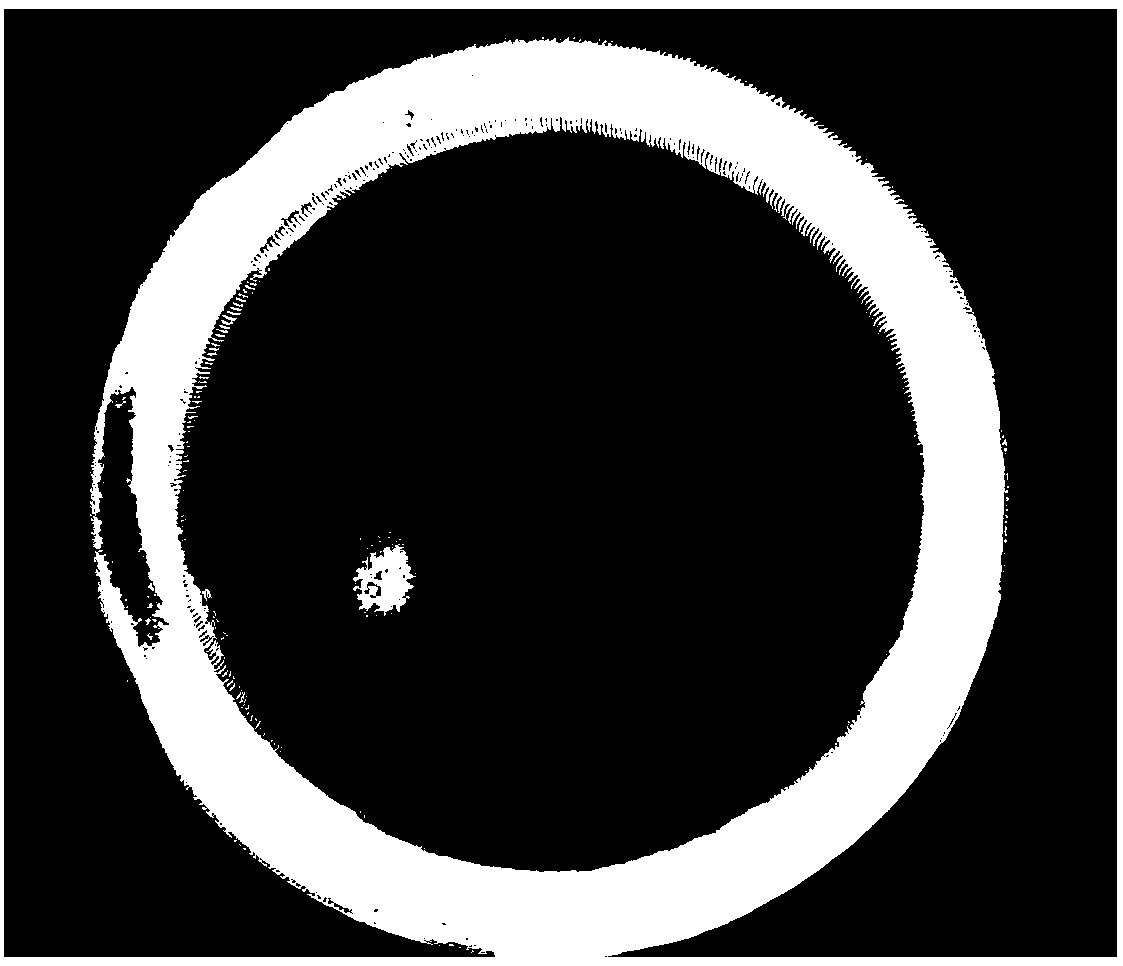

Image

Examples

Embodiment 1

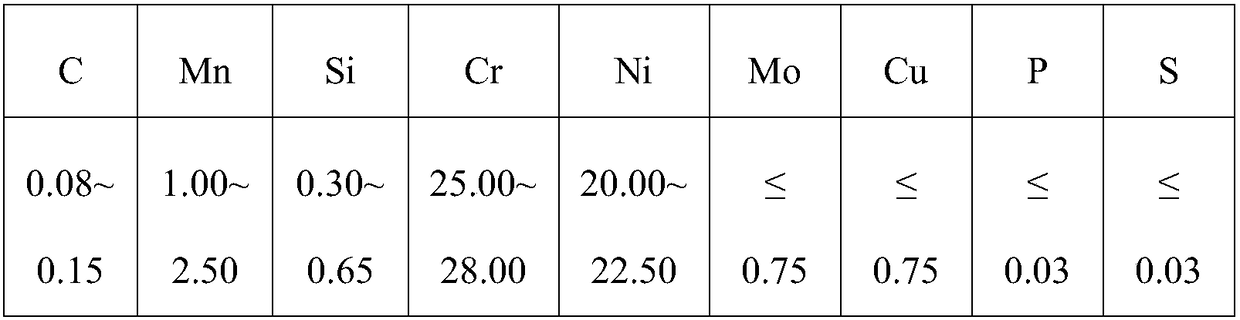

[0043] (1) Welding method and selection of welding materials: AC tungsten argon arc welding is used for transition layer surfacing, and ER310 stainless steel wire with a diameter of 2.5mm is used as the welding wire. The surfacing method of hard alloy surfacing layer adopts plasma arc powder surfacing welding, and the welding material adopts Co-Cr-Mo-Si-rare earth alloy powder.

[0044] (2) Preparation before welding: Flatten the sealing surface of the valve to be surfacing, without defects such as cracks and pits, and then clean the surface to be surfacing with acetone to ensure that there is no water, oil, etc., and ER310 welding wire and Co-Cr -Mo-Si-rare earth alloy powders were baked at 150°C for 2h.

[0045] Wherein, the chemical composition (wt.%) of the Co-Cr-Mo-Si-rare earth alloy powder is specifically Cr: 12%; Mo: 20%; Si: 2.5%; Al: 3%; Ta: 1.5% ; Yttrium oxide: 0.3%; Cerium oxide: 0.1%; The balance is Co, and the particle size range of the original powder is 200-3...

Embodiment 2

[0055] (1) Welding method and selection of welding materials: AC tungsten argon arc welding is used for transition layer surfacing, and ER310 stainless steel wire with a diameter of 2.5mm is used as the welding wire. The surfacing method of hard alloy surfacing layer adopts plasma arc powder surfacing welding, and the welding material adopts Co-Cr-Mo-Si-rare earth alloy powder.

[0056] (2) Preparation before welding: Flatten the surface of the valve sealing ring to be surfacing without cracks, pits and other defects, then clean the surface to be surfacing with acetone to ensure that there is no water, oil, etc., and put ER310 welding wire and Co- Cr-Mo-Si-rare earth alloy powders were baked at 180°C for 2.5h.

[0057] (3) Surfacing transition layer:

[0058] AC tungsten argon arc welding is used to surfacing welding ER310 welding wire on the flat sealing surface of the car. Multi-layer and multi-pass welding is used. After one welding is completed, the next one is welded unt...

Embodiment 3

[0065] (1) Welding method and selection of welding materials: AC tungsten argon arc welding is used for transition layer surfacing, and ER310 stainless steel wire with a diameter of 2.5mm is used as the welding wire. The surfacing method of hard alloy surfacing layer adopts plasma arc powder surfacing welding, and the welding material adopts Co-Cr-Mo-Si-rare earth alloy powder.

[0066] (2) Preparation before welding: Flatten the surface of the valve sealing ring to be surfacing without cracks, pits and other defects, then clean the surface to be surfacing with acetone to ensure that there is no water, oil, etc., and put ER310 welding wire and Co- Cr-Mo-Si-rare earth alloy powders were baked at 200°C for 3h.

[0067] (3) Surfacing transition layer:

[0068] AC tungsten argon arc welding is used to overlay welding ER310 welding wire on the flat sealing surface of the car. Multi-layer and multi-pass welding is used. After one welding is completed, the next one is welded until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com