Plastering head

A technology of mortar and fixed cylinder, which is applied in the direction of construction and building structure, etc. It can solve the problems of mechanical failure, easy jamming of aggregate and reamer, etc., and achieve the effect of protecting machine parts, avoiding machine head vibration and improving plastering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

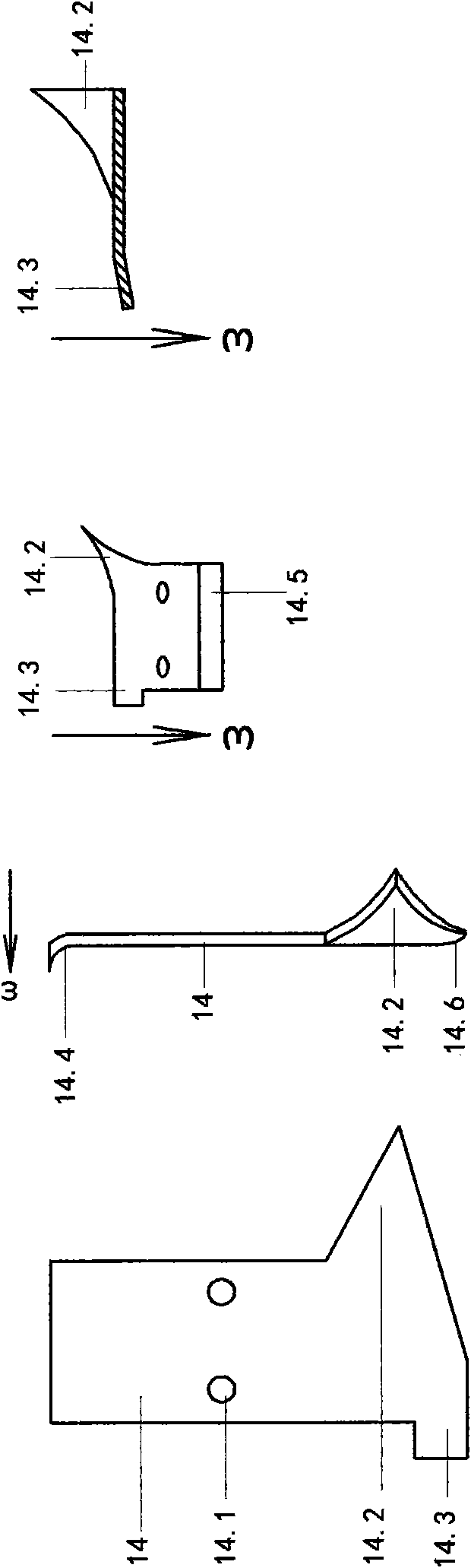

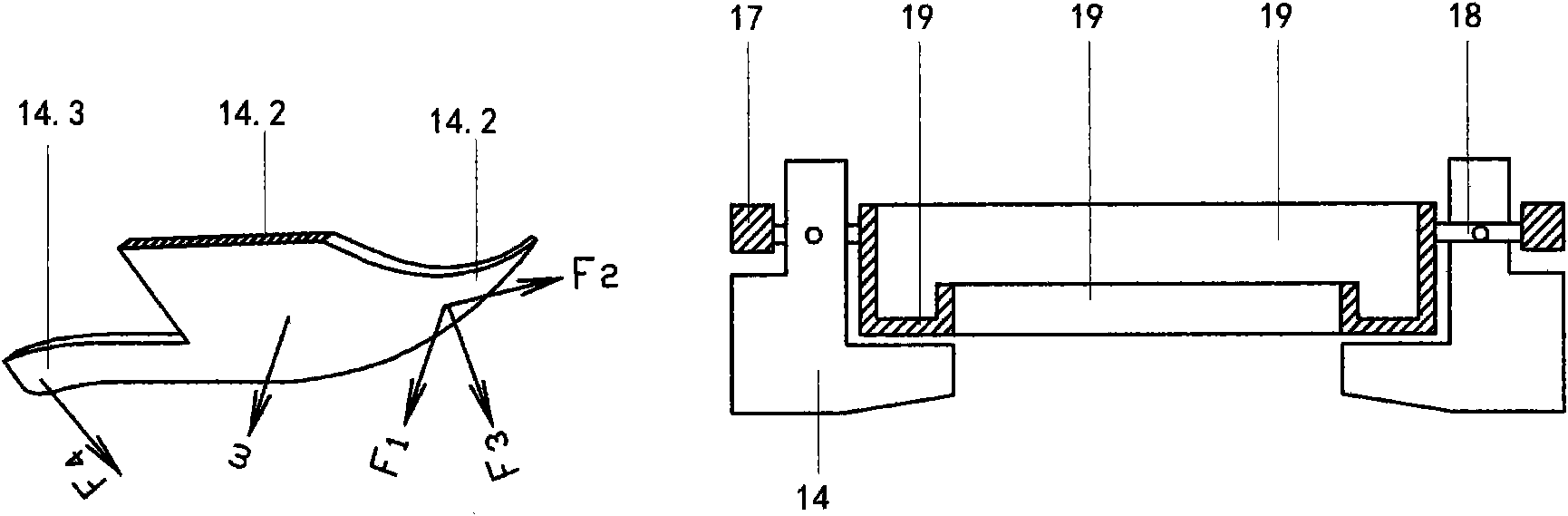

[0061] 1. Choose A, B, C, D four kinds of pipes, the pipe diameters are in descending order, A is the outer cylinder, B is the auxiliary cylinder of the fixed cylinder, C is the main cylinder of the fixed cylinder, and D is the inner cylinder; The diameter difference between AB and CD meets the thickness requirements of the bearing, and the width of the upper part of the middle knife is left between BC; cut and process four kinds of tubes according to the different structural sizes, and set steps, keyways, and connecting holes on each tube Etc. installation structure; ash outlet is set on pipe A; window is opened on the upper part of pipe C, and ash outlet is opened on the lower part.

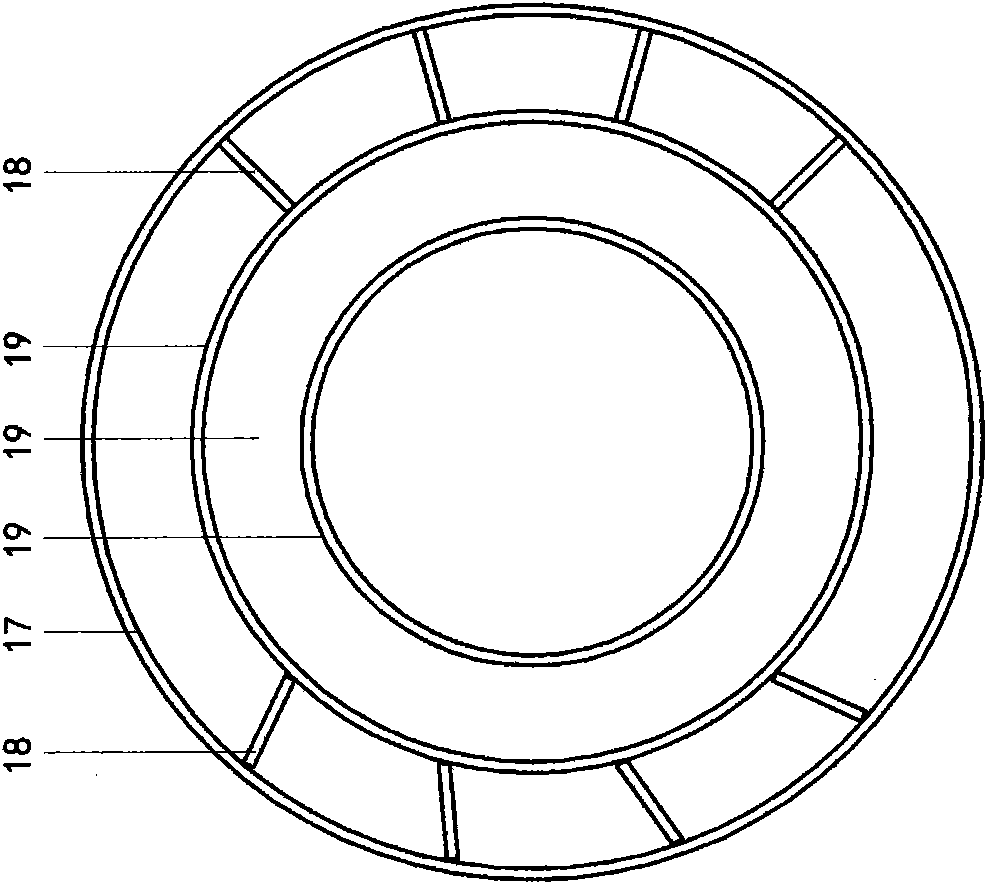

[0062] 2. Make a ring-shaped ash baffle, choose a flat plate and cut the ring-shaped plate, the inner circle is the same as the outer diameter of the C pipe, and the outer circle is the same as the inner diameter of the B-pipe; the mortar input port is set on the ring plate, the number and shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com