Grouting apparatus

The technology of a plastering machine and a plastering device, which is applied in the direction of construction and building construction, can solve the problems of inconvenient operation, high labor intensity, and many required personnel, and achieve flexible and convenient movement, convenient left and right movement, and easy disassembly and assembly. Convenient and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

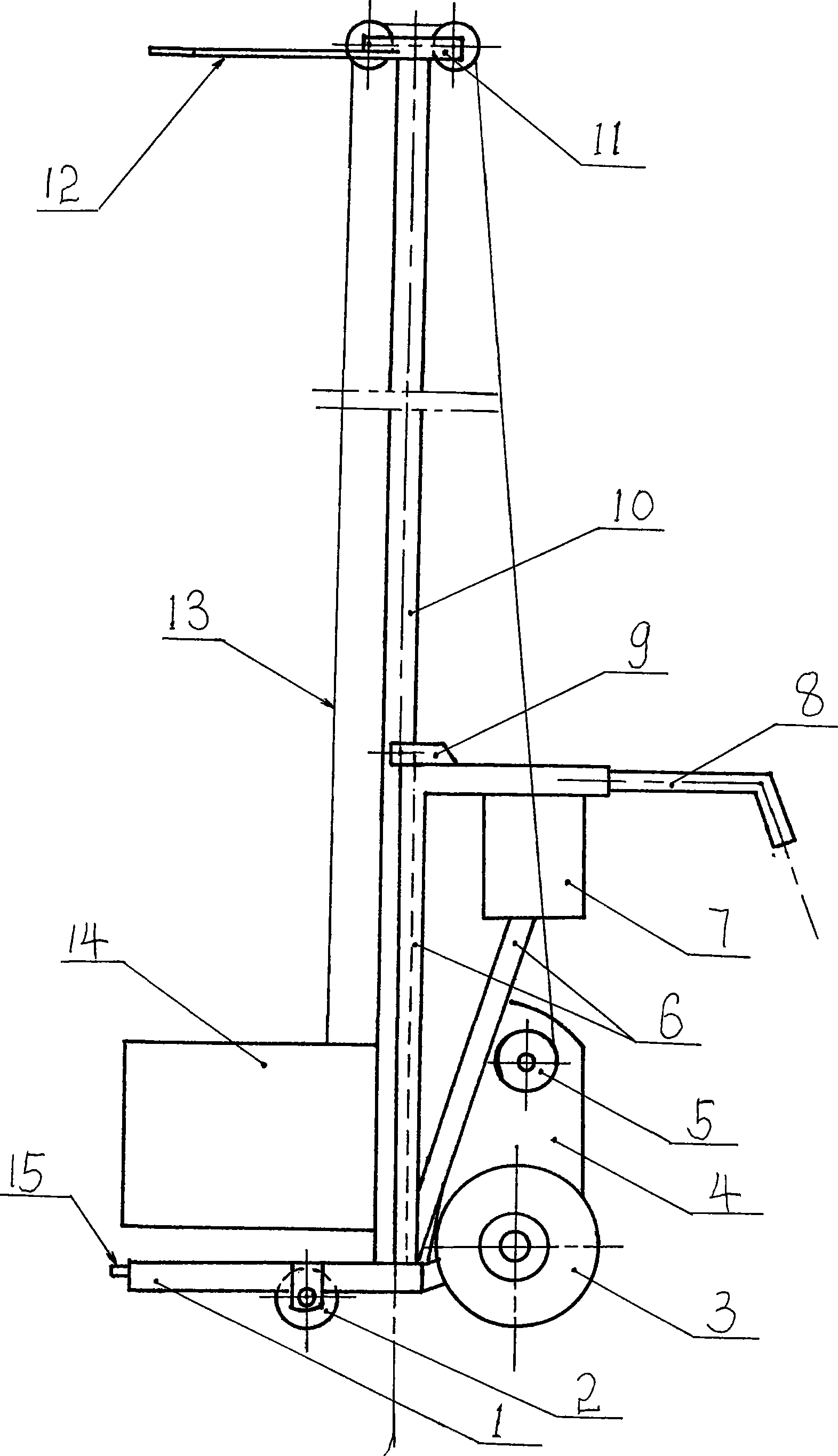

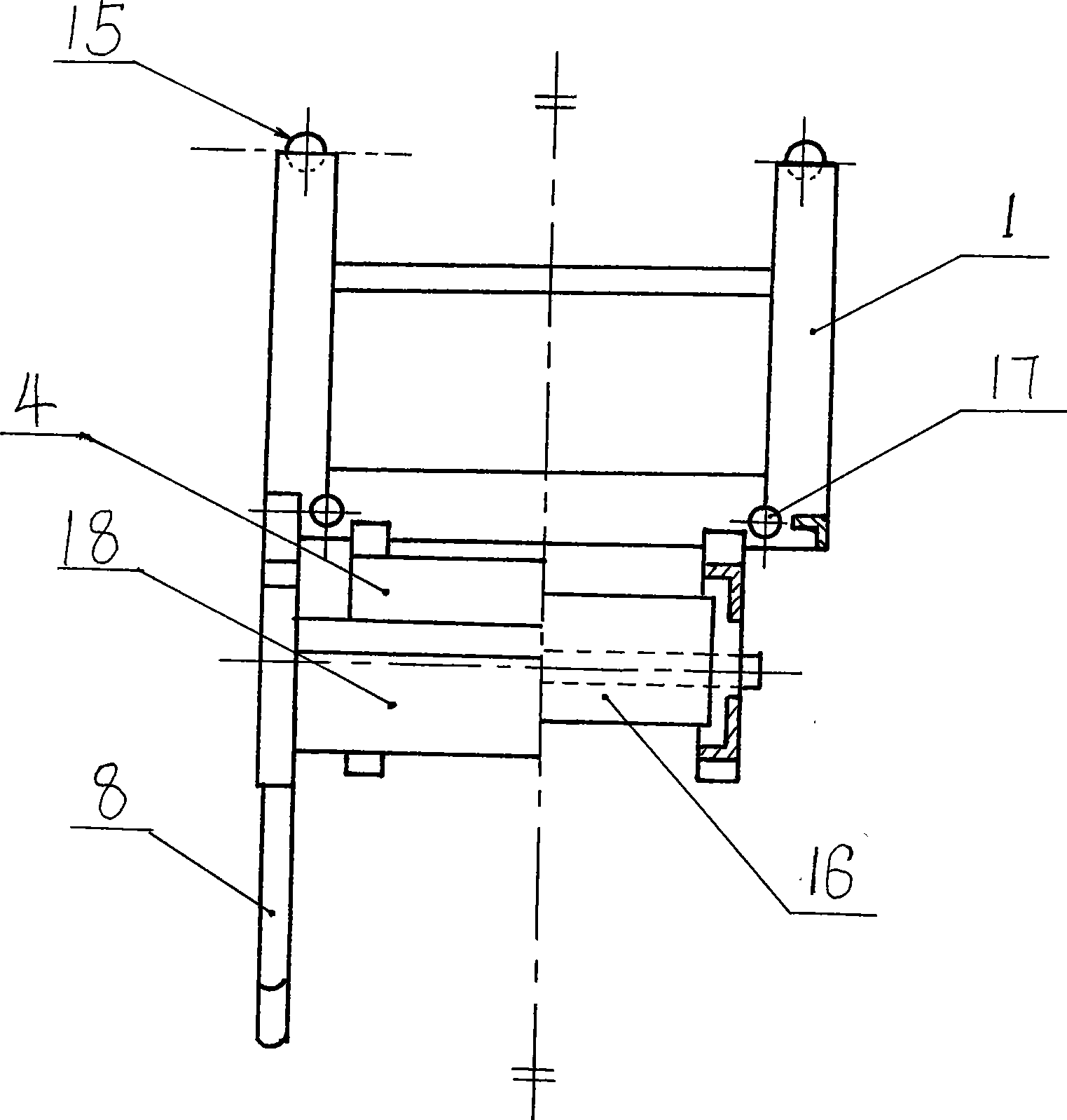

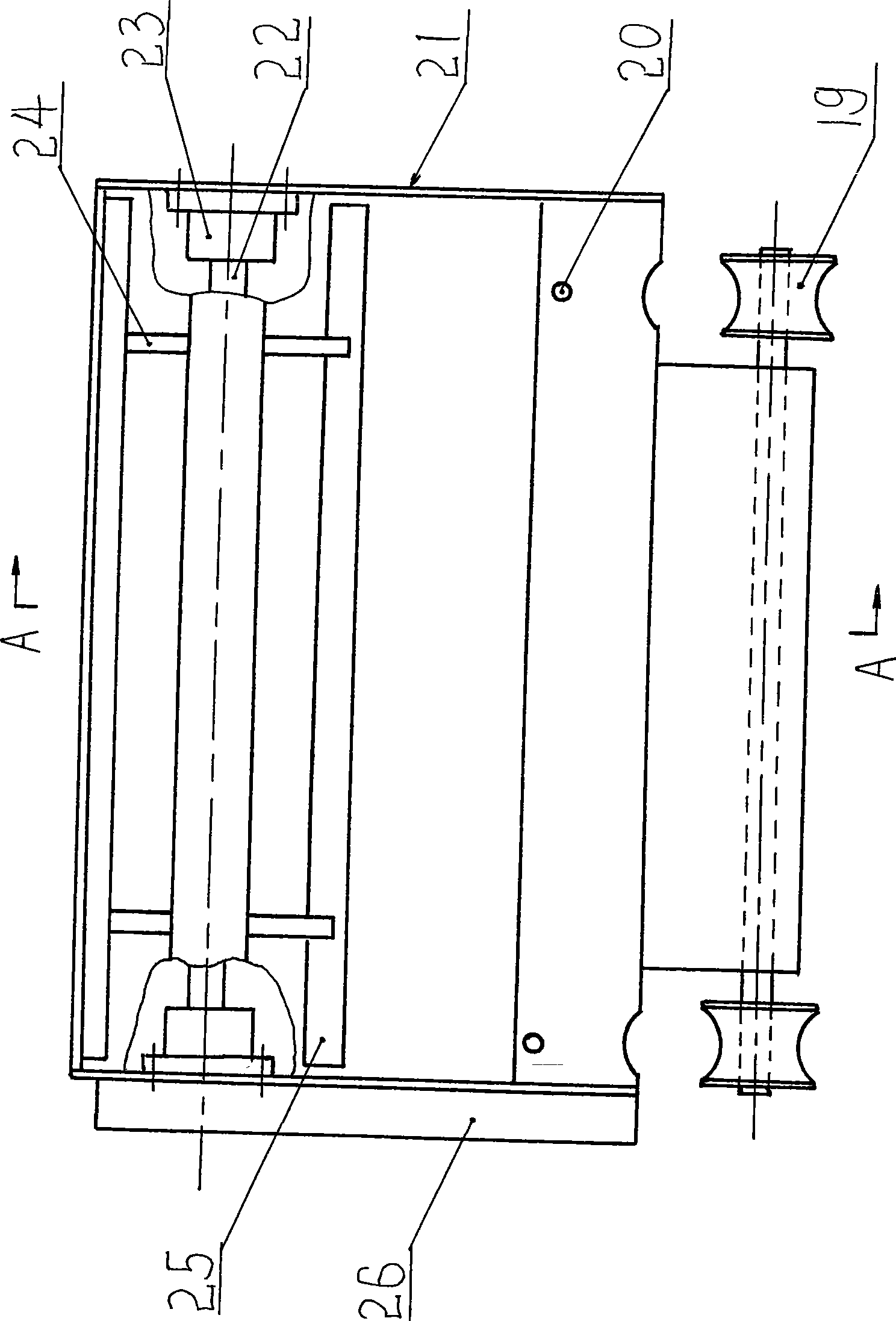

[0038] figure 1 It is the left side view of the plastering machine of the present invention, as figure 1 As shown, the plastering machine is made up of handle frame, plastering device 14, pulling mechanism, column 10, electric control system and supporting part. figure 2 It is the frame structure assembly drawing of the plastering machine of the present invention, as figure 2 As shown, the traction mechanism frame 16 is narrower than the plasterer base 1 and is welded at the rear of the frame 1 . The puller frame 4 is installed on the puller base 16 , and the top of the puller frame 4 is connected with the cross bar of the handlebar bracket 6 . The front end of handlebar support 6 is vertical with plasterer base 1, and its height can be about 70-150 centimeters, and the upper end of handlebar support 6 is equipped with the fixed bearing 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com